Patents

Literature

107results about How to "Reduce overall consumables" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

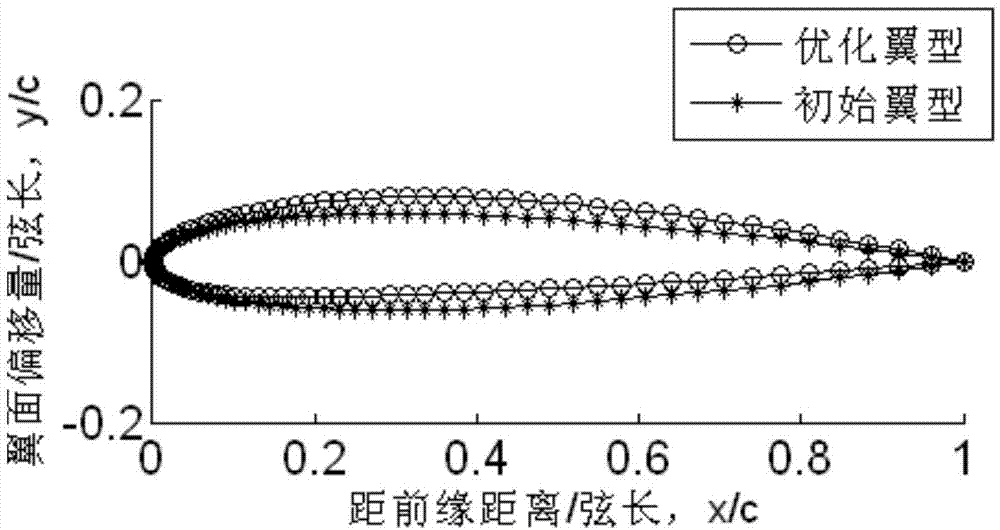

Aircraft multi-objective optimization method based on self-adaptive agent model

ActiveCN104866692ASave optimization design costImprove approximation accuracySpecial data processing applicationsPhysical planningEngineering

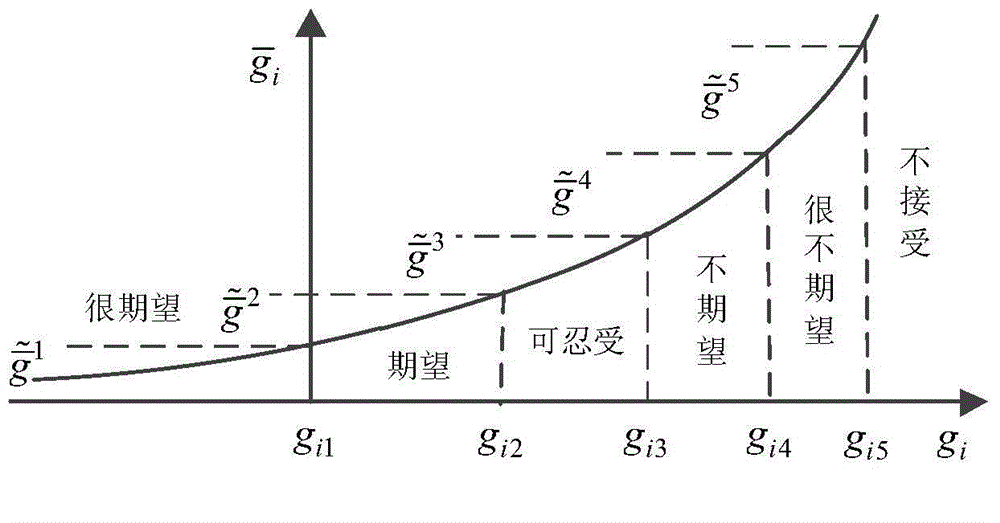

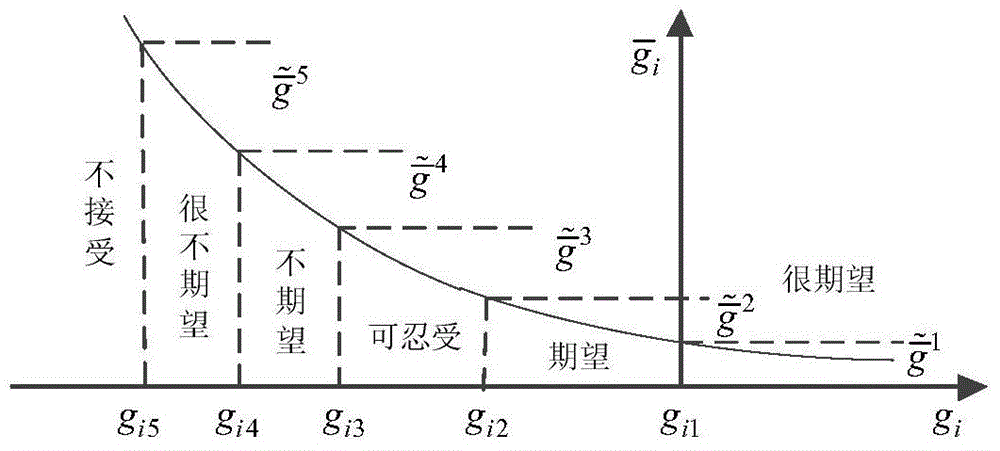

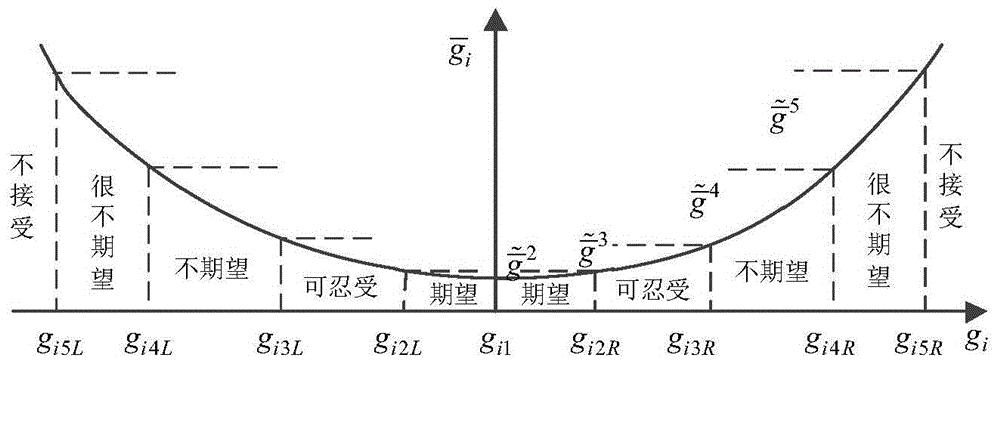

The invention discloses an aircraft multi-objective optimization method based on a self-adaptive agent model, relates to a multi-objective optimization method for treating complex aircraft design, and belongs to the field of aircraft design optimization. According to the aircraft multi-objective optimization method, an integrated preference function is constructed by use of a physical planning method to realize the conversion of the multi-objective optimization problem into a single-objective optimization problem reflecting design preference; next, the self-adaptive agent model is constructed from the integrated preference function and constraint conditions to take the place of a high-accuracy analysis model, and therefore, the problem of great time taken in calculation of optimization design is solved; finally, the constraint problem is converted into a non-constraint problem by use of an augmentation Lagrange multiplier method, and the non-constraint problem is solved by use of a genetic algorithm. The aircraft multi-objective optimization method has the advantages that the solving process of the aircraft multi-objective optimization method taking much time in calculation is simple and efficient, and therefore, a Pareto noninferior solution meeting the requirements of a user can be obtained quickly to shorten the design period of the aircraft, and the design cost is reduced. Besides, the aircraft multi-objective optimization method is high in universality and convenient for program development.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

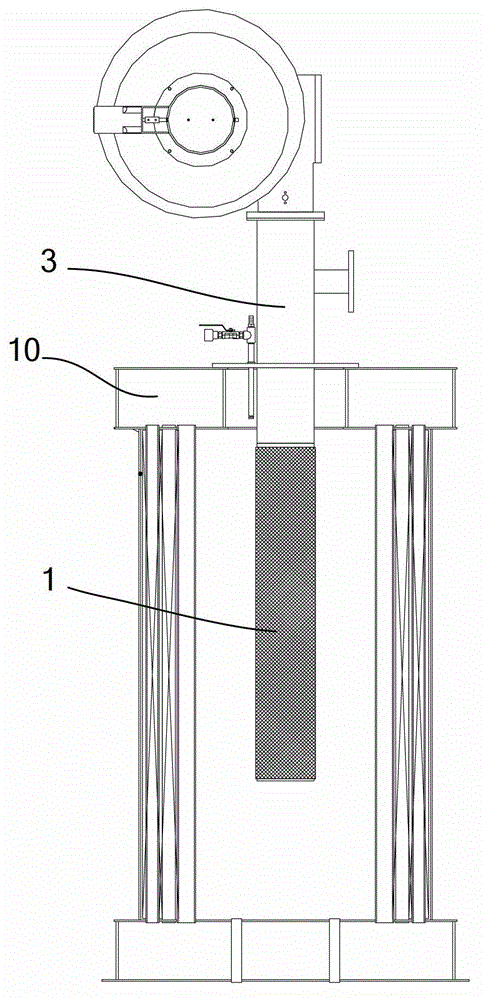

Metal fiber post-mixing type burner and boiler employing same

InactiveCN102913909AReduce volumeUniform surface distributionGaseous fuel burnerDiameter ratioMaterial consumption

The invention relates to the field of gas burners in the boiler industry, in particular to a metal fiber post-mixing type burner and a gas-fired boiler. The burner comprises a combustion head, a blower and a mixer, wherein a gas-fired swirl device is arranged in the mixer. When the burner is in operation, both fuel gas and air fed into the mixer by the blower flow into the mixer and enter the combustion head for burning after being uniformly mixed by the gas-fired swirl device. The boiler employs the above burner. According to the invention, the part of the burner in a metal fiber post-mixing burning mode, which is arranged outside the boiler, is compact in size; flame on the surfaces of the metal fibers is more uniform; the ignition reliability is improved; and the shaft diameter ratio of the combustion head is increased. The boiler is matched with the burner in a compact shape, so that more than half of the steel material consumption of the boiler is reduced and the occupied area for installation of the matched boiler is reduced by more than a half.

Owner:上海钜荷热力技术有限公司

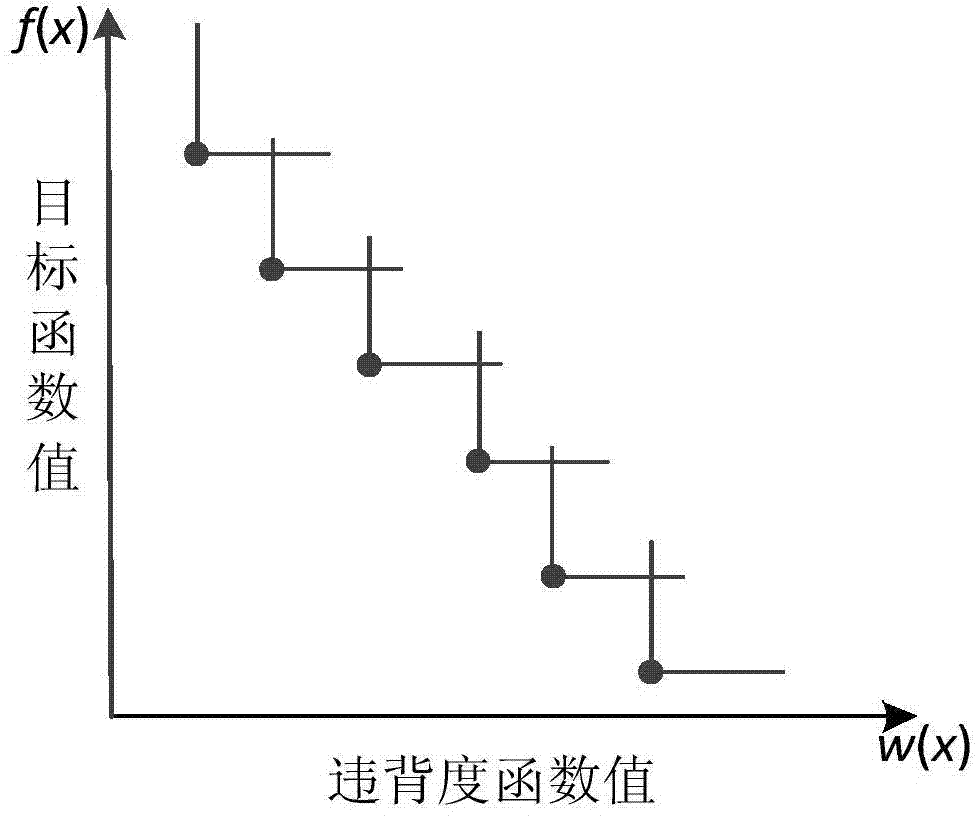

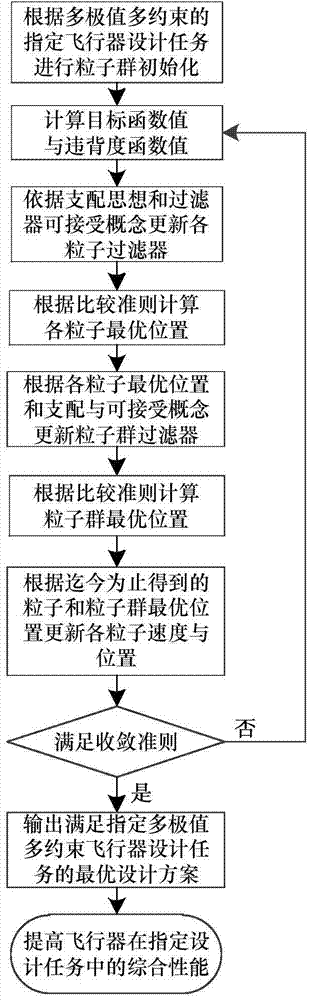

Optimization method for processing multiple extreme values and multiple restricted problems in flight vehicle design

InactiveCN104750948AGuaranteed feasibilityAvoid duplication of effortSpecial data processing applicationsFlight vehicleDesign cycle

The invention discloses an optimization method for processing multiple extreme values and multiple restricted problems in flight vehicle design, relates to an optimization method of multiple extreme values and multiple restricted problems in processing flight vehicle design, and belongs to the field of flight vehicle design optimization. The optimization method combines a filter principle and a particle cluster optimization, forms a design method with ability of processing global optimization, realizes the data processing and solution of multiple extreme values and multiple restricted problems in the flight vehicle design, ensures the understanding feasibility, avoids the repeated work of setting penalty factors in traditional design solution, and improves the design efficiency and solving precision. The data processing and solving process of the optimization method is separated from a flight vehicle design optimization model, thus the universality of the optimization method is increased. The optimized design result under the conditions of multiple extreme values and multiple restrictions is applied to the flight vehicle project design; the optimization method is indirectly possessed of the advantages of shortening the design cycle of the flight vehicle, reducing cost and consumable items of appointed design task, and realizes the improvement of comprehensive performance of the flight vehicle in the appointed design task.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

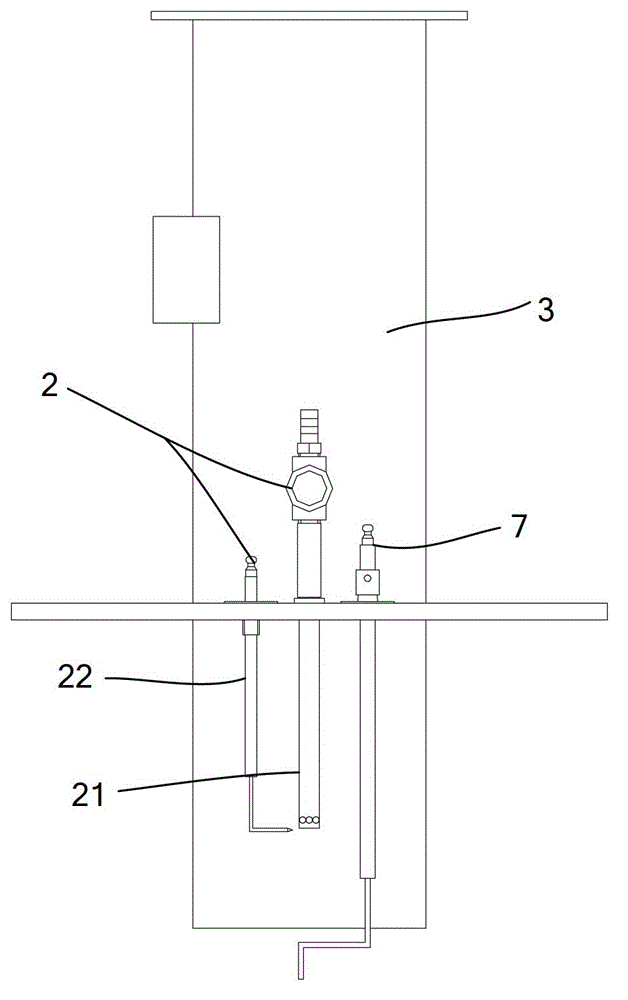

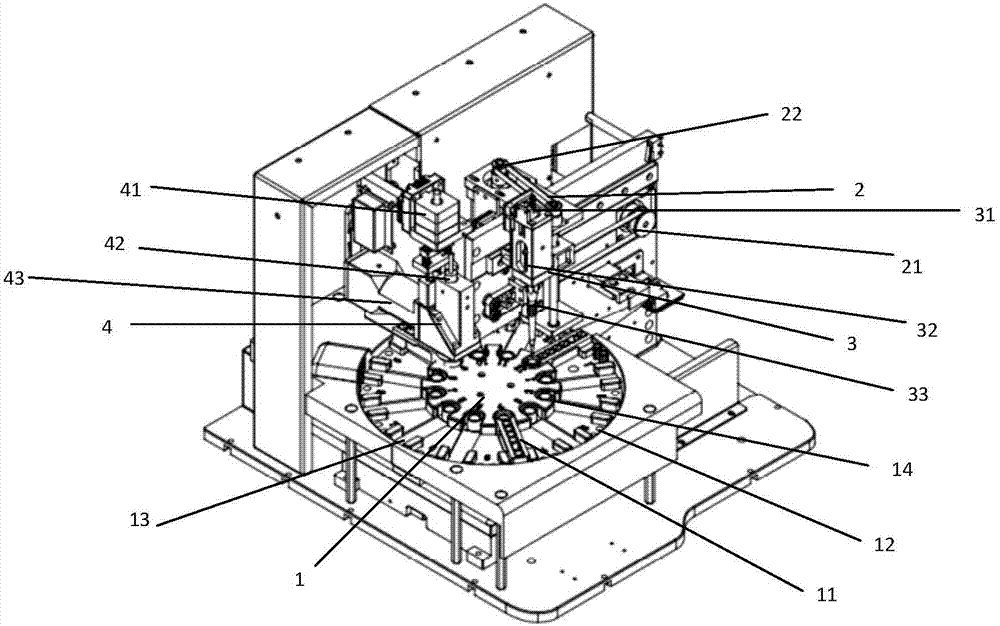

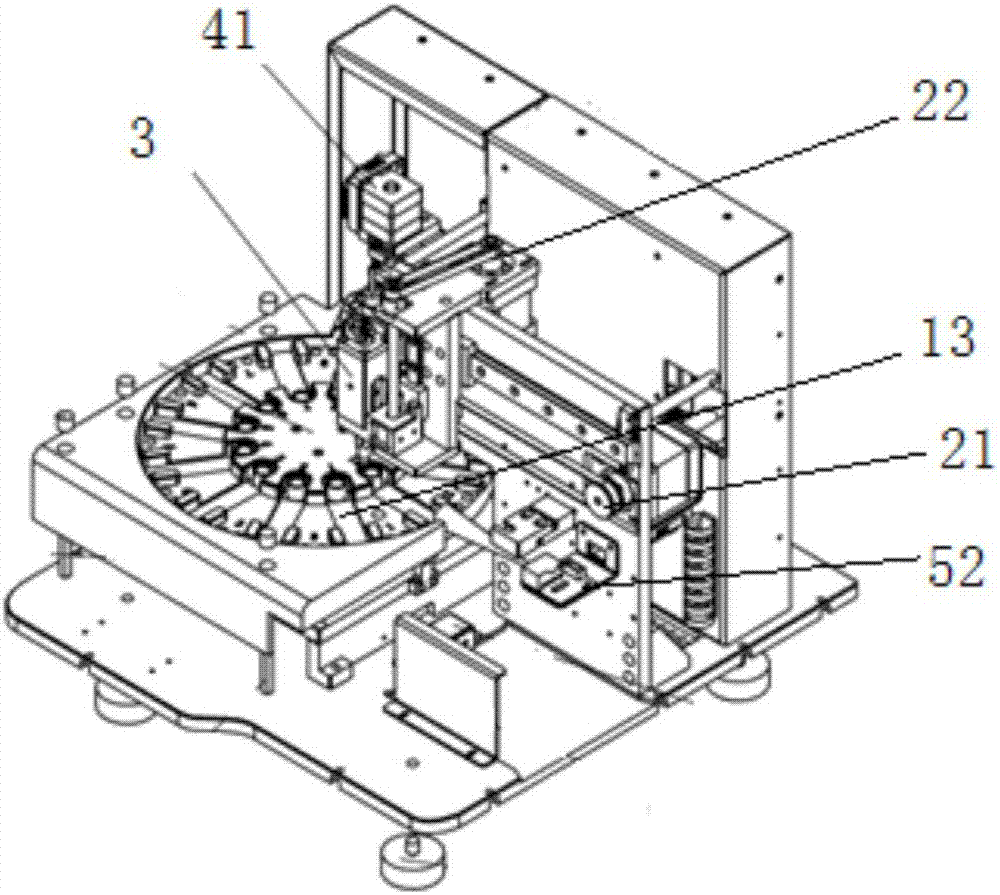

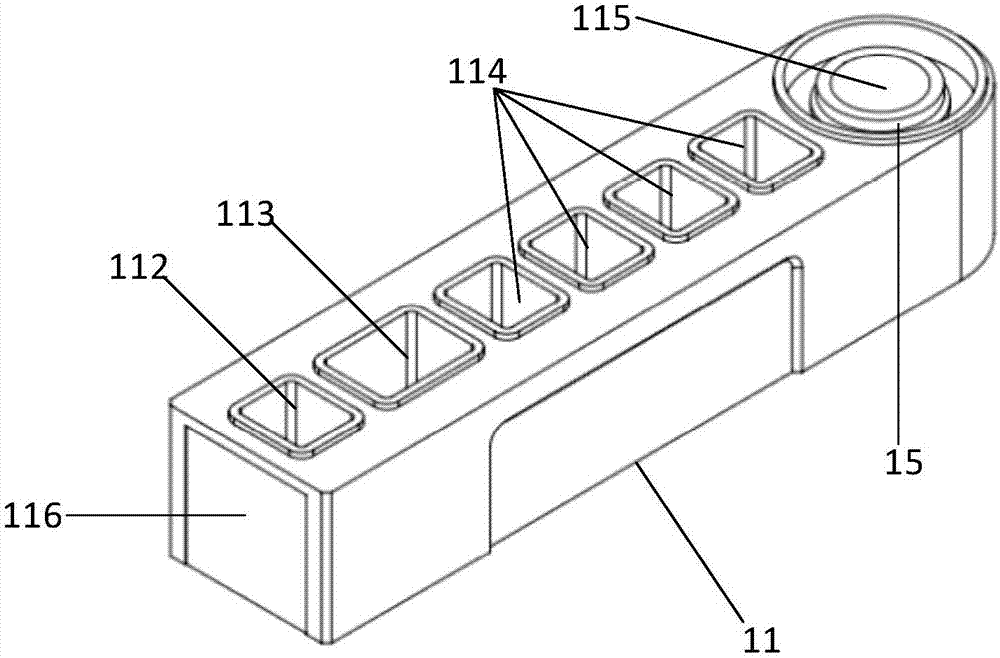

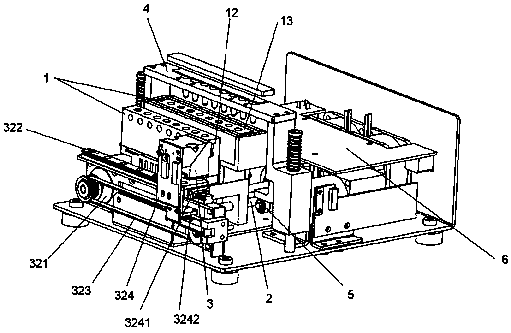

Light initiated chemiluminescence instant detection system

PendingCN107356587AReduce experimental errorHigh precisionChemiluminescene/bioluminescenceEngineeringLiquid transfer

The invention discloses a light initiated chemiluminescence instant detection system, which comprises a kit, a kit platform and an instant detection system, wherein the kit is provided with a plurality of reagent positions required by a test; the kit platform is used for carrying the kit; the instant detection system comprises a liquid transferring mechanism used for liquid transferring and a detection mechanism used for collecting reaction system luminescence information in the kit. The light initiated chemiluminescence instant detection system has the advantages that magnetic beads as carriers are not needed; the problems due to magnetic bead loss or unclean cleaning are avoided; the detection accuracy is improved.

Owner:BEIJING BEITAI TECH +1

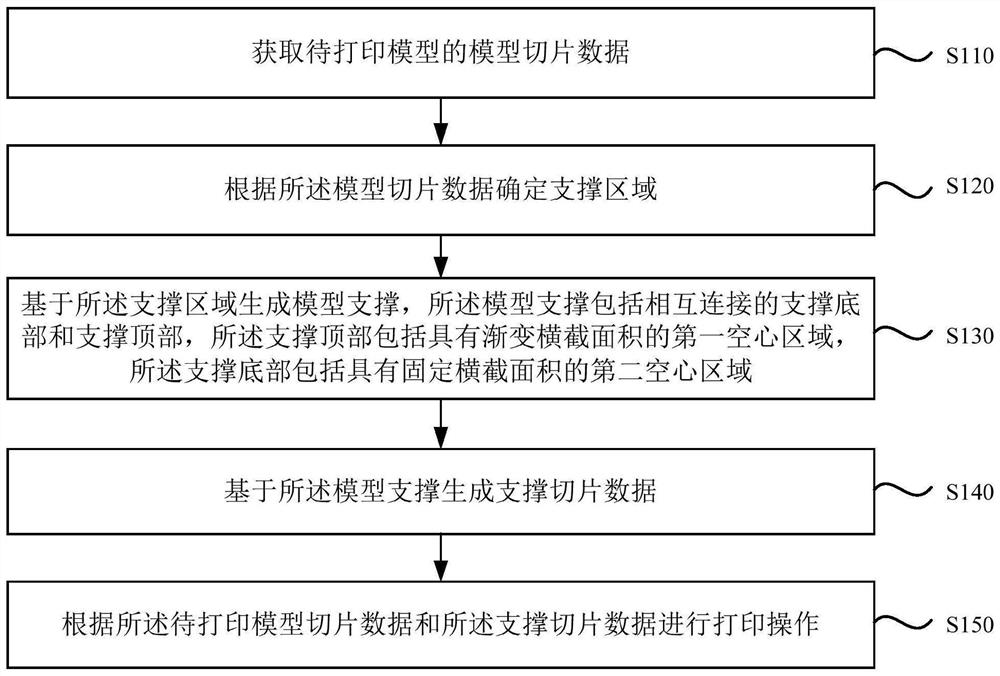

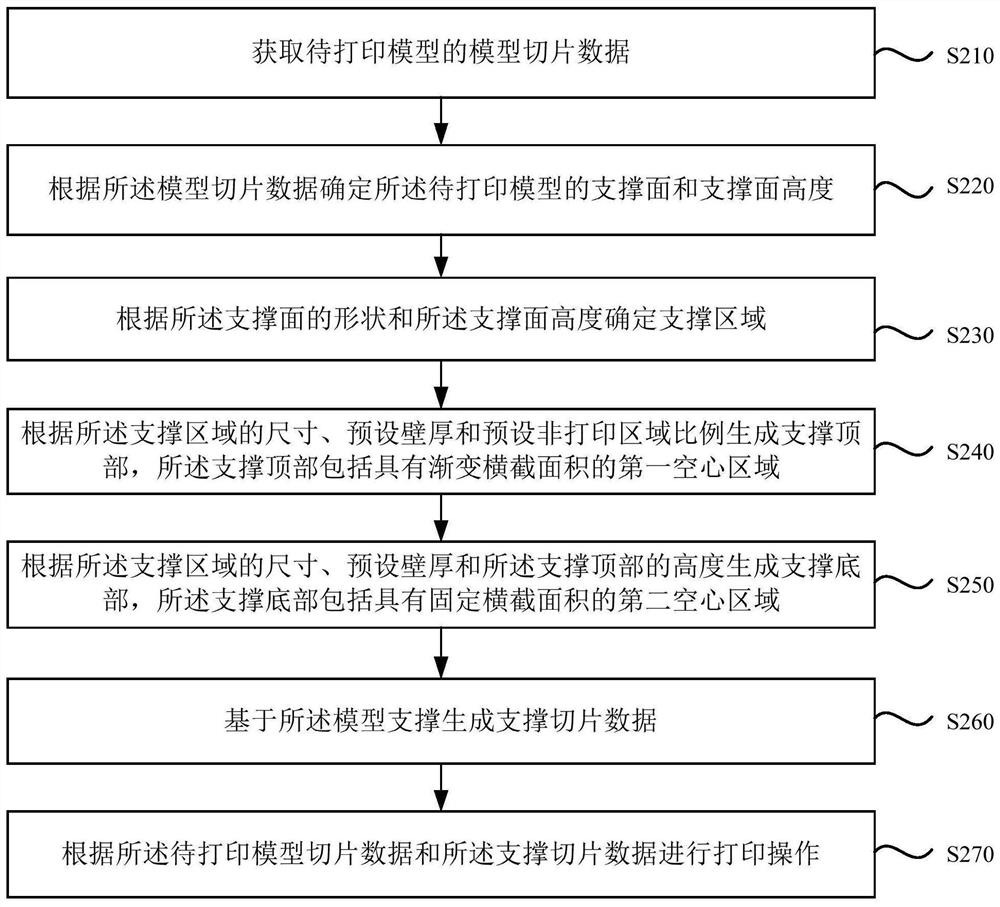

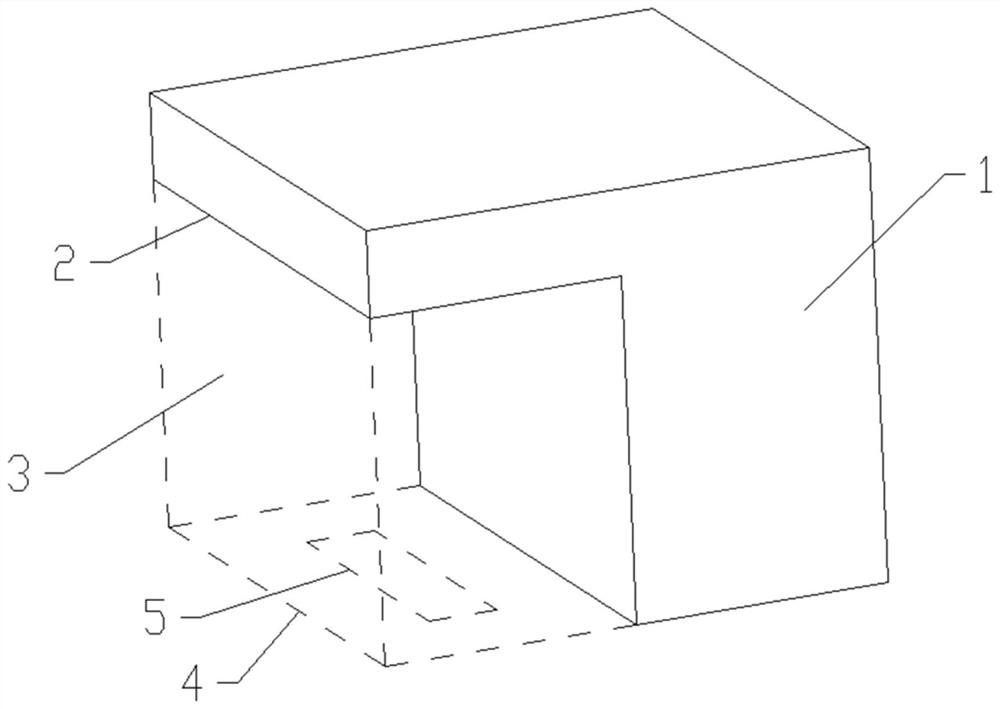

3D printing method, supporting structure, device, equipment and storage medium

PendingCN112936870AGuaranteed load-bearing strengthEnsure support functionAdditive manufacturing apparatus3D object support structuresSlicingProcess engineering

The embodiment of the invention discloses a 3D printing method, a supporting structure, a device, equipment and a storage medium. The 3D printing method comprises the steps that model slicing data of a to-be-printed model is obtained; a supporting area is determined according to the model slicing data; a model support is generated based on the supporting area, the model support comprises a supporting bottom and a supporting top which are connected with each other, the supporting top comprises a first hollow area with a gradually-changed cross section area, and the supporting bottom comprises a second hollow area with a fixed cross section area; support slicing data are generated based on the model support; and printing operation is carried out according to the to-be-printed model slicing data and the support slicing data. According to the embodiment, it is guaranteed that the model support has certain bearing strength, the supporting function of the model support on the to-be-printed model is guaranteed, consumables and consumed time during printing of a supporting structure are reduced, the printing speed is increased, and the printing cost is reduced.

Owner:SHENZHEN CREALITY 3D TECH CO LTD

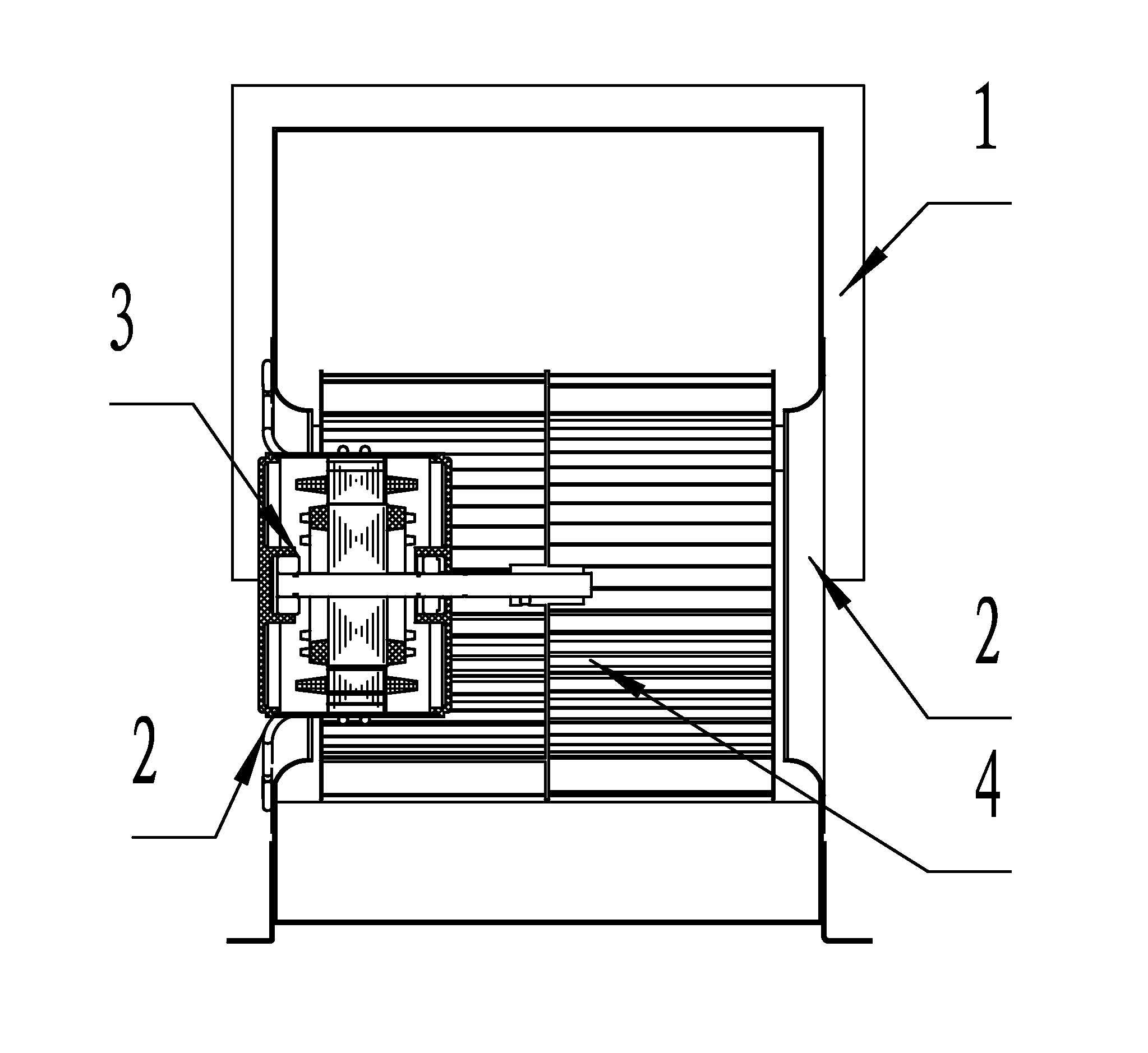

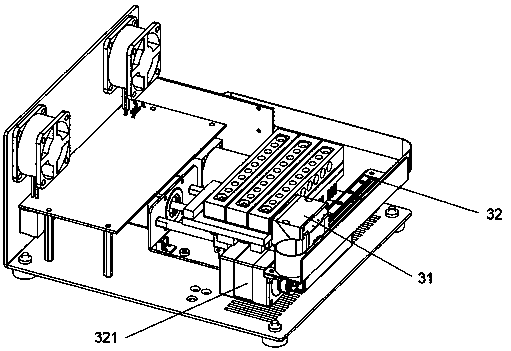

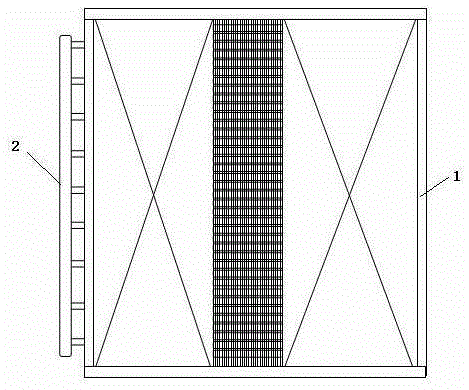

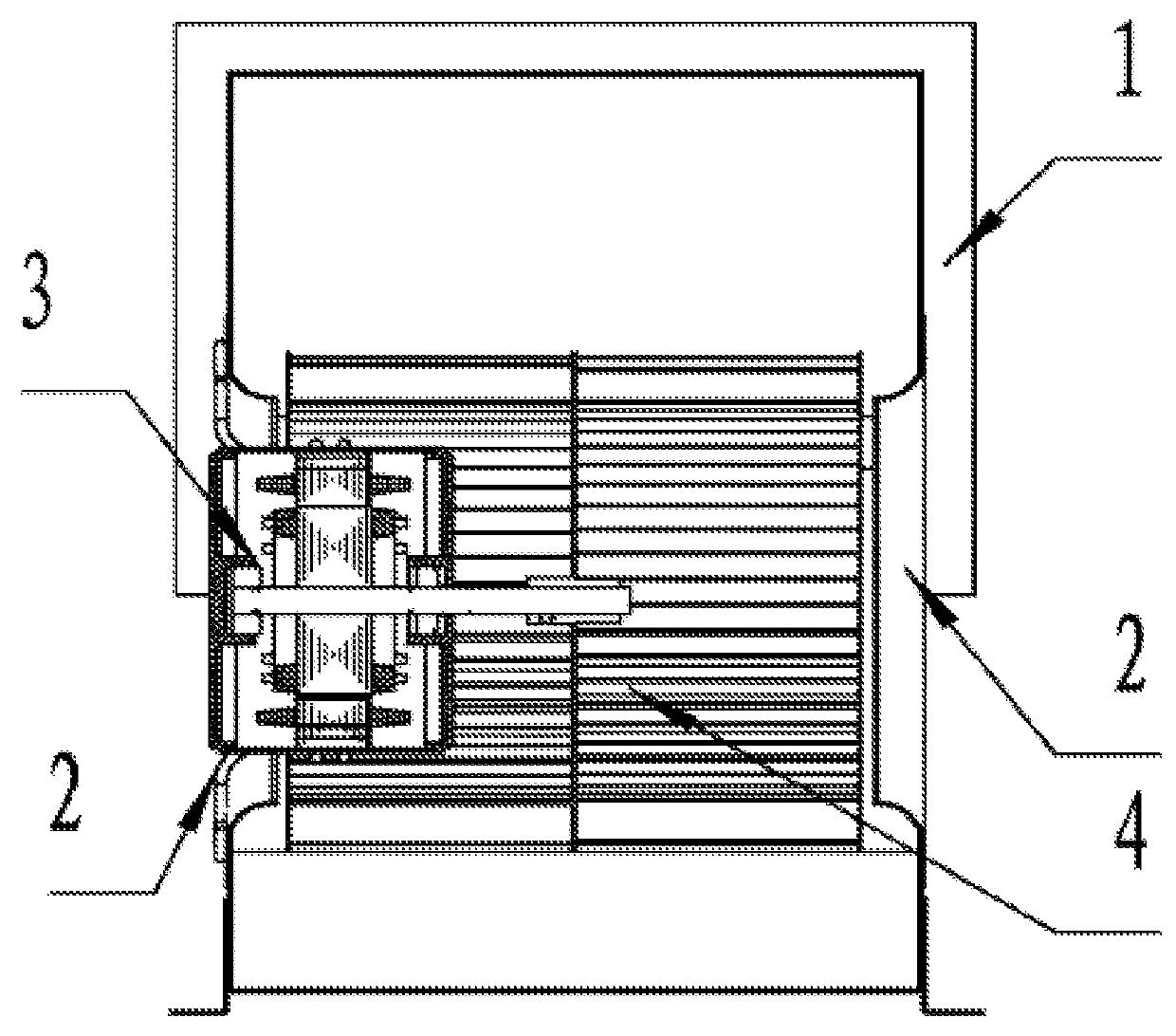

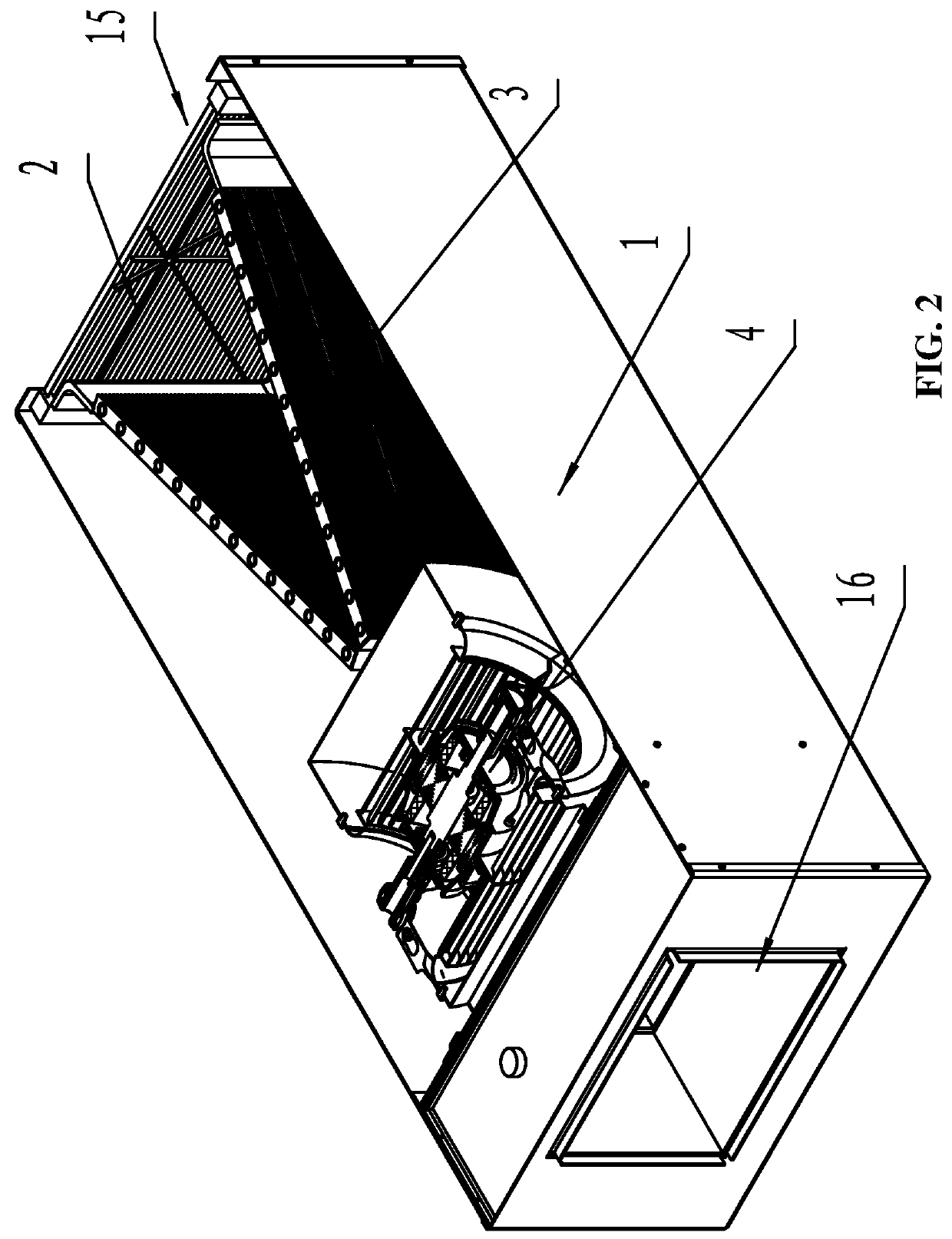

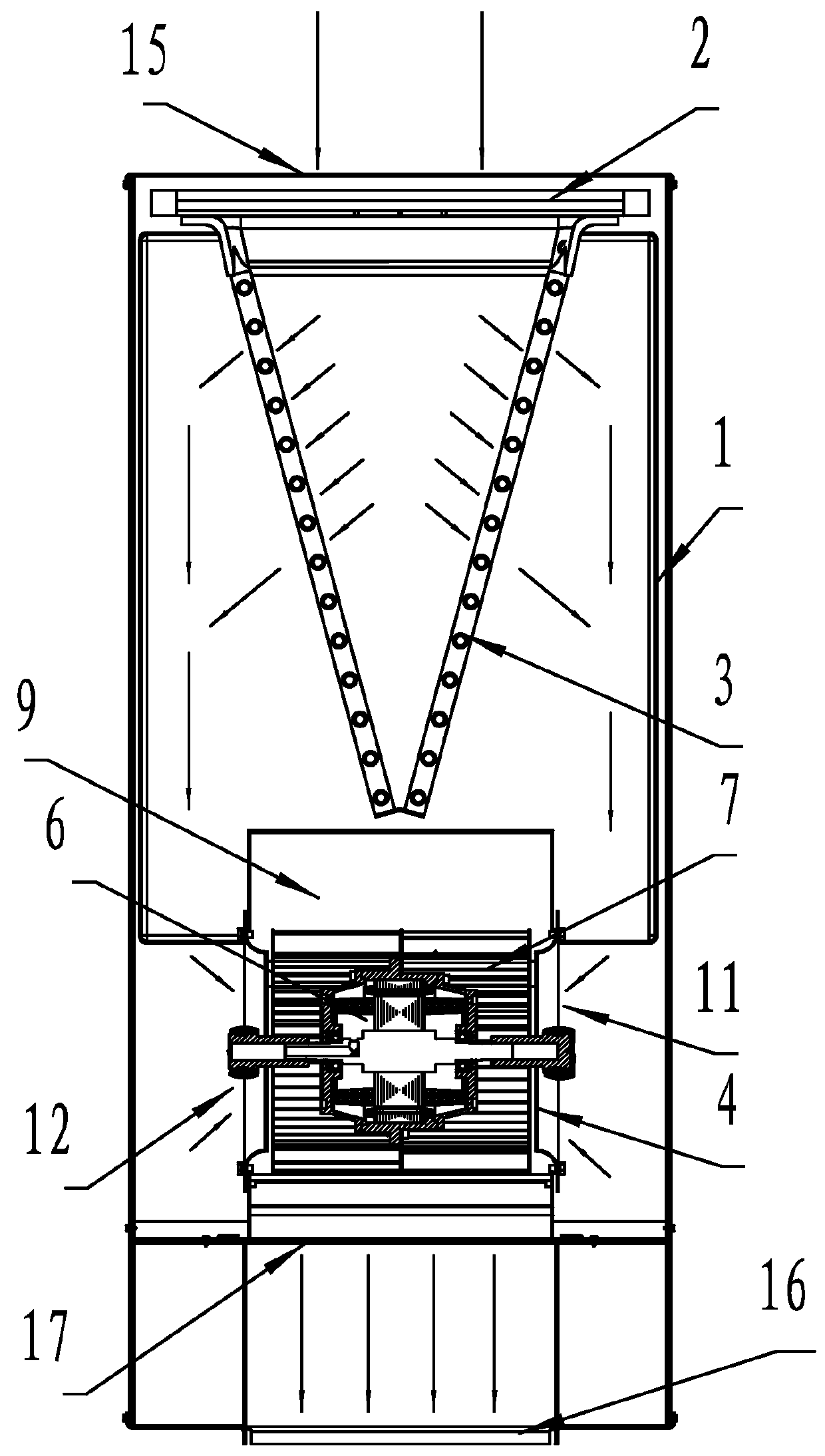

Heat exchanger for an indoor unit of an air conditioner

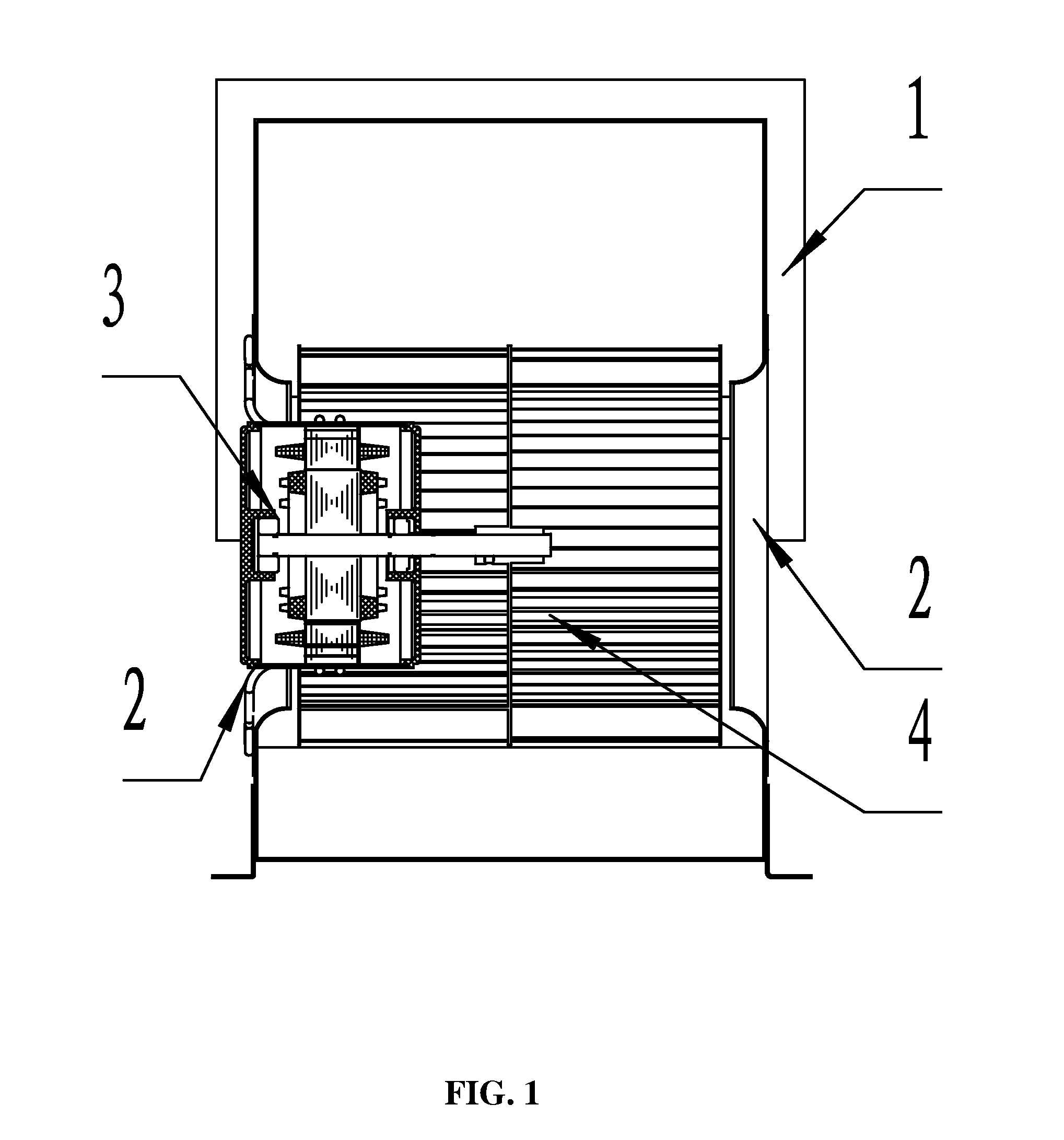

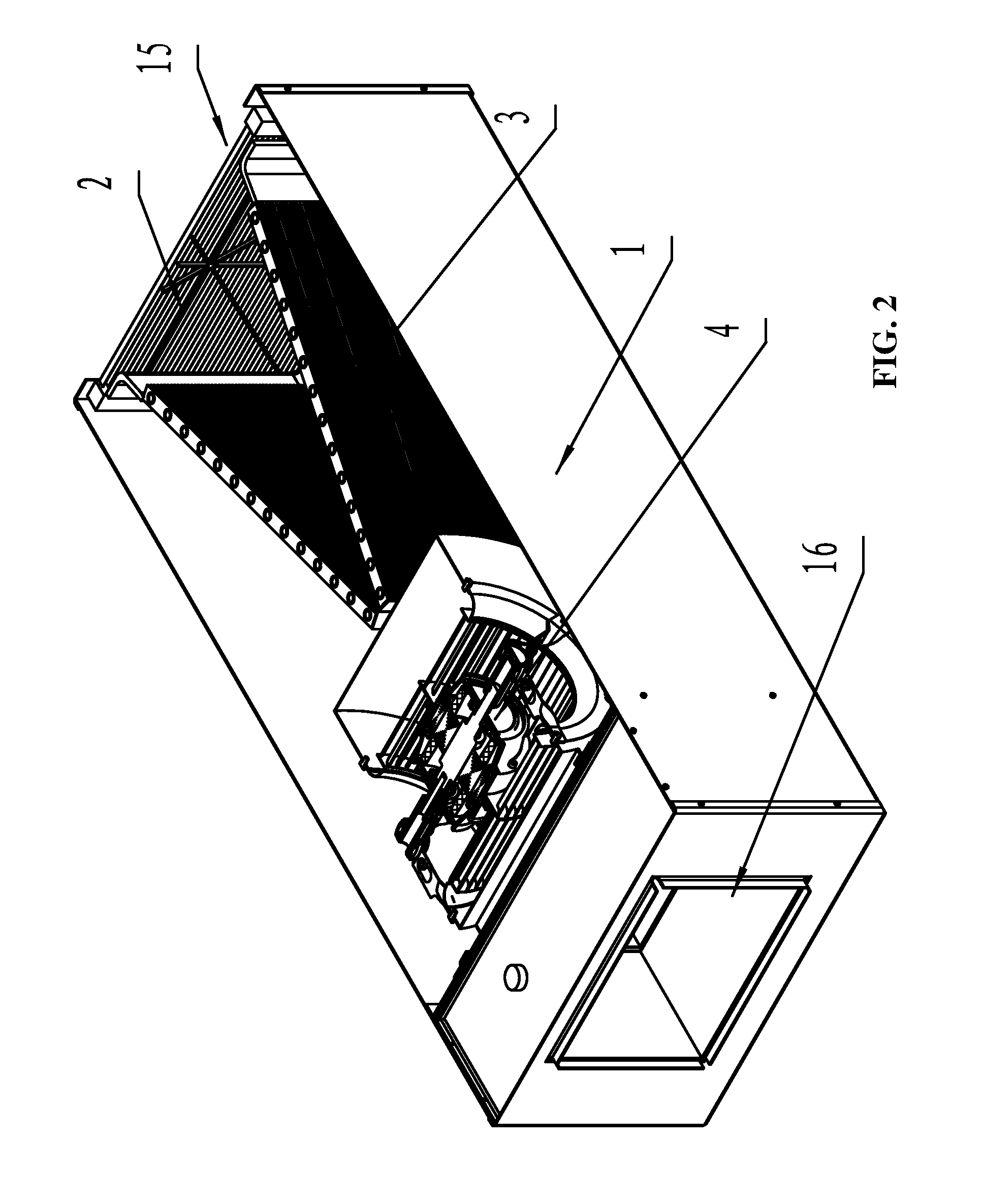

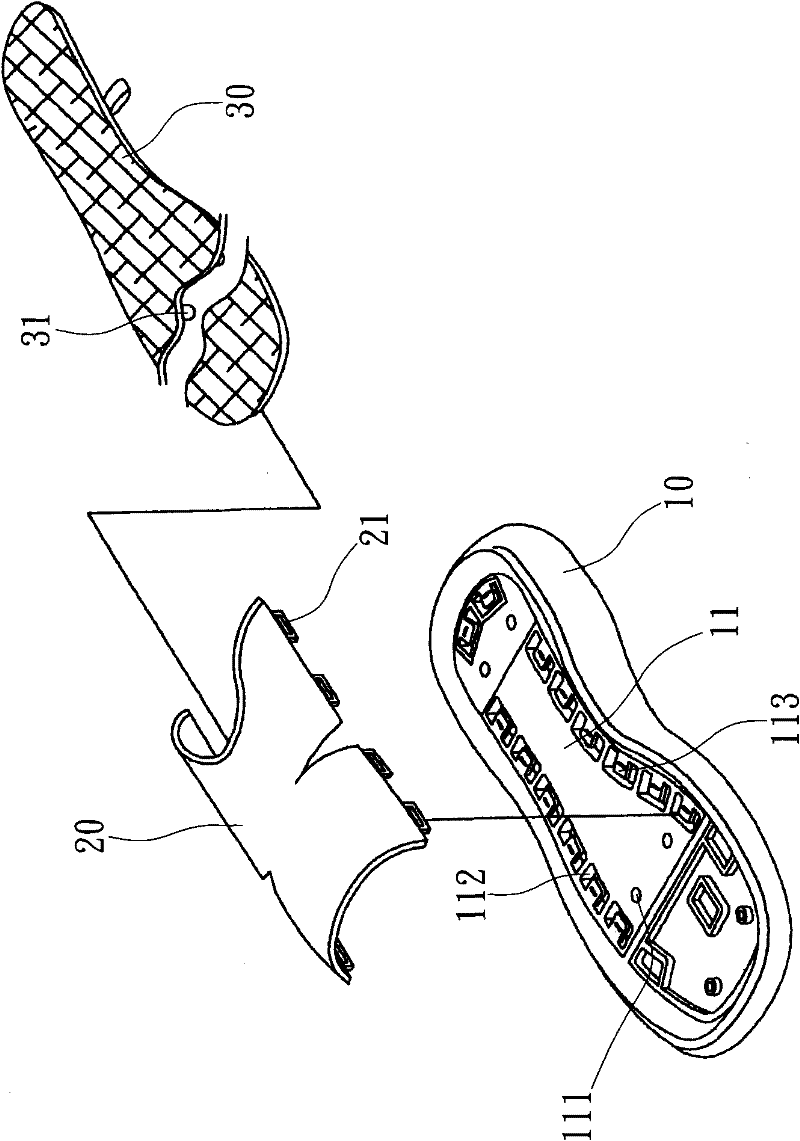

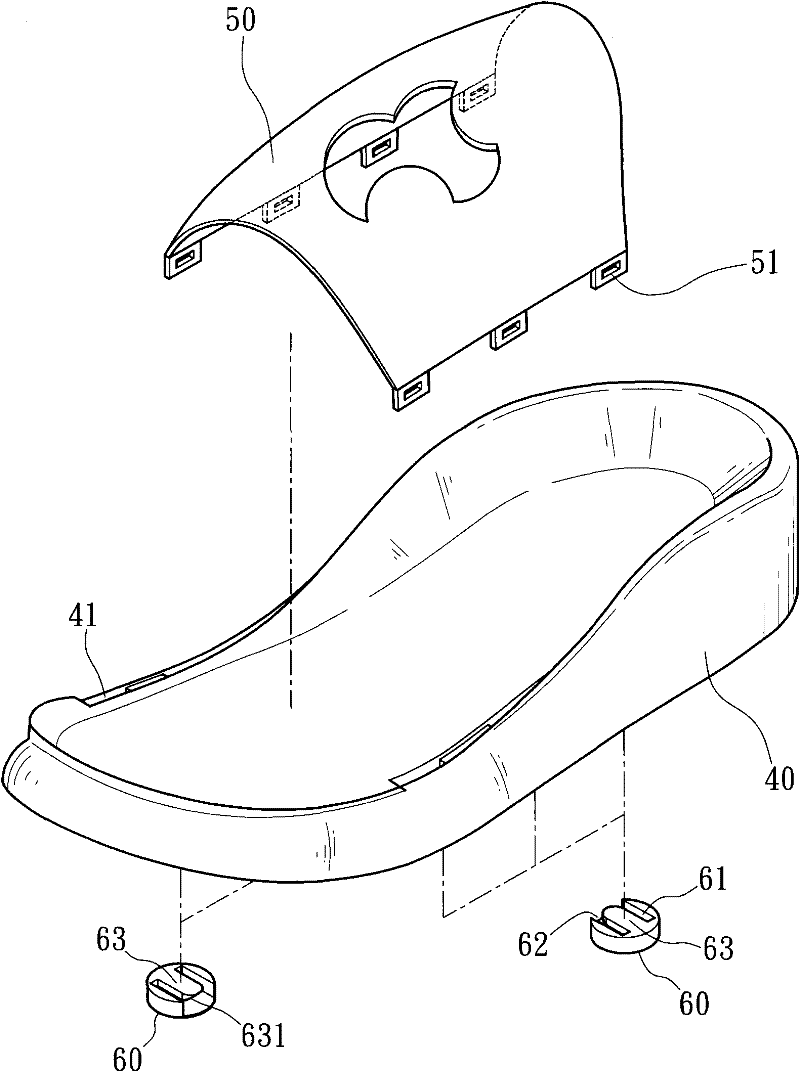

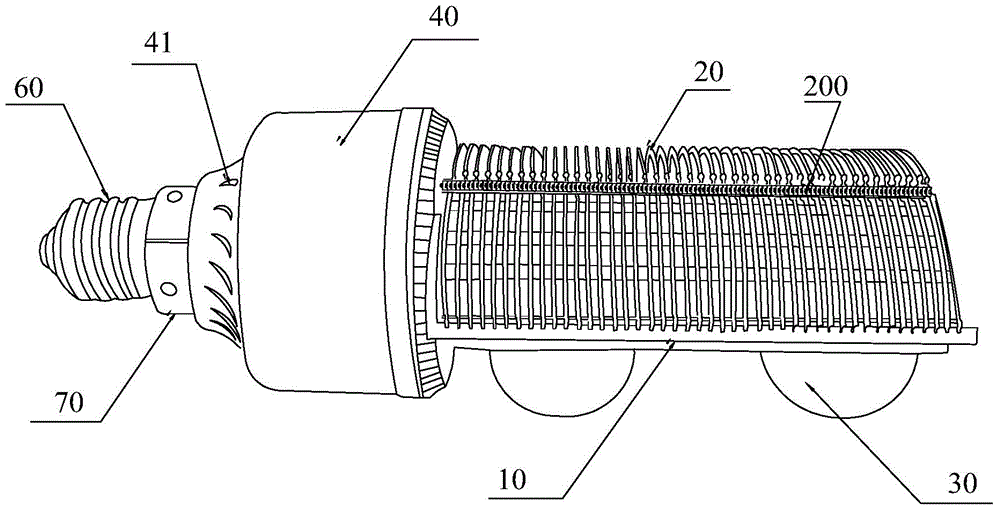

ActiveUS20110240262A1Large air volumeImprove blowing efficiencyHeating and ventilation casings/coversIndirect heat exchangersCooling coilEngineering

A heat exchanger for an indoor unit of an air conditioner, including at least a housing (1) having an air inlet (15) and an air outlet (16), a cooling coil (3), and a centrifugal blower (4) having an air exit (17), a volute housing (5), a motor (6) and a centrifugal wind wheel (7). The cooling coil (3) and the centrifugal blower (4) are disposed in the housing (1). The air inlet (15) and the air outlet (16) are disposed on both ends of the housing (1). The cooling coil (3) is disposed at the back of the air inlet (15). The centrifugal blower (4) is disposed at the back of the cooling coil (3). The air exit (17) of the centrifugal blower (4) is connected to the air outlet (16) of the housing (1). The motor (6) is an external rotor motor and fits in the center of a cavity in the centrifugal wind wheel (7). A left air intake (11) and a right air intake (12) are formed on both sides of the volute housing (5). The heat exchanger features large air input and air output, and high blowing efficiency.

Owner:ZHONGSHAN BROAD OCEAN MOTOR MFG

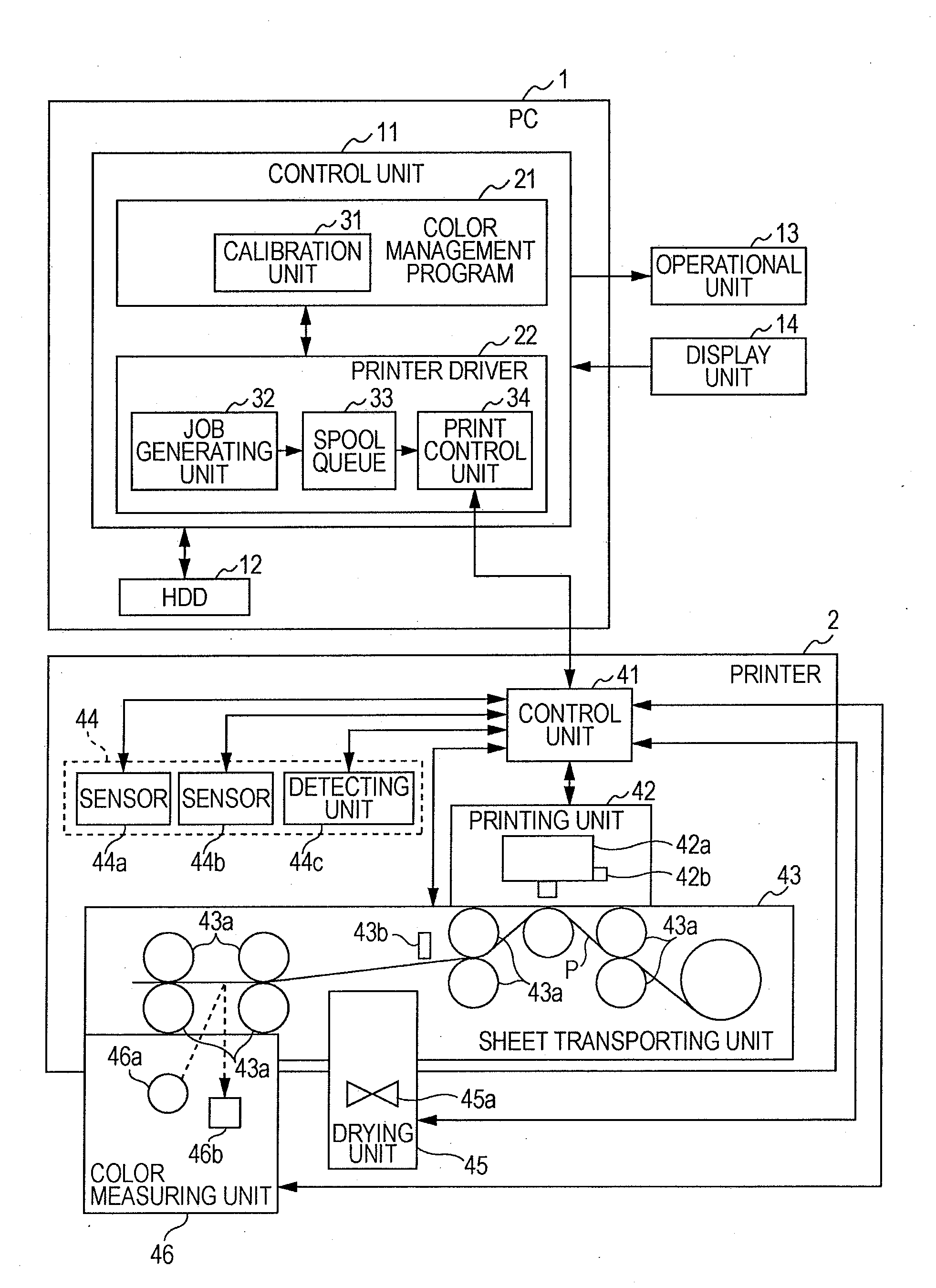

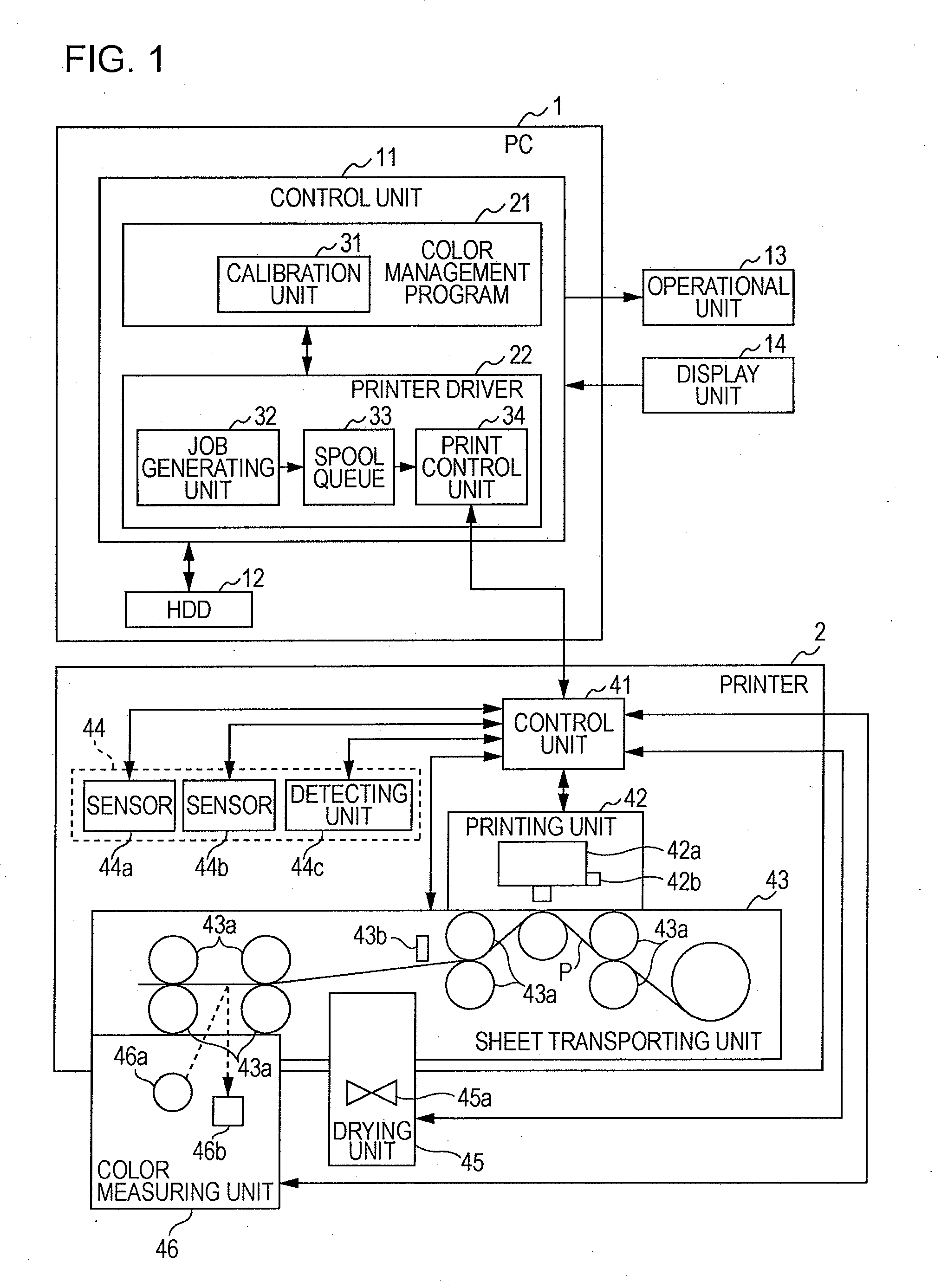

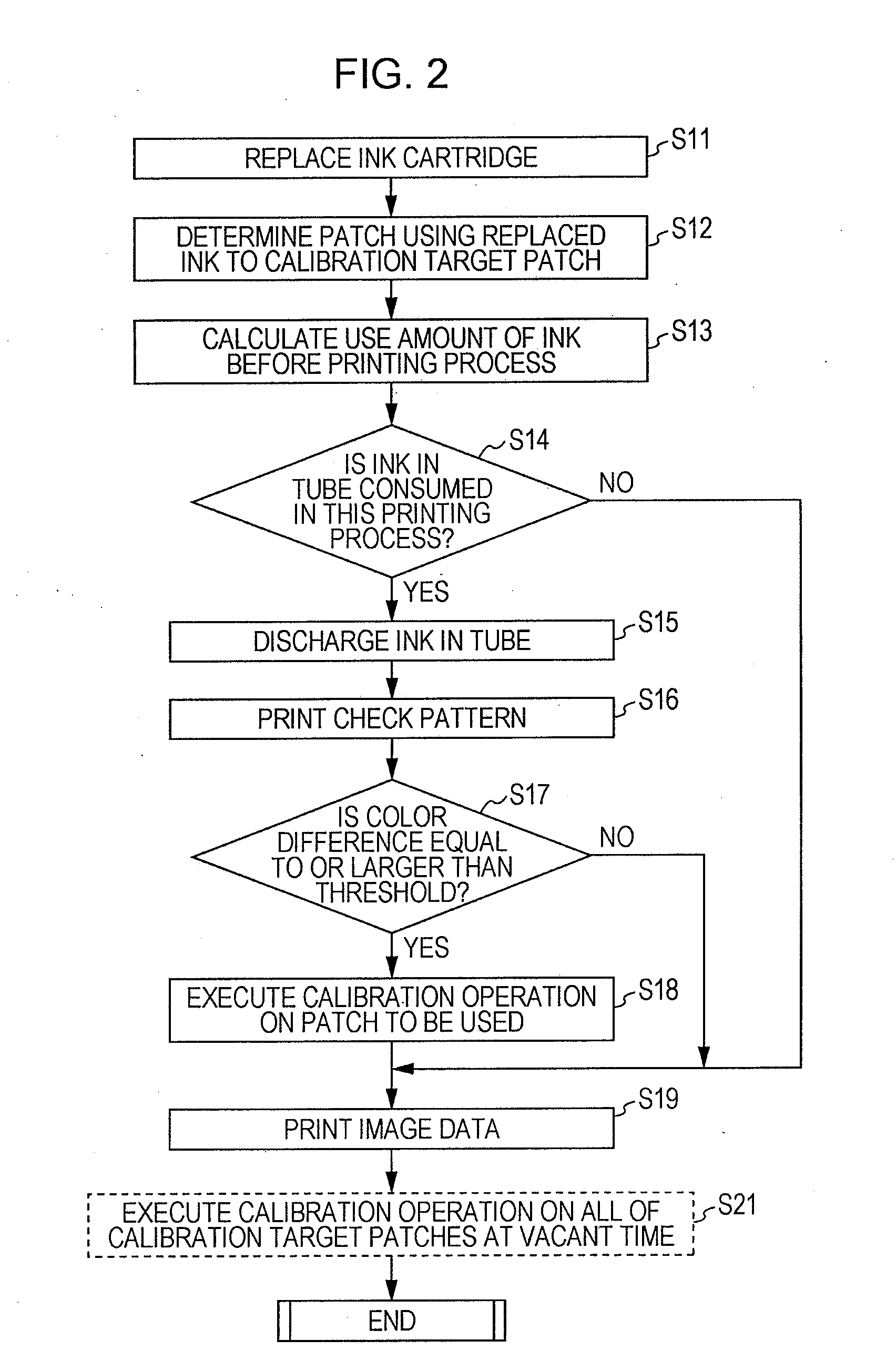

Printing apparatus, color correcting method, and program

InactiveUS20100171971A1Reduce consumptionReduce overall consumablesDigitally marking record carriersDigital computer detailsComputer hardwareCorrection method

Owner:SEIKO EPSON CORP

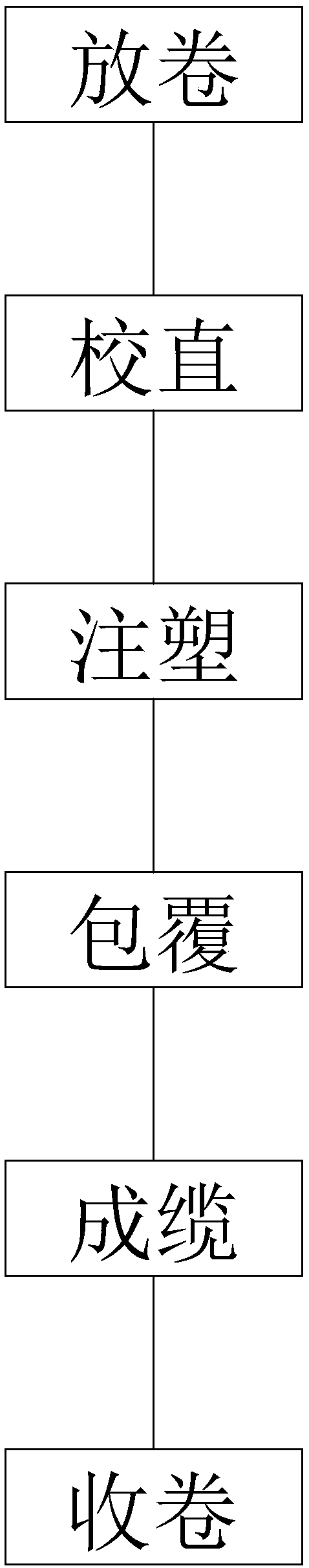

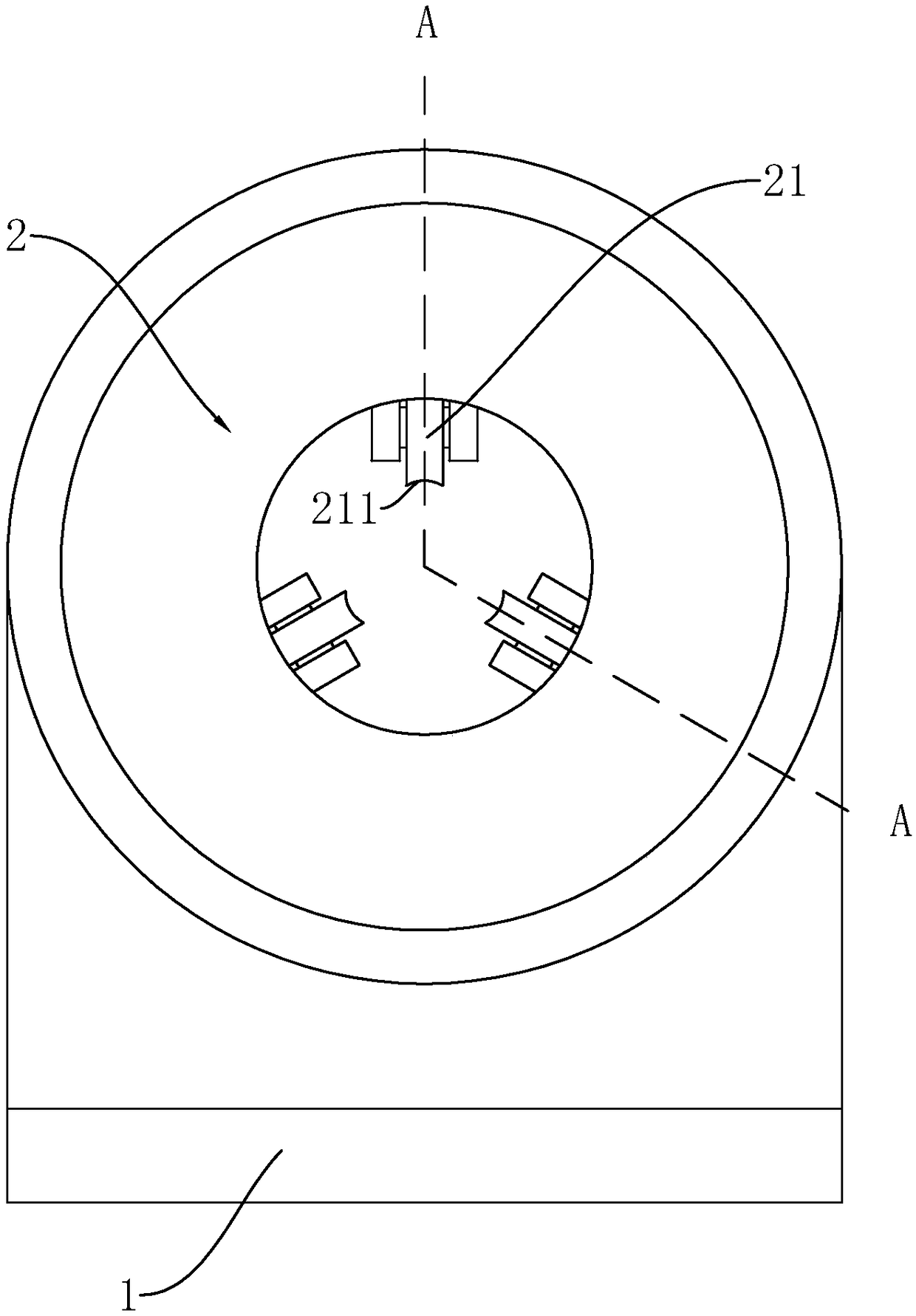

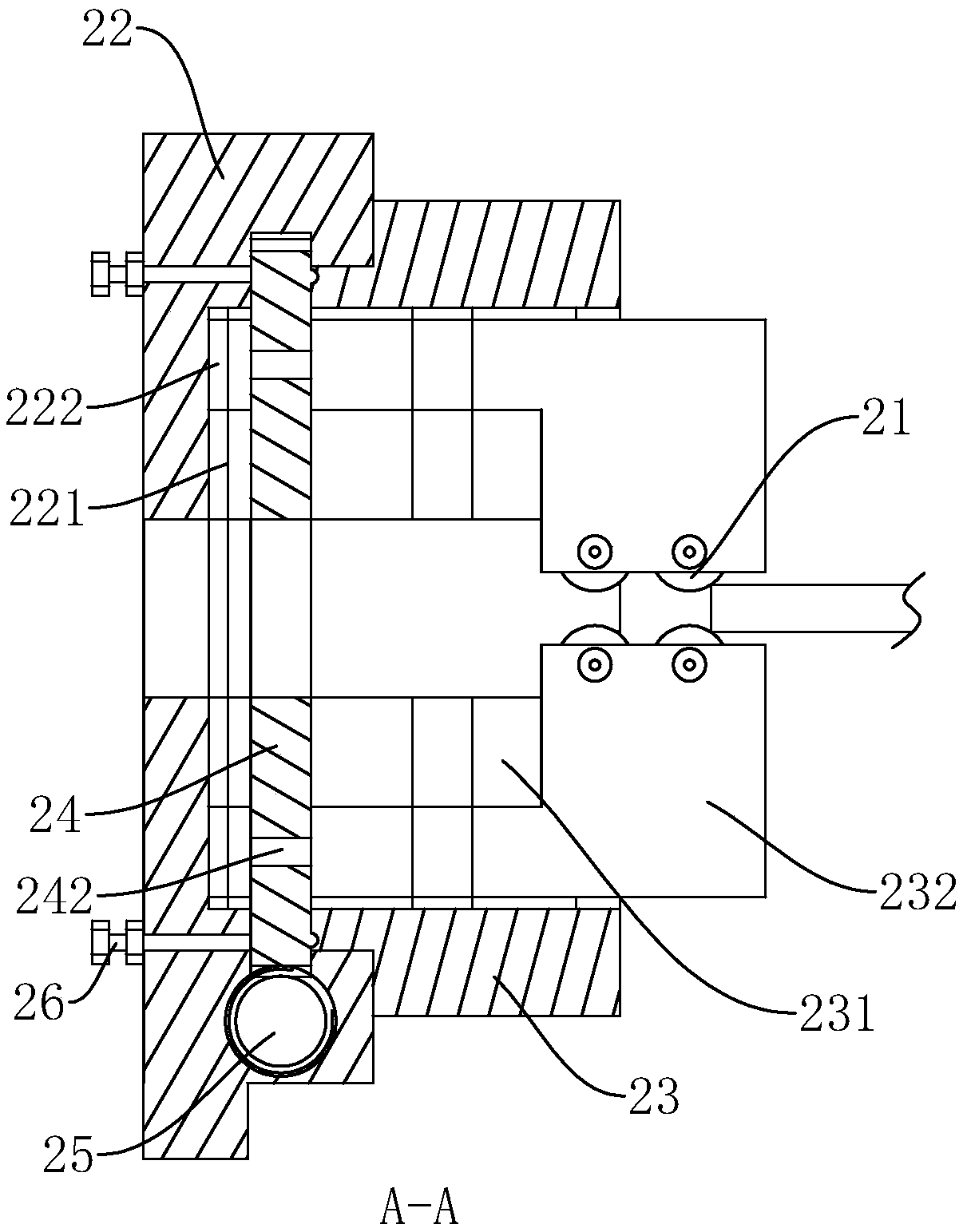

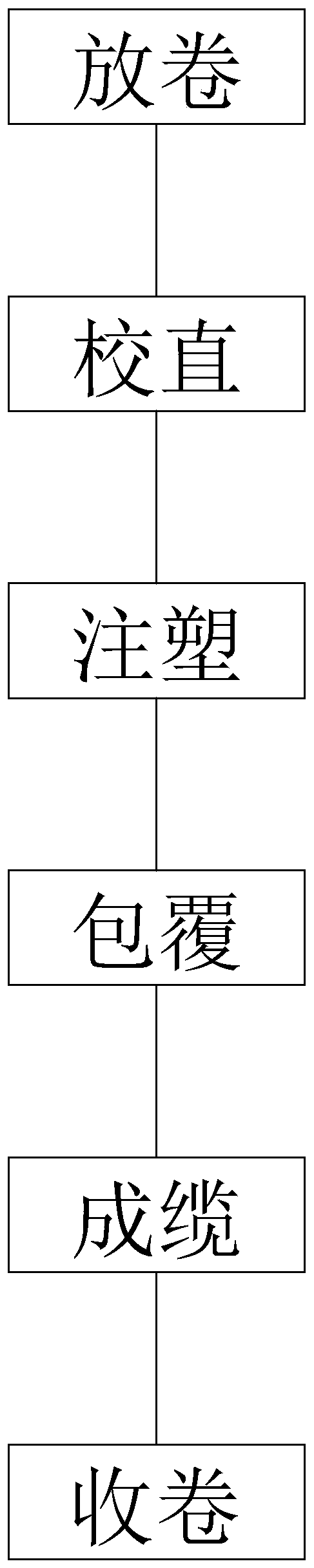

Fireproof flexible cable production process and flexible fireproof cable produced thereby

ActiveCN108962495AReduce weightReduce overall consumablesPower cablesFlexible cablesEngineeringCopper

The invention discloses a power transmission line, in particular to a fireproof flexible cable production process and a flexible fireproof cable produced thereby. The fireproof flexible cable production process includes unwinding, straightening, injection molding, coating, cable forming and winding. Straightening setting is first performed, and the cable can be straightened during processing, so that the cable does not have uneven wall thickness during injection molding, the frictional force born by the cable is relatively small during pulling of the cable, and the injection molding is relatively uniform. An insulating layer subjected to injection molding is coated by coating to form a fireproof layer, and a sheath is coated on the outermost surface to form the whole. A single-core coppercore dense inside is adopted, and the copper core cross-section is the transmission cross section of the cable, so that there is no extra space inside the cable, and the weight and the consumable items per unit length of the transmission line can be reduced. Since the secondary stranding of the copper core is not required, twisting is avoided, and the cable is relatively flexible.

Owner:上海安捷防火智能电缆有限公司

Padding mortar used indoor and outdoor and construction method thereof

ActiveCN101774795ALow thermal conductivityImprove heat insulation and noise reduction functionCement mixing apparatusHeat conductingPortland cement

A light super-fluidity padding mortar used indoor and outdoor is formed by mixing 28 to 32 parts by weightof R325 type or better ordinary Portland cement, 5 to 10 parts by weightof CA-50 type aluminate cement, 4 to 5 parts by weightof gypsum having a fineness more than 75 meshes, 8 to 12 parts by weightof light aggregate, 40 to 50 parts by weightof heavy aggregate (river sand), and 1.0 part by weight of compound auxiliary agent, wherein the light aggregate is an inorganic vitrified hollow pore material which has a fineness less than 100 meshes, and the compound auxiliary agent is formed by mixing 0.5 part by weightof air entraining agent, 0.3 part by weightof cellulose ether, 0.1 part by weightof re-scattering latex powder and 0.1 part by weightof water reducer. The padding mortar is diluted by adding 30 to 50 percent by weight of water and then the mixture is mixed uniformly by mechanically or manually stirring so as to reach a viscosity fit for mechanically coating or manually constructing in order to coat mechanically or construct manually. The mortar uses the specific light aggregate so the mortar has the advantages of light weight, good fluidity, excellent pasting property, difficulty to form empty drum, low heat conducting factor, energy saving, low manufacturing cost for unit area, wide indoor and outdoor application and great popularizing value.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

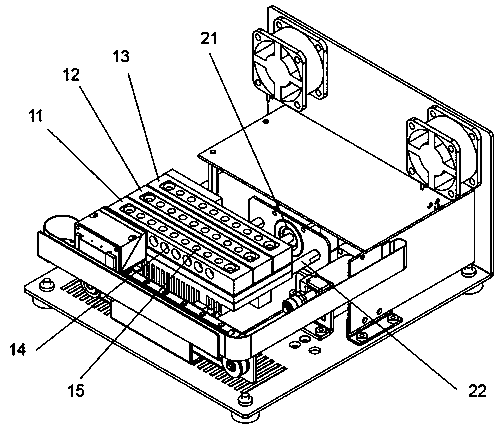

Extreme speed PCR reaction detecting device and detecting method

PendingCN110387325AEasy to moveMove fastBioreactor/fermenter combinationsBiological substance pretreatmentsHorizontal transmissionTemperature control

The invention provides an extreme speed PCR reaction detecting device, which comprises a temperature control system, a horizontal transmission mechanism, a reaction tube fixing device, and a perpendicular transmission mechanism.The horizontal transmission mechanism drives the temperature control system to move horizontally, the reaction tube fixing device is connected with the perpendiculartransmission mechanism and capable of moving up and down along an eccentric wheel of the perpendiculartransmission mechanism so as to realize the relative reciprocating movement of a reaction tube on the reaction tube fixing device between temperature control modules. The extreme speed PCR reaction detecting device is compact in structure, the moving speed is fast, the temperature rising and falling speed of reaction liquid in the reaction tube can be increased by the temperature setting of a high temperature module and a low temperature module, the two aspects of increasing the temperature rising and falling speed of the reaction tube and the moving speed between the reaction tube and the temperature control modules are set about to achieve the purpose of shortening the time required for PCR reaction, at the same time, the detection result of the extreme speed fluorescence PCR reaction detecting device is good in repeatability, and the result is accurate.

Owner:GUANGZHOU ANGEL BIOSAFETY TECH CO LTD

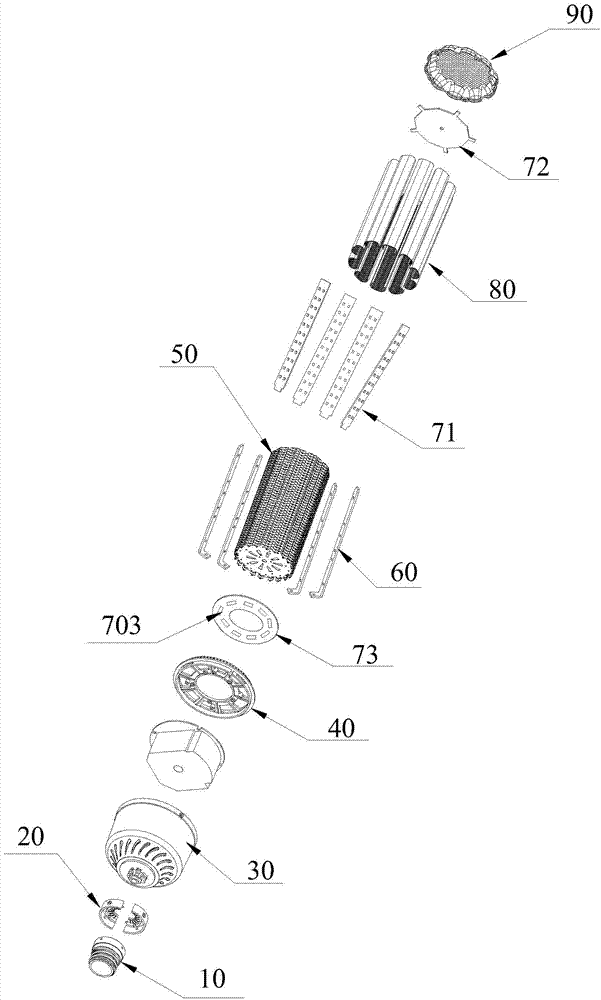

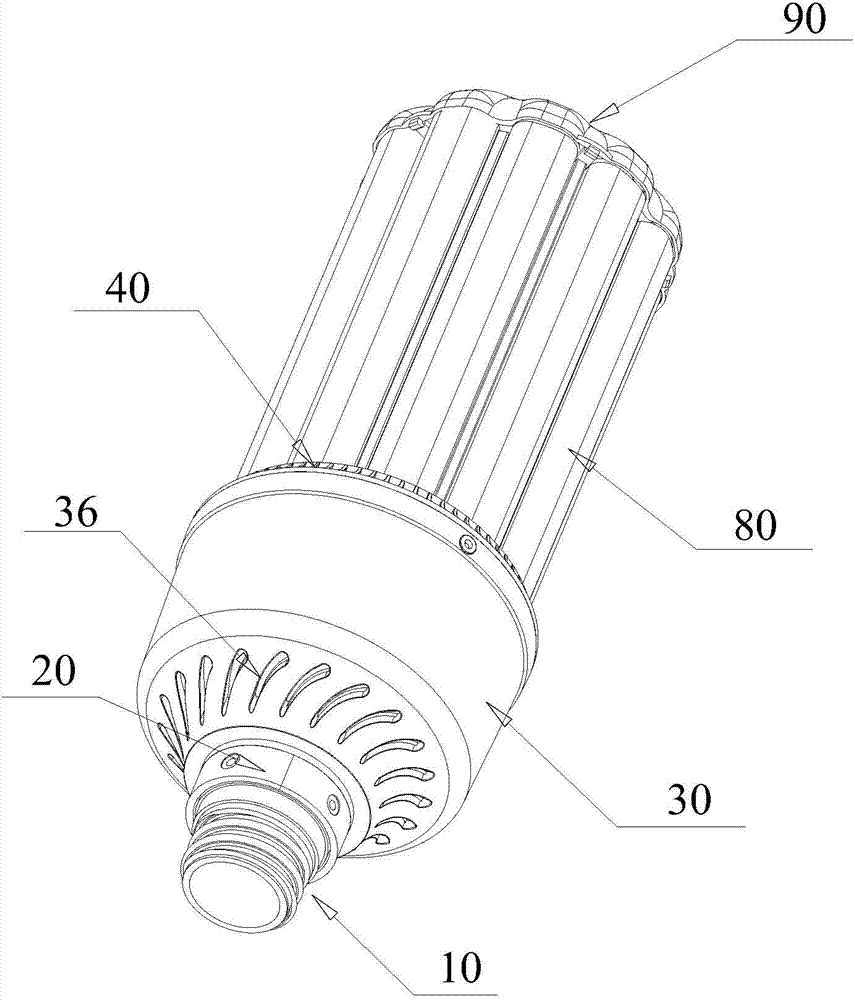

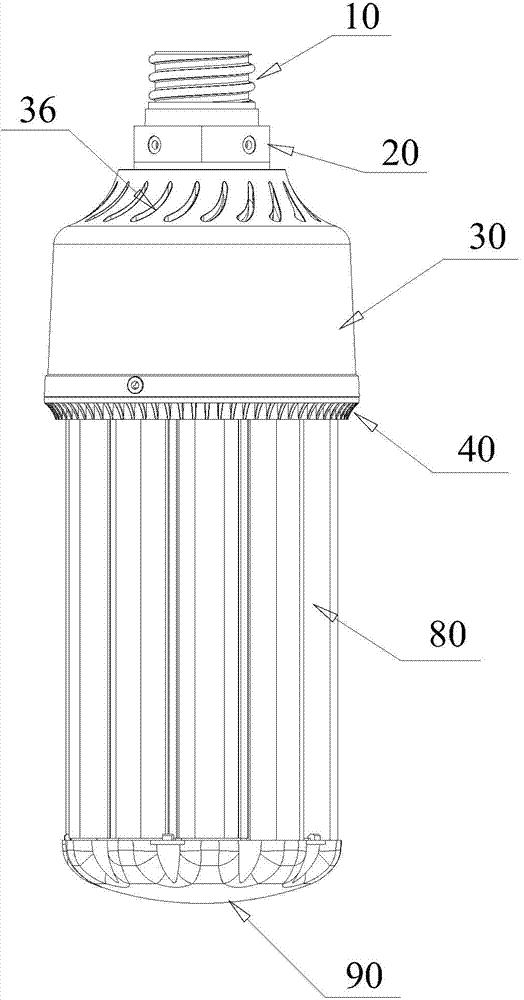

LED (light-emitting diode) corn light

ActiveCN104214576AEasy to install and operateImprove assembly efficiencyPoint-like light sourceElectric circuit arrangementsLight sourceCantilever

The invention discloses an LED (light-emitting diode) corn light which comprises a radiator, an LED light source and a lampshade component. The LED light source comprises an end light source board and a plurality of side light source boards, wherein the end light source board is mounted on one end face of the radiator, and the side light source boards are mounted on the side wall of the radiator. The lampshade component comprises an end diffuser and side diffusers, a plurality of outward projecting clamp strips are radially arranged at the edge of the end light source board by taking the center of the end light source board as a circle center, a plurality of cantilever hooks are arranged at the edge of the lower end of the end diffuser, the upper end faces of hook portions of the cantilever hooks are opposite to the lower end face of the end diffuser, the distance between the upper end face of the hook portion of each cantilever hook and the lower end face of the end diffuser is matched with the thickness of each clamp strip, the clamp strips and the cantilever hooks form a rotary fastening structure, the end diffuser and the end light source board relatively rotate, the clamp strips are rotatably connected with the cantilever hooks in a fastened manner, so that the end diffuser is connected, covers the end light source board and can be rapidly, simply and conveniently mounted, and assembly efficiency is improved.

Owner:杨小晨

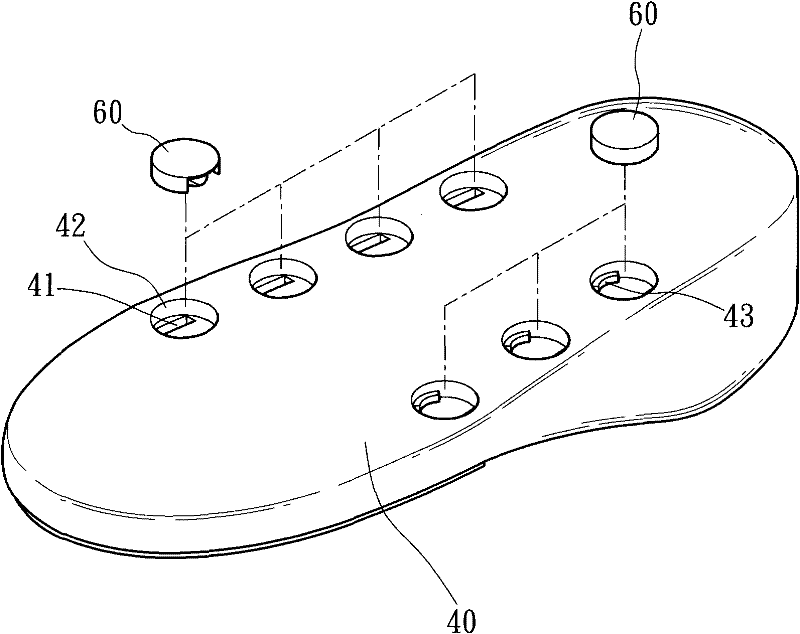

Convertible shoe body

Owner:杨成义

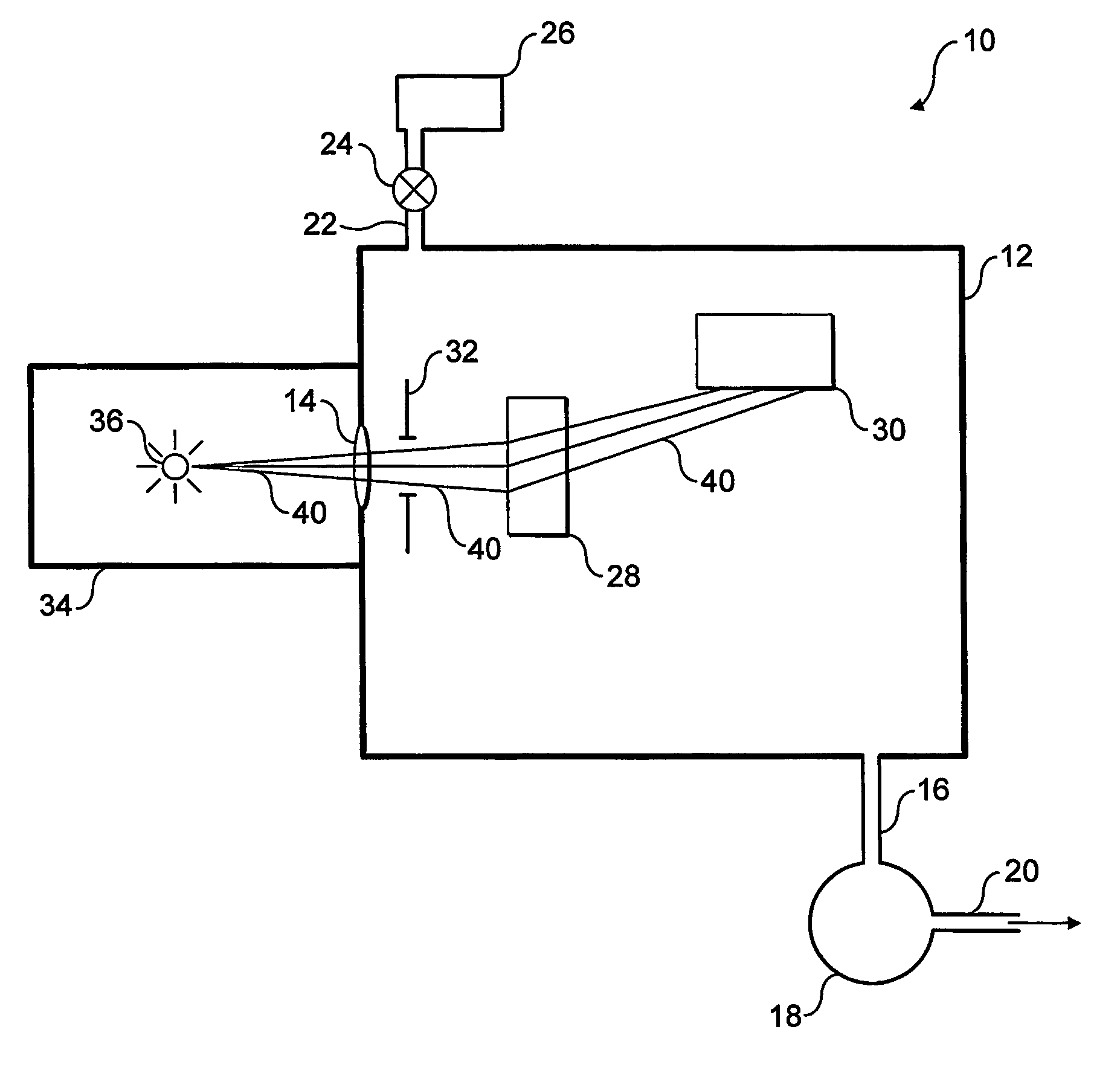

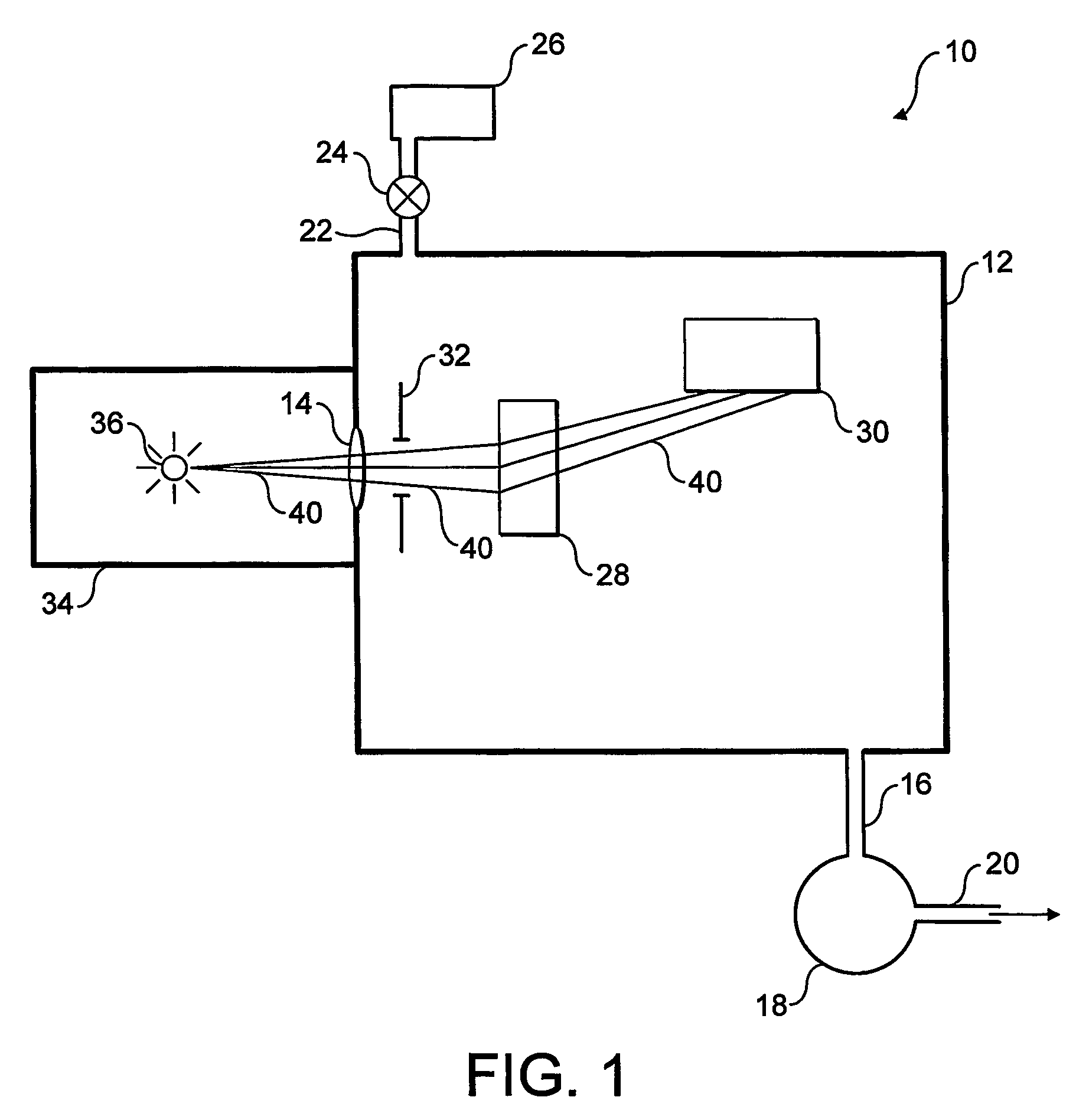

Apparatus and method for detection of vacuum ultraviolet radiation

ActiveUS20060289778A1Less costlyReduce absorptionEmission spectroscopyMaterial analysis by optical meansPhysicsFree space

Vacuum ultraviolet radiation detection apparatus (10) comprises a radiation detector (30) in a chamber (12). The detector (30) receives ultraviolet radiation from a radiation source (36). The chamber is evacuated using a dry vacuum pump (18) to a relatively poor vacuum of no less than 5 Pa. UV transparent gas is supplied from a gas supply (26), into the chamber (12) at a relatively low flow rate (around 0.1 litres / minute) so as to provide an overall pressure in the chamber (12) of between 100 and 1,000 Pa. The use of a relatively inexpensive pump coupled with a lower gas flow rate provides significant cost savings.

Owner:THERMO FISHER SCIENTIFIC INC

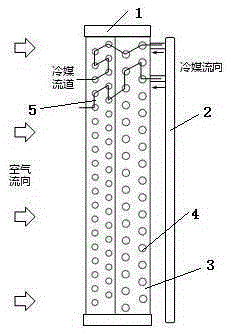

Composite air-cooling pipe finned heat exchanger structure

InactiveCN106802027AReduce spacingFacilitate the realization of replacementEvaporators/condensersEngineeringAir conditioning

A composite air-cooling pipe finned heat exchanger structure relates to the technical field of air conditioning refrigeration and comprises a heat exchanger set formed by two or more sub-air heat exchangers in serial and parallel connection or a serial-parallel connection combined way. Copper tubes and fins in each sub-air heat exchangers are independent to each other; the tube diameters of the copper tubes of each sub-air heat exchangers are different; the sub-air heat exchangers in the heat exchanger arranged in a serial-connection structure are orderly arrayed according to the sizes of the tube diameters of the copper tubes; the sub-air heat exchangers of the heat exchanger arranged in the parallel-connection structure are orderly arrayed according to the size of air-side resistance; each cold medium flow paths of the heat exchanger arranged in the parallel-connection structure only flow through the same sub-air heat exchanger; each cold medium flow path of the heat exchanger arranged in the serial or parallel-connection structures or the serial-parallel mixing structure orderly flows through each sub-air heat exchanger. Problems of unevenness of wind speed, great change of intra-tube refrigerant flowing speed and great air exchanging resistance of small tube diameter can be overcome; and comprehensive performance of the air heat exchanger can be obviously improved, so performance of an air source heat pump can be optimized.

Owner:TONGFANG ARTIFICIAL ENVIRONMENT

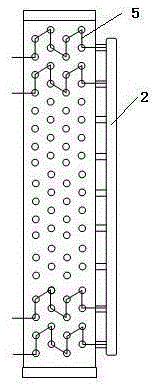

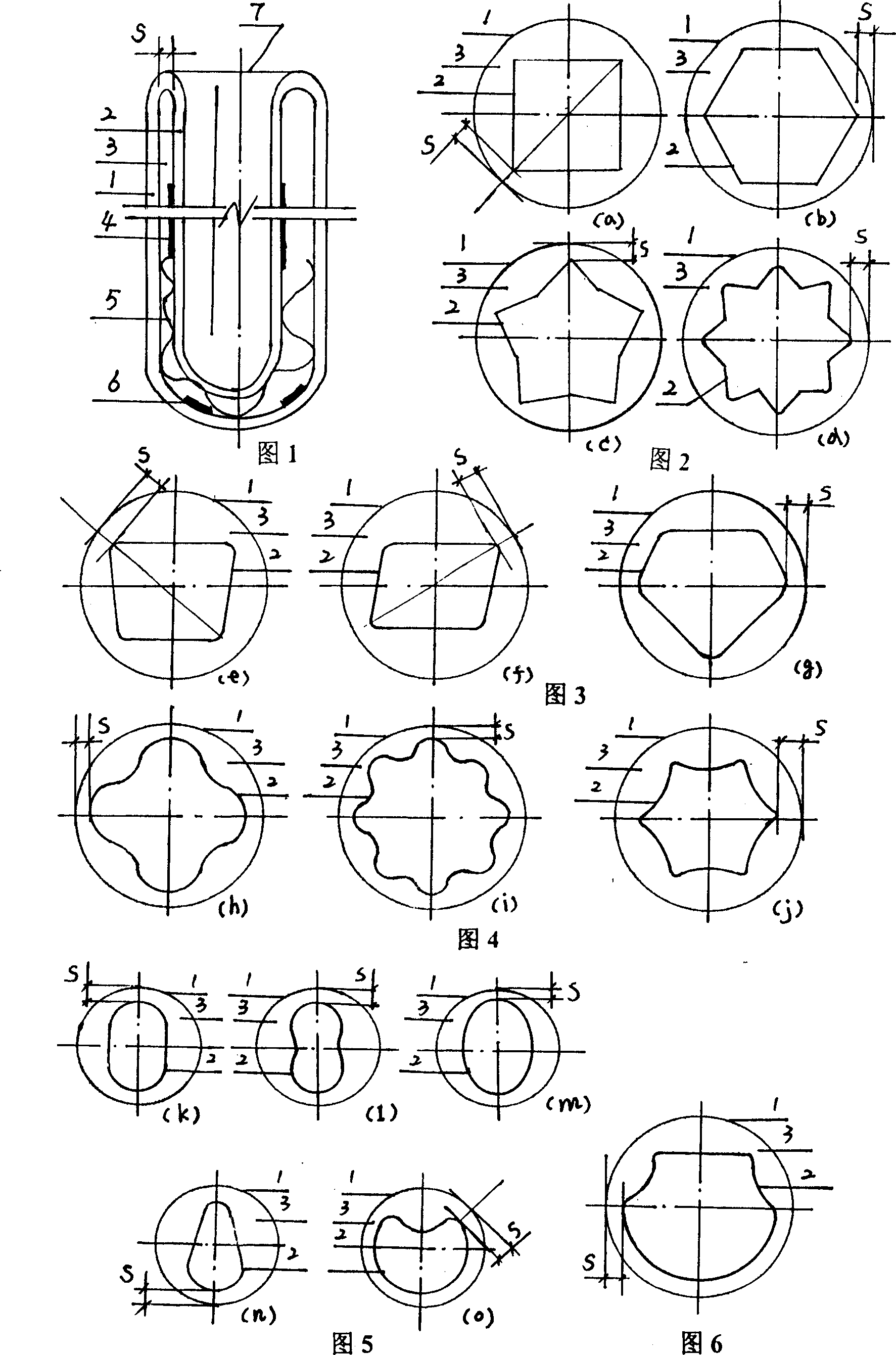

Profiled inner pipe all-glass vacuum solar collector tube

InactiveCN101008528AReplaceabilityEasy to replaceSolar heating energySolar heat devicesWater volumePore water pressure

A special-shaped inner tube all-glass vacuum solar-energy collecting tube is characterized in that: the wall of inner tube (2) is a polyhedral cylinder axially extending along the inner tube (2); the inner and outer faces of the wall of inner tube (2) are relative to the cylinder; the radial section of inner tube (2) is relative to the polyhedral cylinder of the wall of inner tube (2); the face of polyhedral cylinder is plane, or the convex arc or the concave arc. The invention has the advantages in the replace function on the general full-glass vacuum solar-energy collecting tube, to improve the inner and outer faces of inner tube (2), to improve heat adsorption, reduce the water volume of inner tube, improve the heat efficiency and improve the strength, while it can resist the inner water pressure, the axial bend and the explosion. The invention has simple production and low cost.

Owner:于学德 +2

A fireproof flexible cable production process and the flexible fireproof cable produced therewith

ActiveCN108962495BReduce weightReduce overall consumablesPower cablesFlexible cablesEngineeringCopper

The invention discloses a power transmission line, in particular to a fireproof flexible cable production process and a flexible fireproof cable produced thereby. The fireproof flexible cable production process includes unwinding, straightening, injection molding, coating, cable forming and winding. Straightening setting is first performed, and the cable can be straightened during processing, so that the cable does not have uneven wall thickness during injection molding, the frictional force born by the cable is relatively small during pulling of the cable, and the injection molding is relatively uniform. An insulating layer subjected to injection molding is coated by coating to form a fireproof layer, and a sheath is coated on the outermost surface to form the whole. A single-core coppercore dense inside is adopted, and the copper core cross-section is the transmission cross section of the cable, so that there is no extra space inside the cable, and the weight and the consumable items per unit length of the transmission line can be reduced. Since the secondary stranding of the copper core is not required, twisting is avoided, and the cable is relatively flexible.

Owner:上海安捷防火智能电缆有限公司

Heat sink

InactiveCN104214745AReduce the difficulty of production and processingLow costPoint-like light sourceLighting heating/cooling arrangementsEngineeringTongue and groove

The invention discloses a heat sink. The heat sink is formed by stacking and assembling a plurality of cooling fins, the production process of one single cooling fin is simple, the production machining difficulty of the heat sink can be reduced, and the production efficiency is improved; a plurality of connecting pieces are perpendicularly arranged on the edge of each cooling fin, groove openings with openings in the upper ends are formed in the upper portions of the connecting pieces, inserting pieces matched with the groove openings are arranged on the lower portions of the connecting pieces, tenons which protrude outwards are arranged on the upper end sides of the groove openings, and mortises matched with the tenons are arranged on the inserting pieces; the cooling fins are placed in a stacking mode, the positions of the connecting pieces on the adjacent cooling fins are aligned with one another in a one-to-one mode, when the cooling fins are assembled, inserting pieces on the upper layer connecting pieces are inserted into inserting openings in the lower layer connecting pieces, meanwhile, the tenons on the inserting openings are buckled into the mortises on the inserting pieces, the adjacent cooling fins are connected, the assembling and operation are easy, and can be rapidly completed, and the assembling efficiency is high. After assembly, the opposite faces of the adjacent cooling fins are distanced by gaps, ventilation and heat dissipation are facilitated, each cooling fin can be in full contact with air, and the heat dissipation efficiency is improved.

Owner:杨小晨

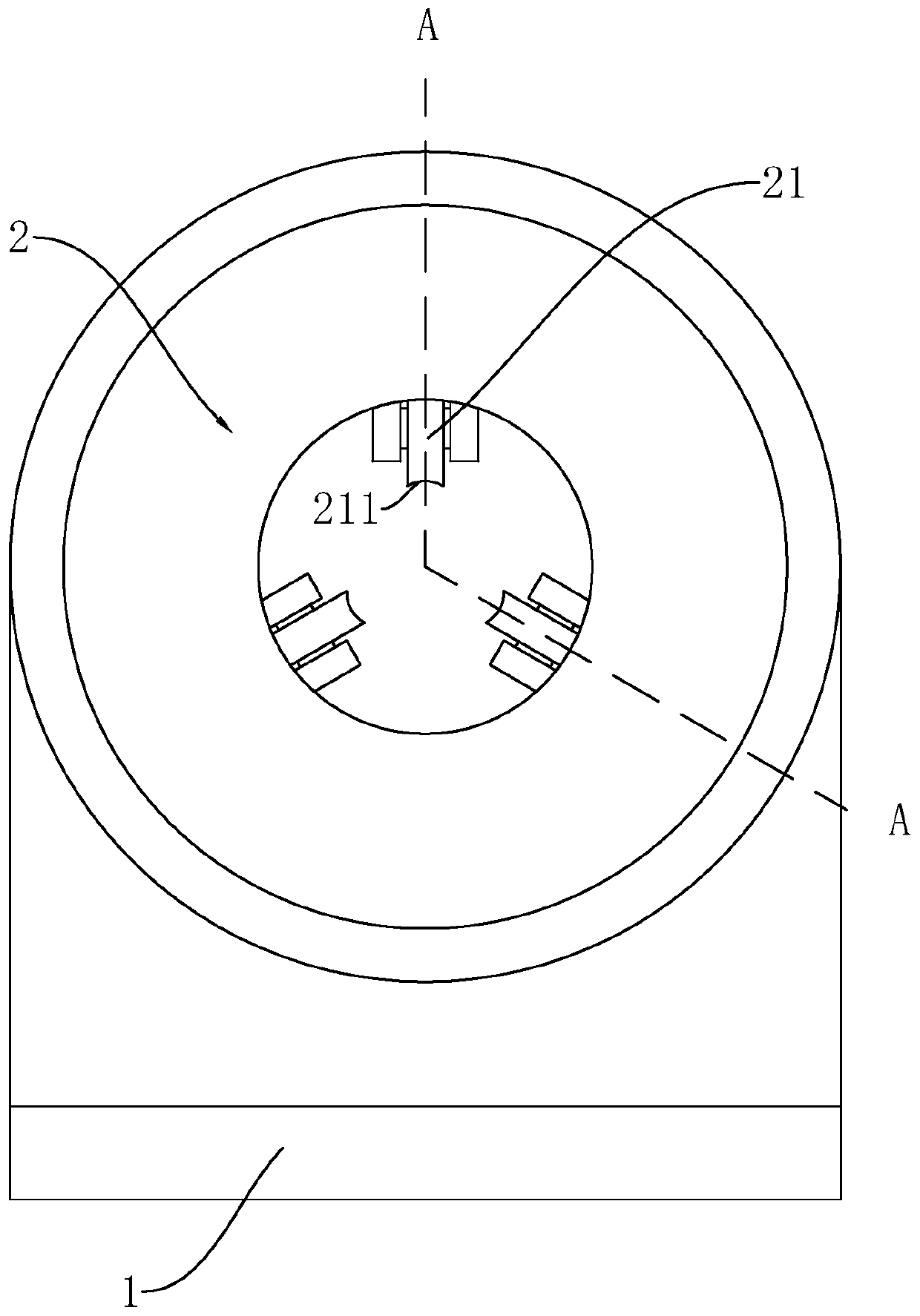

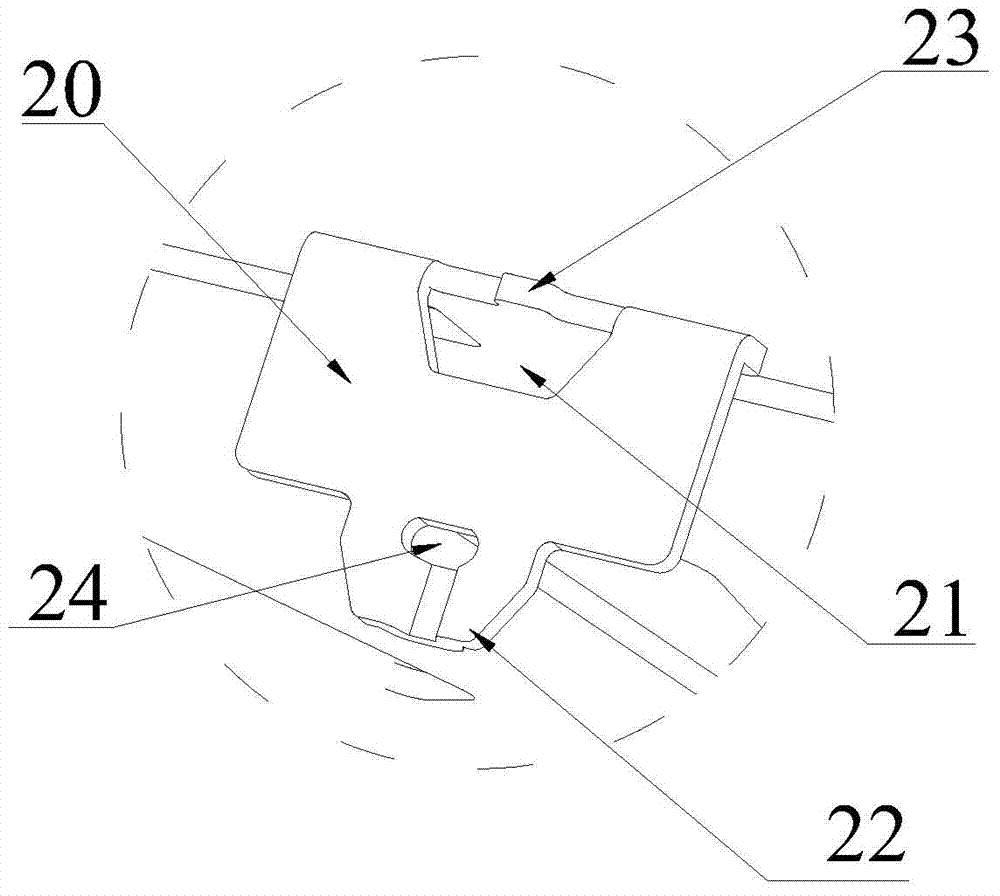

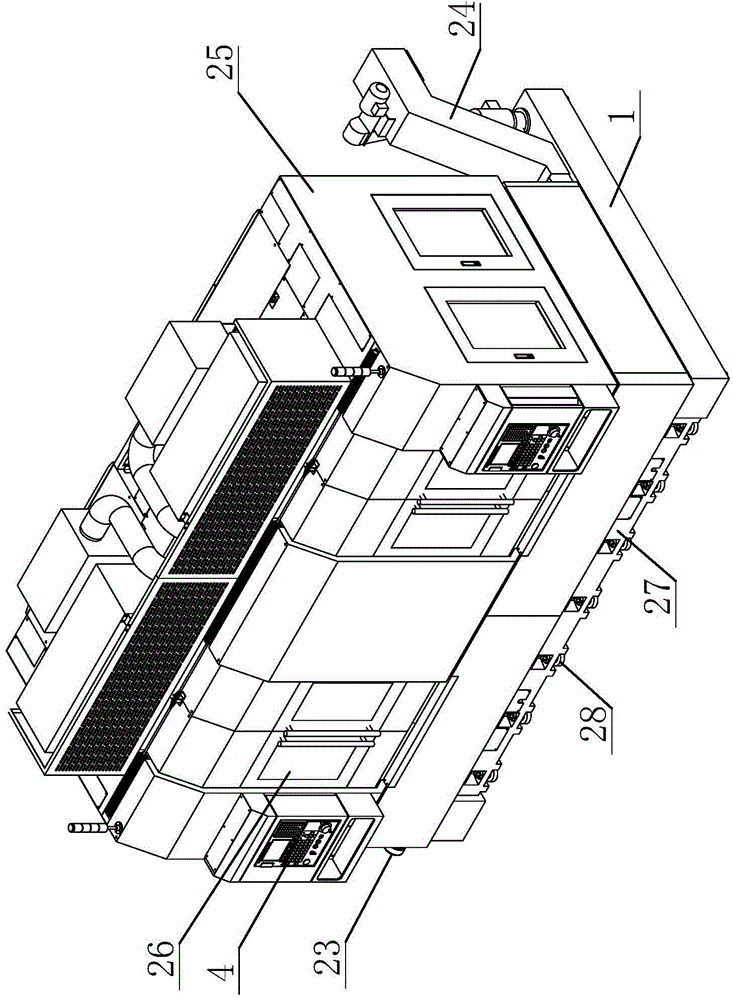

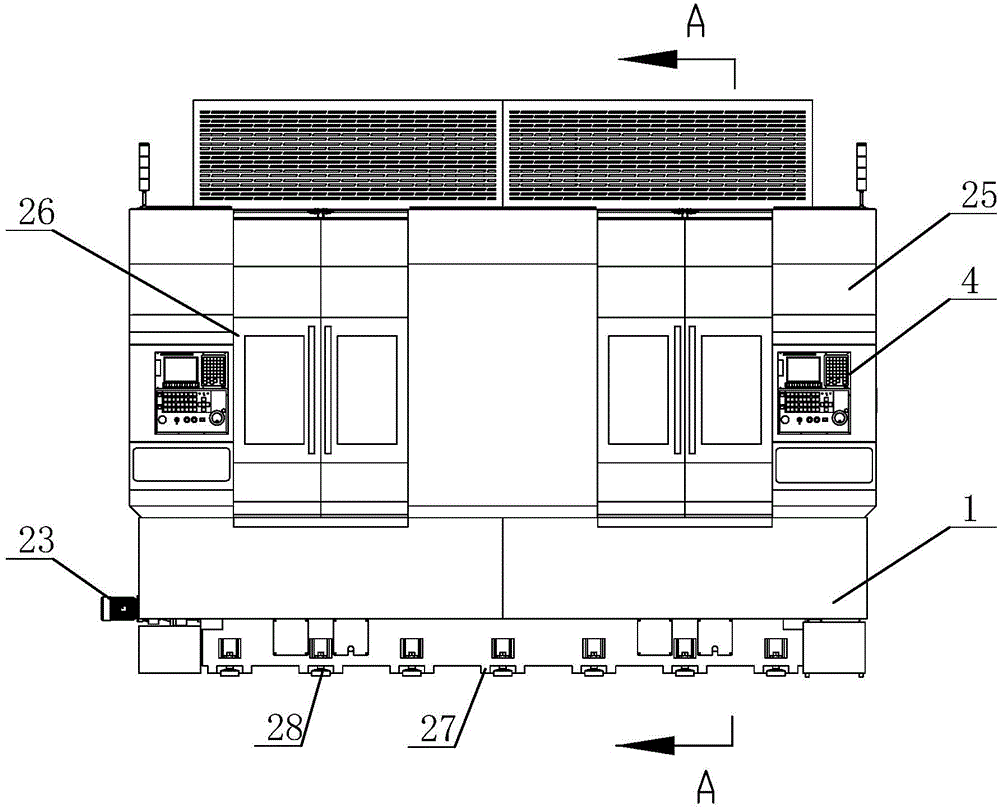

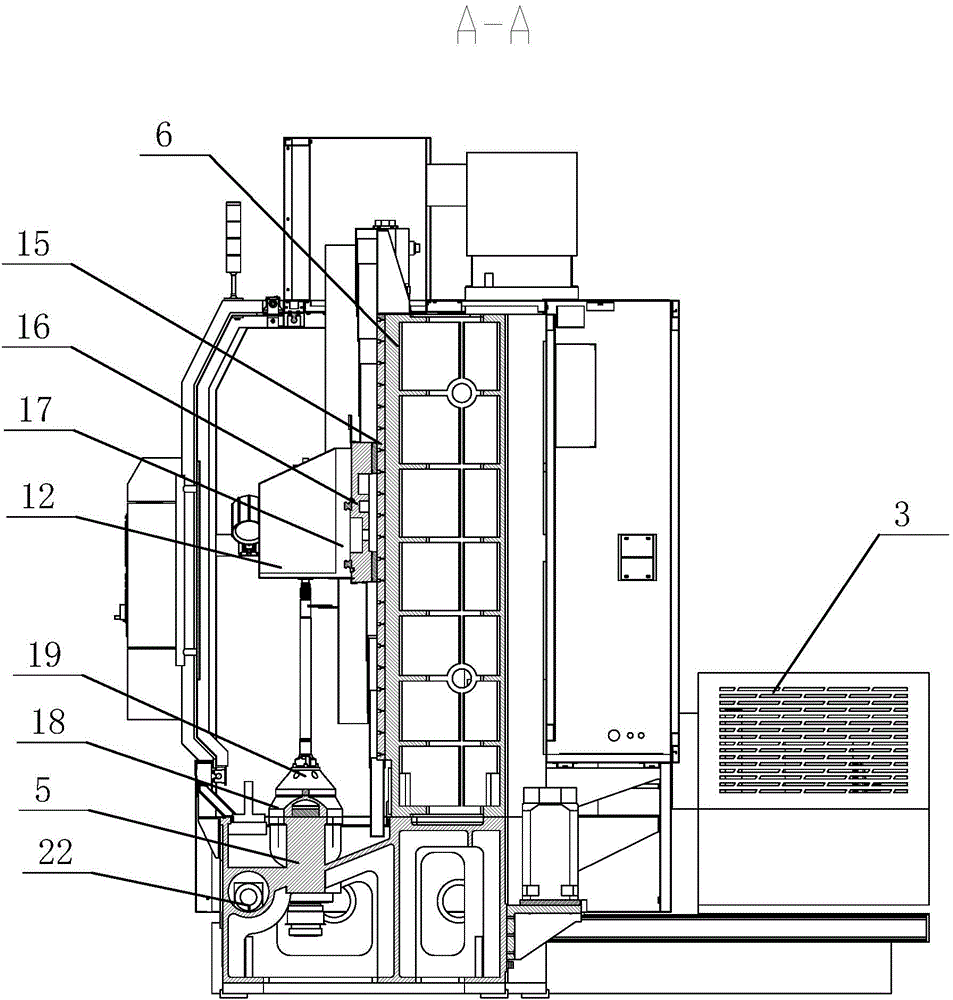

Multi-spindle numerical control vertical type special lathe

ActiveCN104801727AReduce manufacturing costLabor savingCamsAutomatic/semiautomatic turning machinesNumerical controlEngineering

The invention relates to a multi-spindle numerical control vertical type special lathe, which comprises a base, wherein a processing mechanism is arranged on the base and comprises two vertical spindle units, the two spindle units are closely arranged along the transverse direction, a vertical column is arranged at the back side of each spindle unit, a vertical tail seat unit and two feeding units are arranged on each vertical column, and the two feeding units are respectively arranged at the two transverse sides of the corresponding tail seat unit; each tail seat unit comprises a first slide device, a tail seat is arranged on each first slide device, and two vertical tail seat sleeve cylinders are arranged at the lower part of each tail seat, are positioned above spindles, and are correspondingly arranged; each feeding unit comprises a second slide device and a transverse movement device, each transverse movement device is arranged on the corresponding second slide device, a knife holder is arranged on each transverse movement device, each first slide device and each second slide device can be moved on the corresponding vertical column along the vertical direction, and each transverse movement device is moved on the corresponding second slide device along the transverse direction. The multi-spindle numerical control vertical type special lathe has the advantages that multiple different types of camshaft parts can be simultaneously processed, and the production efficiency is high; the whole land occupation area of the equipment is small.

Owner:JINAN FIRST MACHINE TOOL GROUP

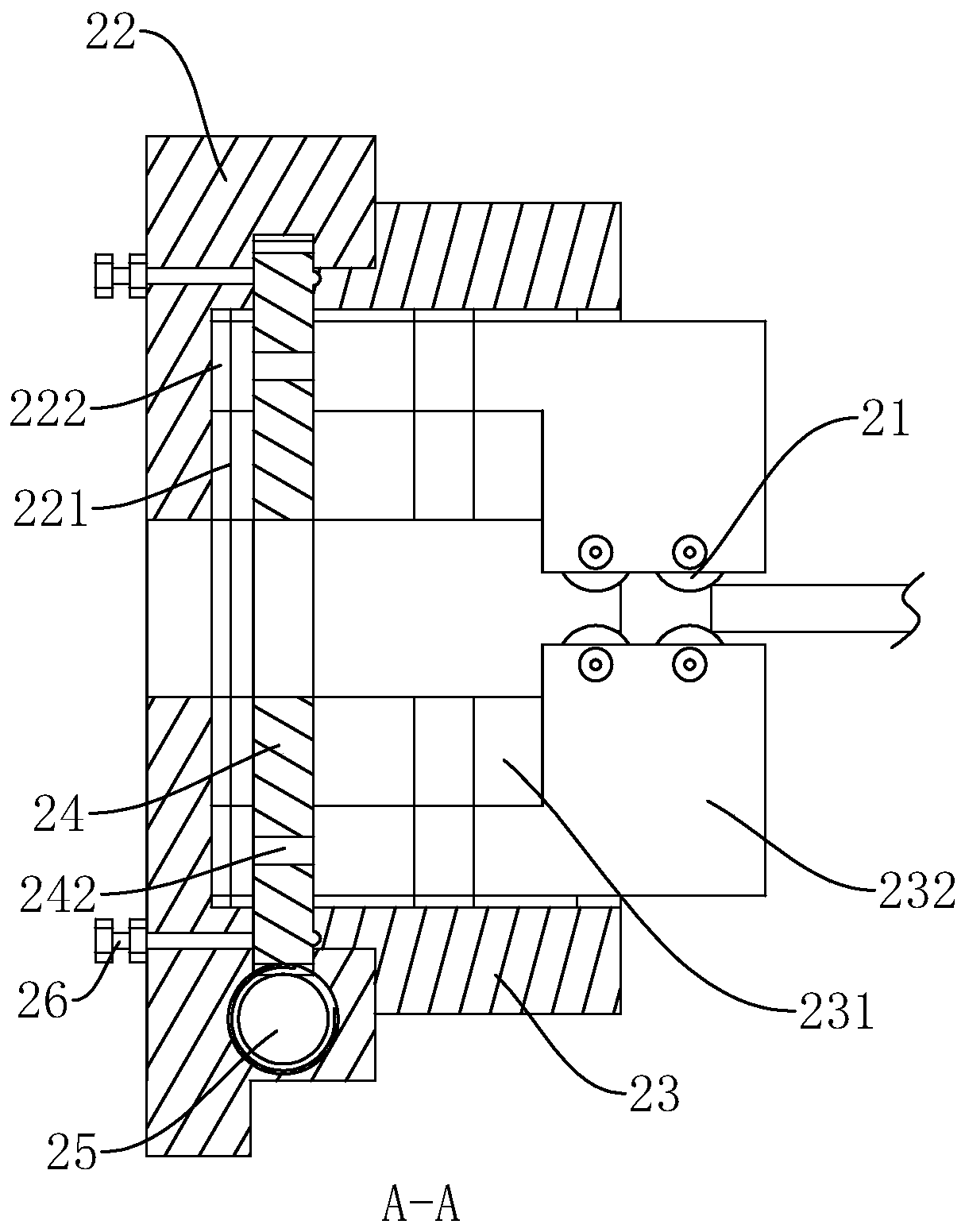

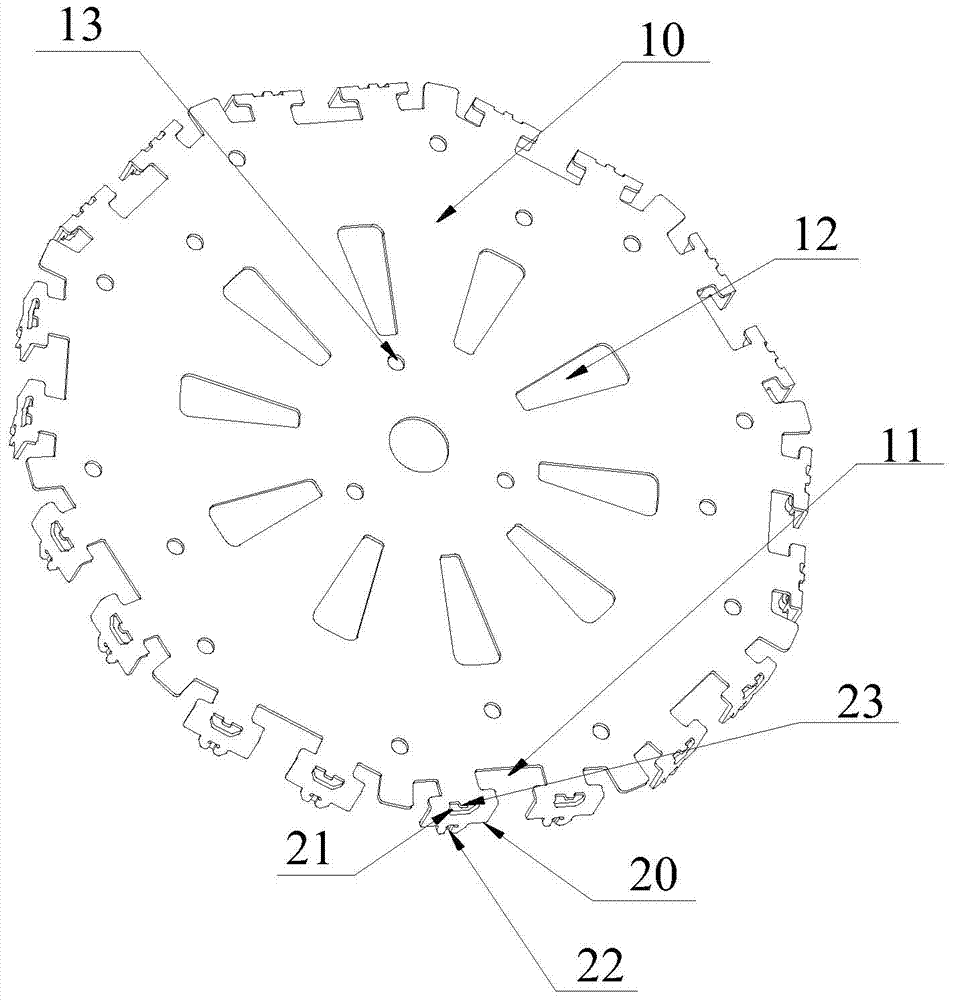

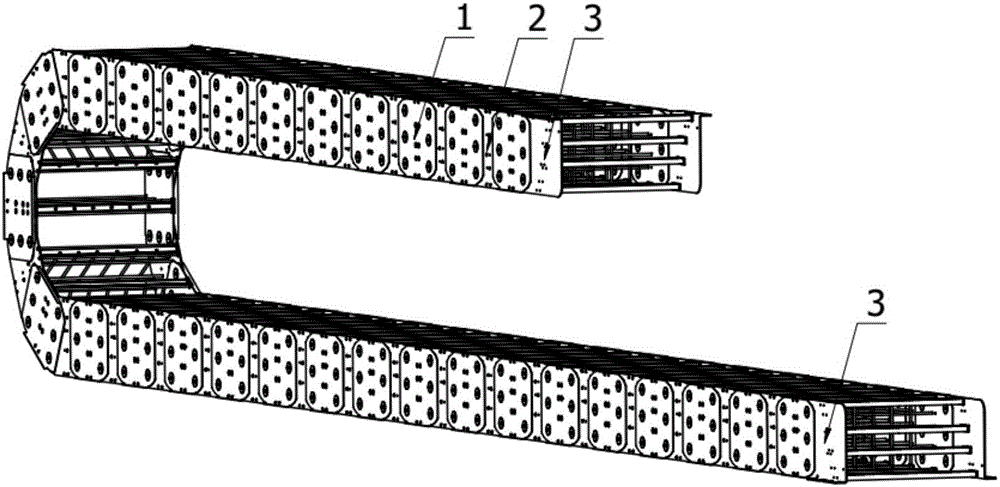

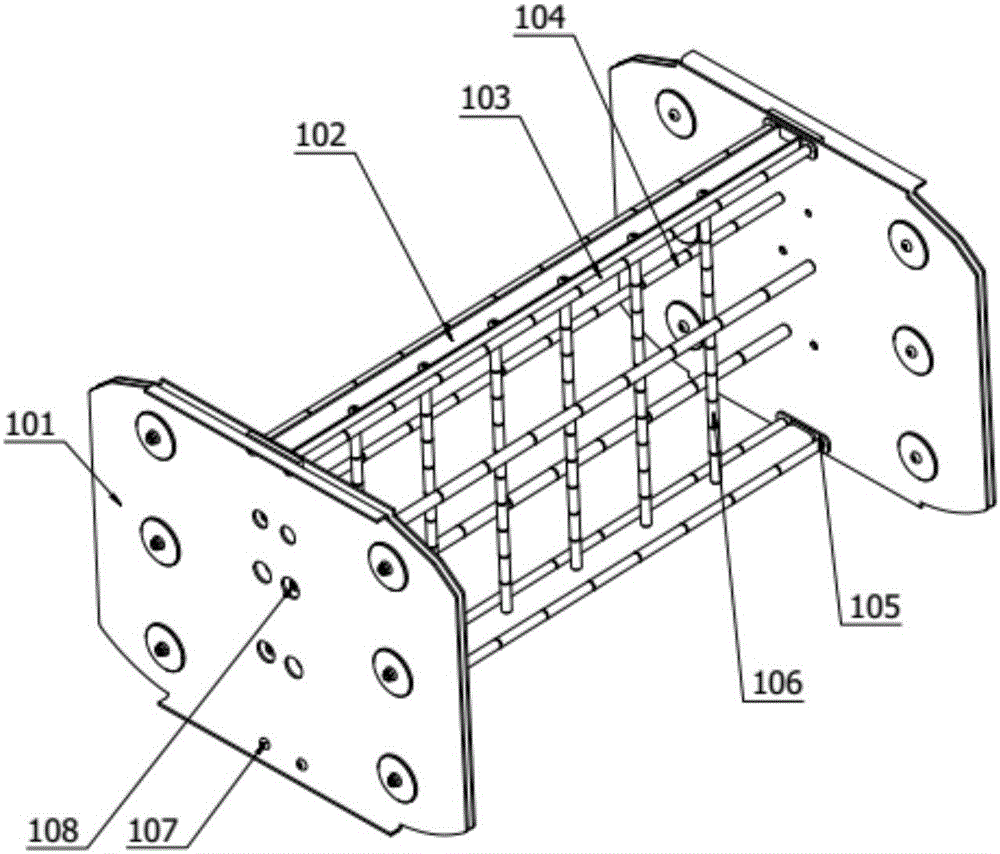

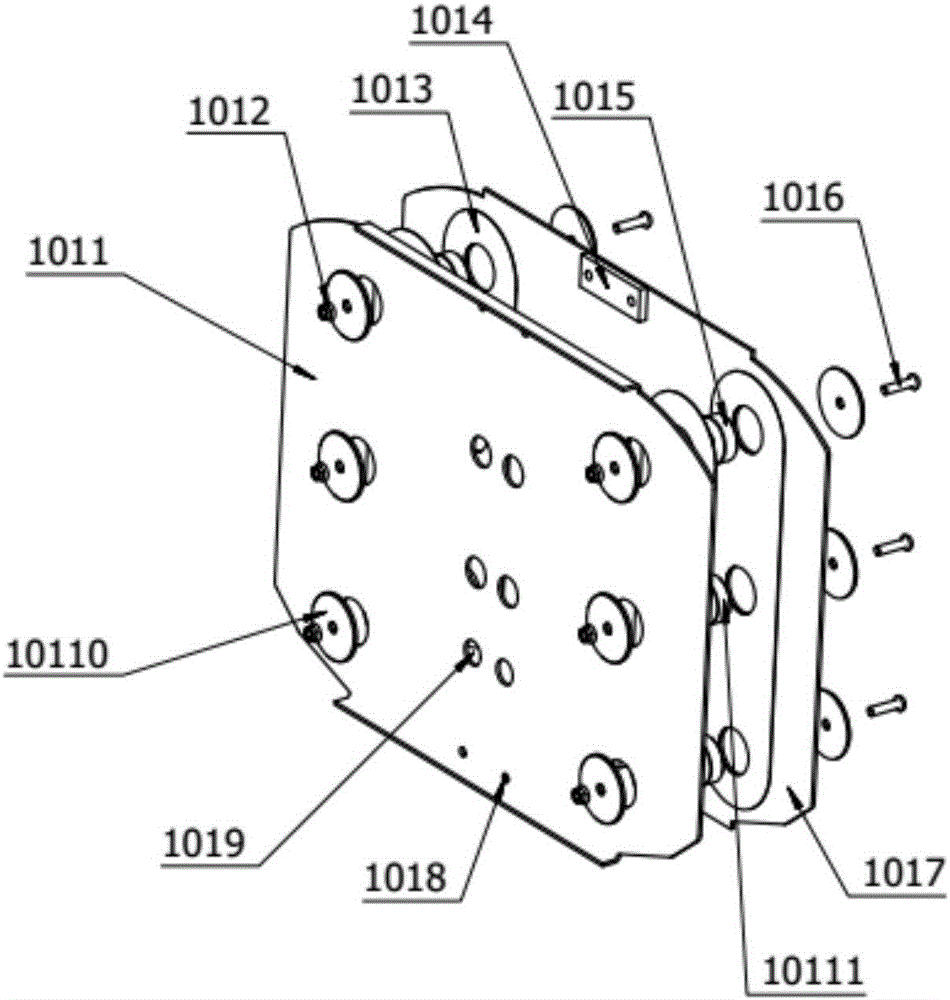

Multilayer multi-pipeline large steel drag chain system for offshore platform

ActiveCN106195126AReduced carrying capacityDoes not reduce structural rigidityHauling chainsHoisting chainsLine tubingMarine engineering

The invention discloses a multilayer multi-pipeline large steel drag chain system for an offshore platform. The system comprises a plurality of outer chaining units, a plurality of inner chaining units and a pair of base units; two sides of the inner chaining units are hinged to the outer chaining units, and the outer chaining units at the two ends are each hinged to one base unit. According to the multilayer multi-pipeline large steel drag chain system for the offshore platform, a medium pipeline is sufficiently protected against damage in the drag chain reciprocating dragging process, the medium pipeline has the independent transfer space, motion of the medium pipeline is in order, the attractive effect in vision is achieved, the service life of the medium pipeline is prolonged, on the premise of not reducing the bearing capacity and structural rigidity of the drag chain system, main structural parts reduce self weight and consumables of the drag chain system through the metal sheet design, and strength and rigidity of the structural parts are improved.

Owner:谷丽丽 +1

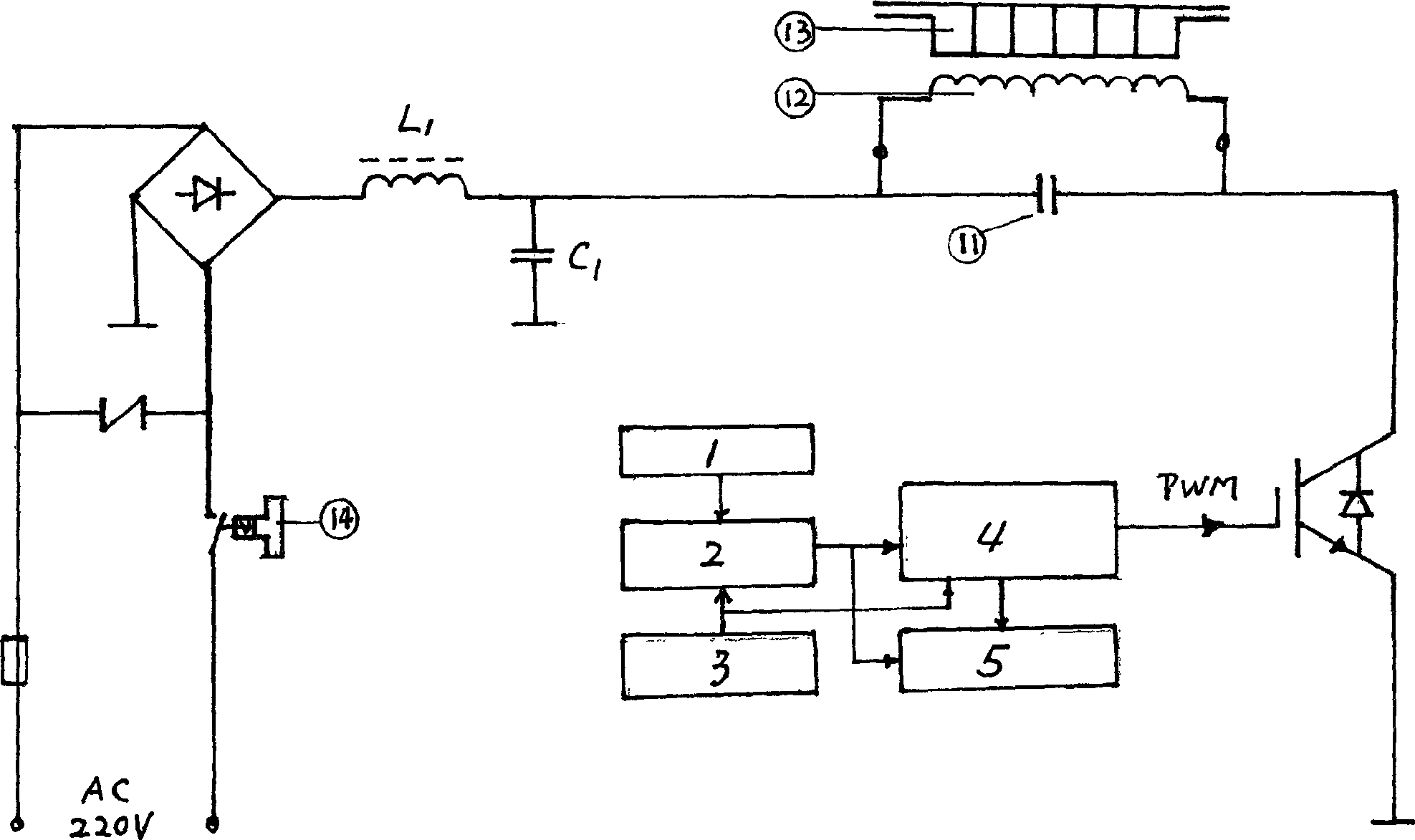

Electronic water heater

The invention relates to an electronic water heater, which comprises an power electronic frequency conversion magnetic inductive loop heating and plate type thermal interchange box. The invention realizes high thermal efficiency, easy production and low cost.

Owner:洪祥鹰

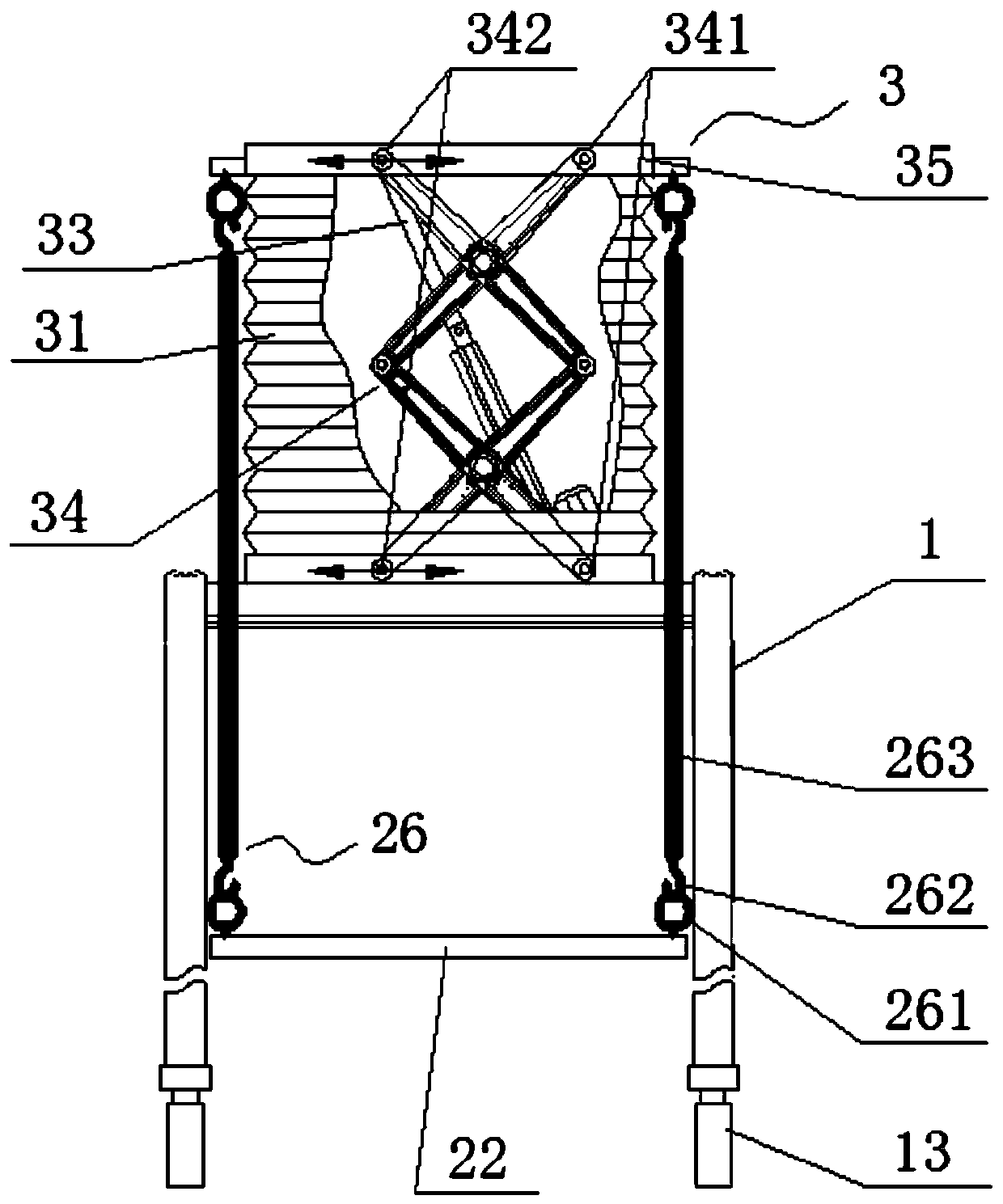

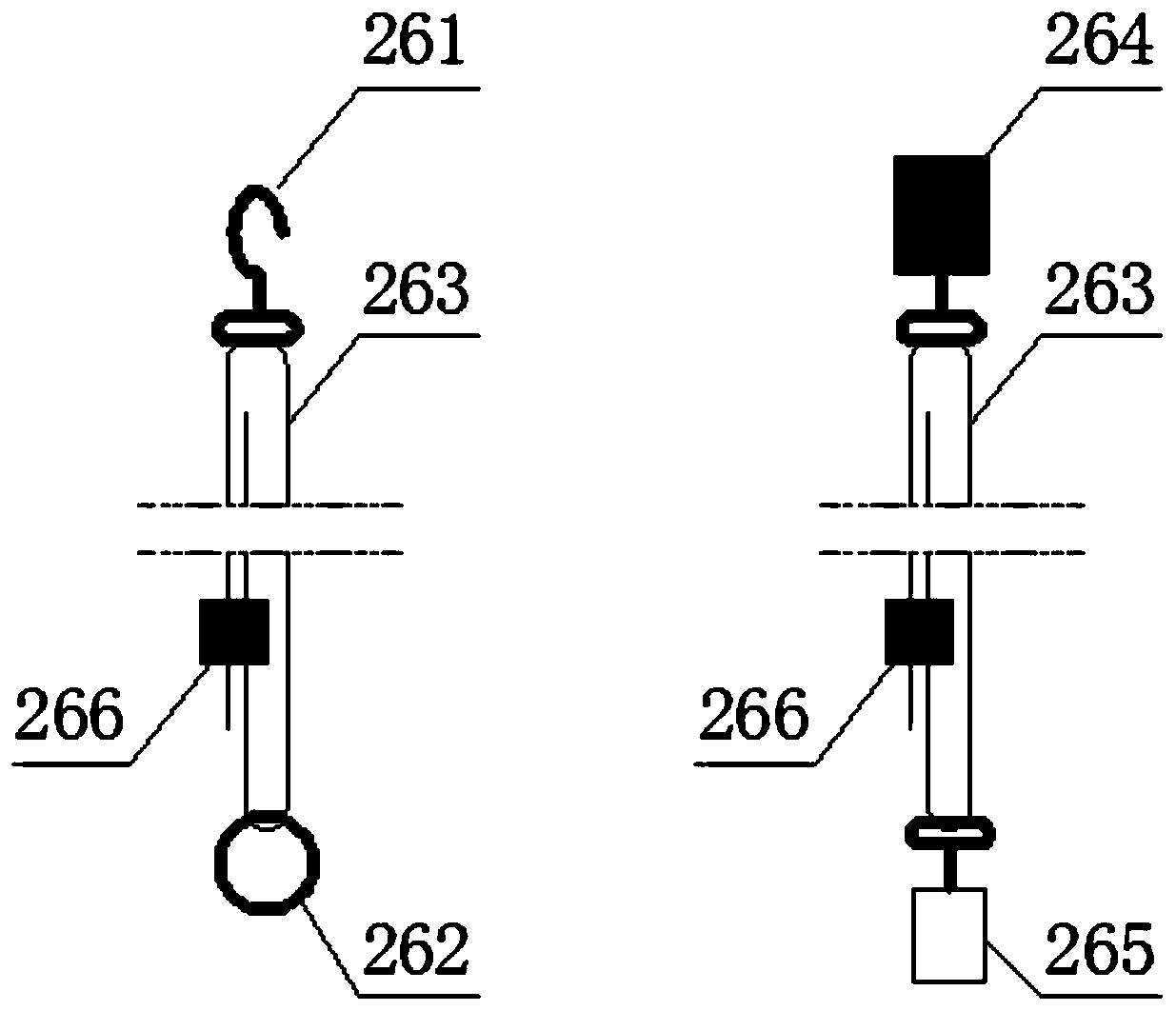

Shifting machine suitable for multiple poses of human body

ActiveCN110292499AEasy to operateImprove work efficiencyNursing bedsAmbulance serviceHuman bodyEngineering

The invention relates to a shifting machine suitable for multiple poses of a human body. The machine comprises a mobile rack, a lifting mechanism which is arranged on the mobile rack and has a vertical lifting end face, a sling bearing the human body and multiple suspenders making the sling connected to the lifting end face of the lifting mechanism, and the sling performs vertical lifting movementalong with rising and falling of the lifting mechanism. Accordingly, the human body needing to be shifted is hoisted through the lifting mechanism with the vertical lifting end face, multiple parallel slinging points together act on the sling, the human body in the shifting process cannot shake, the shifting center of gravity is located on the bearing surface formed by the mobile rack all the time, the human body moving is very stable, and operators do not need to perform the action of stably hoisting the human body except pushing the shifting machine; meanwhile, the hoisting plane is large,the machine is suitable for shifting of the human body in various postures, especially the human body posture needing a large hoisting plane, such as stable shifting in a flat posture, and thus the machine adapts to different usage scenarios.

Owner:NANJING KANGNI MECHANICAL & ELECTRICAL

Radiator and LED lamp

InactiveCN104879728ALow costReduce weightPoint-like light sourceLighting heating/cooling arrangementsEngineeringLED lamp

The invention discloses a radiator and an LED lamp. The radiator comprises a heat conduction plate and heat radiation fins, wherein the heat radiation fins are produced in a split manner, the production technology of a single heat radiation fin is simpler, the production difficulty can be reduced, and the production efficiency can be improved; the heat radiation fins are connected onto the back of the heat conduction plate in a mortise and tenon connection manner and are simple to assemble and convenient to assemble and disassemble; during assembly of the heat radiation fins, inserting pieces on front connecting pieces are inserted in grooves in back connecting pieces, tenons at grooves are buckled in mortises in the inserting pieces, adjacent heat radiation fins are mutually connected, the heat radiation fins are simple and quick to assemble, and the assembly efficiency is high; the heat conduction plate is set in a dihedral angle manner, the heat radiation fins are mounted on the back side of a first panel of the heat conduction plate, the front side of the first panel is used for mounting an LED light source, and a second panel is used for mounting an electrical box. The radiator is exquisite and reasonable in design, convenient to assemble, attractive in appearance and good in heat radiation effect; the radiator is applied to the LED lamp, the heat radiation effect is good, and assembly operation is simple.

Owner:杨小晨

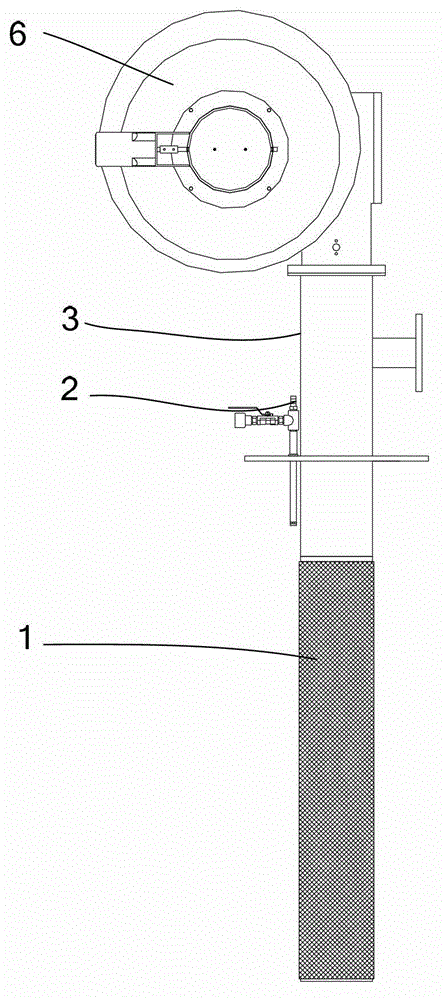

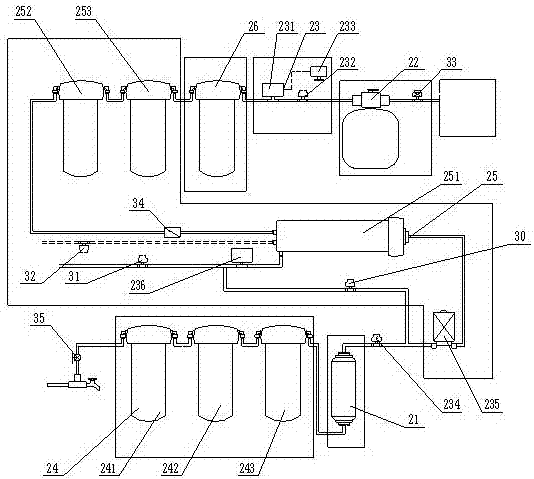

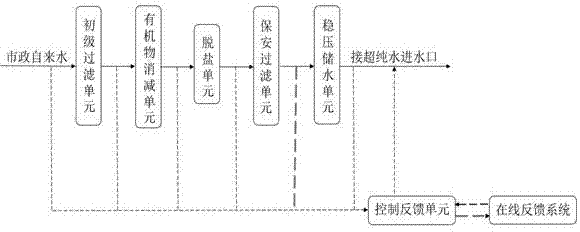

Pretreatment equipment for water supply of ultra-pure water machine

ActiveCN107162079AImprove water qualityGuaranteed stabilityWater treatment parameter controlWater/sewage treatment by irradiationElectricityWater storage tank

The invention discloses pretreatment equipment for water supply of an ultra-pure water machine. The equipment comprises a pretreatment system and a water storage system, wherein the pretreatment system comprises a water treatment reactor; the water storage system comprises a water storage tank; a water inlet end of the water treatment reactor is communicated and connected with a tap water pipe; a valve switch is also arranged on a water pipeline between the tap water pipe and the water treatment reactor; a water outlet end of the water treatment reactor is communicated and connected with a water inlet end of the water storage tank; a water outlet end of the water storage tank is communicated and connected with a water inlet end of the ultra-pure water machine; the equipment further comprises a control feedback unit; the control feedback unit comprises an electromagnetic valve and a resistivity monitoring device; the resistivity monitoring device and the electromagnetic valve are connected in series with a water pipeline between the water treatment reactor and the water storage tank; the electromagnetic valve is located on a water outlet side of the resistivity monitoring device; the resistivity monitoring device and the electromagnetic valve are electrically connected with an on-line feedback system. The equipment can improve influent quality of the ultra-pure water machine and prolong the service life of the ultra-pure water machine.

Owner:CHONGQING XINHE QIYUE TECH CO LTD

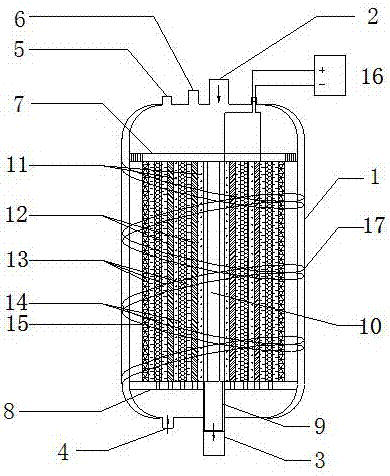

Sintering flue gas dioxin and particulate matter synergism purification equipment and method

InactiveCN103877795AGuaranteed concentrationReduce consumptionDispersed particle filtrationParticulatesPurification methods

The invention discloses a sintering flue gas dioxin and particulate matter synergism purification equipment and a sintering flue gas dioxin and particulate matter synergism purification method. The equipment comprises a filtering device, wherein the filtering device comprises a dust-containing flue gas inlet and a fresh air outlet; a flat sheet membrane reactor is arranged in the filtering device; a selective permeable membrane through which dioxin and oxygen can pass is arranged on the flat sheet membrane reactor; the flat sheet membrane reactor is separated to form a gas permeation cavity positioned on the lower part and a liquid permeation cavity positioned on the upper part through the selective permeable membrane; dioxin degradation reaction liquid is arranged in the liquid permeation cavity. According to the purification equipment and the purification method, the dioxin and particulate matters in the sintering flue gas can be synchronously removed, and the equipment is simple in structure and safe and stable in operation and has the advantages that the dust removal efficiency is high, secondary pollution is avoided and the like.

Owner:CISDI ENG CO LTD

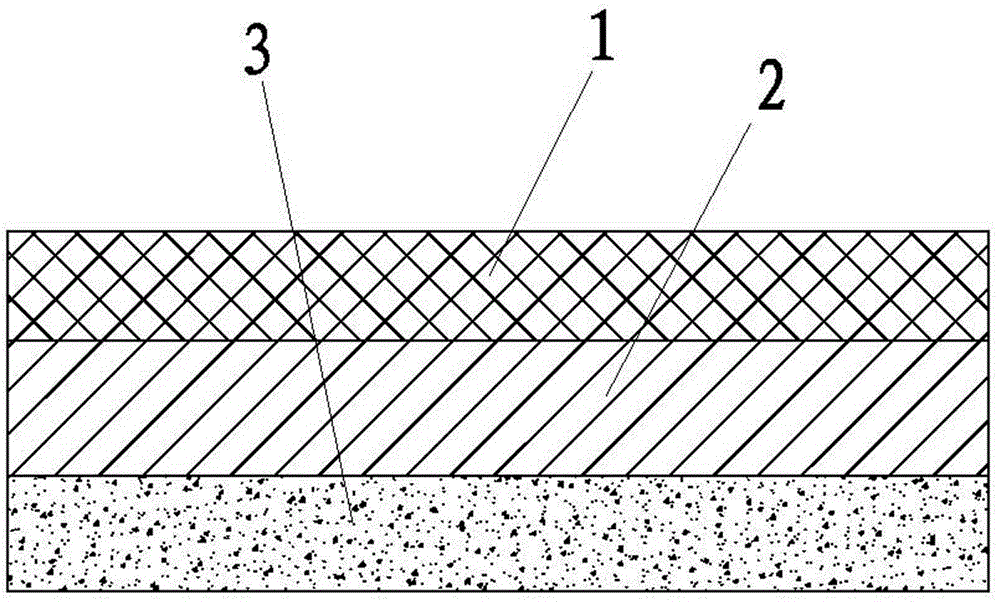

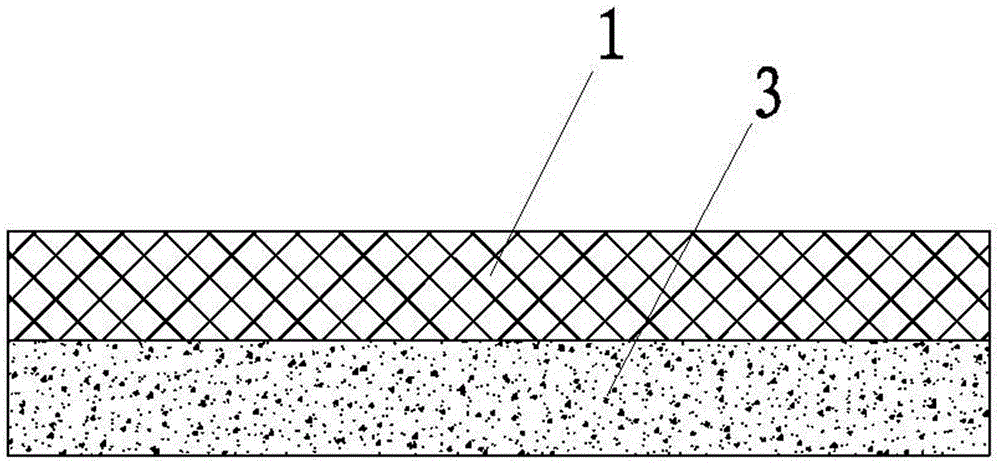

Photovoltaic thin film backboard

InactiveCN103337539AWarpage suppressionAvoid deformationSynthetic resin layered productsPhotovoltaic energy generationEngineeringDiffuse reflection

The invention relates to a component, particularly to a photovoltaic thin film backboard. The technical purpose of the invention is realized through the following technical scheme: the photovoltaic thin film backboard comprises a multi-microvesicle polymer film layer. The photovoltaic thin film backboard has high diffuse reflection performance to increase the use ratio of sunlight in unit area, to improve the integral photovoltaic conversion efficiency of a battery pack, particularly a crystal silicon battery pack; in addition, the photovoltaic thin film backboard is lower in cost and light in weight, and can effectively reduce the consumable items and weight ratio of photovoltaic backboards.

Owner:中国科学院宁波材料技术与工程研究所湖州新能源产业创新中心

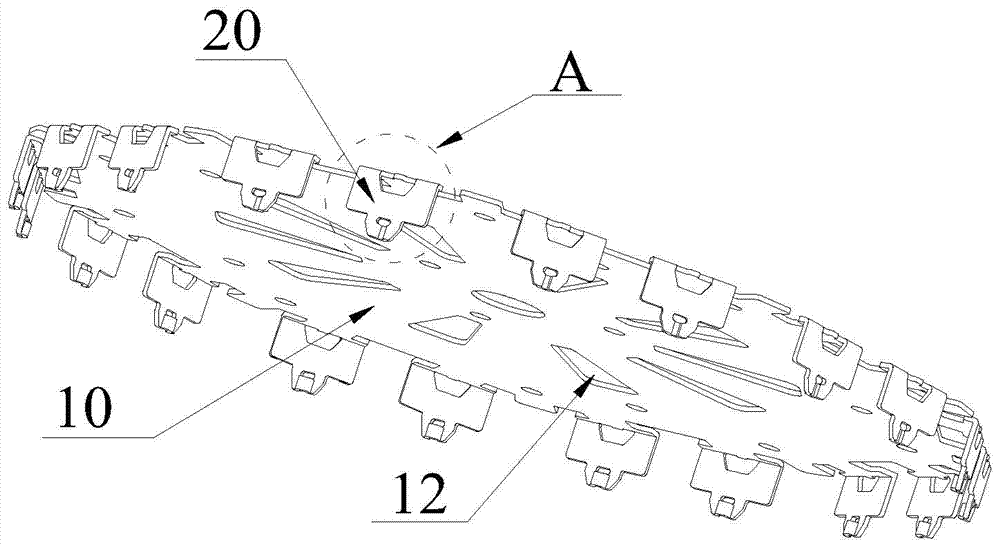

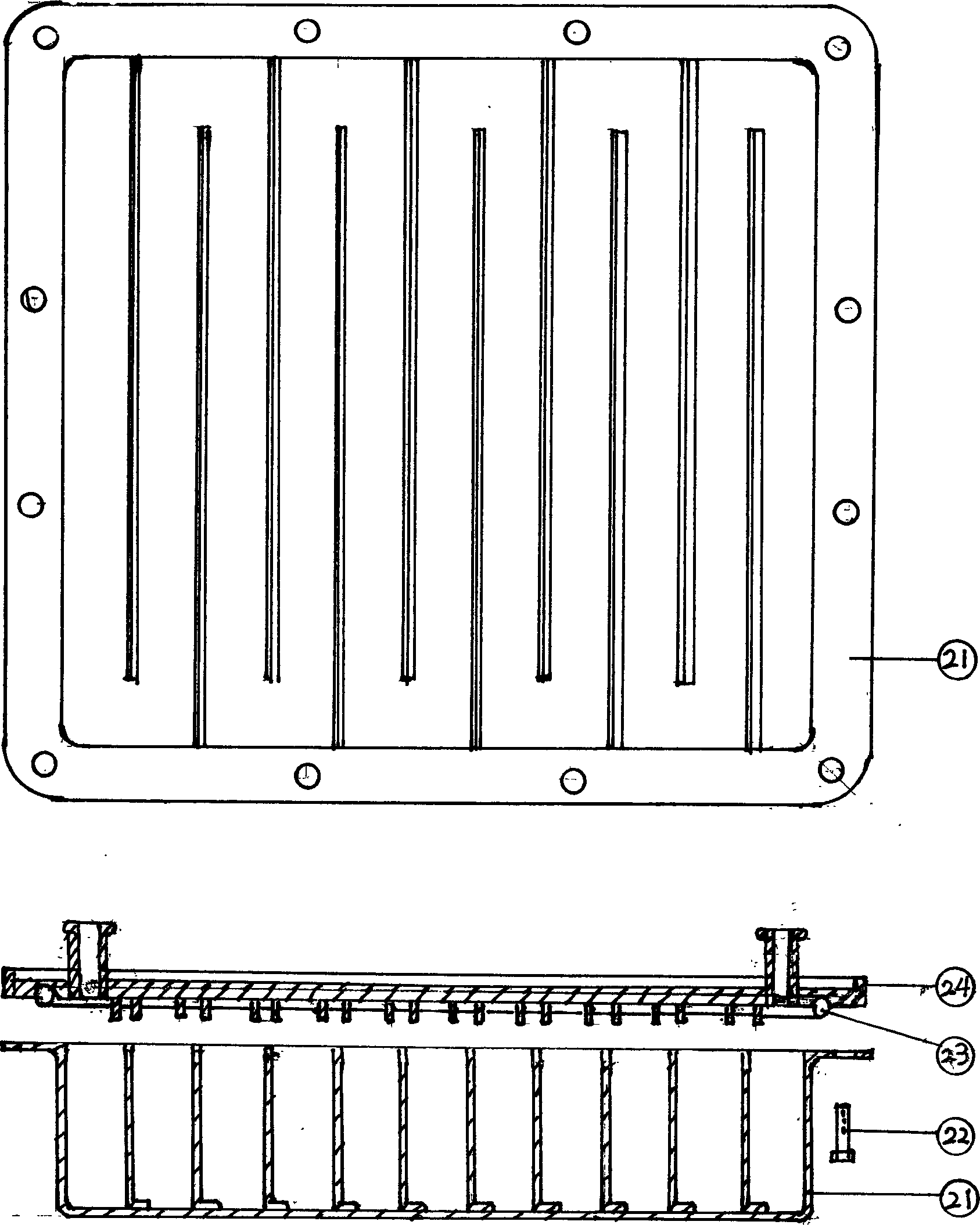

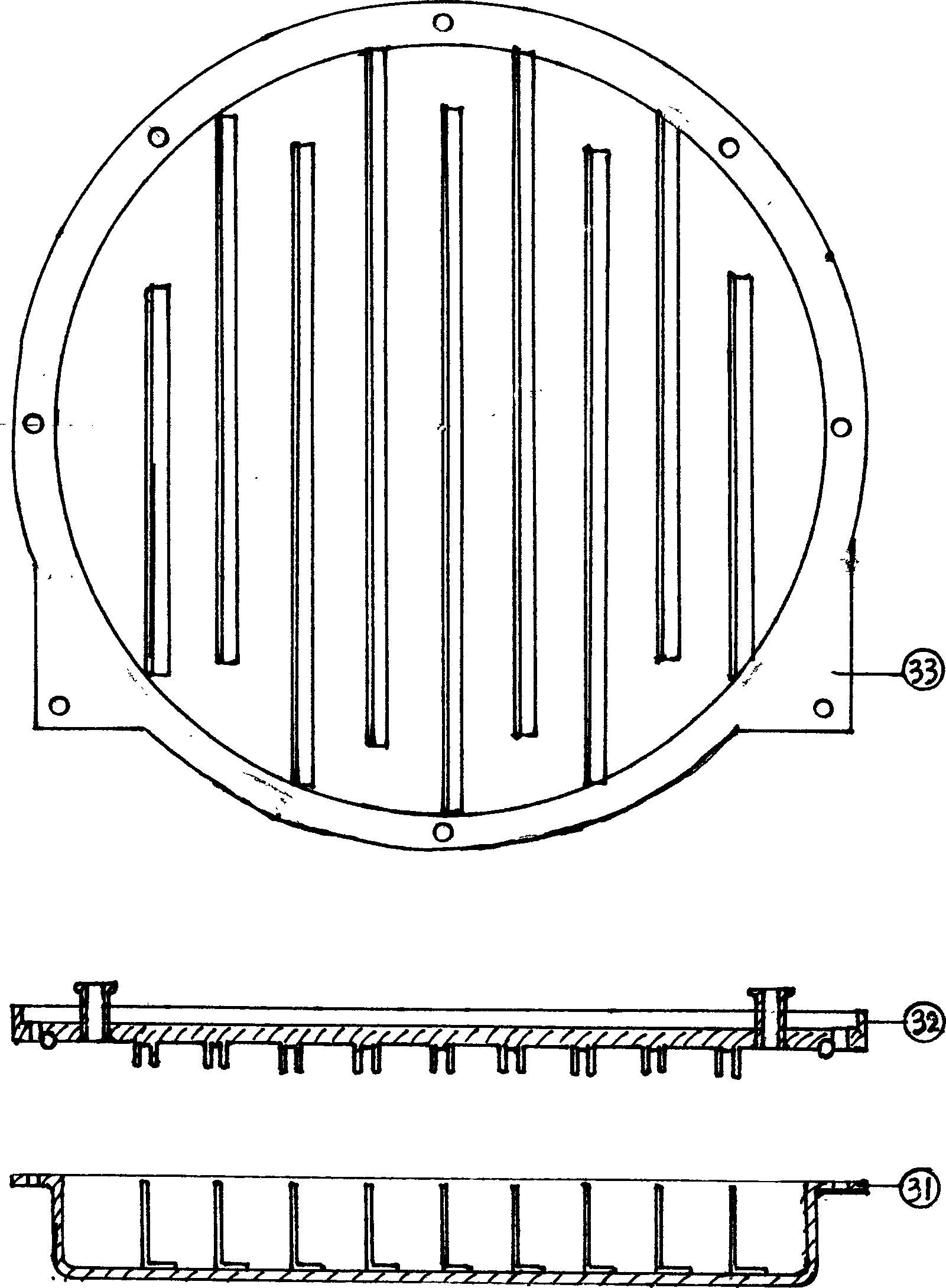

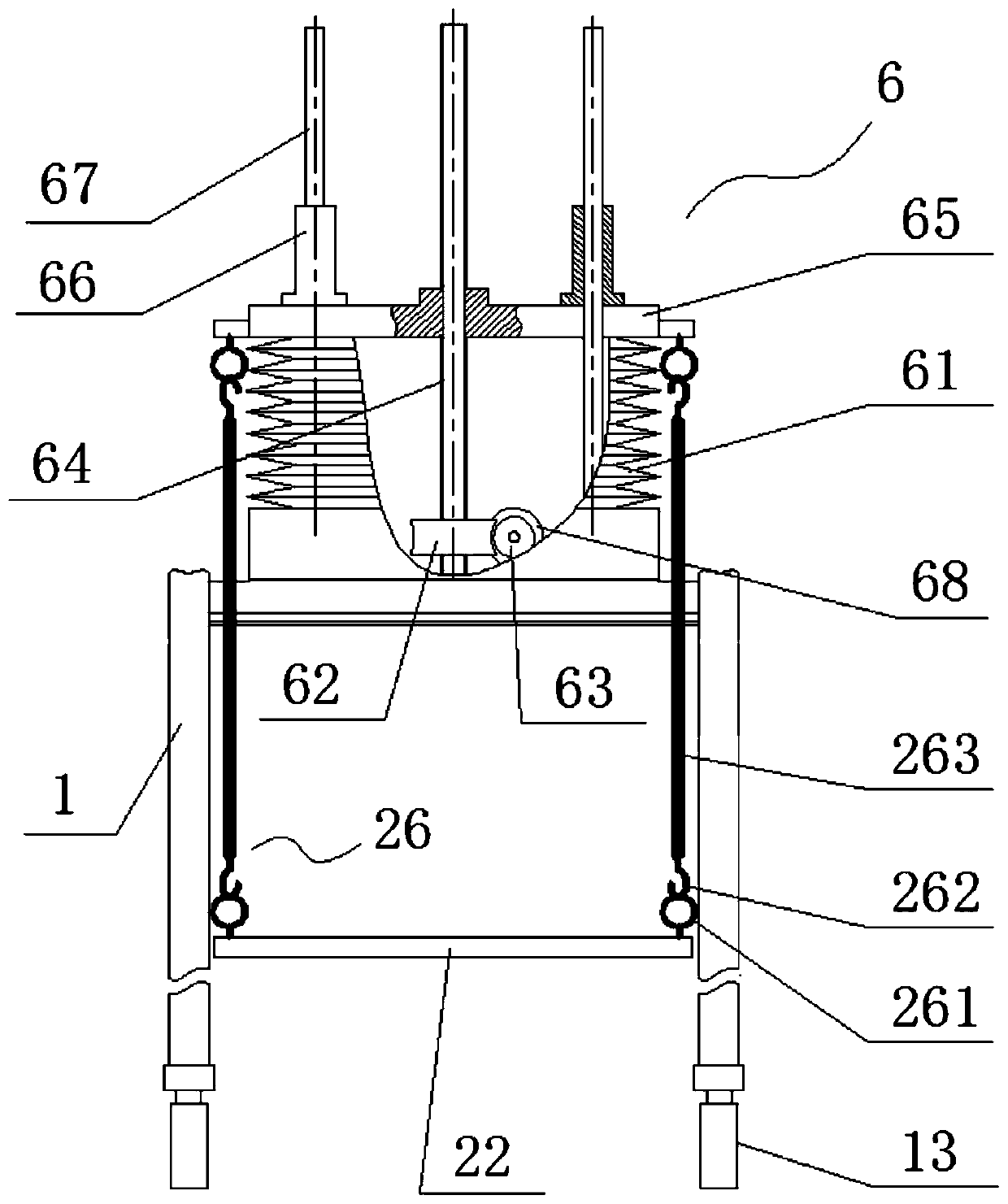

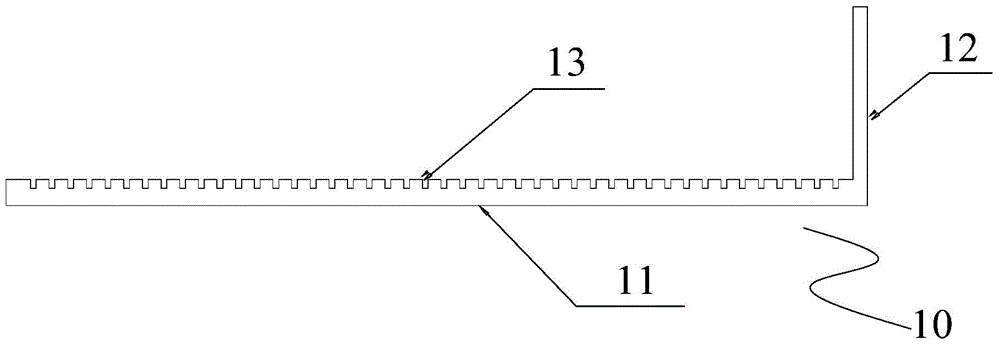

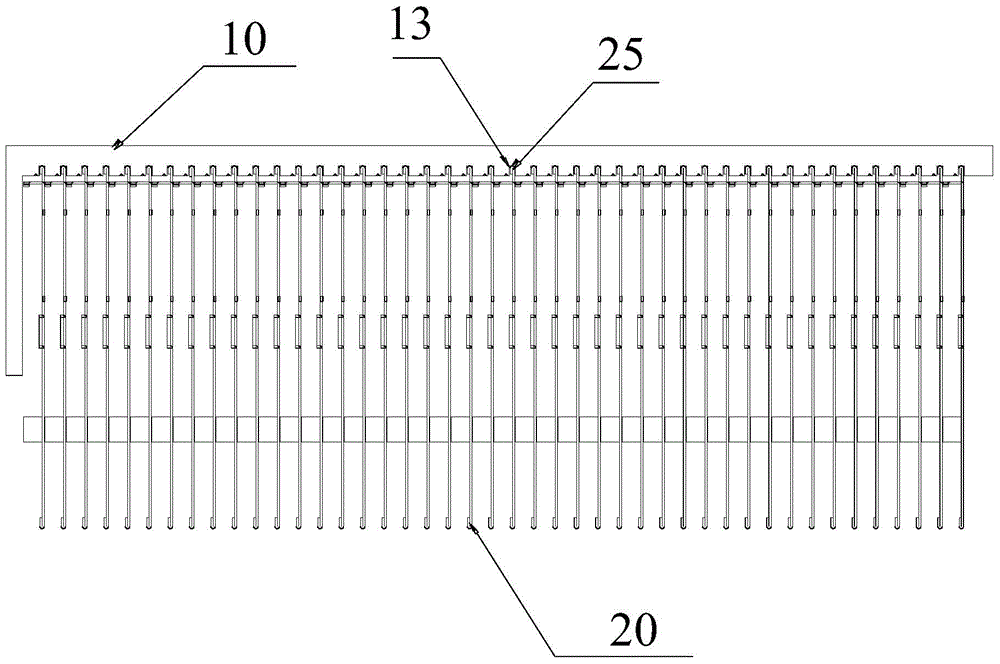

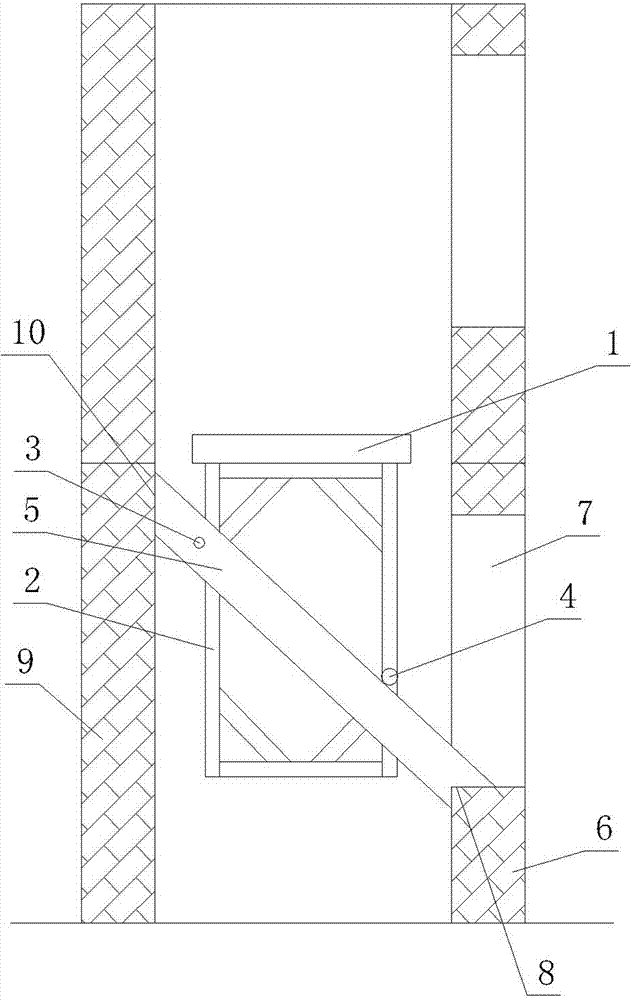

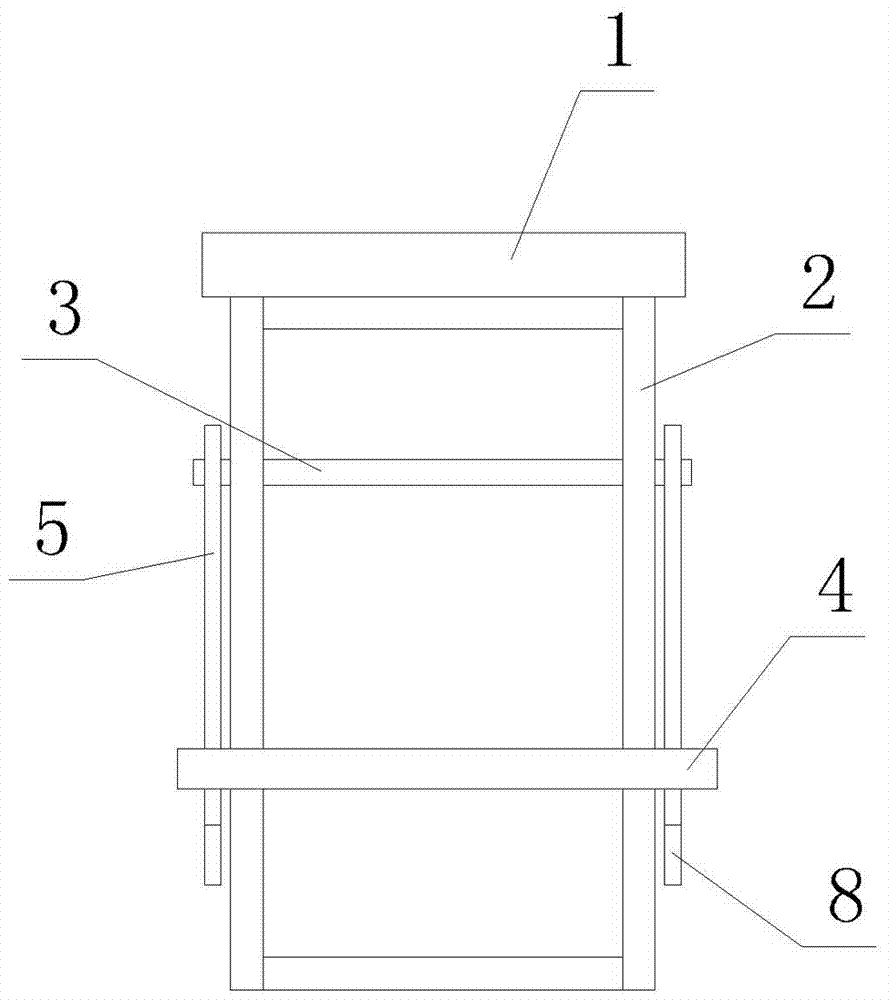

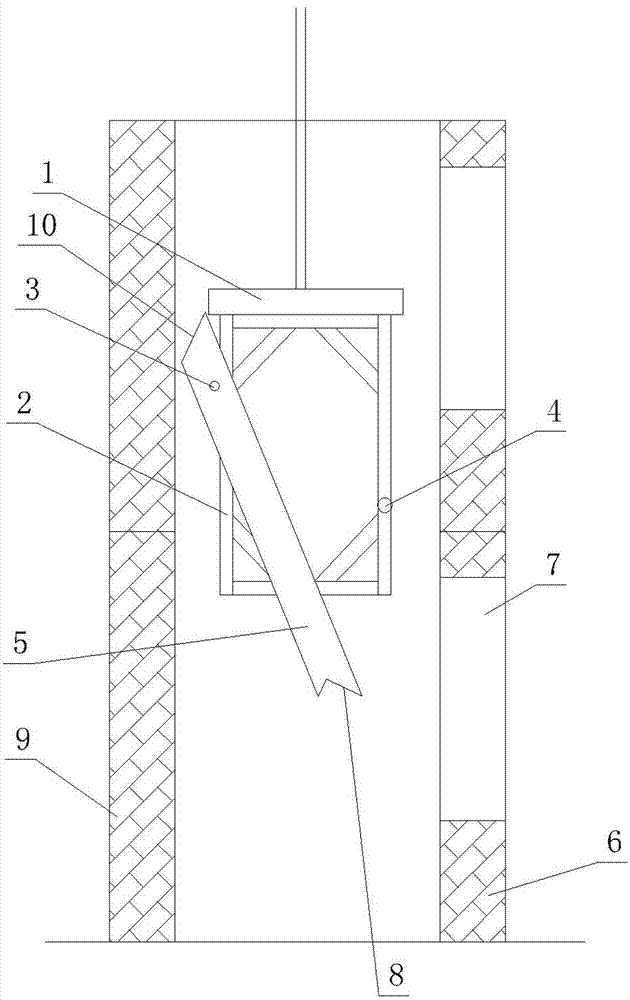

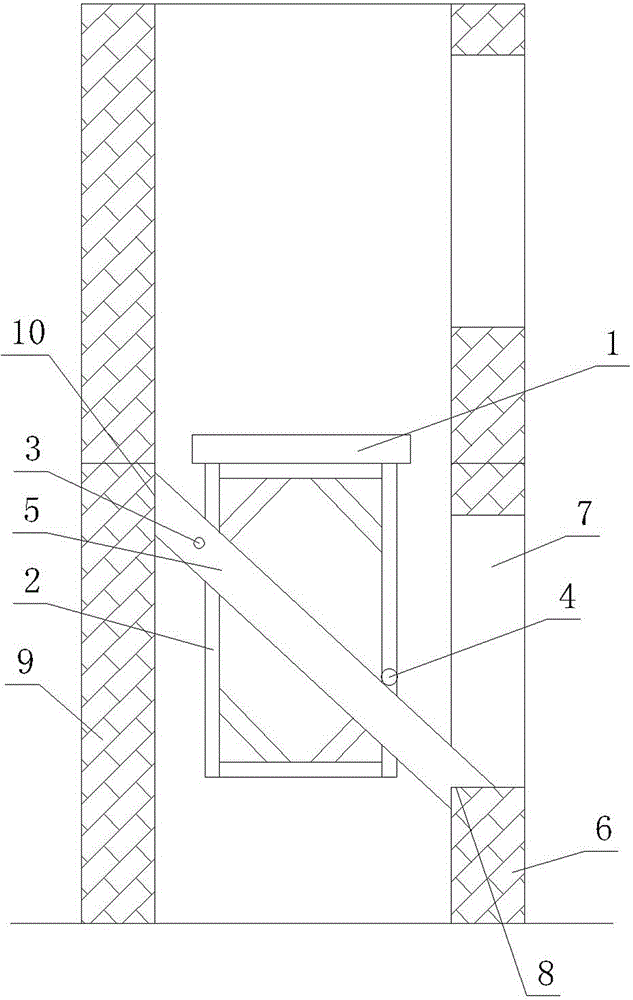

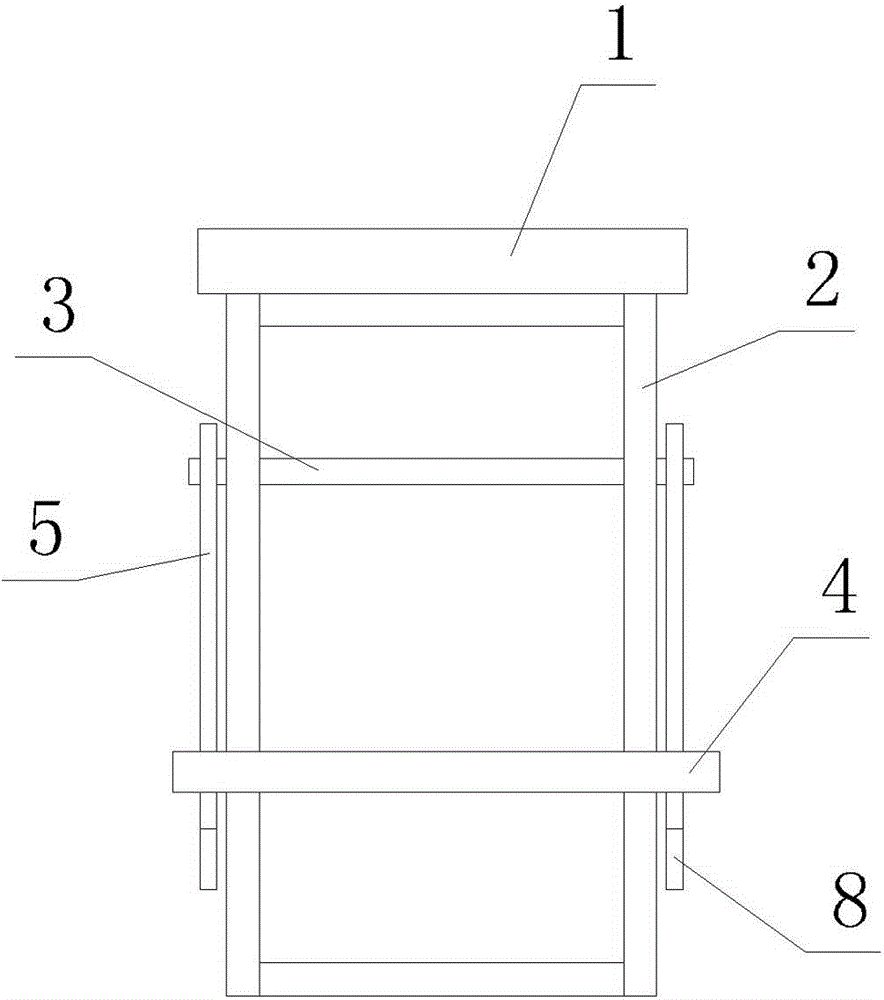

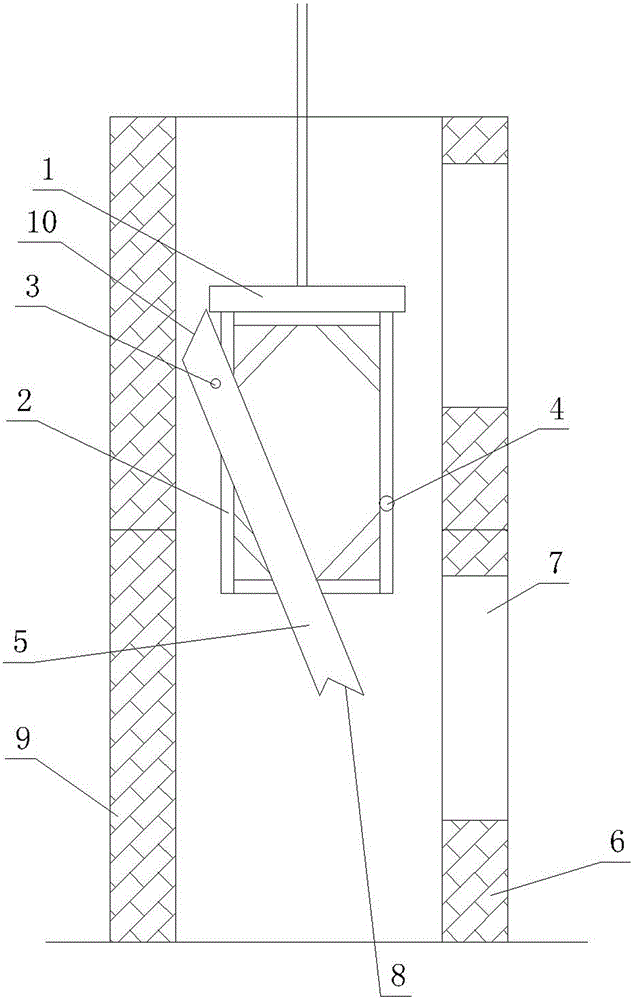

Construction platform of elevator shaft and method for utilizing construction platform to construct elevator shaft

ActiveCN103195232AEasy to disengageEasy to disassembleBuilding material handlingBuilding support scaffoldsArchitectural engineeringBuilding construction

The invention discloses a construction platform of an elevator shaft. The construction platform comprises a platform body (1) and a platform support (2). A rotating shaft (3) is fixed on the rear side of the platform support (2), a pressure rod (4) is fixed on the front side of the platform support (2), at least two support plates (5) are rotatably sleeved on the rotating shaft (3), the lower end of every support plate (5) is provided with a notch (8) stuck with the bottom surface of a door opening (7) of a front side wall (6) of the elevator shaft, the upper end of every support plate (5) is provided with a straight edge (10) which is parallel to a rear side wall (9) of the elevator shaft and abuts against the rear side wall (9), and the pressure rod (4) is tightly pressed on the two support plates (5). The invention further discloses a method for utilizing the construction platform to construct the elevator shaft. The method comprises the key steps of enabling the construction platform to be placed firmly on one layer of elevator shaft and enabling constructors to stand on the construction platform to install a template of an upper layer of elevator shaft and deposit concrete. According to the construction platform and the method, materials can be saved, the speed is quick, and the construction process is simple and convenient.

Owner:NINGBO DONGXIN CONSTR

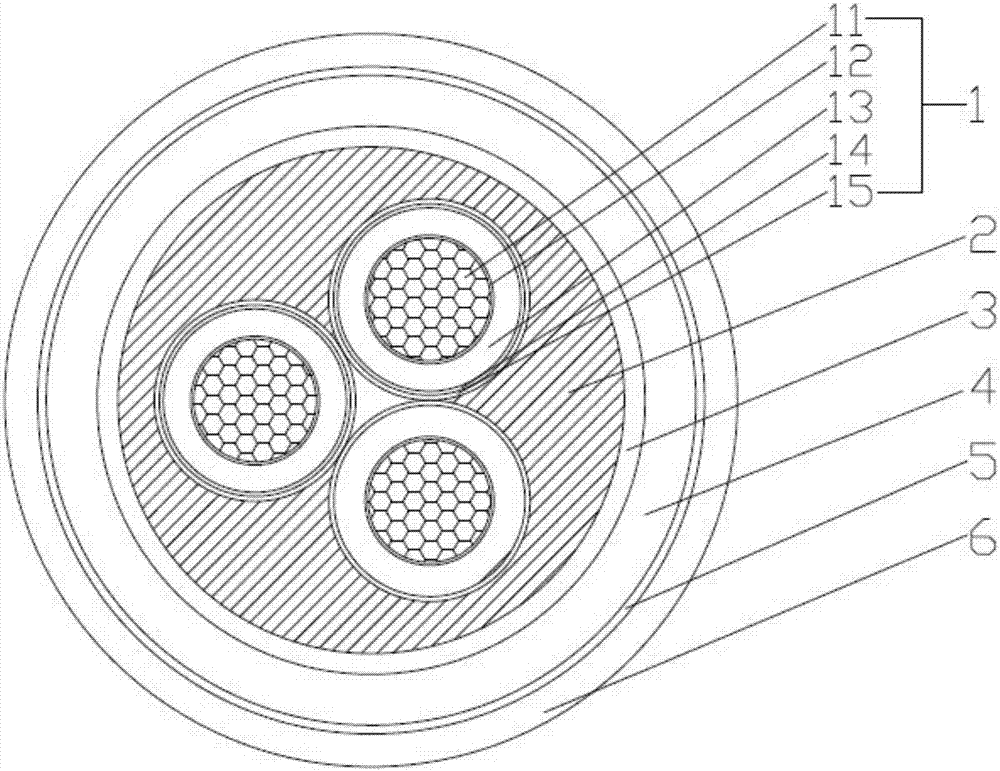

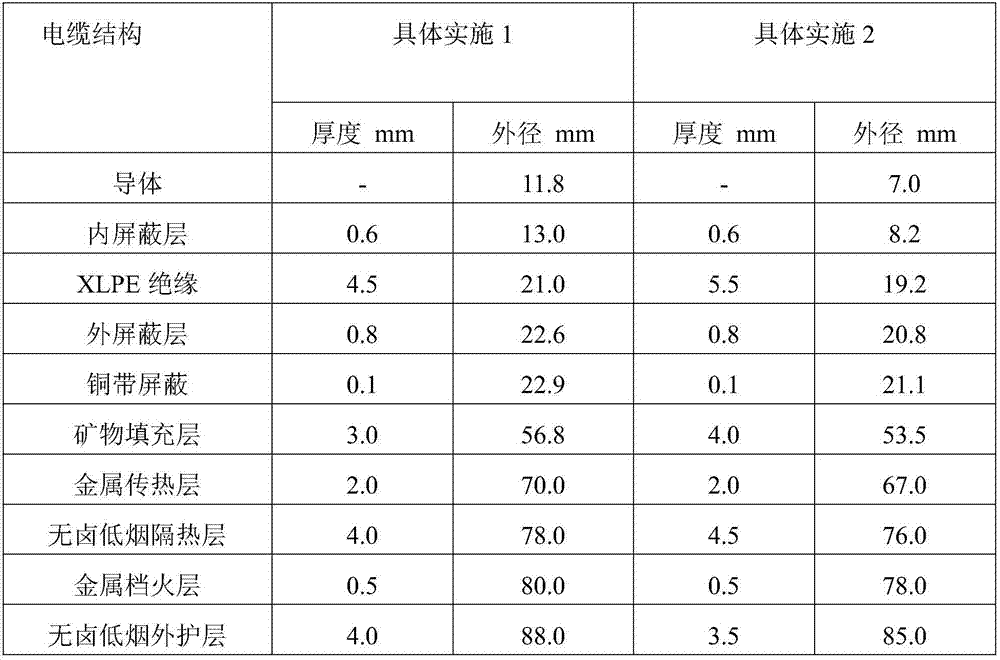

Medium-voltage fireproof cable for green building

ActiveCN107068275AFast heat transferUniform heat transferInsulated cablesInsulated conductorsHeat conductingFire resistance

The invention discloses a medium-voltage fireproof cable for a green building. From the inside to the outside, the cable sequentially comprises a cable core, a metal heat conducting layer, a low-smoke halogen-free thermal insulating layer, a metal fire-blocking layer and a low-smoke halogen-free external sheath layer, wherein the cable core consists of an insulating wire core and a mineral filling layer. The metal heat conducting layer is a metal tape which is arranges spirally, wherein the thickness of the metal tape is 2mm, and the interval between the peak and valley of the spiral is 3-5 mm. The external diameter is 13-15mm greater than the external diameter of the cable core after the metal heat conducting layer is set. According to the invention, the performance of the cable meets the requirements of fireproof, impact and water spraying testing of the standard BS8491: 2008. The test fire temperature is 830-870 DEG C, and the fire resistance test is carried out for 120min. The cable can withstand impacts for 12 times and water spraying for three times while withstanding the fire resistance test, and is a real medium-voltage fireproof cable.

Owner:FAR EAST CABLE +2

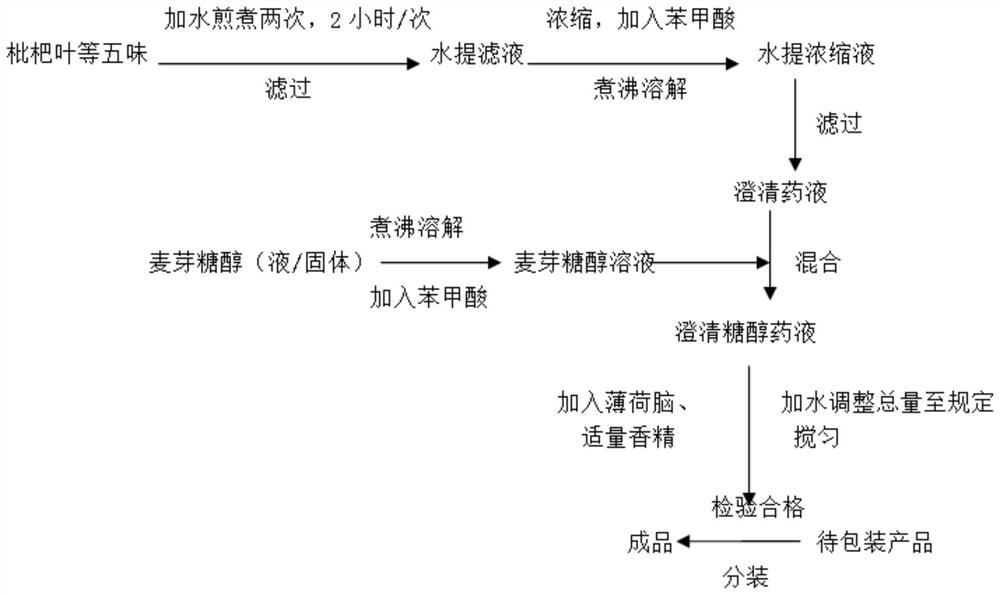

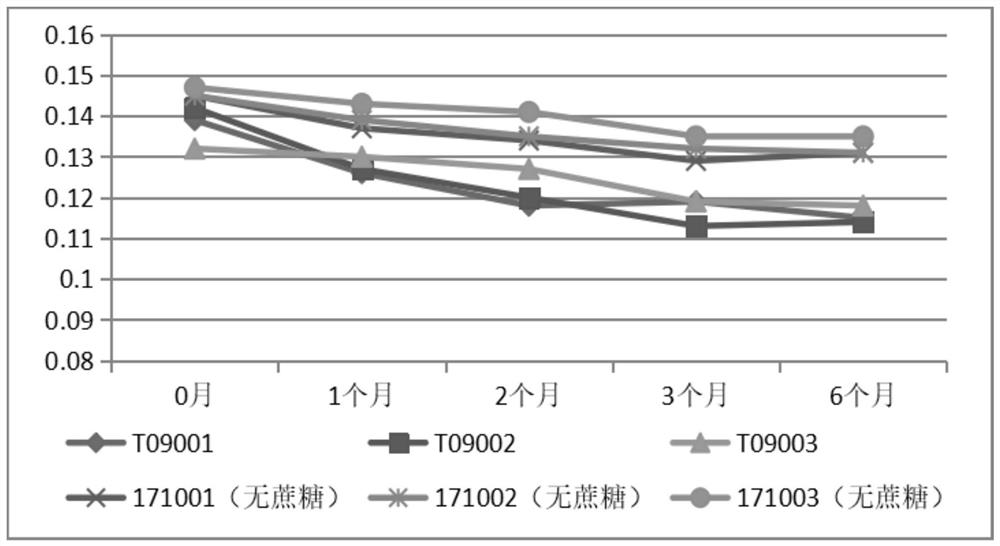

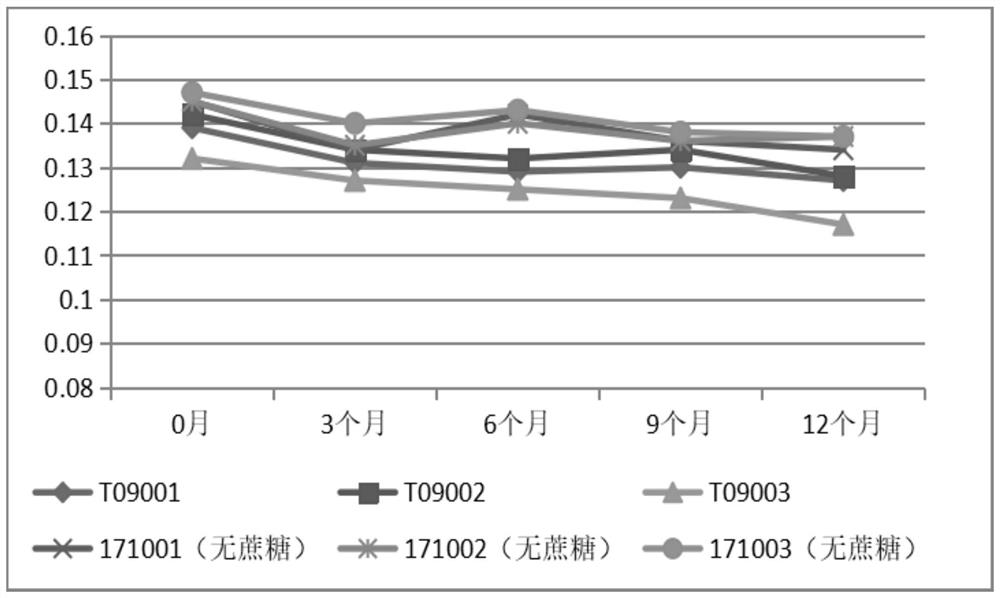

Composition for treating cough, preparation method and preparation

InactiveCN112386661AReduce time consumptionReduce overall consumablesDispersion deliveryHydroxy compound active ingredientsMentholMaltitol

The invention relates to a composition for treating cough, a preparation method and a preparation. The composition is prepared from the following raw materials in parts by weight: 200-500 parts of maltitol liquid or 200-500 parts of maltitol, 120-140 parts of folium eriobotryae, 15-30 parts of radix stemonae, 10-20 parts of radix peucedani, 8-10 parts of platycodon grandiflorum, 8-10 parts of cortex mori radicis and 0.10-0.20 part of menthol. The composition for treating cough is low in sugar content, good in taste, clear in product and stable in quality.

Owner:广州白云山潘高寿药业股份有限公司

Construction platform of elevator shaft and method for utilizing construction platform to construct elevator shaft

ActiveCN103195232BEasy to disengageEasy to disassembleBuilding material handlingBuilding support scaffoldsArchitectural engineeringBuilding construction

The invention discloses a construction platform of an elevator shaft. The construction platform comprises a platform body (1) and a platform support (2). A rotating shaft (3) is fixed on the rear side of the platform support (2), a pressure rod (4) is fixed on the front side of the platform support (2), at least two support plates (5) are rotatably sleeved on the rotating shaft (3), the lower end of every support plate (5) is provided with a notch (8) stuck with the bottom surface of a door opening (7) of a front side wall (6) of the elevator shaft, the upper end of every support plate (5) is provided with a straight edge (10) which is parallel to a rear side wall (9) of the elevator shaft and abuts against the rear side wall (9), and the pressure rod (4) is tightly pressed on the two support plates (5). The invention further discloses a method for utilizing the construction platform to construct the elevator shaft. The method comprises the key steps of enabling the construction platform to be placed firmly on one layer of elevator shaft and enabling constructors to stand on the construction platform to install a template of an upper layer of elevator shaft and deposit concrete. According to the construction platform and the method, materials can be saved, the speed is quick, and the construction process is simple and convenient.

Owner:NINGBO DONGXIN CONSTR

Heat exchanger for an indoor unit of an air conditioner

ActiveUS9383118B2Large air volumeImprove blowing efficiencyHeating and ventilation casings/coversIndirect heat exchangersCooling coilEngineering

A heat exchanger for an indoor unit of an air conditioner, including at least a housing (1) having an air inlet (15) and an air outlet (16), a cooling coil (3), and a centrifugal blower (4) having an air exit (17), a volute housing (5), a motor (6) and a centrifugal wind wheel (7). The cooling coil (3) and the centrifugal blower (4) are disposed in the housing (1). The air inlet (15) and the air outlet (16) are disposed on both ends of the housing (1). The cooling coil (3) is disposed at the back of the air inlet (15). The centrifugal blower (4) is disposed at the back of the cooling coil (3). The air exit (17) of the centrifugal blower (4) is connected to the air outlet (16) of the housing (1). The motor (6) is an external rotor motor and fits in the center of a cavity in the centrifugal wind wheel (7). A left air intake (11) and a right air intake (12) are formed on both sides of the volute housing (5). The heat exchanger features large air input and air output, and high blowing efficiency.

Owner:ZHONGSHAN BROAD OCEAN MOTOR MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com