Cloth printing system

A printing system and cloth technology, applied in printing, printing machines, rotary printing machines, etc., can solve problems such as inconvenient maintenance of printing parts, troublesome staff, and affecting printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0109] In order to further explain the technical solutions of the present invention, specific examples are given below to illustrate in detail.

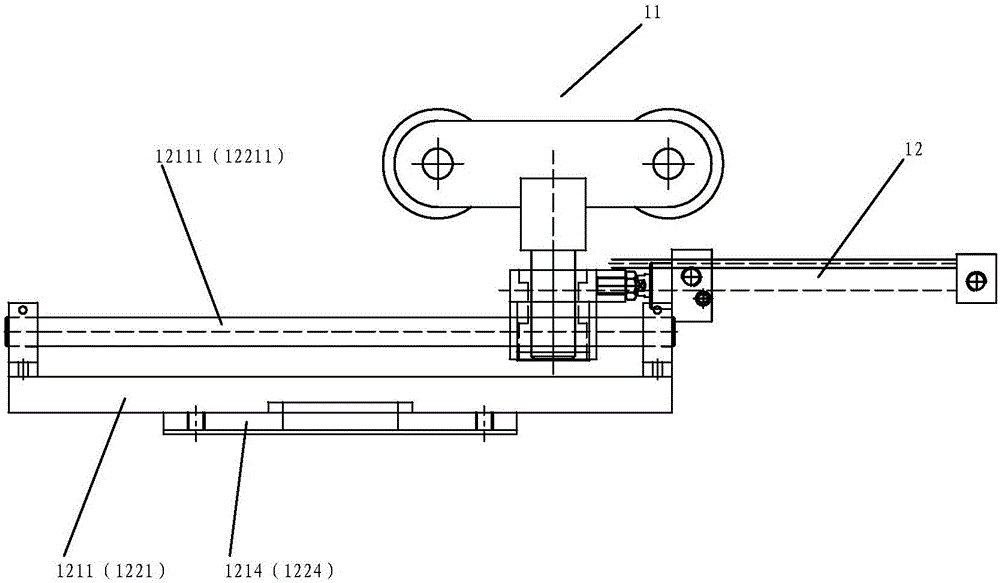

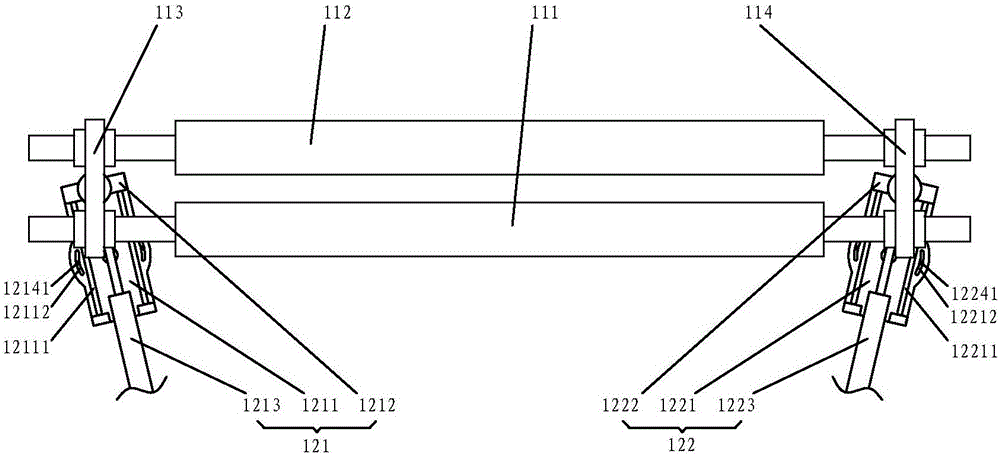

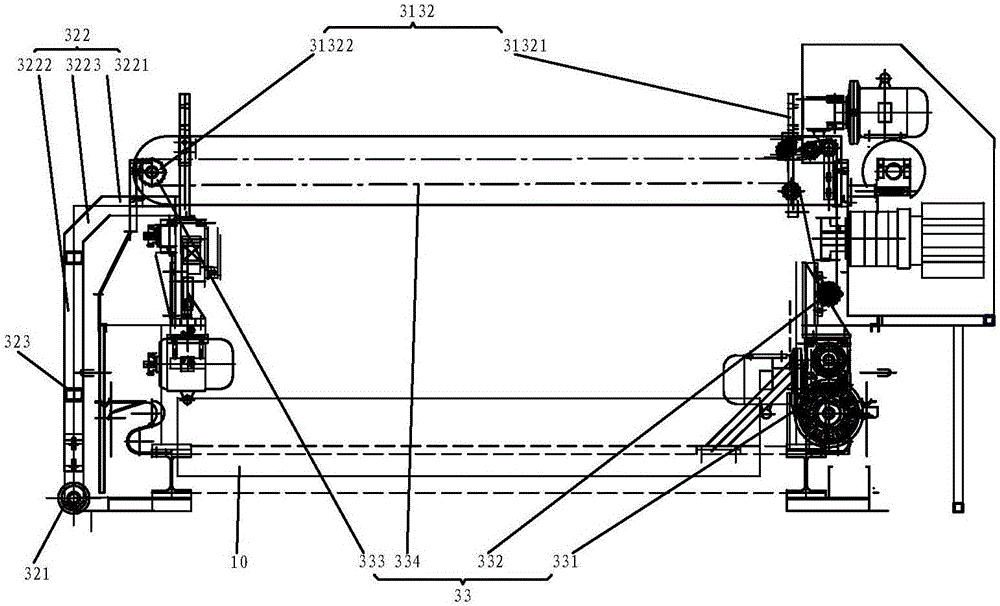

[0110] A kind of cloth printing system of the present invention, as Figure 1-18 As shown, it includes a frame 10, a cloth straightening device for initially straightening the printed cloth, a plurality of printing devices downstream of the cloth straightening device, and a plurality of printing devices corresponding to the printing devices one by one and carrying parts of the printing devices. The bracket, the printing correction device for correcting the printing device, the scraper device for scraping the ink, a plurality of one-to-one corresponding spread drying devices arranged upstream of the printing device, the conveyor belt 20 for driving the cloth, and the conveyor belt 20 for A glue brushing device for brushing glue, an ink scrubbing mechanism for scrubbing the ink on the conveyor belt 20, and a conveyor belt cleaning devi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com