High-strength and easy-to-clean silica sol shell making process

A silica sol, high-strength technology, used in manufacturing tools, metal processing equipment, casting and molding equipment, etc., can solve the problems of rough surface of castings affecting surface quality, affecting enterprise production efficiency, product quality, and difficulty in cleaning sand in shell-making processes. To achieve good molding and coating effect, reduce the number of sizing layers, and improve the effect of anti-cracking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

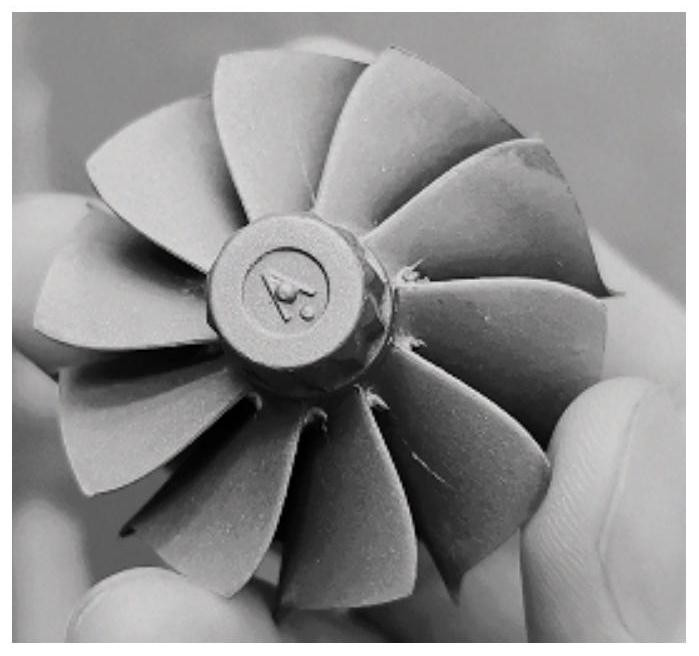

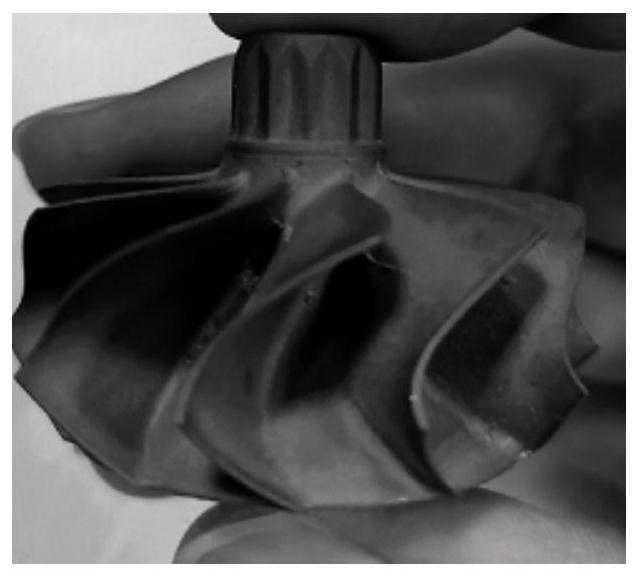

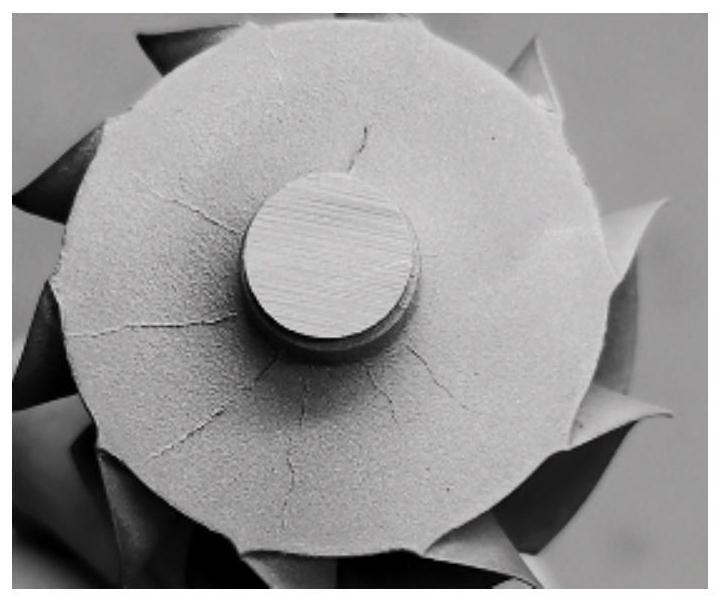

Image

Examples

Embodiment 1

[0035] High-strength, easy-to-clean silica sol shell manufacturing process is as follows:

[0036] After coating the surface of the wax model with the surface layer slurry, pour zircon sand with a mesh number of 30-60, dry at 55°C for 5 hours, then coat with the back layer slurry, and finally seal the slurry;

[0037] The surface layer slurry is made up of the following raw materials in parts by weight:

[0038] 15 parts of nano-zirconium sol, 40 parts of zirconium powder, 0.5 parts of polyoxyethylene ether, 0.15 parts of trihydrogen phosphate, 0.15 parts of polyether modified silicone oil, 0.02 parts of HX-006 anti-cracking agent, 0.016 parts of HX-007 inoculant, 35 parts of distilled water;

[0039] Wherein, the preparation method of nano zirconium sol is as follows:

[0040] Under stirring, slowly add basic cobalt carbonate to glacial acetic acid, after 8 minutes of insulated stirring at 40°C, add ethanol and continue stirring for 1 hour, then add triethanolamine to adjus...

Embodiment 2

[0050] High-strength, easy-to-clean silica sol shell manufacturing process is as follows:

[0051] After coating the surface of the wax model with the surface layer of slurry, pour zircon sand with a mesh number of 30-60, dry at 50°C for 5 hours, then coat with the back layer of slurry, and finally seal the slurry;

[0052] The surface layer slurry is made up of the following raw materials in parts by weight:

[0053]14 parts of nano zirconium sol, 40 parts of zirconium powder, 0.3 parts of polyoxyethylene ether, 0.1 part of trihydrogen phosphate, 0.4 parts of polyether modified silicone oil, 0.02 parts of HX-006 anti-cracking agent, 0.015 parts of HX-007 inoculant, 35 parts of distilled water;

[0054] Wherein, the preparation method of nano zirconium sol is as follows:

[0055] Under stirring, slowly add basic cobalt carbonate to glacial acetic acid, keep stirring at 40°C for 10 minutes, add ethanol and continue stirring for 1.5 hours, then add triethanolamine to adjust th...

Embodiment 3

[0065] High-strength, easy-to-clean silica sol shell manufacturing process is as follows:

[0066] After coating the surface of the wax model with the surface layer of slurry, pour zircon sand with a mesh number of 30-60, dry at 40°C for 3 hours, then coat with the back layer of slurry, and finally seal the slurry;

[0067] The surface layer slurry is made up of the following raw materials in parts by weight:

[0068] 13 parts of nano-zirconium sol, 30 parts of zirconium powder, 0.1 part of polyoxyethylene ether, 0.1 part of trihydrogen phosphate, 0.1 part of polyether modified silicone oil, 0.015 parts of HX-006 anti-cracking agent, 0.015 parts of HX-007 inoculant, 30 parts of distilled water;

[0069] Wherein, the preparation method of nano zirconium sol is as follows:

[0070] Under stirring, slowly add cobalt basic carbonate to glacial acetic acid, keep stirring at 35°C for 5 minutes, add ethanol and continue to stir for 1 hour, and then add triethanolamine to adjust the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com