Mirror frame pulp wrapping machine

A technology of hanging pulp machine and mirror frame, which is applied in the directions of liquid injection device, pretreatment surface, injection device, etc., can solve the problems of increasing manufacturing cost, wasting pulp, uneven coating on the surface of the mirror frame, etc., to accelerate the solidification speed and save money. cost, and the effect of improving the efficiency of hanging pulp

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

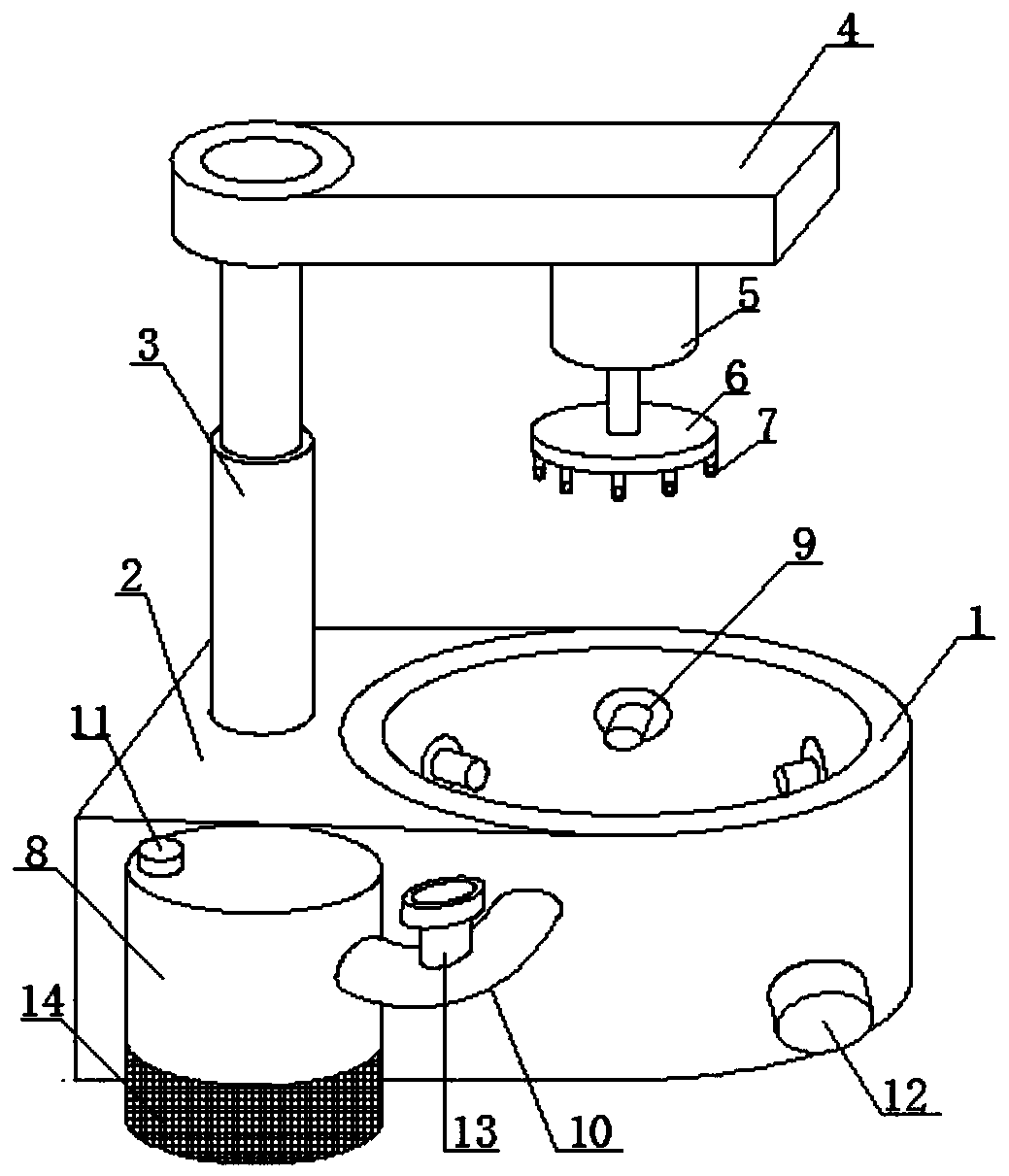

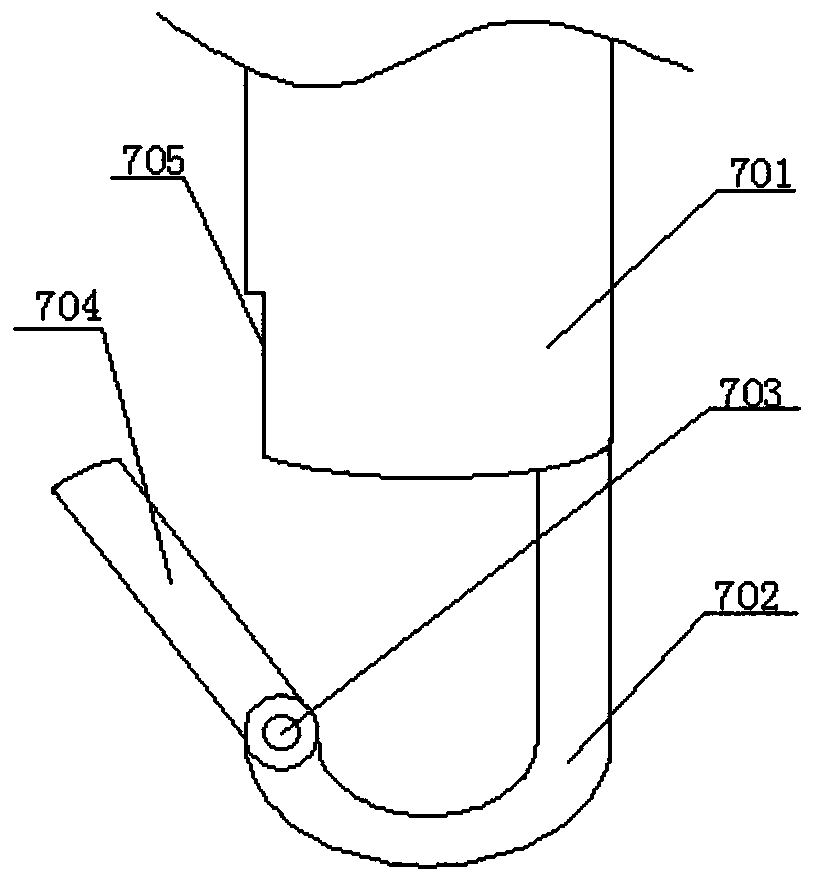

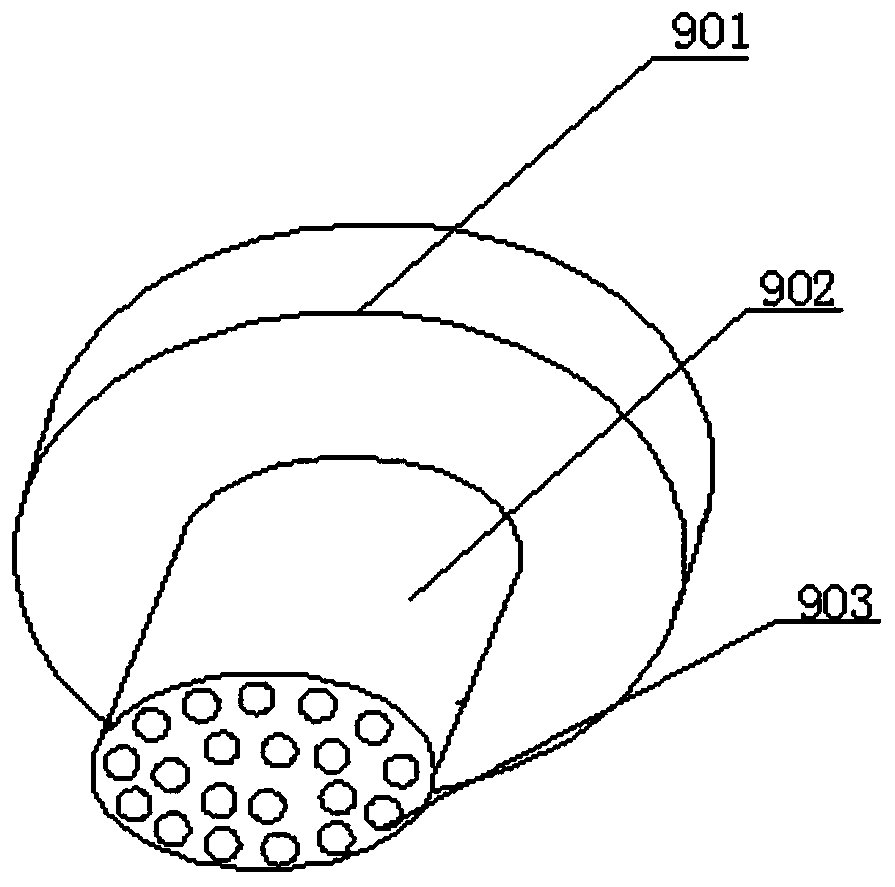

[0023] Embodiments of the present invention provide a frame hanger, such as Figure 1-5 As shown, including the slurry tank 1, the left side of the slurry tank 1 is fixedly welded with an equipment platform 2, and the upper surface of the equipment platform 2 is fixedly welded with a telescopic rod 3, and the up and down movement of the picture frame is realized by the telescopic rod 3. The upper end is movably connected with a rotating plate 4, the lower surface of the rotating plate 4 is fixedly connected with a servo motor 5, the output end of the servo motor 5 is connected with a turntable 6, the lower surface of the turntable 6 is fixedly connected with a hook 7, and the side of the equipment table 2 A slurry tank 8 is provided, a booster pump 14 is provided on the lower surface of the slurry tank 8, the slurry tank 8 communicates with the slurry tank 1 through a feed pipe 10, and a control valve 13 is provided on the outer surface of the feed pipe 10 The inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com