Rollers

A technology of shaft center and connecting part, applied in the field of rollers, can solve the problems of chip collapse, inability to press the adhesive tape evenly, and poor sticking, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

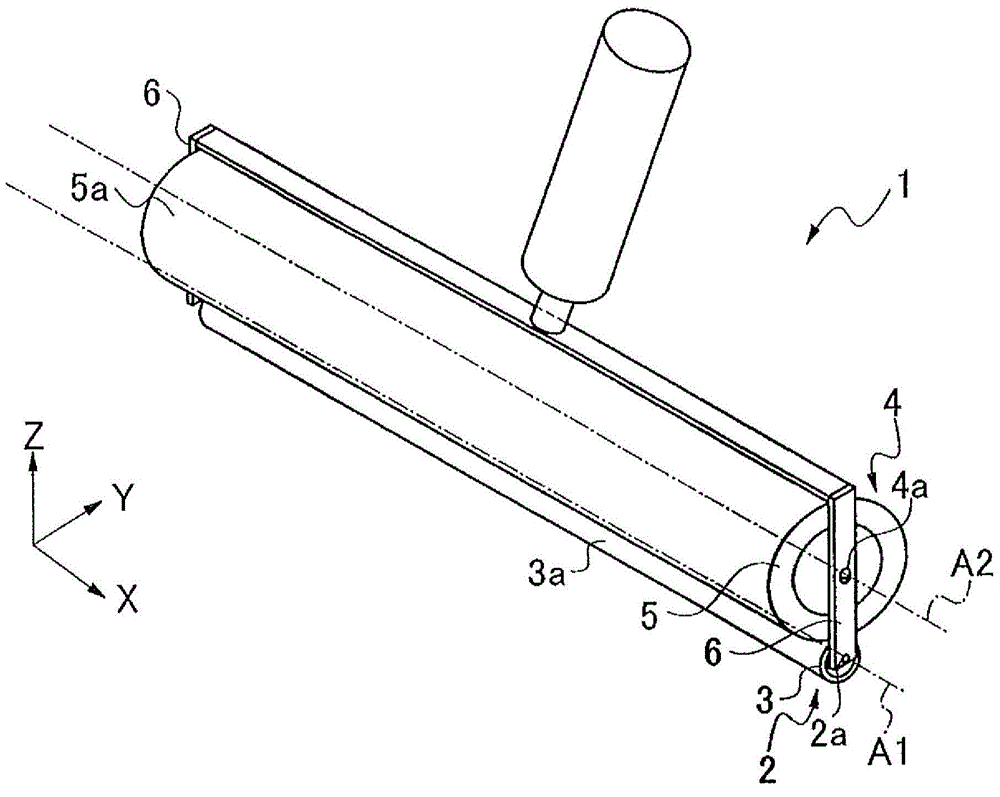

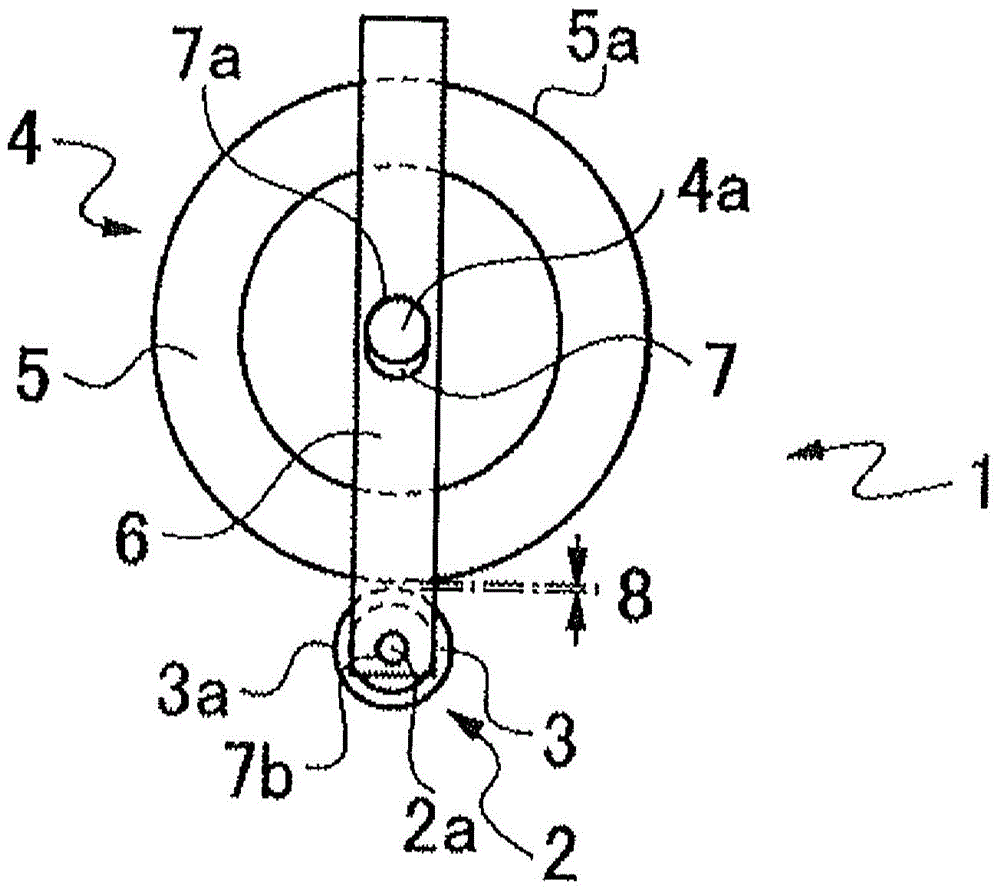

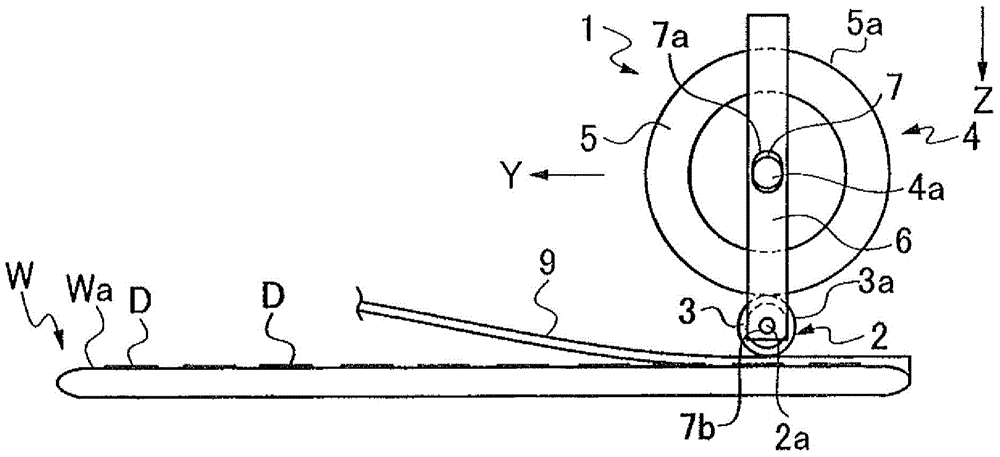

[0031] figure 1 The shown roller 1 is a first example of a roller for pressing an object such as an adhesive tape and sticking it to a plate-like object. The roller 1 includes: a pressing roller 2 for pressing an object; a deflection prevention roller 4 for preventing the deflection of the pressing roller 2; and a connecting portion 6 for rollingly connecting the pressing roller 2 and the deflection prevention roller 4 .

[0032] The pressing roller 2 includes a shaft portion 2 a having an axis A1 in the horizontal direction (X-axis direction), and an annular outer peripheral portion 3 , and the pressing roller 2 is rotatable about the axis A1 . At least the outer peripheral portion 3 of the pressing roller 2 is preferably formed by an elastic member. As the elastic member, for example, silicone rubber can be used. Furthermore, it is preferable that the pressing roller 2 is formed to have a small diameter, for example, a diameter of 6 mm to 8 mm. When the diameter of the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com