Patents

Literature

130results about How to "High chemical inertness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

D-Dimer measuring kit (latex immunonephelometry method)

ActiveCN101819202AHigh refractive indexHigh chemical inertnessMaterial analysisFreeze-dryingPreservative

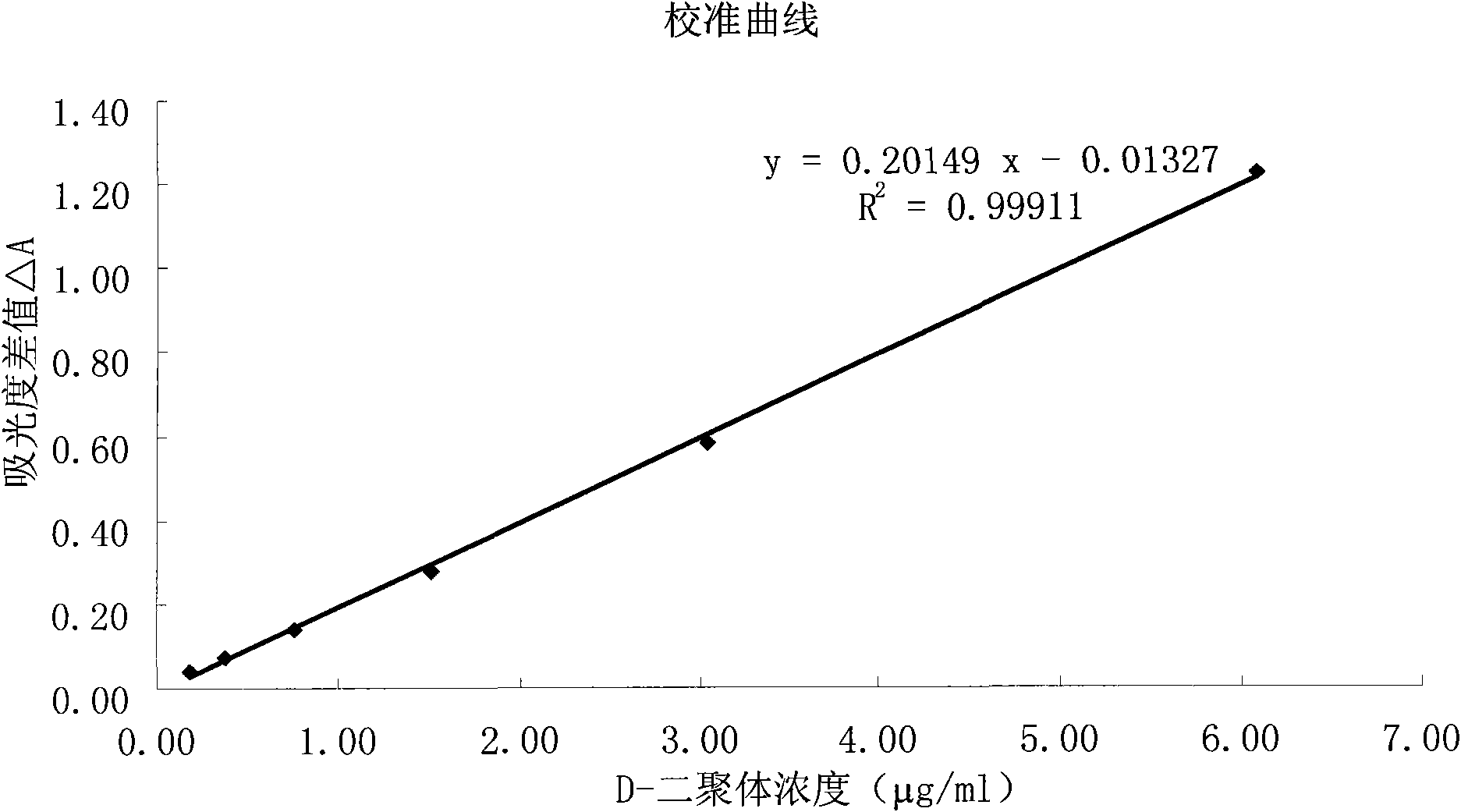

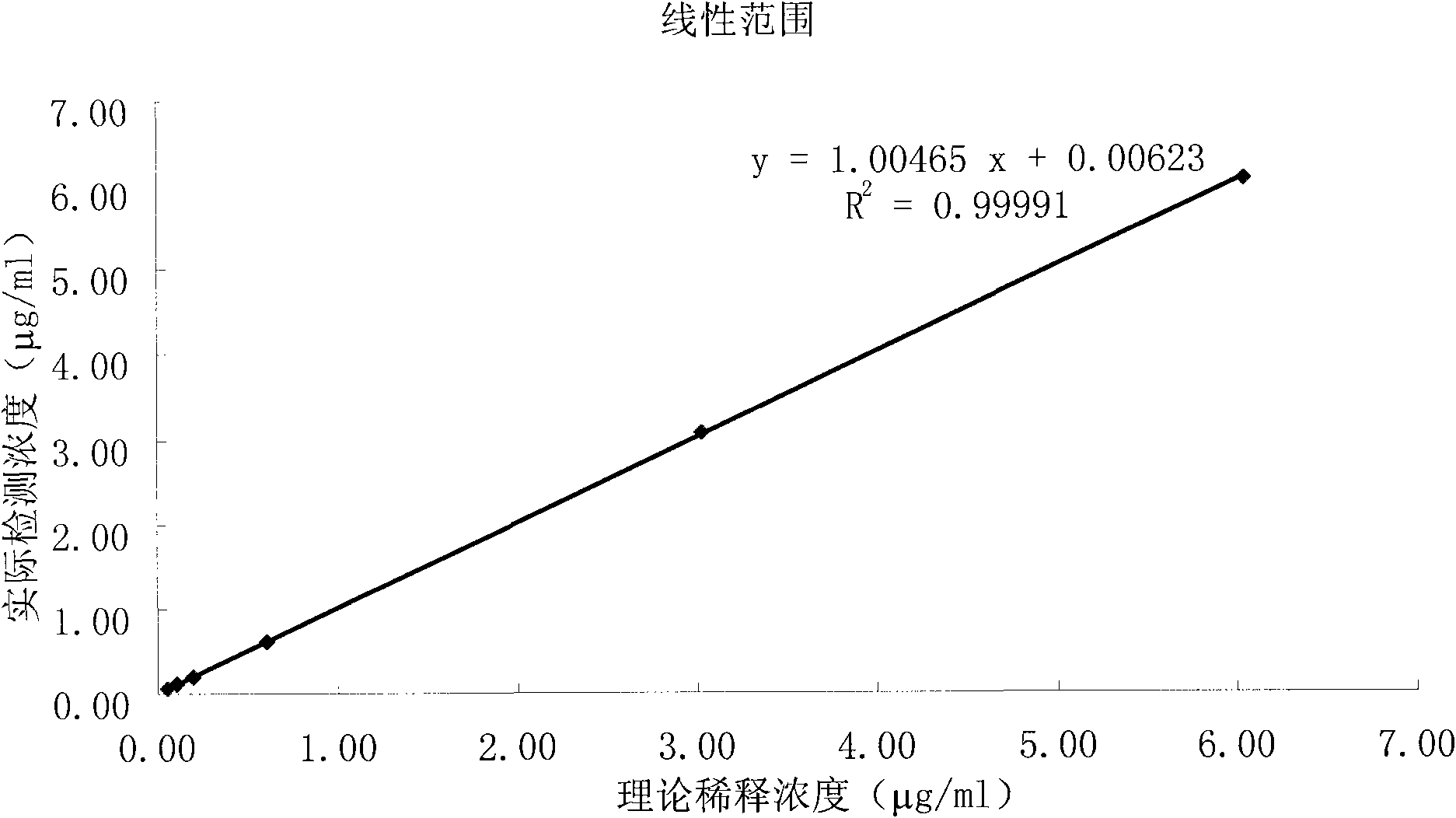

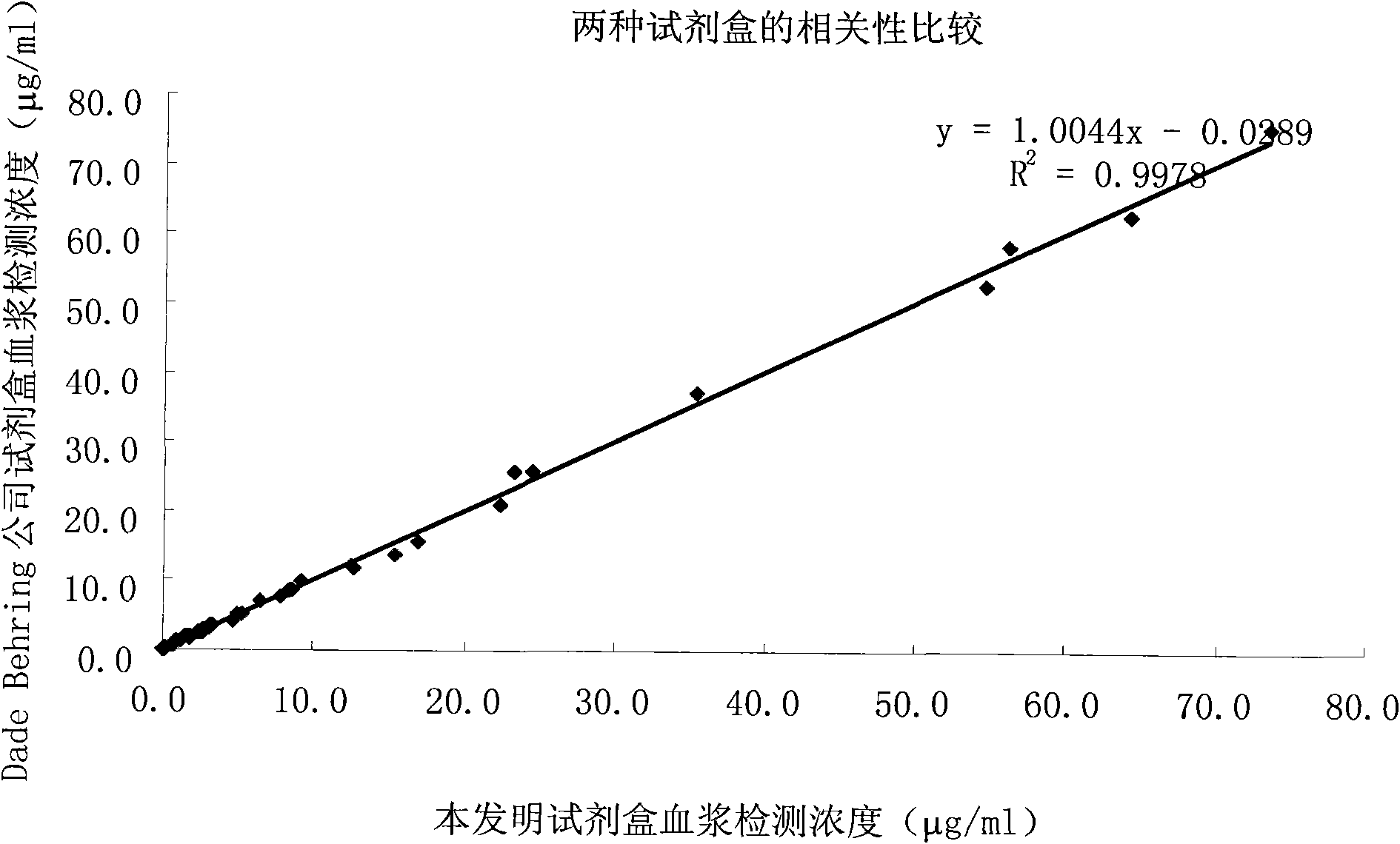

The invention relates to a kit for measuring the D-Dimer content by adopting a latex immunonephelometry method. The kit comprises a D-Dimer reagent R1, a D-Dimer reagent R2, a D-Dimer diluent and a D-Dimer calibration product, wherein the D-Dimer reagent R1 comprises a buffering solution, a stabilizing agent (1), coagulant and preservative; the D-Dimer reagent R2 comprises mouse anti-human D-Dimer monoclonal antibody latex enhanced particles, a buffering solution, a stabilizing agent (2) and preservative; the D-Dimer diluent comprises a buffering solution and preservative; and the D-Dimer calibration product is prepared by subpacking and freeze-drying a solution comprising a fibrin degradation product D-Dimer, a buffering solution, a stabilizing agent (3), excipient and preservative. The kit has the advantages of simple and rapid operation, accurate quantification, high sensitivity, strong specificity, low detection cost and strong instrument compatibility and is suitable for being popularized and used in various big-scale and small-scale hospitals.

Owner:SHANGHAI SUNBIO TECH

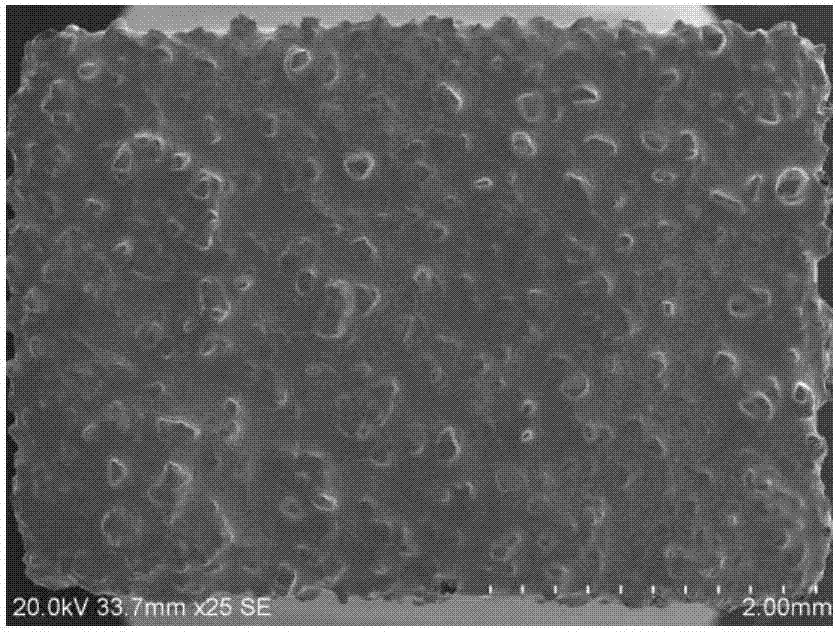

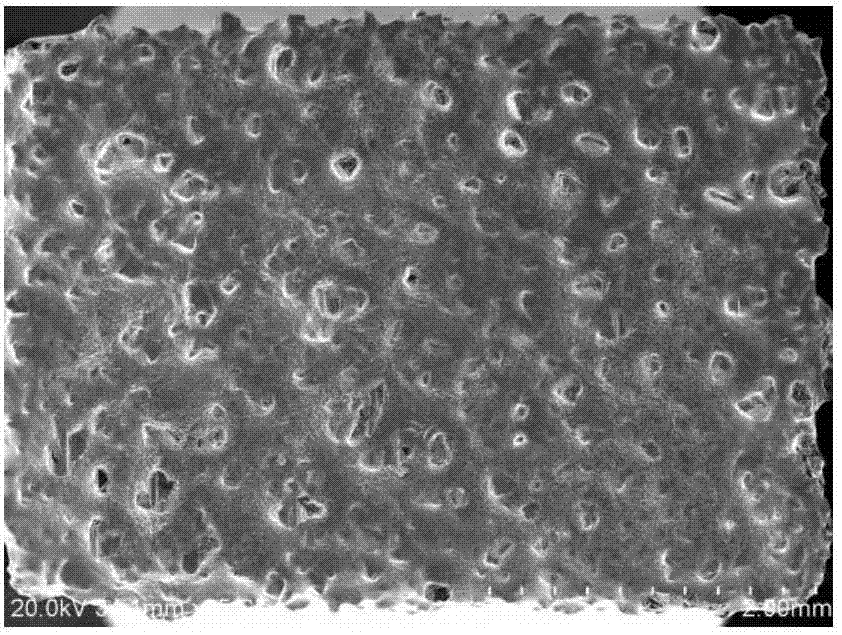

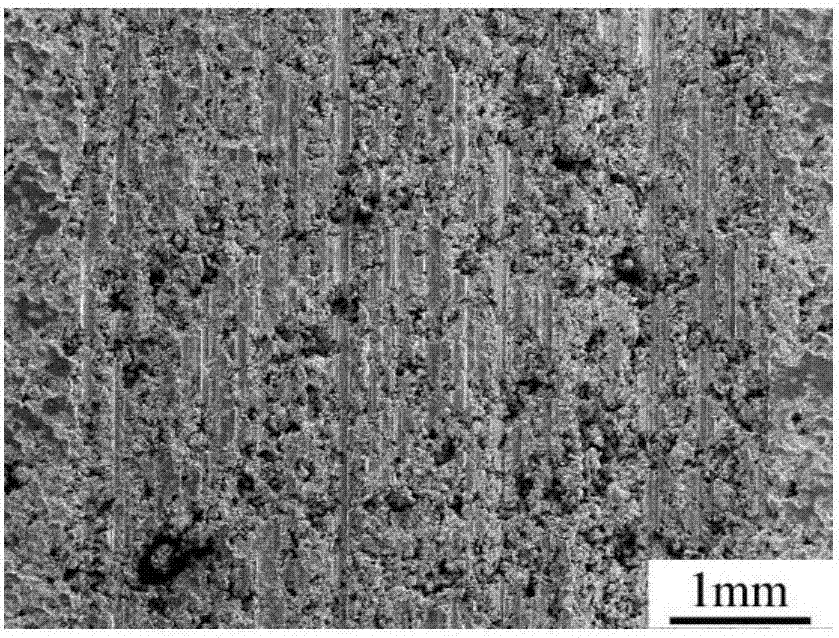

Silvered aramid conductive fiber and preparation method thereof

The invention provides a silvered aramid conductive fiber and a preparation method thereof. The preparation method is conducted according to the steps as follows: a. coarsening: coarsening the aramid fiber through putting the fiber into a mixed solution of sodium hydroxide, absolute ethanol and the balance of water, and neutralizing the fiber by rinsing; b. hydrolyzing: hydrolyzing the coarsened aramid fiber by putting the fiber into an acid solution; c. activation of palladium salt: activating the hydrolyzed aramid fiber subjected to activation of palladium salt in step b by putting the fiber into a mixed solution of hydrochloric acid, palladium chloride, stannous chloride and the balance of water; d. reducing: reducing the palladium salt activated aramid fiber in step c by putting the fiber into a mixed solution of hydrochloric acid, sodium hypophosphite and the balance of water; e. chemical silvering: chemical silvering the reduced aramid fiber in step d by putting the fiber into a chemical silvering solution of silver nitrate, sodium hydroxide, aqua ammonia, a complex agent, a reducing agent and the balance of water; f. drying: drying the chemical silvered aramid fiber in step e in the conventional manner to obtain the silvered aramid conductive fiber.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

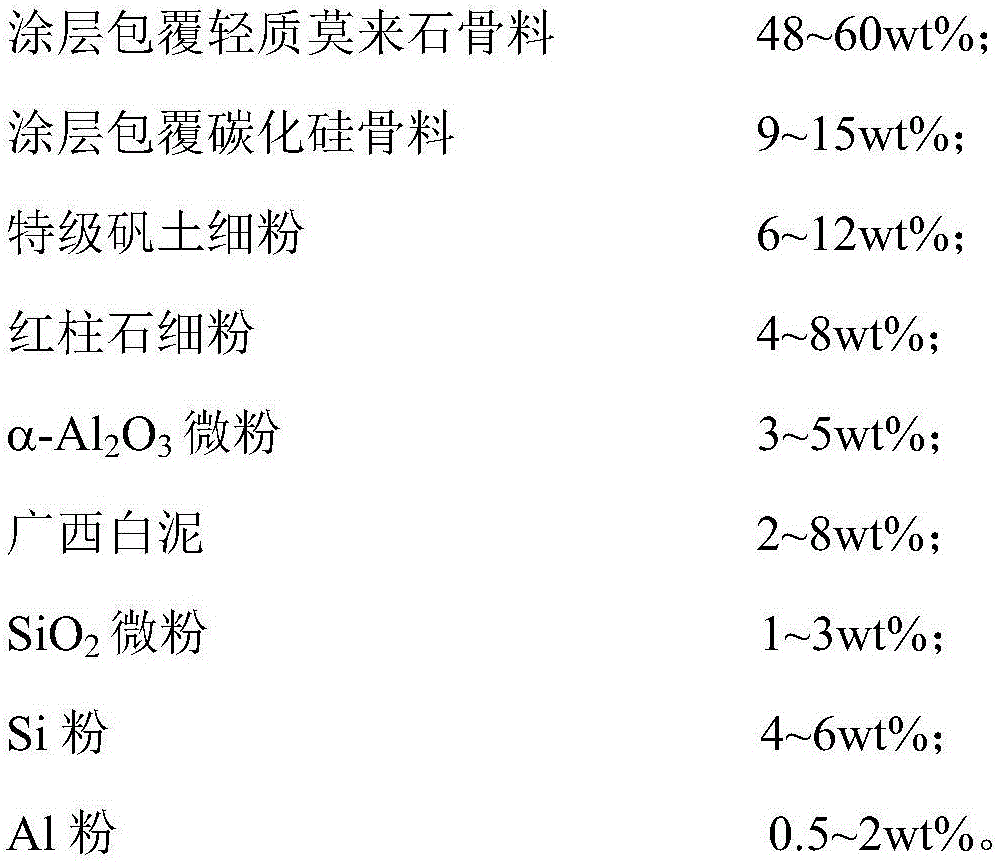

Mullite silicon carbide complex-phase fireproof material and preparation method thereof

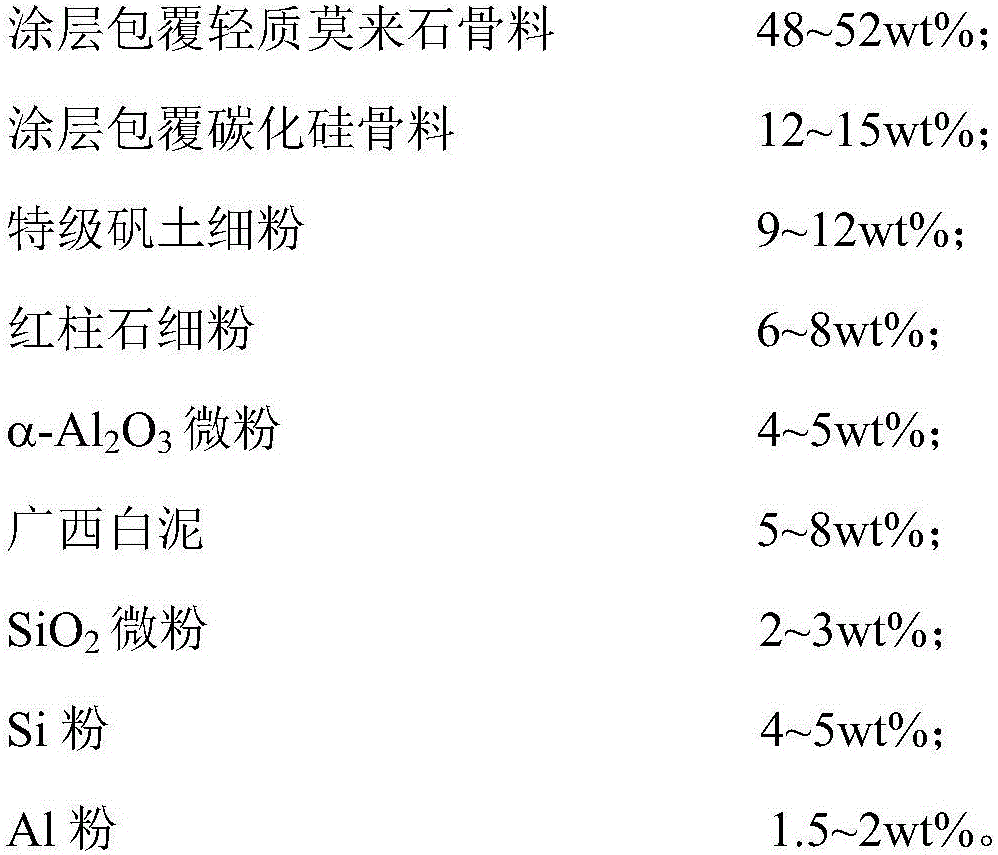

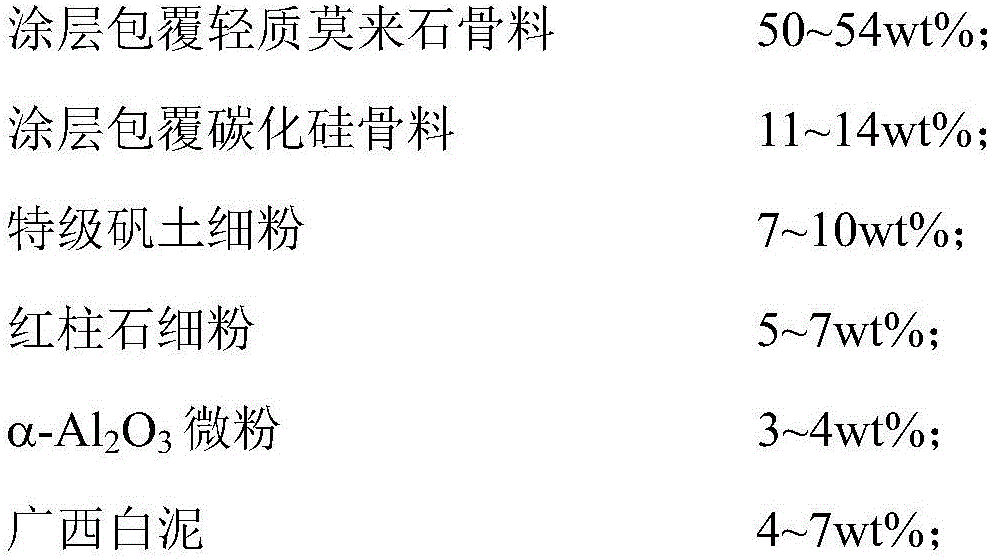

The invention relates to a mullite silicon carbide complex-phase fireproof material and a preparation method thereof. The mullite silicon carbide complex-phase fireproof material is characterized in that 48-60wt% of coating cladding mullite light aggregate, 9-15wt% of coating cladding silicon carbide aggregate, 6-12wt% of top-grade bauxite fine powder, 4-8wt% of andalusite fine powder, 3-5wt% of alpha-Al2O3 micro powder, 4-8wt% of Guangxi white clay, 1-3wt% of SiO2 micro powder, 4-6wt% of Si powder and 0.5-2wt% of Al powder are used as raw materials. The preparation method comprises the following steps of firstly mixing two kinds of the aggregate in the raw materials, adding a bonding agent, then performing mixed refining on the mixed aggregate, the bonding agent and other raw materials, performing material trapping, performing compression moulding, performing drying, and performing baking under the condition of 1250-1400 DEG C so as to obtain the mullite silicon carbide complex-phase fireproof material. The mullite silicon carbide complex-phase fireproof material prepared by the preparation method disclosed by the invention has the excellent characteristics of being low in heat conduction coefficients, good in erosion resistance, and high in intensity.

Owner:WUHAN UNIV OF SCI & TECH

Coated cbn

InactiveUS20100213247A1Reduced strengthHigh retention ratePigmenting treatmentOther chemical processesSecondary layerBoride

The invention relates to a coated boron or nitrogen containing superhard abrasive material selected from cBN, boron suboxide and boron carbide comprising: cBN, boron suboxide and / or boron carbide superhard abrasive material substrate; a primary layer of a carbide / nitride / boride forming metal, such metal preferably being Ti and preferably being substantially in the form of the carbide, nitride or boride; a secondary layer of a high melting point metal selected from W, Mo, Cr, Ni, Ta, Au, Pt, Pd and alloys thereof; and an overcoat of Ag, Ni, Cu, Au, Pd, Pt, Rh, Os, Ir, Re, combinations and alloys thereof such as bronze (Cu / Sn), silver / bronze and silver / tin, the metal of the secondary layer being different to the metal of the overcoat. The invention further relates to methods for the manufacture of such material, use of such materials in tools and tools including such material.

Owner:ELEMENT SIX LTD

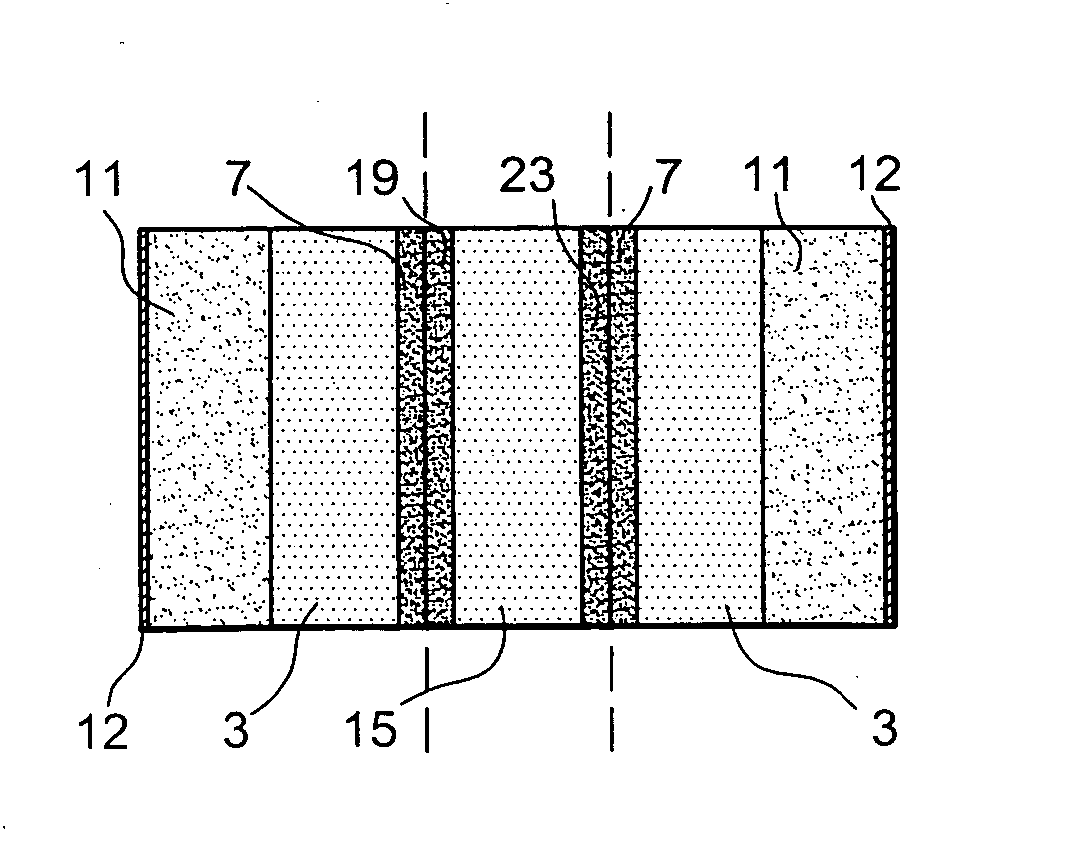

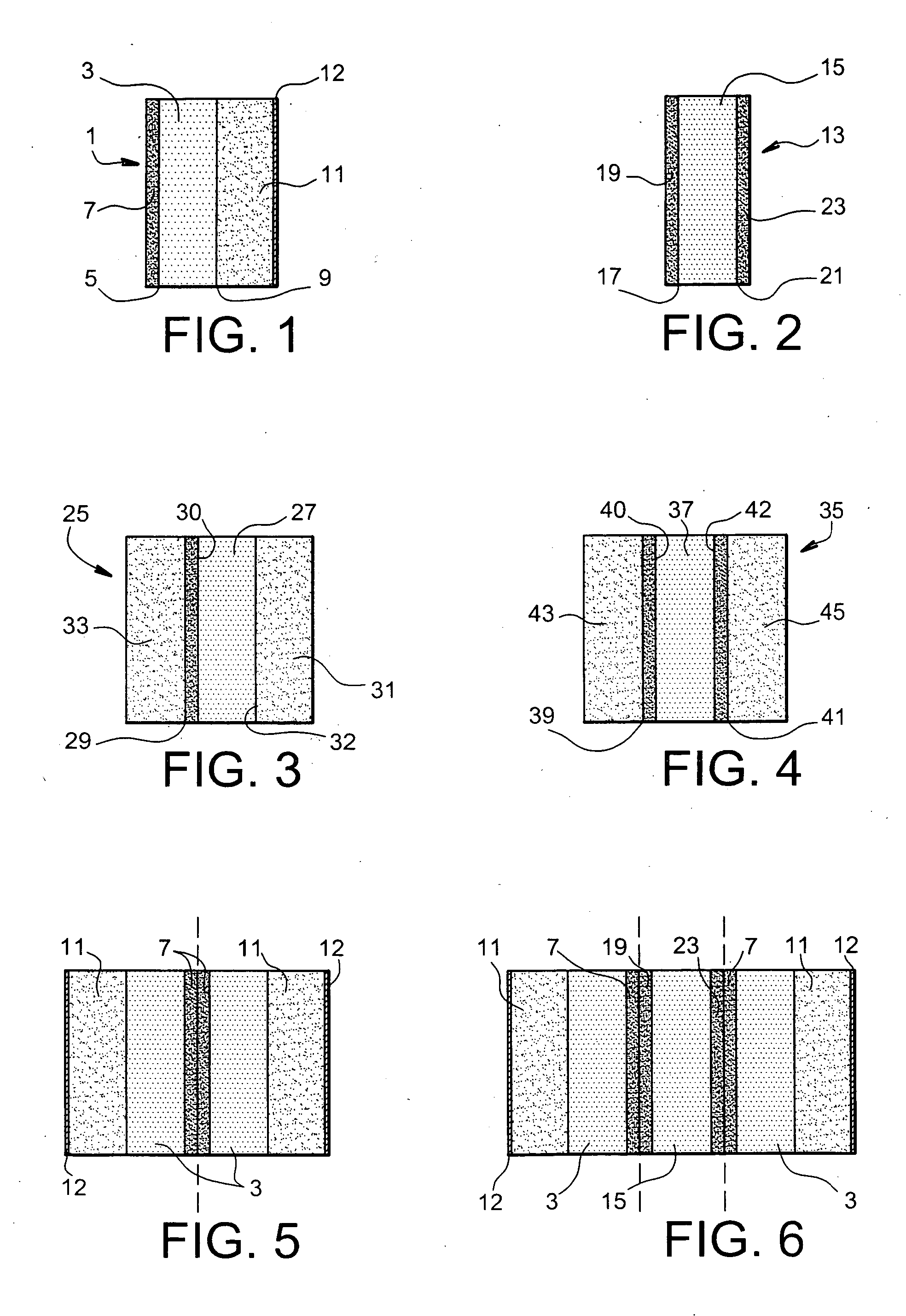

Porous structures useful as bipolar plates and methods for preparing same

InactiveUS20060183300A1Reduce porosityExcellent electrochemicalFinal product manufactureSemiconductor/solid-state device manufacturingFuel cellsCarbon fibers

The invention relates to a porous structure, characterized in that it comprises a porous matrix (15) made of carbon fabric, said porous matrix being bounded on at least one of its faces (17, 21) by an impermeable layer (19, 23) made of an element chosen from carbon fibres, carbon nanotubes and glassy carbon, said impermeable layer being linked to the porous matrix via carbon-carbon bonds. The invention also relates to a process for manufacturing such porous structures. Application to the fields of fuel cells and heat exchangers.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

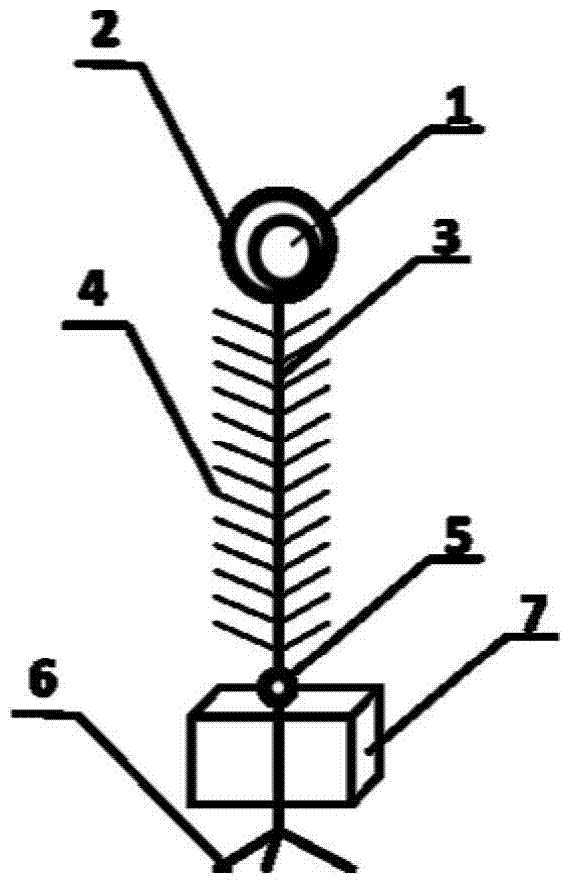

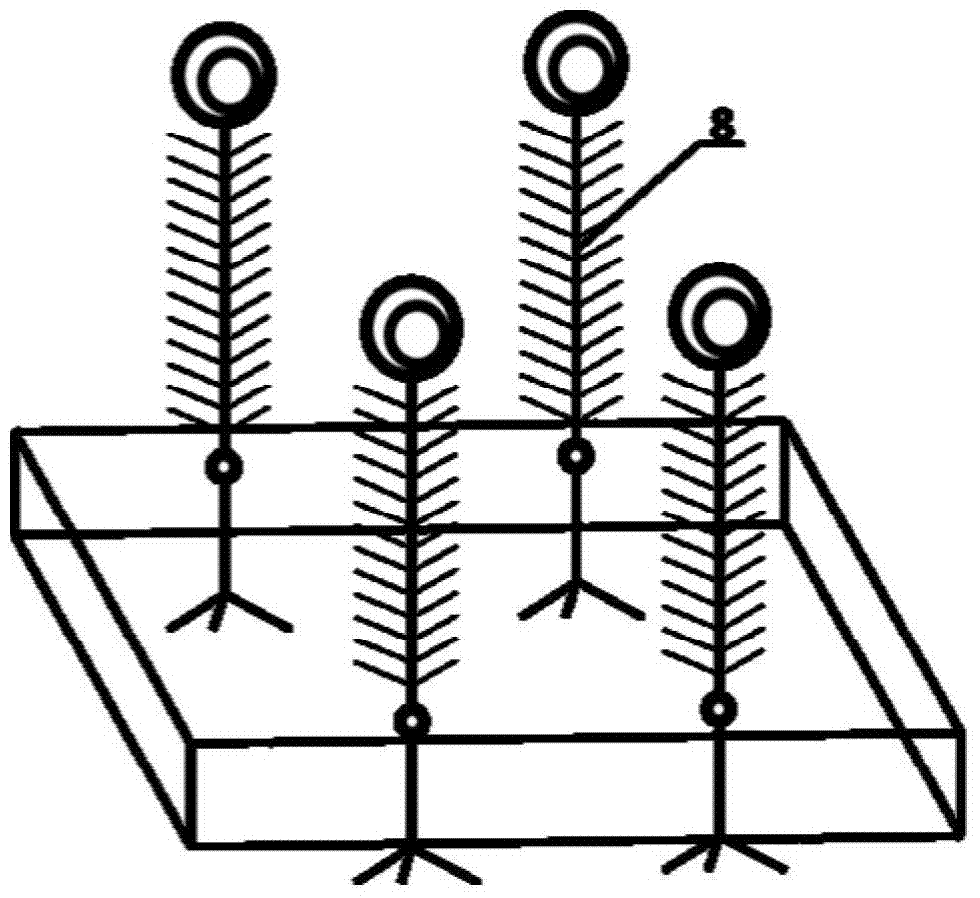

Combined type multifunctional artificial seaweed

ActiveCN104496038AHigh chemical inertnessStrong oxidation abilityBiological water/sewage treatmentBiologySeaweed food

The invention discloses combined type multifunctional artificial seaweed. The combined type multifunctional artificial seaweed comprises a functional floater, an artificial seaweed body, a fixed system and a functional falling weight, wherein the functional floater is fixedly connected with the top end of the artificial seaweed body; the lower end of the artificial seaweed body is connected with the fixed system and the functional falling weight; the functional floater consists of a foamed ceramic shell and a plastic inner core; the plastic inner core is arranged in the shell; and foamed ceramic is doped with a photocatalyst TiO2. The combined type multifunctional artificial seaweed disclosed by the invention has the advantages that by common action of all the parts, a water body is treated in different or common time periods by high efficiency, so that the time cost is saved and a better water-body treating effect is obtained.

Owner:GUANGXI BOSSCO ENVIRONMENTAL PROTECTION TECH

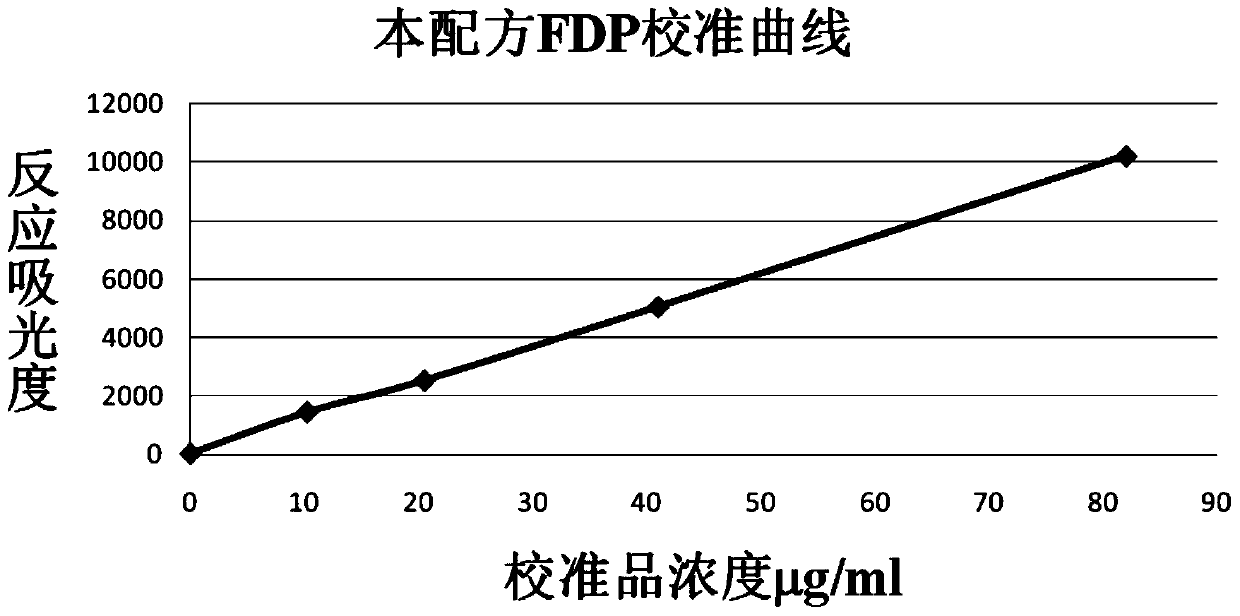

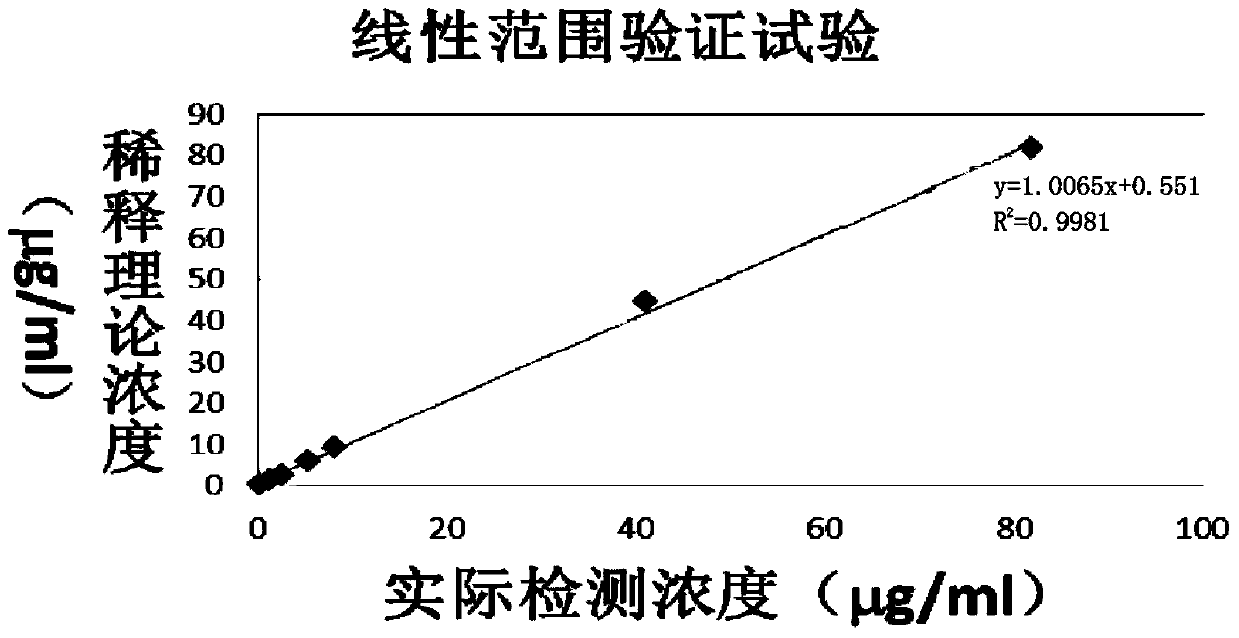

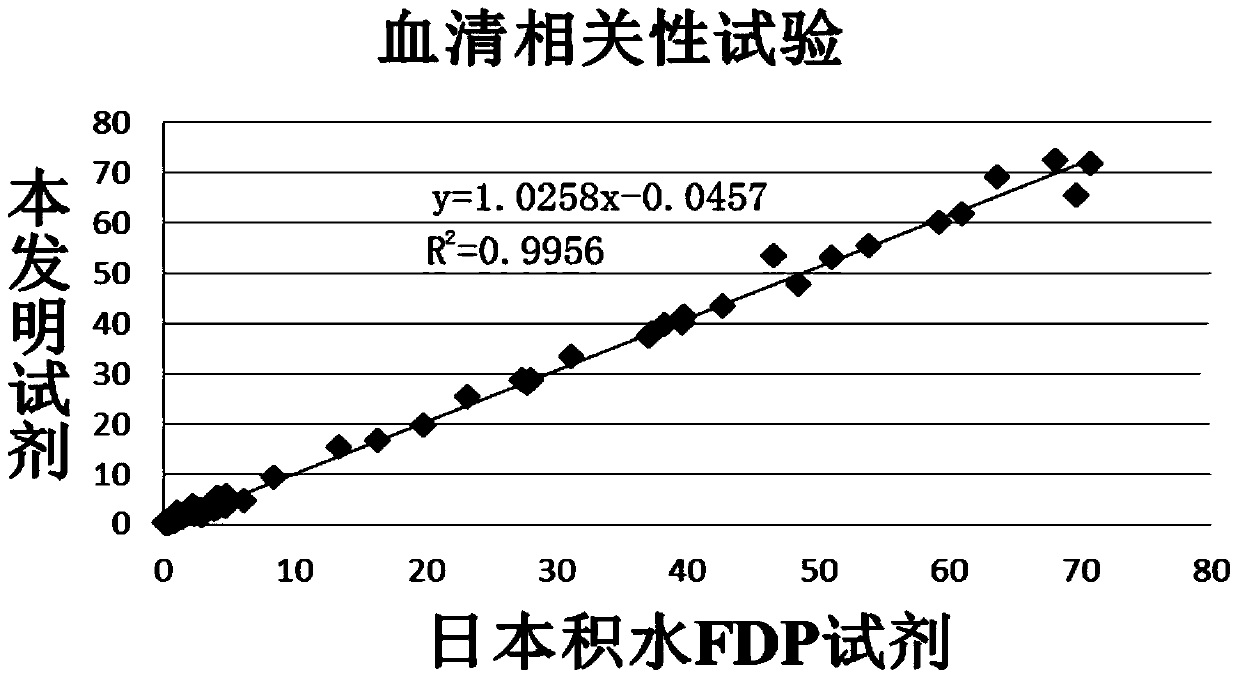

Detection kit for fibrous protein or fibrinogen degradation products

ActiveCN104198724AHigh refractive indexHigh chemical inertnessBiological testingFiberFibrinogen degradation product

The invention relates to a detection kit for of fibrous protein or fibrinogen degradation products. The detection kit consists of an FDP R1 reagent, an FDP R2 reagent and an FDP standard product which are independent respectively. The invention establishes a method for determining the content of FDP in serum or blood plasma of a human body by coupling FDP antibodies and latex particles and adopting a latex-enhanced turbidimetry. Compared with the prior art, the kit can be used for detecting the FDP with the concentration range being 0.25-80microgram / ml in the serum or the blood plasma, and the problem of narrow detection linearity of the existing kit is solved; simultaneously, when being applied to carry out FDP test, the kit has the advantages of simplicity in operation, high accuracy, good repeatability and high sensitivity, and can be used on a full-automatic biochemical analyzer, a special protein instrument and a spectrophotometer.

Owner:上海睿康生物科技有限公司

MnO2-TiO2 carbon nanotube-porous inorganic ceramic membrane low-temperature catalytic denitrification self-cleaning material and its preparation method

ActiveCN102728346AEvenly dispersedImprove conversion rateCatalyst protectionDispersed particle separationFoaming agentCarbon nanotube

A MnO2-TiO2 carbon nanotube-porous inorganic ceramic membrane low-temperature catalytic denitrification self-cleaning material and its preparation method belong to the field of low-temperature catalytic denitrification. A porous inorganic ceramic membrane is used as a carrier; a compound of MnO2, TiO2 and carbon nanotube is loaded on the surface of the carrier so as to obtain a catalyst; and a fluorocarbon resin material is loaded on the surface of the catalyst, wherein the mass percents of the fluorocarbon resin material and the catalyst itself are respectively 30% and 70%; in the catalyst, the mass percent of the porous inorganic ceramic membrane is 50-80%, and the mass percent of the compound of MnO2, TiO2 and graphene is 20-50%. As coal ash in a thermal power plant is used as a raw material and charcoal is used as a foaming agent to prepare the porous inorganic ceramic membrane, the price is low; as the porous inorganic ceramic membrane has a porous structure and large specific surface area, more active centers can be provided for catalytic reaction; the carbon nanotube has large specific surface area, high chemical inertness and tunnel conductivity of large delocalized pi bond, catalytic performance of the material at low temperature can be raised; and the fluorocarbon resin compound on the surface of the catalyst has a self-cleaning function.

Owner:SHANXI PULI ENVIRONMENT ENG CO LTD

Rubber film

The invention discloses a rubber film. The rubber film comprises, by weight, 100 parts of rubber, 15 to 45 parts of a hardening agent, 1 to 3 parts of a yellowing-resistant agent, 1 to 5 parts of a vulcanizing agent, 1 to 5 parts of a vulcanizing accelerating agent, 1 to 3 parts of an aging resistant agent and 1 to 10 parts of an inorganic pigment. The rubber film has high chemical inertness, resists high-corrosivity substances such as acids and alkalis, has certain hardness and deflection, has good luster and an appropriate color, has a low production cost and an appropriate price, can effectively satisfy demands, and is scratched difficultly or has wear resistance.

Owner:LONGMEN DUOTAI IND

Ddelay coking defoaming agent composition and preparation method thereof

ActiveCN103768832AImprove defoaming abilityReduce the amount addedThermal non-catalytic crackingFoam dispersion/preventionAlcoholSolvent

The invention relates to a delay coking defoaming agent composition and a preparation method thereof, the defoaming agent is prepared by compounding fluorine-containing polysiloxane, glycerin type dendritic polyether, high carbon alcohol and a solvent. The preparation method of the defoaming agent is as follows: dispersing the fluorine-containing polysiloxane in the high carbon alcohol, stirring for 1 to 2 hours at 10-30 DEG C, then adding the glycerin type dendritic polyether and the solvent, stirring for 1 to 5 hours at 100-150 DEG C, and cooling to obtain a defoaming agent product. The delay coking defoaming agent has excellent defoaming antifoaming performances at 400-500 DEG C, in a high temperature delay coking process, the delay coking defoaming agent can still maintain good defoaming antifoaming performances and stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparing method of titanium fire resistance coating

ActiveCN107138878AHigh hardnessHigh temperature oxidation resistanceWelding/cutting media/materialsSoldering mediaAlloyFire resistance

The invention discloses a preparing method of a titanium fire resistance coating. A continuous strip-shaped Ti-37.5Zr-15Cu-10Ni base amorphous alloy is selected to serve as brazing filler metal, CBN particles are selected as hard wear-resisting particles, strip-shaped brazing filler metal is placed on the blade tip in advance, and wraps the blade tip required to be coated with the titanium fire resistance coating, an organic bonding agent is used for being mixed with Ni-plated CBN particles, and the brazing filler metal is evenly coated with the bonding agent; in the vacuum environment, a medium-frequency induction coil is used for locally heating a rotor blade tip, the heating temperature is kept between 840 DEG C to 850 DEG C and is kept for a certain time, the brazing filler metal can be completely molten, the brazing filler metal is naturally cooled in the high-vacuum environment, and the titanium fire resistance coating is formed; and the titanium fire resistance coating obtained through the preparing method of the titanium fire resistance coating has high hardness, high wear resistance, high impact resistance, high temperature oxidability resistance, high fire resistance and high combination strength, meanwhile, the property of the base body cannot be affected, and the base body anti-fatigue property is ensured.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

Preparation method of WC-Co-cBN composite material

The invention belongs to the technical field of material preparation and in particular relates to a preparation method of a WC-Co-cBN composite material. The preparation method of the WC-Co-cBN composite material comprises the following steps: firstly weighing WC, metal Co powder and cBN raw material in proportion, uniformly mixing, mixing by carrying out ball milling, drying the mixed raw materials in a drying oven at the temperature of 50-200 DEG C, then sieving with a sieve of 100-300 meshes, putting the dried raw materials into a mould, then placing the mould into a hot-pressing sintering furnace, heating the sintering furnace to 1200-1400 DEG C at a speed of 30-50 DEG C / min, insulating for 5-30 minutes, and maintaining pressure to be 20-50MPa, so that the WC-Co-cBN composite material is obtained. The preparation method of the WC-Co-cBN composite material has the advantages that the hot-pressing method is adopted, the sintering temperature is low, sintering time is short, and no phase transformation of cBN can be guaranteed while the WC-Co-cBN composite material has high shrinkage percentage and high volume density; meanwhile, hot pressing energy consumption is low, cost is low, operation is easy, and safety coefficient is high.

Owner:NORTHEASTERN UNIV

Organic-inorganic silicon modified polyurethane super-hydrophobic coating and preparation method thereof

PendingCN110616032AImprove hydrophobicityStabilize hydrogen bondsPolyurea/polyurethane coatingsAlkaneCarbon nanotube

The invention relates to the technical field of polyurethane super-hydrophobic coatings and discloses an organic-inorganic silicon modified polyurethane super-hydrophobic coating and a preparation method thereof, wherein the coating is prepared from the following formula raw materials: octadecyltriethoxysilane, nano silicon dioxide, carbon nanotubes, a curing agent, isophorone diisocyanate, 1,5-pentanediol, dimethylolpropionic acid, hydroxyl-terminated polysiloxane silicone oil, a neutralizer and hydrazine hydrate. The invention discloses an organic-inorganic silicon modified polyurethane super-hydrophobic coating and a preparation method thereof, wherein the organic silicon dihydroxyl-terminated polysiloxane silicone oil is used as a chain extender to prepare modified polyurethane; compared with the prior art, the polyurethane coating contains a large amount of hydrophobic groups methyl and alkane chains, the hydrophobic performance of polyurethane is greatly enhanced, SiO2 and carbonnanotubes have high chemical inertness and good mechanical properties and mechanical properties, the chemical stability and toughness of the polyurethane coating are improved, and the phenomenon thatthe coating is prone to loss and falling off in the long-time use process is avoided.

Owner:姚国江

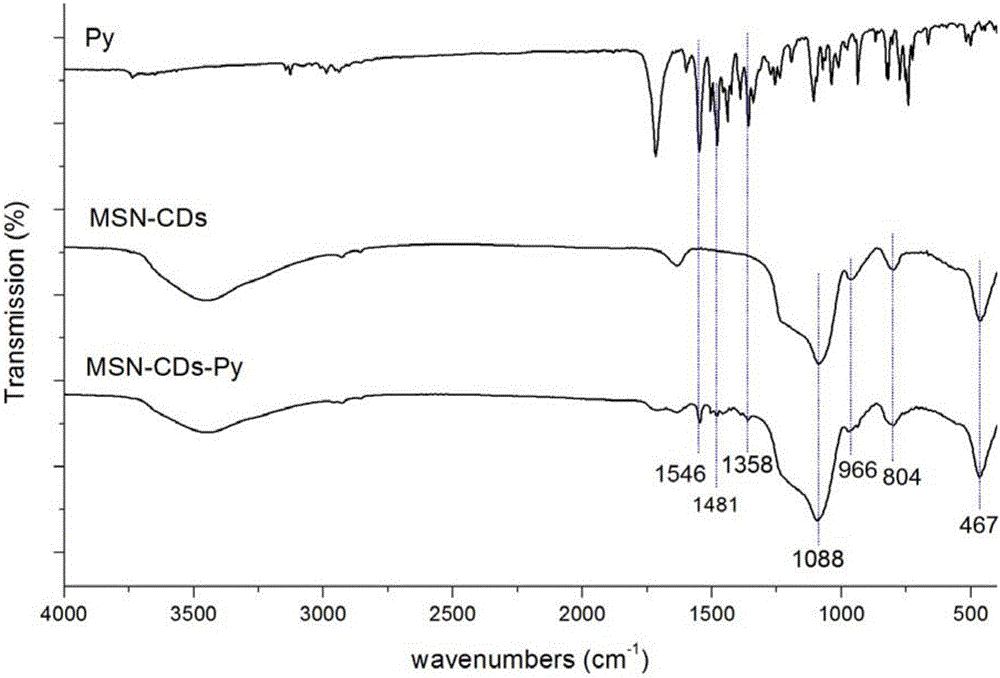

Preparation method and application of pesticide pyraclostrobin supported sample as well as application of pesticide pyraclostrobin supported sample in fluorescent tracing of pathogenic bacteria of asparagus stem blight

ActiveCN106644640ALarge specific surface areaGood biocompatibilityBiocideWeighing by removing componentMesoporous silicaPathogenic bacteria

The invention discloses a preparation method and an application of a pesticide pyraclostrobin supported sample as well as the application of the pesticide pyraclostrobin supported sample in fluorescent tracing of pathogenic bacteria of asparagus stem blight. The preparation method of the pesticide pyraclostrobin supported sample comprises the following steps: (1) preparation of a supporter material: a mesoporous silica carbon quantum dot material is prepared as the supporter material; (2) the pesticide pyraclostrobin is supported on the mesoporous silica carbon quantum dot material, and the pesticide pyraclostrobin supported sample is obtained. The prepared pesticide pyraclostrobin supported system can support and release pyraclostrobin, can be used for inhibiting the pathogenic bacteria of asparagus stem blight and can be applied to fluorescent tracing of the pathogenic bacteria of asparagus stem blight.

Owner:INST OF PLANT PROTECTION CHINESE ACAD OF AGRI SCI +1

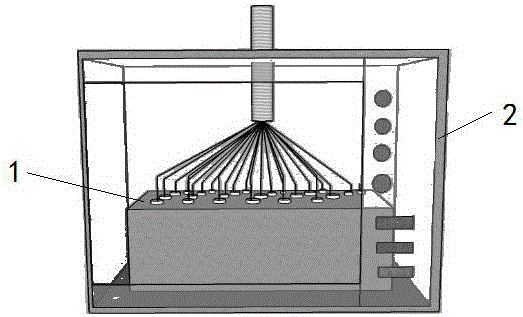

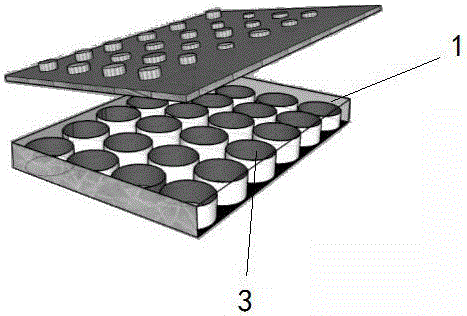

Method for preparing polycrystalline materials by aid of high-throughput hybridization microwave synthesis processes

InactiveCN106191991ARapid parallel preparationShorten experiment timePolycrystalline material growthSingle crystal growth detailsRare-earth elementReaction temperature

The invention discloses a method for preparing polycrystalline materials by the aid of high-throughput hybridization microwave synthesis processes. The method includes weighing high-purity substance powder in glove boxes according to molar ratios; sufficiently grinding and mixing the high-purity substance powder and manufacturing wafer biscuits by the aid of tablet presses; arranging reactants in cylindrical aluminum oxide crucibles; heating the reactants in microwave ovens by the aid of SiC which is used as a heat conduction material. The method has the advantages that a plurality of samples or different composition points of the same sample can be simultaneously prepared in a high-throughput manner; the samples can be heated by the aid of microwave, the SiC is used as the heat conduction material, accordingly, the temperatures of the samples can reach required reaction temperatures within extremely short time, and the polycrystalline materials can be quickly and economically synthesized in a high-throughput manner; the polycrystalline materials can be prepared in the high-throughput manner by the aid of the method, the shortcoming of limitation on the reaction temperature and the reaction time in existing sample preparation procedures can be overcome, and the polycrystalline materials can be efficiently synthesized; synthesized tungsten bronze series AxWO3 (A=Na, Ca and B) and rare earth titanium compounds RTiO3 (R represents rare earth elements) which are prepared by the aid of the method are crystals, and accordingly the method can be widely applied to the field of technologies for preparing magnetic, superconducting and relevant materials.

Owner:SHANGHAI UNIV

Thick film nanometer gold electrode slurry and preparation method thereof

InactiveCN101436441ASmall particle sizeChange the microstructureConductive materialNon-conductive material with dispersed conductive materialCelluloseSlurry

The invention relates to a lead-free thick film nanometer gold electrode slurry which selects nanometer gold powder as a main functional phase, in particular to a thick film nanometer gold electrode slurry and a method for preparing the same. The thick film nanometer gold electrode slurry is characterized by comprising the following components by weight portion: 60 to 90 portions of inorganic part and 40 to 10 portions of organic solvent, wherein the inorganic part comprises the following components by weight portion: 90 to 98 portions of noble metal nanometer gold powder, 2 to 10 portions of lead-free glass powder and 0 to 6 portions of inorganic additive; and the organic solvent comprises the following components by weight portion: 40 to 90 portions of terpineol, 4 to 10 portions of ethyl cellulose, 3 to 30 portions of ethyl caproate, 1 to 6 portions of nitro cellulose, 1 to 25 portions of triethanolamine, and 1 to 6 portions of sodium dodecylsulphonate. The invention changes the microstructure of the gold electrode slurry so as to change the conductivity, the printing performance and the connecting firmness of the slurry, thus the application of the gold electrode slurry to electronic parts and components, in particular high precision electronic parts and components is greatly expanded.

Owner:IRICO

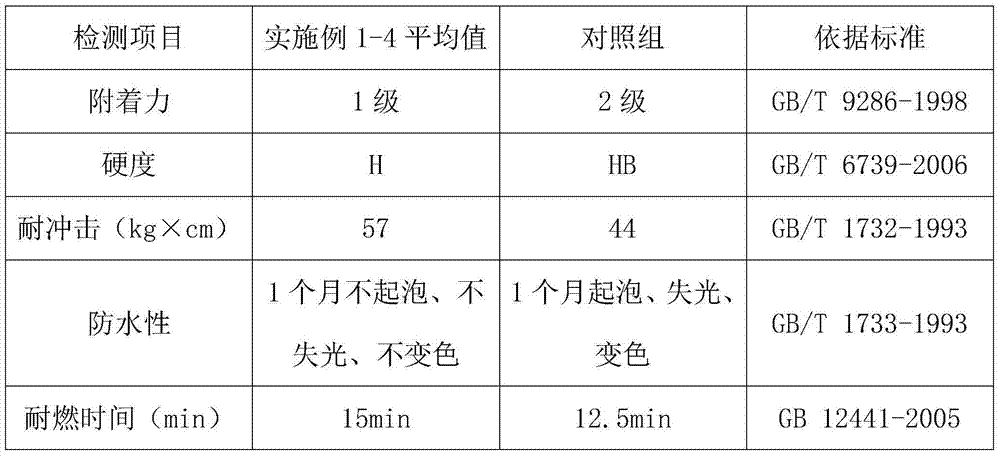

High-adhesion high-strength flame-retardant water-based paint

ActiveCN104845483AGood dispersionImprove adhesionFireproof paintsAnti-corrosive paintsWater basedSilicon dioxide

The invention discloses a high-adhesion high-strength flame-retardant water-based paint. The paint comprises raw materials of, by weight, 52 parts to 55 parts of core shell fluorinated polyacrylate solutions, 15 parts to 18 parts of chlorosulfonated polyethylene, 3 parts to 6 parts of ethylene-propylene-diene monomer rubber, 15 parts to 18 parts of modified silicon dioxide, 7 parts to 10 parts of attapulgite, 6 parts to 9 parts of zeolite powder, 1.5 parts to 2.5 parts of barium sulfate, 2 parts to 3.5 parts of melamine, 3 parts to 4 parts of ethylene glycol, 2 parts to 5 parts of dispersing agents, 1.3 parts to 1.6 parts of defoamers, 0.8 parts to 1.2 parts of coalescing agents, 1.2 parts to 1.5 parts of advection agent, 0.7 part to 1 part of advection aids, 2 parts to 2.5 parts of thickeners and 20 parts to 40 parts of deionized water. The paint is high in adhesion, good in flame-retardant effect, high in strength, good in fireproof property, high in weather resistance, easy to paint and the like.

Owner:安庆凯锐化工科技有限公司

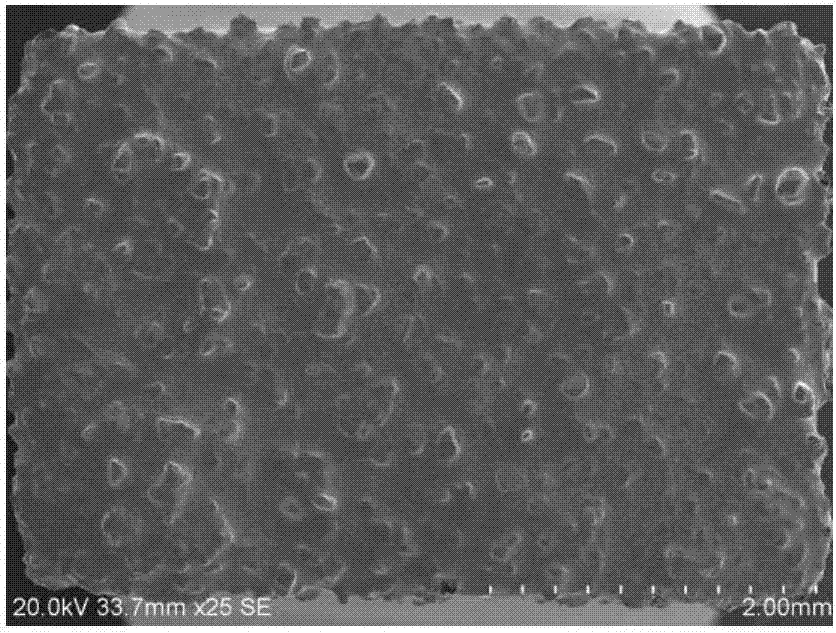

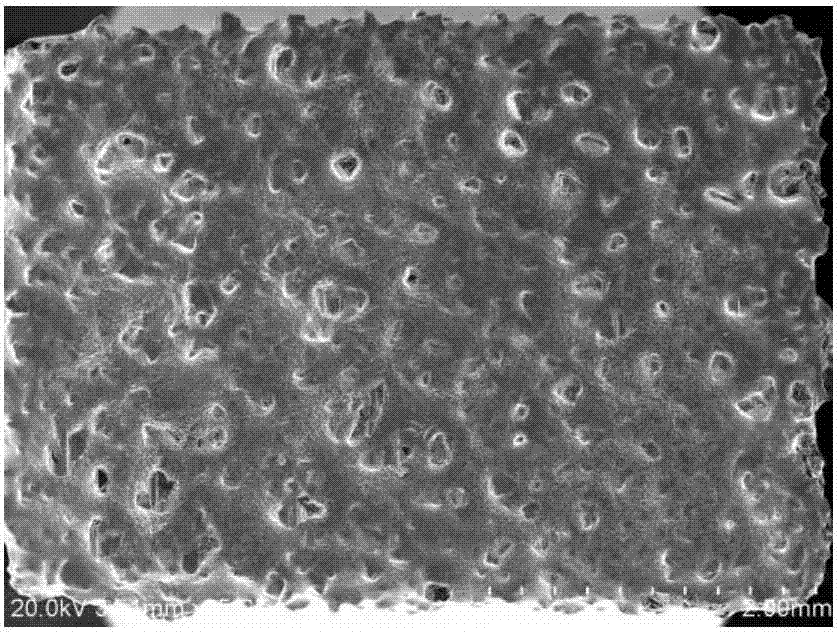

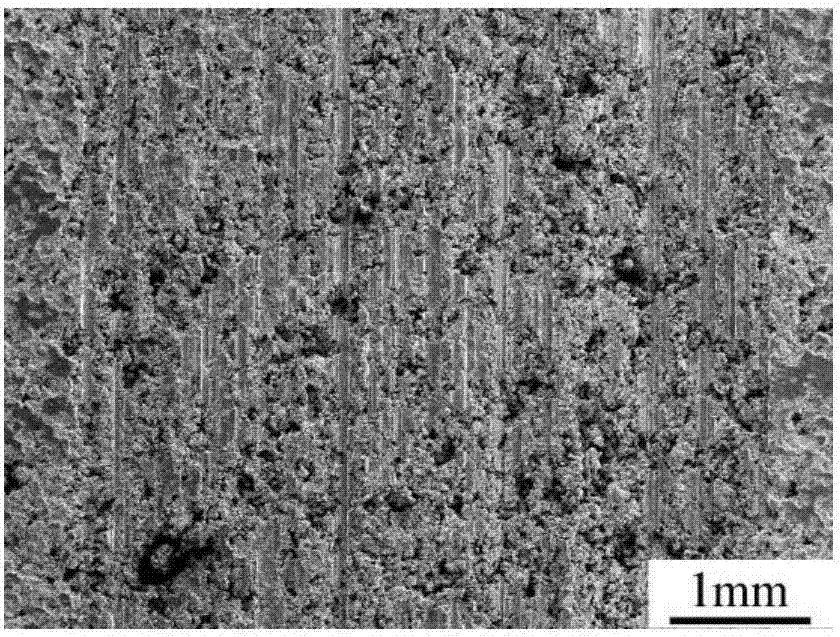

A kind of aramid silver-plated conductive fiber and preparation method thereof

ActiveCN103668944BHigh chemical inertnessReduce surface activityFibre typesSilver plateBiological activation

The invention provides a silvered aramid conductive fiber and a preparation method thereof. The preparation method is conducted according to the steps as follows: a. coarsening: coarsening the aramid fiber through putting the fiber into a mixed solution of sodium hydroxide, absolute ethanol and the balance of water, and neutralizing the fiber by rinsing; b. hydrolyzing: hydrolyzing the coarsened aramid fiber by putting the fiber into an acid solution; c. activation of palladium salt: activating the hydrolyzed aramid fiber subjected to activation of palladium salt in step b by putting the fiber into a mixed solution of hydrochloric acid, palladium chloride, stannous chloride and the balance of water; d. reducing: reducing the palladium salt activated aramid fiber in step c by putting the fiber into a mixed solution of hydrochloric acid, sodium hypophosphite and the balance of water; e. chemical silvering: chemical silvering the reduced aramid fiber in step d by putting the fiber into a chemical silvering solution of silver nitrate, sodium hydroxide, aqua ammonia, a complex agent, a reducing agent and the balance of water; f. drying: drying the chemical silvered aramid fiber in step e in the conventional manner to obtain the silvered aramid conductive fiber.

Owner:TIANNUO PHOTOELECTRIC MATERIAL

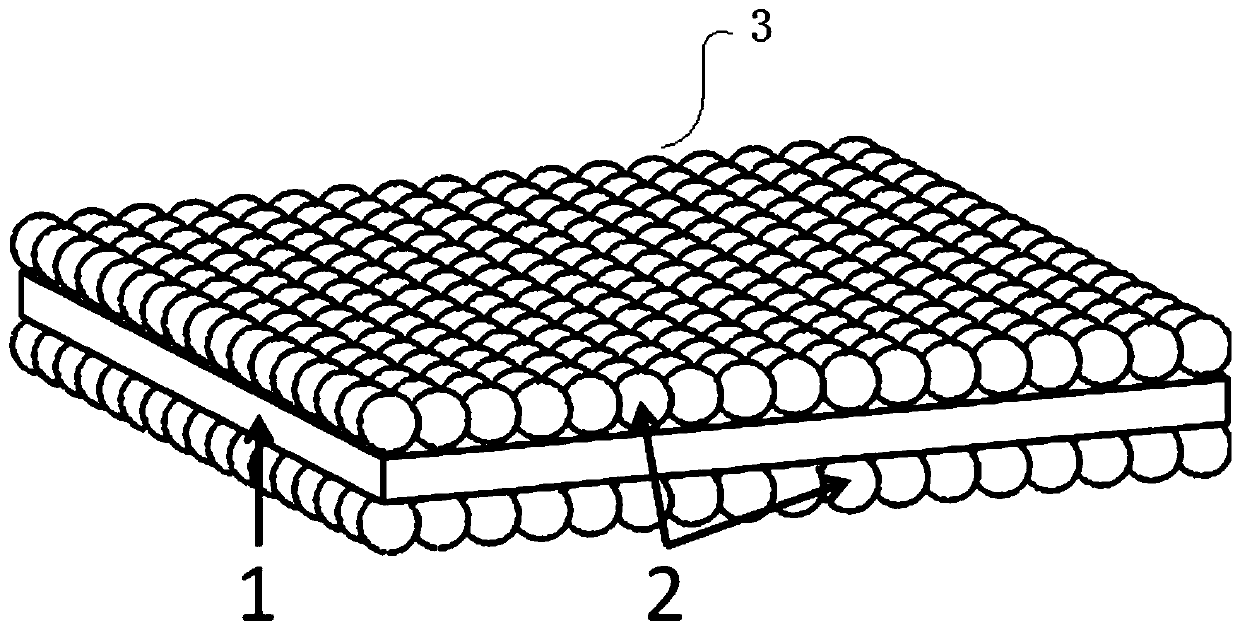

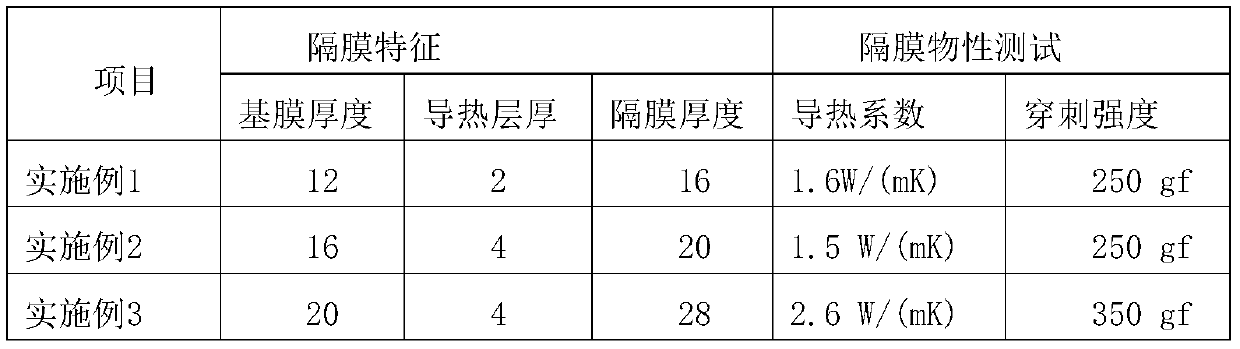

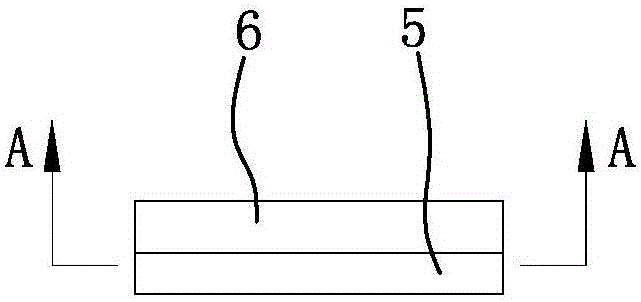

Composite diaphragm with high conductivity material layer and preparation method thereof

InactiveCN109860477AHigh thermal conductivityImprove flexibilitySecondary cellsCell component detailsThermal conductivityIon permeability

The present invention relates to a composite diaphragm with a high conductivity material layer. The composite diaphragm comprises a composite diaphragm main body consisting of a polymer diaphragm andan inorganic nanometer material layer, the polymer diaphragm constructs the polymer diaphragm main body structure bearing and fixes the inorganic nanometer material layer, and the inorganic nanometermaterial layer coats one-side surface or two-sides surfaces of the polymer diaphragm. The preparation method of the composite diaphragm with the high conductivity material layer comprises the steps of: selecting mixed high conductivity nanometer materials, configuring coating slurry, and employing a micro-concave coating process to perform coating of a thermal conductivity material layer at the surface of the polymer diaphragm. The composite diaphragm with the high conductivity material layer has the insulativity, high thermal conductivity feature and the high mechanical strength of the thermal conductivity material and the flexibility, the insulativity and the ion permeability of the polymer diaphragm material to achieve the chemical inertness, the fast heat conduction and the high strength mechanics of the composite heat conduction diaphragm with high heat conduction and high mechanical strength.

Owner:TIANJIN LISHEN BATTERY

Photocatalytic hydrogen peroxide generation and photocatalytic fuel cell coupling system

ActiveCN106486687AStrong oxidation abilityImprove performanceFinal product manufactureRegenerative fuel cellsChemistryCathode

The invention discloses a photocatalytic hydrogen peroxide generation and photocatalytic fuel cell coupling system. A groove-shaped cavity is formed in a reaction cavity body and is sealed by conductive glass, the front portion of the cavity is a reaction chamber, the rear portion is provided with a cathode chamber and an anode chamber arranged side by side and communicated mutually, a photocatalyst layer is arranged in the reaction chamber, a cathode catalyst layer is arranged in the cathode chamber, an anode photocatalyst layer is arranged in the anode chamber, and the photocatalyst layer, the cathode catalyst layer and the anode photocatalyst layer are supported on the conductive glass. The system integrates photocatalytic hydrogen peroxide generation and simultaneous power generation of organic matter from photocatalytic fuel cell disposal, is simple in structure and low in cost and has the advantages of being free of membranes, large in specific surface area, high in mass transfer efficiency, accurate in flow control, short in contact time, easy to enlarge, uniform in lighting, small in optical path loss and the like, and the performance is effectively improved. The organic matter in water can be utilized to generate power, environmental pollution can be controlled, and meanwhile electric energy can be also obtained.

Owner:CHONGQING UNIV

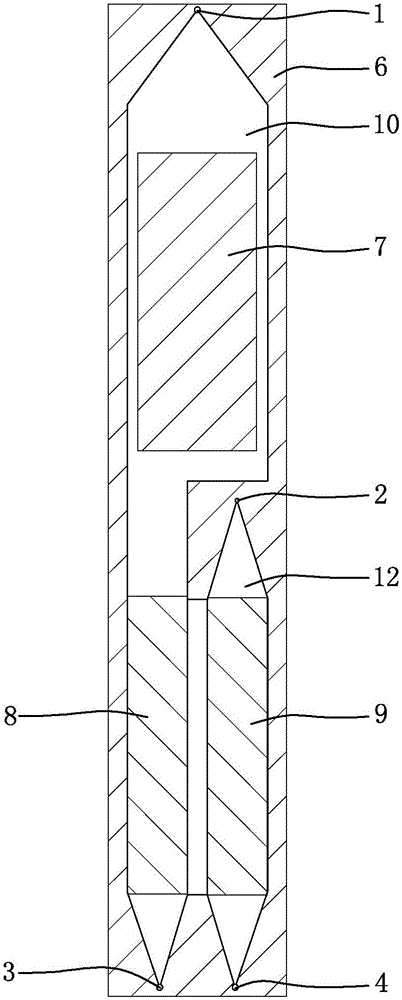

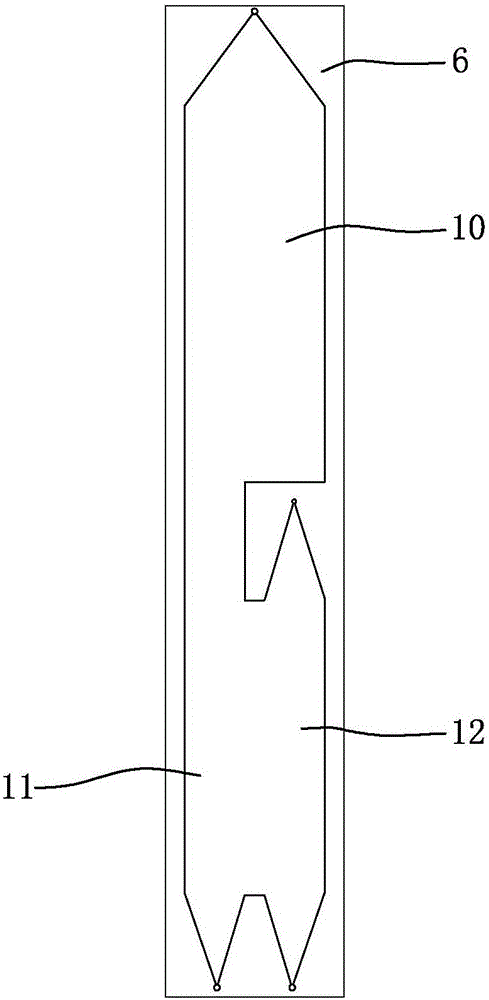

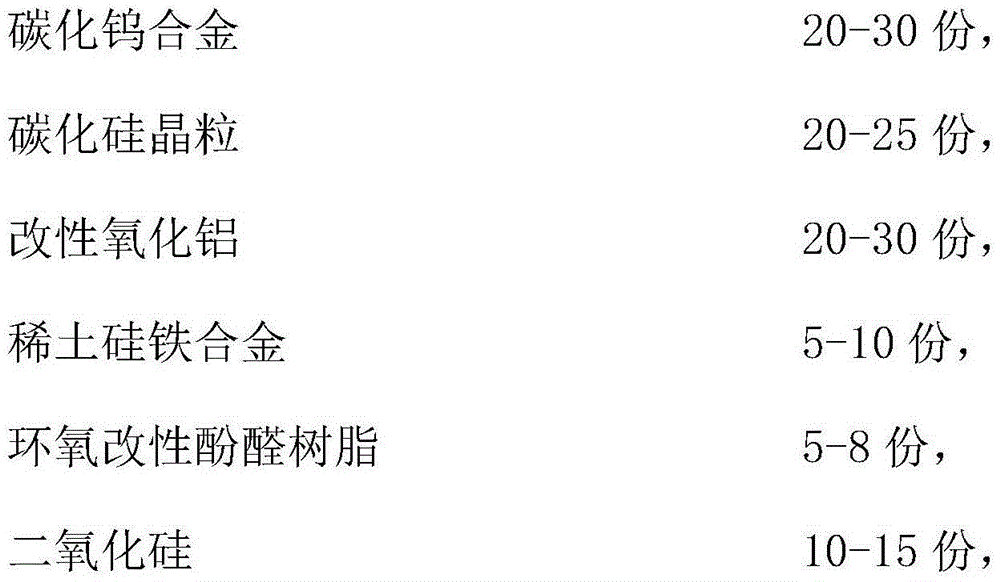

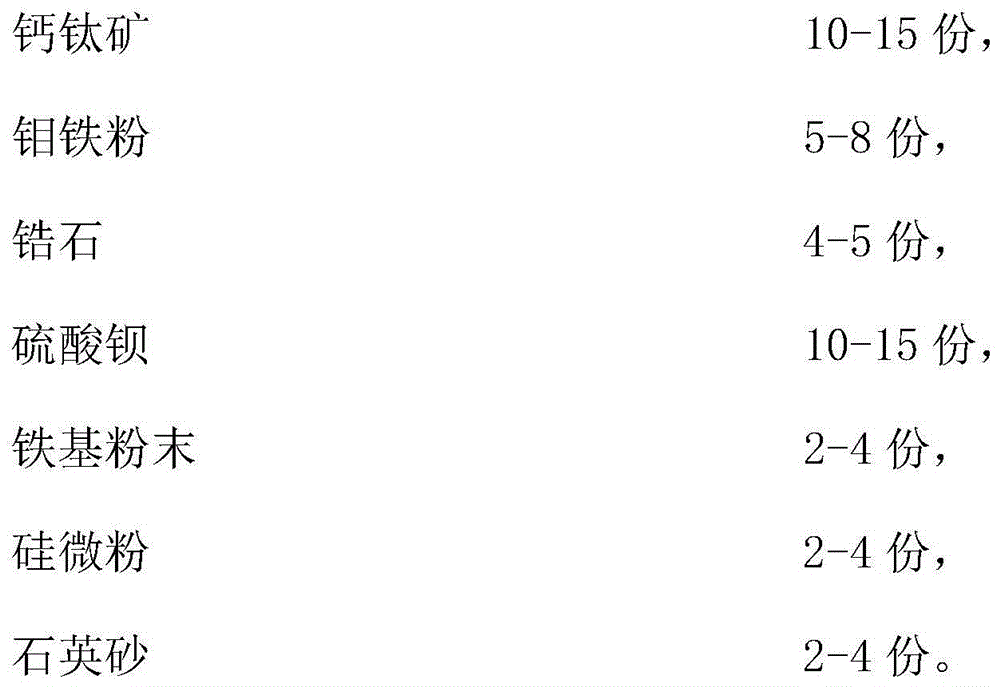

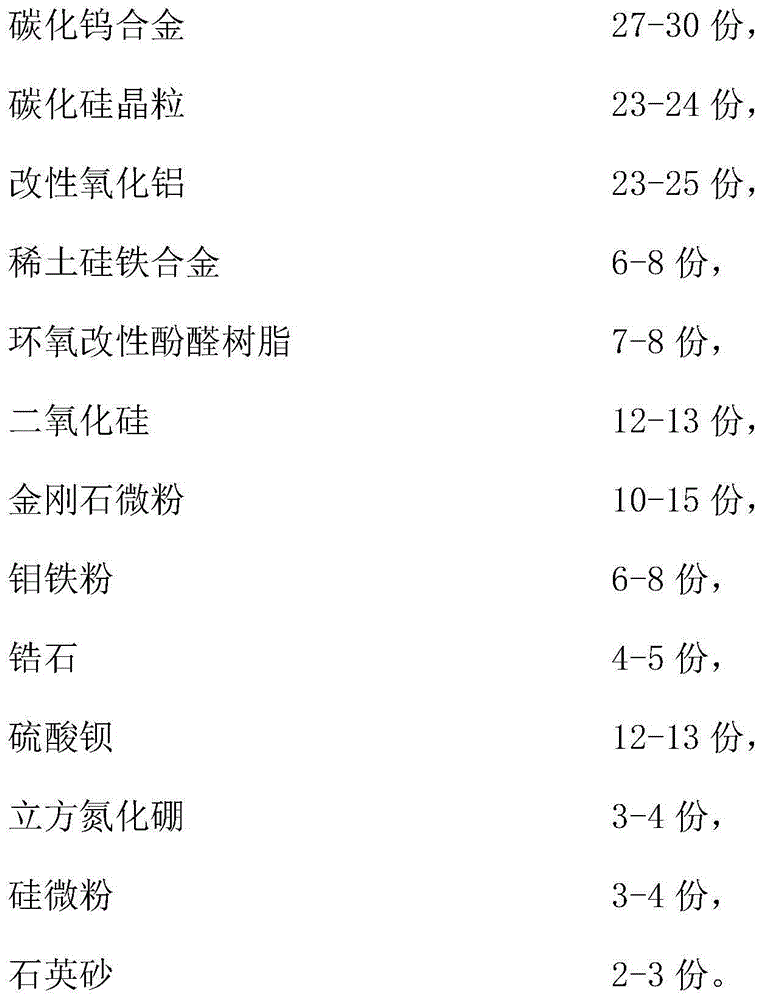

Grinding body for corrosion-resistant high-hardness high-toughness ball mill

The invention discloses a grinding body for a corrosion-resistant high-hardness high-toughness ball mill. The grinding body is characterized by comprising the following raw materials in parts by weight: 20-30 parts of carbon tungsten alloy, 20-25 parts of silicon carbide grains, 20-30 parts of modified aluminum oxide, 5-10 parts of rare earth ferro-silicon alloy, 5-8 parts of epoxy modified phenolic resin, 10-15 parts of silica, 10-15 parts of perovskite, 5-8 parts of ferro-molybdenum powder, 4-5 parts of zircon, 10-15 parts of barium sulfate, 2-4 parts of iron-based powder, 2-4 parts of silica powder and 2-4 parts of quartz sand. The grinding body for the corrosion-resistant high-hardness high-toughness ball mill is high in wear resistance, extremely high in hardness and high in toughness.

Owner:宁国市鑫煌矿冶配件制造有限公司

Coated cBN

InactiveUS8308830B2Exceptional physical and chemical propertiesHigh hardnessPigmenting treatmentOther chemical processesBorideBoron carbide

The invention relates to a coated boron or nitrogen containing superhard abrasive material selected from cBN, boron suboxide and boron carbide comprising: cBN, boron suboxide and / or boron carbide superhard abrasive material substrate; a primary layer of a carbide / nitride / boride forming metal, such metal preferably being Ti and preferably being substantially in the form of the carbide, nitride or boride; a secondary layer of a high melting point metal selected from W, Mo, Cr, Ni, Ta, Au, Pt, Pd and alloys thereof; and an overcoat of Ag, Ni, Cu, Au, Pd, Pt, Rh, Os, Ir, Re, combinations and alloys thereof such as bronze (Cu / Sn), silver / bronze and silver / tin, the metal of the secondary layer being different to the metal of the overcoat. The invention further relates to methods for the manufacture of such material, use of such materials in tools and tools including such material.

Owner:ELEMENT SIX LTD

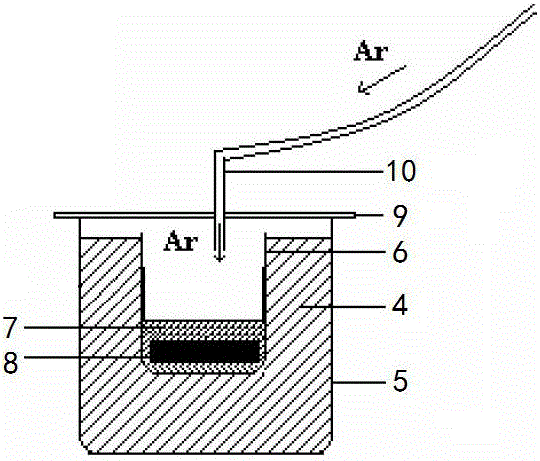

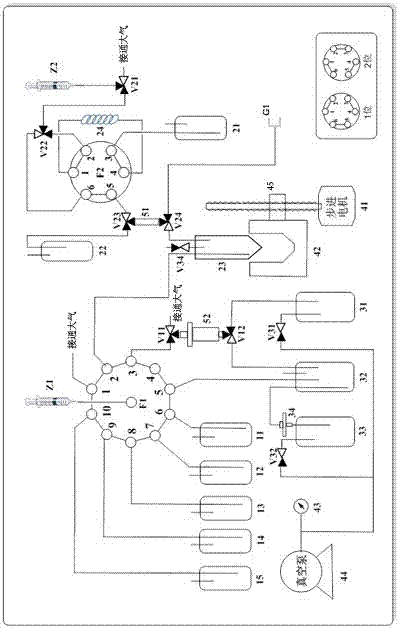

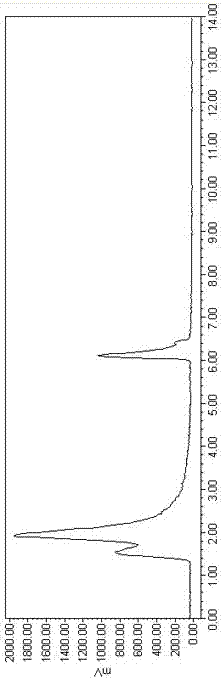

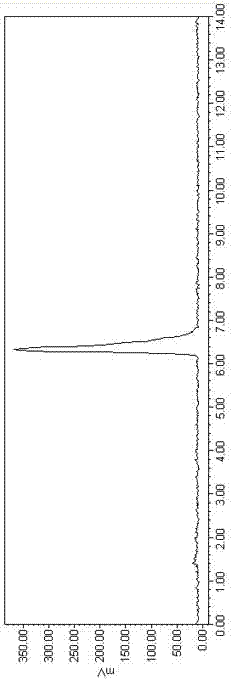

Automatic positive electron radioactive medicine synthesis module based on 18F-BF3 markers

PendingCN107970458AImprove controllabilityEasy to controlRadioactive preparation carriersMolecular imagingTransfer system

The invention discloses an automatic positive electron radioactive medicine synthesis module based on 18F-BF3 markers and belongs to the fields of nuclear medicines and molecular imaging. The synthesis module comprises a 18F-ion adsorption, purification and leaching system, a heating reaction system, a synthesis purification system and a product sterilization treatment and transfer system, whereinthe 18F-ion adsorption, purification and leaching system and the synthesis purification system are respectively connected with the heating reaction system through pipelines; the product sterilizationtreatment and transfer system is connected with the synthesis purification system through a pipeline; the 18F-ion adsorption, purification and leaching system is capable of achieving precise weighingand nondestructive transferring of 18F-ion leacheate of a micro volume through an injection pump Z2, a two-position six-way proportional valve F2 and a quantitative loop. Compared with the prior art,the automatic synthesis module has the characteristics of being novel in design, stable in performance, flexible to use, convenient to maintain, easy to popularize, and the like, and is particularlyapplicable to synthesis of polypeptide positive electron medicines based on 18F-BF3 marker strategies in an aqueous environment.

Owner:SHANDONG RES INST OF TUMOUR PREVENTION TREATMENT

Method for coating titanium dioxide Zr-Al based on sulfate method

InactiveCN104356693ALower free energyHigh chemical inertnessInorganic pigment treatmentWeather resistanceChemistry

The invention belongs to the technical field of sulfate method titanium dioxide production process, and in particular relates to a method for coating titanium dioxide Zr-Al based on a sulfate method. The method is characterized in that the method is a new method of adding zircon salt three times, regulating a pH value and sufficiently dispersing; the aluminum oxide film uniformly wraps the surface of the titanium dioxide through precise control, the aluminum oxide film is uniformly covered, the surface free energy of titanium dioxide is lowered, the chemical inertness is increased, the surface character is changed due to compact film, and the application range is greatly improved; and each process in the enveloping process is seriously controlled, the product stability is improved, the wrapped oxide film is compact and uniform, the lustrousness, covering power and weather resistance of titanium dioxide is improved, the product index is stable, and the percent of pass is high.

Owner:SHANDONG DAWN TITANIUM IND

Porous inorganic ceramic membrane-carbon nanotube-TiO2 photocatalyst composite material and preparation method thereof

InactiveCN102744051AReach the purpose of recyclingLarge specific surface areaPhysical/chemical process catalystsWater/sewage treatment by irradiationSlagActive component

The invention discloses a porous inorganic ceramic membrane-carbon nanotube-TiO2 photocatalyst composite material and a preparation method thereof, and belongs to the field of photocatalytic materials. The porous inorganic ceramic membrane-carbon nanotube-TiO2 photocatalyst composite material is characterized in that a porous inorganic ceramic membrane as a carrier is prepared from coal slag produced by a thermal power plant; a compound of carbon nanotubes and TiO2 is loaded on the surface of the carrier so that the porous inorganic ceramic membrane-carbon nanotube-TiO2 photocatalyst composite material is obtained; the porous inorganic ceramic membrane-carbon nanotube-TiO2 photocatalyst composite material comprises: by mass, 50 to 80% of the carrier and 20 to 50% of the compound of carbon nanotubes and TiO2; and the compound of carbon nanotubes and TiO2 comprises: by mass, 3 to 5% of carbon nanotubes and 95 to 97% of TiO2. The carrier has a well-developed porous structure so that mass transfer on the surface is promoted; a surface adsorption reaction is accelerated; and an organic matter conversion ratio is increased because of a very large specific surface area. Carbon nanotubes have very high specific surface areas, chemical inertness and tunnel conduction characteristics of a delocalized large Pi bond so that material catalytic performances are improved. The porous inorganic ceramic membrane-carbon nanotube-TiO2 photocatalyst composite material has stable active components and multi-component-synergetic catalytic properties.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Method for preparing thermally sprayed ceramic coating of plunger of high-pressure cleaning machine

InactiveCN102212772AHigh hardnessHigh chemical inertnessMolten spray coatingTemperature resistanceCeramic coating

The invention discloses a method for preparing a thermally sprayed ceramic coating of a plunger of a high-pressure cleaning machine. A used plasma sprayed ceramic coating has the characteristics of high hardness, high chemical inertness and good high-temperature resistance. The hardness of the coating cannot be reduced below 540 degrees centigrade; due to low surface friction coefficient, the coating has a function of reducing friction of a friction pair; and due to good corrosion resistance, the coating can be applicable in various types of corrosive conditions and is especially applicable to being used in the plunger of the high-pressure cleaning machine.

Owner:德清县武康镇创智热喷涂厂(普通合伙)

Phase separation self cleaning acrylate stone-like paint emulsion and preparation method thereof

InactiveCN108383941AAvoid stayingHigh electronegativityAntifouling/underwater paintsPaints with biocidesFunctional monomerLatex particle

The invention discloses phase separation self cleaning acrylate stone-like paint emulsion and a preparation method thereof, and belongs to the field of stone-like paint emulsion. The phase separationself cleaning acrylate stone-like paint emulsion is prepared from the following raw materials in parts by weight: 160 to 240 parts of deionized water, 30 to 60 parts of styrene, 30 to 80 parts of methyl methacrylate, 40 to 80 parts of butyl methacrylate, 40 to 80 parts of acrylic acid-2-ethylhexyl acrylate, 10 to 40 parts of functional monomers, 4 to 25 parts of emulsifying agents, 2 to 20 parts of initiators and 1 to 10 parts of pH regulators. The self cleaning acrylate stone-like paint emulsion provided by the invention has the advantages that a copolymerization and shell-core technology composite process is used; a special synthesis processing method is used; special latex particles with two phases in one emulsion are finally obtained; latex particles in the film forming process are mutually interlinked and wound; the formed film is compact and hydrophobic; the pollution particle dwell can be effectively prevented.

Owner:佛山市顺德区巴德富实业有限公司

Titanium fire resistance coating

ActiveCN107142474AHigh hardnessHigh temperature oxidation resistanceMetallic material coating processesBand shapeAlloy

The invention discloses a titanium fire resistance coating. A continuous strip-shaped Ti-37.5Zr-15Cu-10Ni base amorphous alloy is selected to serve as brazing filler metal, CBN particles are selected as hard wear-resisting particles, strip-shaped brazing filler metal is placed on the blade tip in advance, and wraps the blade tip required to be coated with the titanium fire resistance coating, an organic bonding agent is used for being mixed with Ni-plated CBN particles, and the brazing filler metal is evenly coated with the bonding agent; in the vacuum environment, a medium-frequency induction coil is used for locally heating a rotor blade tip, the heating temperature is kept between 840 DEG C to 850 DEG C and is kept for a certain time, the brazing filler metal is completely molten, the brazing filler metal is naturally cooled in the high-vacuum environment, and the titanium fire resistance coating is formed; and the titanium fire resistance coating obtained through the preparing method of the titanium fire resistance coating has high hardness, high wear resistance, high impact resistance, high temperature oxidability resistance, high fire resistance and high combination strength, meanwhile, the property of the base body cannot be affected, and the base body anti-fatigue property is ensured.

Owner:TIANJIN UNIV OF TECH & EDUCATION TEACHER DEV CENT OF CHINA VOCATIONAL TRAINING & GUIDANCE

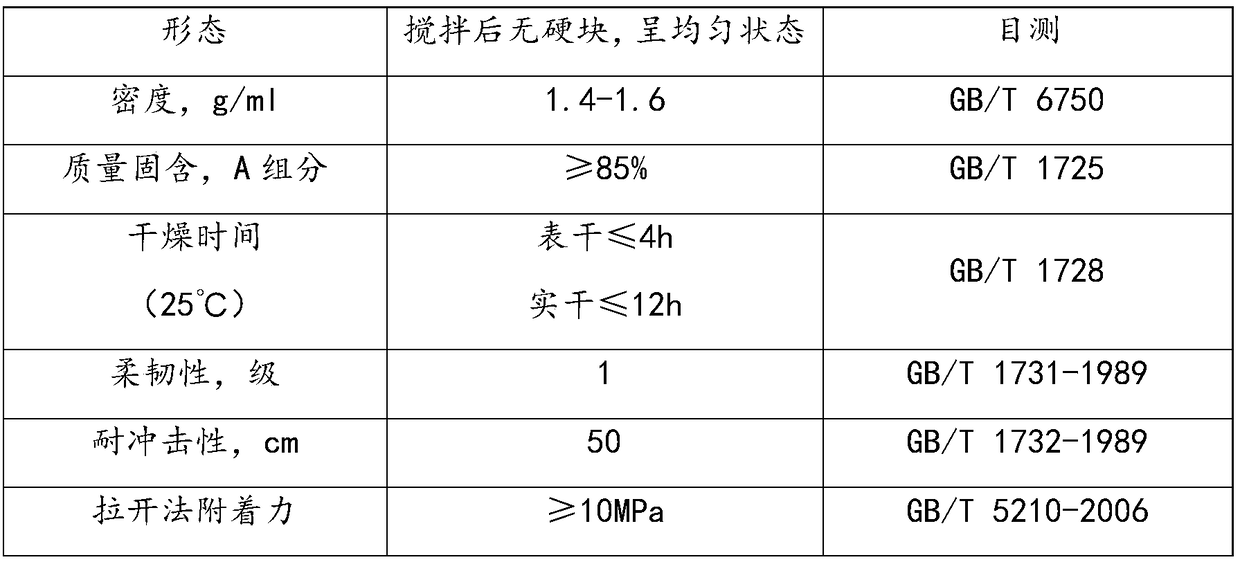

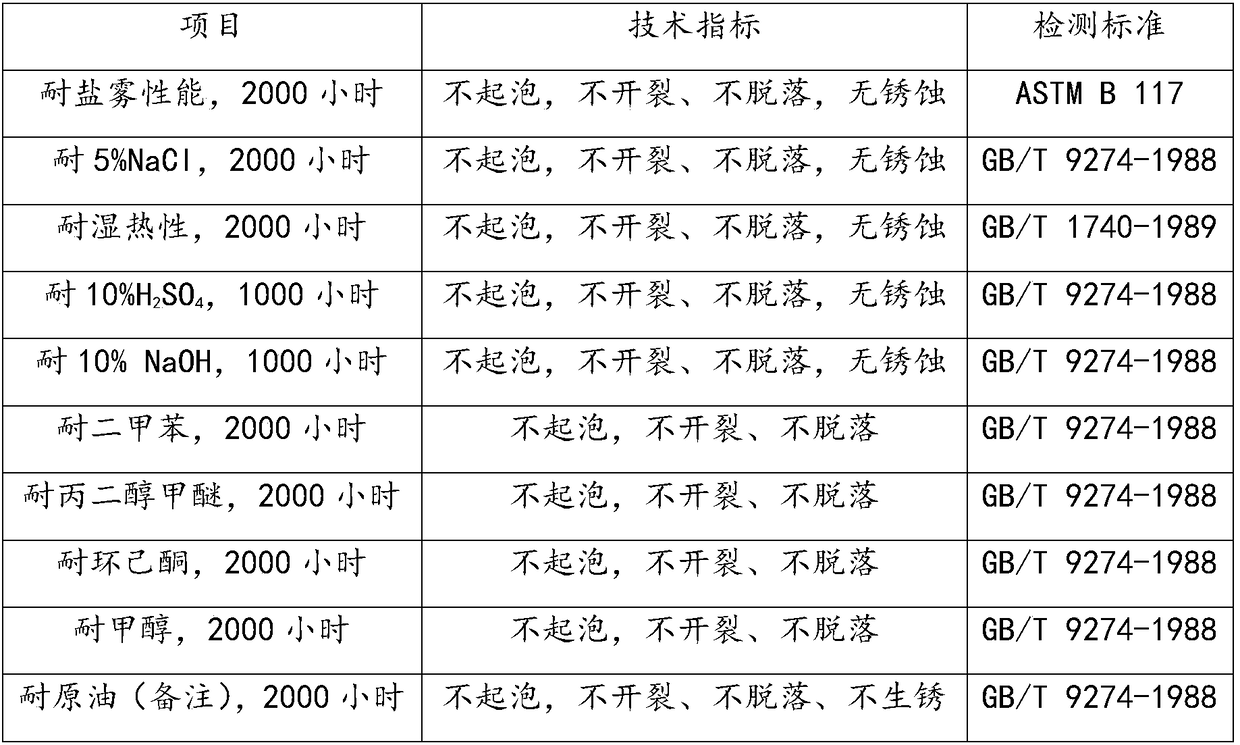

Chemical-resistant epoxy inner lining coating and preparation method thereof

InactiveCN109504234AImprove shielding effectReduce internal stressEpoxy resin coatingsSolventChemistry

The invention relates to the technical field of coatings, and particularly relates to a chemical-resistant epoxy inner lining coating and a preparation method thereof. The chemical-resistant epoxy inner lining coating provided by the invention is prepared from a component A and a component B, wherein the component A is prepared from the following components in parts by weight: 29 to 36 parts of bisphenol F epoxy resin, 0.4 to 0.6 part of a wetting dispersant, 0.3 to 0.5 part of an antifoaming agent, 0.4 to 0.6 part of a thixotropic agent, 10 to 18 parts of pigment, 30 to 32 parts of a filler a, 10 to 16 parts of a filler b and 6 to 10 parts of a mixed solvent; the component B is prepared from the following components in parts by weight: 70 to 75 parts of an aliphatic amine additive product, 22 to 27 parts of an organic solvent, 1.5 to 2 parts of a curing accelerator and 1 to 2 parts of an adhesion promoter; and the weight ratio of the component A to the component B is (3 to 4) to 1. The chemical-resistant epoxy inner lining coating provided by the invention is sufficiently cured in a normal-temperature condition, does not contain any active thinners or plasticizers, and has excellent chemical resistance.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Processing technology for ceramic composite steel pipe

The invention discloses processing technology for a ceramic composite steel pipe, and relates to the processing technology for the ceramic composite steel pipe into which a corundum layer is inserted. The processing technology is characterized in that 5 mass percent of aluminum powder, 75 mass percent of iron oxide red and 20 mass percent of quartz sand are put into an agitator for uniformly stirring. The product of the invention adopts the principle of melting reactants by using heat released by the thermit reaction and separating Al2O3 from Fe under the action of a centrifugal force; and the composite steel pipe orderly comprises a corundum ceramic (Al2O3) layer, an intermediate layer and a steel pipe layer from inside to outside. The product of the invention has the advantages of high hardness of alumina, chemical inertness, high strength and good plasticity, and compared with other pipes, the product of the invention has the remarkable characteristics of excellent comprehensive performance, and good wear-resisting, heat-resisting, anti-corrosion and thermal shock properties.

Owner:扬州金鑫管业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com