Preparation method of all-purpose glue stick

A glue stick and universal technology, applied in the direction of adhesives, adhesive types, non-polymer adhesive additives, etc., can solve problems such as impact on health, large limitations, adverse effects on health, etc., to achieve uniform paste, Versatile Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

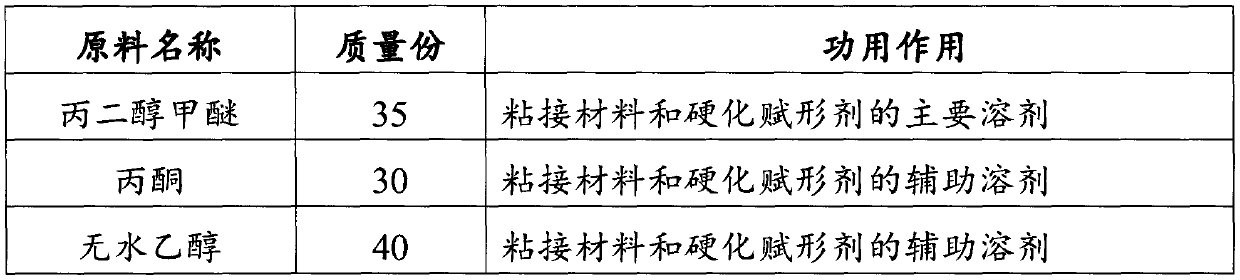

[0016] The preparation method of the universal glue stick provided by the invention comprises the raw materials of following mass parts proportioning:

[0017] 25-40 parts of propylene glycol methyl ether; 25-35 parts of acetone; 30-50 parts of absolute ethanol; 2-8 parts of synthetic rubber; 3-10 parts of resin; 10-20 parts of elastomer; 1-3 parts of excipient; 5-10 parts of hardened excipient;

[0018] Its preparation method is as follows:

[0019] Add propylene glycol methyl ether, acetone, and absolute ethanol to the reaction kettle, start stirring, and stir evenly. While stirring, add synthetic rubber, resin, and elastomer in turn to dissolve for 6 to 12 hours. After the dissolution is complete, turn on the condensation reflux device, and simultaneously Stir and heat up, add co-solvent, dispersant, and hardening excipient while stirring, raise the temperature to 85-90°C, control the temperature at 85-90°C and vigorously stir and disperse for 20-30 hours, so that all soli...

Embodiment 1

[0022] The mass proportioning of the main components of the universal glue stick of the present embodiment:

[0023] raw material name

parts by mass

function

Propylene Glycol Methyl Ether

30

Primary solvent for bonding materials and hardening vehicles

acetone

35

Auxiliary solvent for bonding materials and hardening vehicles

Absolute ethanol

40

Auxiliary solvent for bonding materials and hardening vehicles

synthetic rubber

5

Main bonding material

resin

8

Auxiliary bonding material

16

Auxiliary bonding material

Co-solvent

2

Improves the inter-bonding properties between solvents and bonding materials

Dispersant

3

Improve the solubility of bonding materials in solvents

hardening excipient

6

Product curing molding

[0024] The preparation method of the universal glue stick of the present embodiment is as follows:

[0025] Add pr...

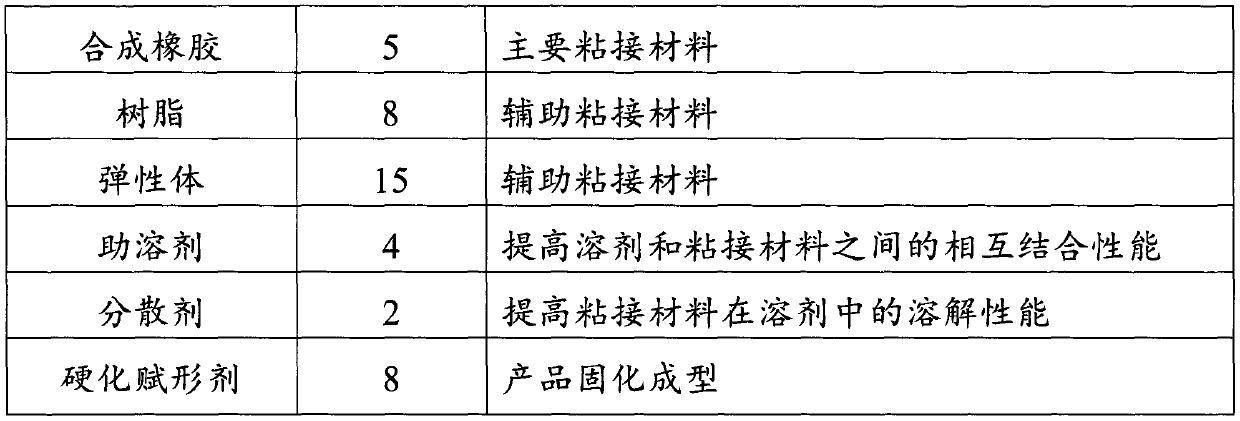

Embodiment 2

[0027] The mass proportioning of the main components of the universal glue stick of the present embodiment:

[0028] raw material name

parts by mass

function

Propylene Glycol Methyl Ether

40

Primary solvent for bonding materials and hardening vehicles

acetone

35

Auxiliary solvent for bonding materials and hardening vehicles

Absolute ethanol

50

Auxiliary solvent for bonding materials and hardening vehicles

synthetic rubber

8

Main bonding material

resin

10

Auxiliary bonding material

elastomer

20

Auxiliary bonding material

Co-solvent

5

Improves the inter-bonding properties between solvents and bonding materials

Dispersant

3

Improve the solubility of bonding materials in solvents

hardening excipient

5

Product curing molding

[0029] The preparation method of the universal glue stick of the present embodiment is as follows:

[0030] Add p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com