Method for preparing polycrystalline materials by aid of high-throughput hybridization microwave synthesis processes

A polycrystalline material and microwave synthesis technology, applied in the magnetic field, can solve the problems of slow heating rate and achieve the effects of high heating efficiency, high heating rate and shortened synthesis time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

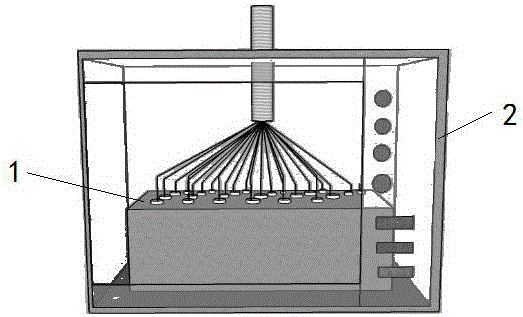

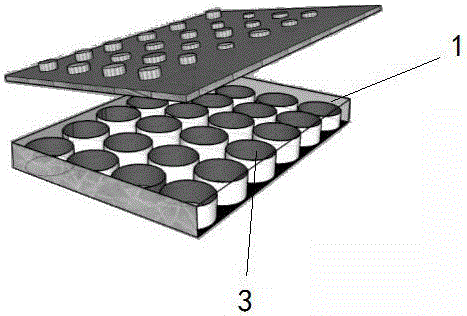

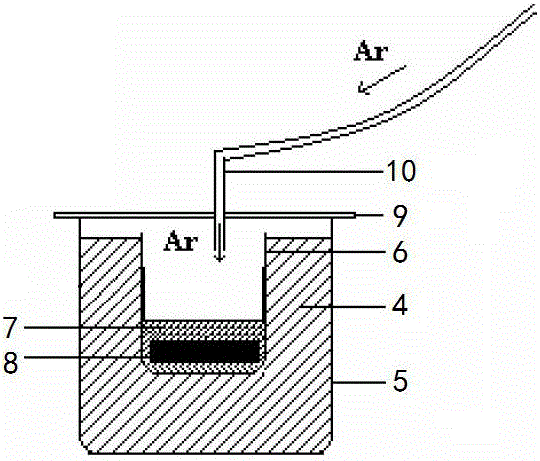

[0052] In this example, see Figure 1~3 , a high-throughput hybrid microwave synthesis method R TiO 3 A method for a polycrystalline material, comprising the steps of:

[0053] (1) Preparation of initial raw materials and preforming process:

[0054] The purity is 99.8% Ti respectively 2 o 3 and Nd with a purity of 99.9% 2 o 3 、Sm 2 o 3 and La 2 o 3 As the starting material, the Sm 2 o 3 、Nd 2 o 3 and La 2 o 3 respectively with Ti 2 o 3 After weighing according to the molar ratio of 1:1, the Sm 2 o 3 、Nd 2 o 3 and La 2 o 3 respectively with Ti 2 o 3 Fully mixed, in a hand box under an inert gas environment, grind and fully mix 3 kinds of reaction raw materials with different proportions with an agate mortar to obtain 3 kinds of mixed raw material powders;

[0055] (2) Blank forming:

[0056] The mixed raw material powders fully mixed in the step (1) were put into the mold respectively, and then isostatically pressed under a pressure of 10 MPa to prep...

Embodiment 2

[0062] This embodiment is basically the same as Embodiment 1, especially in that:

[0063] In this example, a high-throughput hybrid microwave synthesis method was used to prepare Na x WO 3 A method for a polycrystalline material, comprising the steps of:

[0064] ① Preparation of initial raw materials and preforming process:

[0065] Using pure WO 3 、Na 2 WO 4 2H 2 O and W powder are used as initial reaction raw materials, according to the following reaction equation:

[0066] Na 2 WO 4 + WO3+ W=Na x WO 3

[0067] The ratio of the reactants participating in the chemical reaction is matched, and the ratio of 0x x WO 3 Prepare a series of initial reaction raw material mixtures for each component point, and then use an agate mortar to grind and fully mix the reaction raw material mixtures with different proportions in a hand box under an inert gas environment to obtain a mixed raw material powder;

[0068] ② Blank forming:

[0069] The mixed raw material powd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com