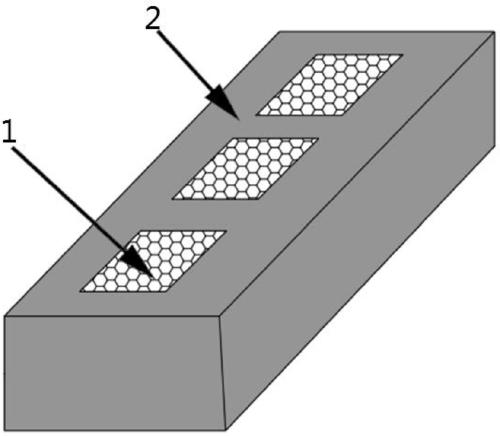

Preparation method of porous reticulated ceramic enhanced steel-based compound brake block

A brake pad and mesh technology is applied in the field of preparation of porous mesh ceramic reinforced steel-based composite brake pads, which can solve the problems of low mechanical strength, large amount of wear, poor heat resistance, etc., and achieves good wettability and high resistance. oxidative effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] A method for preparing a porous network ceramic reinforced steel-based composite brake block of the present invention comprises the following steps:

[0030] S1, the TiB 2 Add powder and additives to deionized water and stir well to obtain ceramic slurry suspension;

[0031] Additives include stainless steel powder, ammonium citrate, carboxymethyl cellulose, and silica sol.

[0032] TiB 2 Powder accounts for 60-80% of the total mass of ceramic slurry, additives account for 10-30% of the total mass of ceramic slurry, deionized water accounts for 10-25%; stainless steel powder accounts for 60-80% of additive mass, ammonium citrate accounts for 5-8% of the mass of the additive, carboxymethyl cellulose accounts for 4-6% of the mass of the additive, and silica sol accounts for 10-30% of the mass of the additive.

[0033] S2. Select an organic foam with a suitable pore size, dip it in the ceramic slurry, take it out after 1-5 minutes and squeeze out the excess slurry;

[...

Embodiment 1

[0041] 1) First, 99.4g TiB 2 Powder, 42.6g of stainless steel powder, 1.42g of ammonium citrate and 0.71g of carboxymethyl cellulose were added to 32mL of deionized water and 8mL of silica sol were added, and stirred well to obtain a ceramic slurry suspension;

[0042] 2) Secondly, select 5PPI soft polyurethane foam, dip it in the ceramic slurry, take it out after 1min and squeeze out the excess slurry;

[0043] 3) After drying the impregnated organic foam, raise the temperature from room temperature to 600°C at a rate of 1°C / min in a vacuum furnace and keep it warm for 55 minutes, then raise the temperature to 1200°C at a rate of 10°C / min, and then Sinter at 1550°C for 1 hour at a heating rate of 5°C / min, and cool down with the furnace to obtain a porous mesh preform;

[0044] 4) Fix the prefabricated body on the end surface or the working surface of the casting mold, pour the metal liquid of the steel matrix material by casting infiltration process, and obtain the composite...

Embodiment 2

[0046] 1) First, put 84g TiB 2 Powder, 36g of stainless steel powder, 1.42g of ammonium citrate and 0.71g of carboxymethyl cellulose were added to 32mL of deionized water and 8mL of silica sol were added, and stirred well to obtain a ceramic slurry suspension;

[0047] 2) Secondly, select 15PPI soft polyurethane foam, dip it in the ceramic slurry, take it out after 5 minutes and squeeze out the excess slurry;

[0048] 3) After drying the impregnated organic foam, raise the temperature from room temperature to 800°C at a rate of 2°C / min in a vacuum furnace and keep it warm for 60 minutes, then raise the temperature to 1000°C at a rate of 9°C / min, and then Sinter at a rate of 2°C / min to 1550°C for 1.5 hours, and cool down with the furnace to obtain a porous mesh preform;

[0049] 4) Fix the prefabricated body on the end surface or the working surface of the casting mold, pour the metal liquid of the steel matrix material by casting infiltration process, and obtain the composite...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com