High-oxygen-permeability orthokeratology lens

A technology of orthokeratology and high oxygen permeability, which is applied in glasses/goggles, optics, instruments, etc. It can solve the problems of eyelid discomfort, inconvenience for users to wear or take off the orthokeratology lens, easy to fall off, etc., and achieve comfortable wearing effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

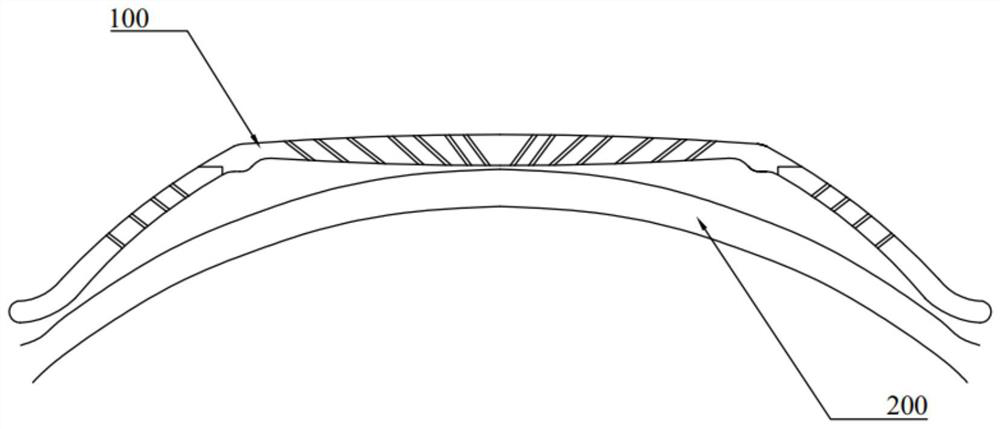

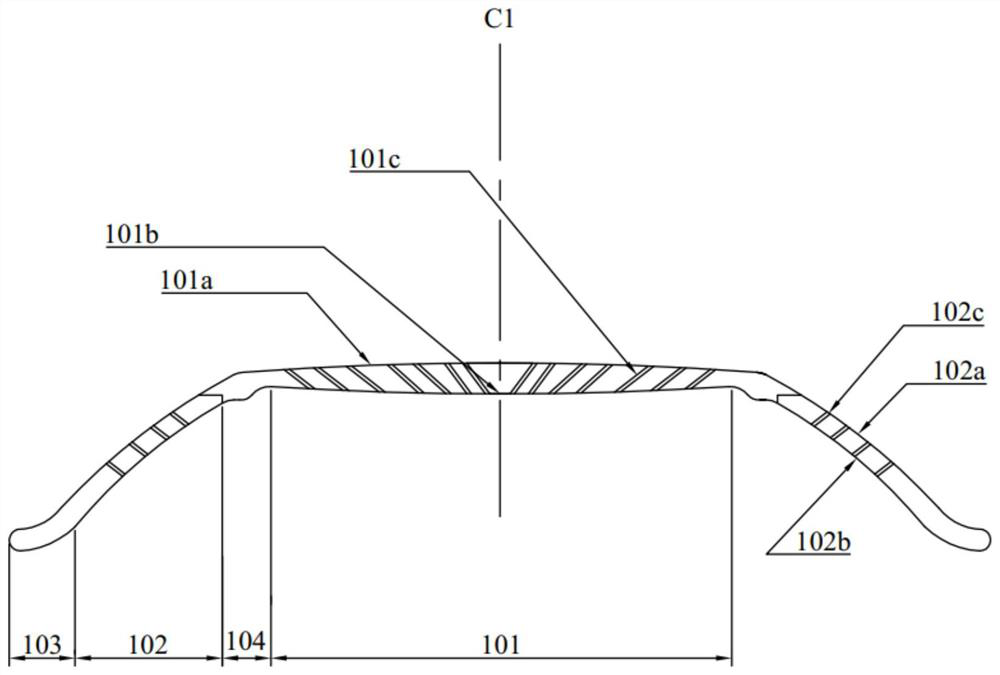

[0047] refer to Figure 1 to Figure 5 In the first embodiment shown, the orthokeratology lens includes a lens body 100 .

[0048] The lens body 100 can be made of hard RGP material or a combination of hard RGP material and soft RGP material. As an alternative, silicone methacrylate, fluorosilicone acrylate, polymethyl One of the methyl acrylates and their modified materials, such as modified materials with silicon or / and fluorine added.

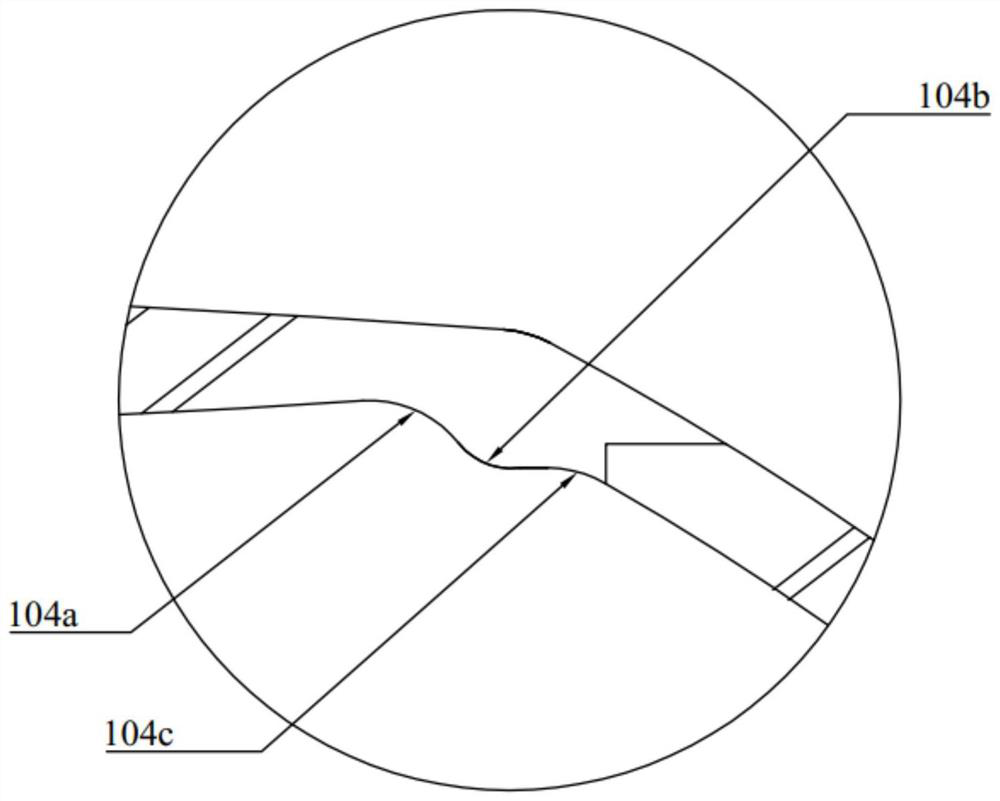

[0049] Specifically, the lens body 100 includes: a central correction portion 101 , a peripheral extension portion 102 , an edge contact portion 103 , and a connection structure portion 104 .

[0050] Among them, the central correction part 101 is used to correct the central part of the eyeball 200; the peripheral extension part 102 is used to cover the peripheral part of the eyeball 200; the edge contact part 103 is used to contact the peripheral part of the eyeball 200.

[0051] Specifically, on the one hand, the central correcting part 101...

Embodiment 2

[0080] refer to Figure 6 to Figure 9 The second embodiment shown, an orthokeratology lens includes a lens body 300 .

[0081] The lens body 300 can be made of hard RGP material or a combination of hard RGP material and soft RGP material. As an alternative, silicone methacrylate, fluorosilicone acrylate, polymethyl One of the methyl acrylates and their modified materials, such as modified materials with silicon or / and fluorine added.

[0082] Specifically, the lens body 300 includes: a central correction portion 301 , a peripheral extension portion 302 , and an edge contact portion 303 .

[0083] Among them, the central correction part 301 is used to correct the central part of the eyeball 200; the peripheral extension part 302 is used to cover the peripheral part of the eyeball 200; the edge contact part 303 is used to contact the peripheral part of the eyeball 200.

[0084] Specifically, on the one hand, the central correcting part 301 physically compresses the central par...

Embodiment 3

[0112] refer to Figure 9 to Figure 14 The third embodiment shown, an orthokeratology lens includes a lens body 400 .

[0113] The lens body 400 can be made of hard RGP material or a combination of hard RGP material and soft RGP material. As an alternative, silicone methacrylate, fluorosilicone acrylate, polymethyl One of the methyl acrylates and their modified materials, such as modified materials with silicon or / and fluorine added.

[0114] Specifically, the lens body 400 includes: a central correction portion 401 , a peripheral extension portion 402 , and an edge contact portion 403 .

[0115] Among them, the central correction part 401 is used to correct the central part of the eyeball 300 ; the peripheral extension part 402 is used to cover the peripheral part of the eyeball 300 ; and the edge contact part 403 is used to contact the peripheral part of the eyeball 200 .

[0116] Specifically, on the one hand, the central correcting part 401 presses the central part of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com