3D printing method, supporting structure, device, equipment and storage medium

A 3D printing and supporting structure technology, applied in the field of 3D printing, can solve the problems of prolonging printing time, reducing printing speed, and multiplying printing materials, etc., to achieve the effect of increasing printing speed, reducing consumables and time-consuming, and reducing printing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

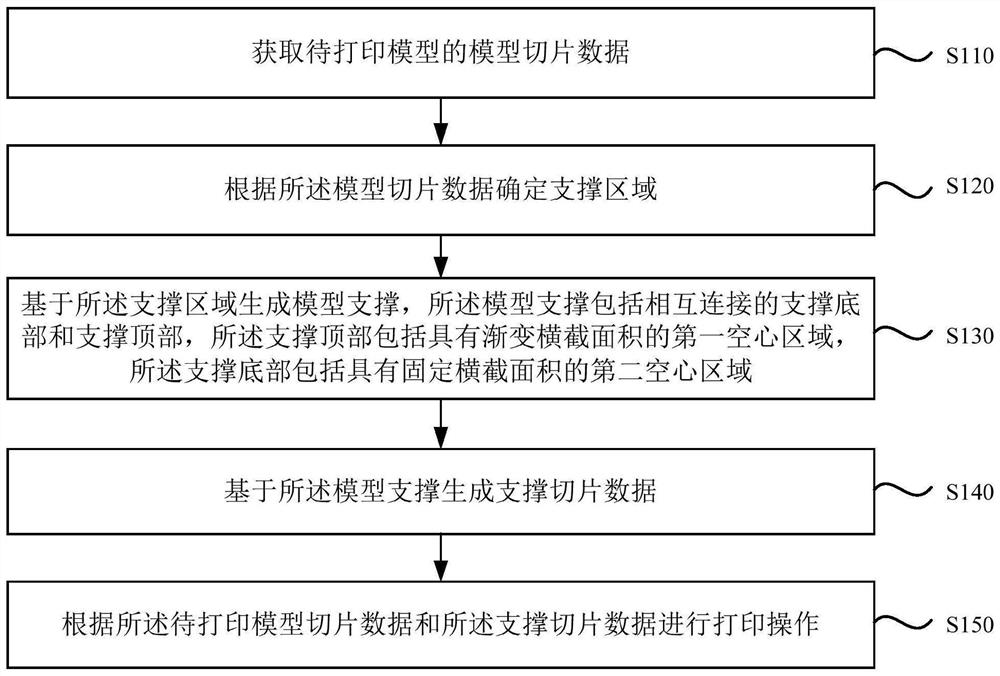

[0054] figure 1 It is a schematic flowchart of a 3D printing method provided by Embodiment 1 of the present invention. Such as figure 1 As shown, the 3D printing method provided by Embodiment 1 of the present invention includes:

[0055] S110. Obtain model slice data of the model to be printed.

[0056] Specifically, the model to be printed refers to a three-dimensional model that needs to be printed, and the model to be printed is loaded into the slicing software, and the slicing software slices it according to user requirements to generate model slicing data.

[0057] S120. Determine a support region according to the model slice data.

[0058] Specifically, the support area refers to the area where the support structure needs to be printed during the printing process. Support regions can be automatically identified by slicing software or manually set by the user. For example, in general, the model slice data actually defines the shape and printing area of each slice l...

Embodiment 2

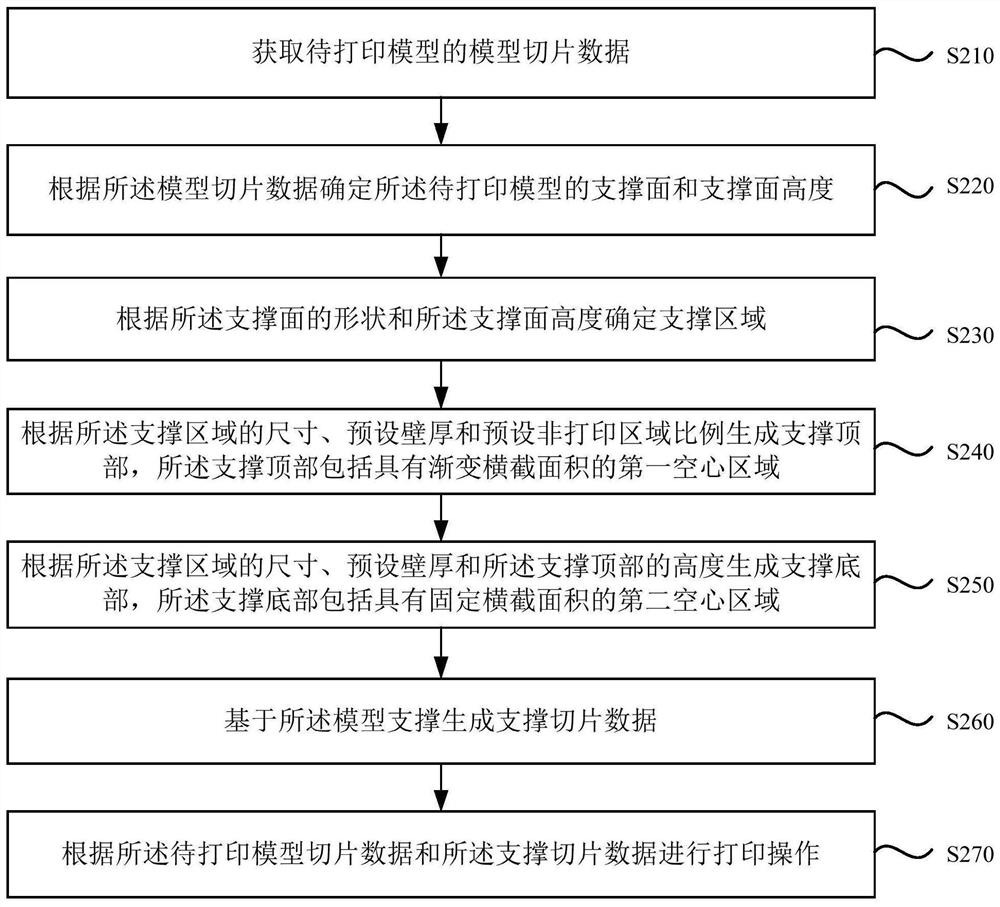

[0069] figure 2 It is a schematic flowchart of a 3D printing method provided by Embodiment 2 of the present invention. This embodiment is a further refinement of the above-mentioned embodiment. like figure 2 As shown, the 3D printing method provided by Embodiment 2 of the present invention includes:

[0070] S210. Obtain model slice data of the model to be printed.

[0071] S220. Determine the support surface and the height of the support surface of the model to be printed according to the model slice data.

[0072] Specifically, the support surface of the model to be printed is the surface of the model to be printed that needs to provide an additional support structure. The support surface can be automatically identified by the slicing software, or manually set by the user. For example, when it is detected that the printing area represented by the current slice layer data of the model is greater than the print area represented by the previous slice data and reaches the p...

Embodiment 3

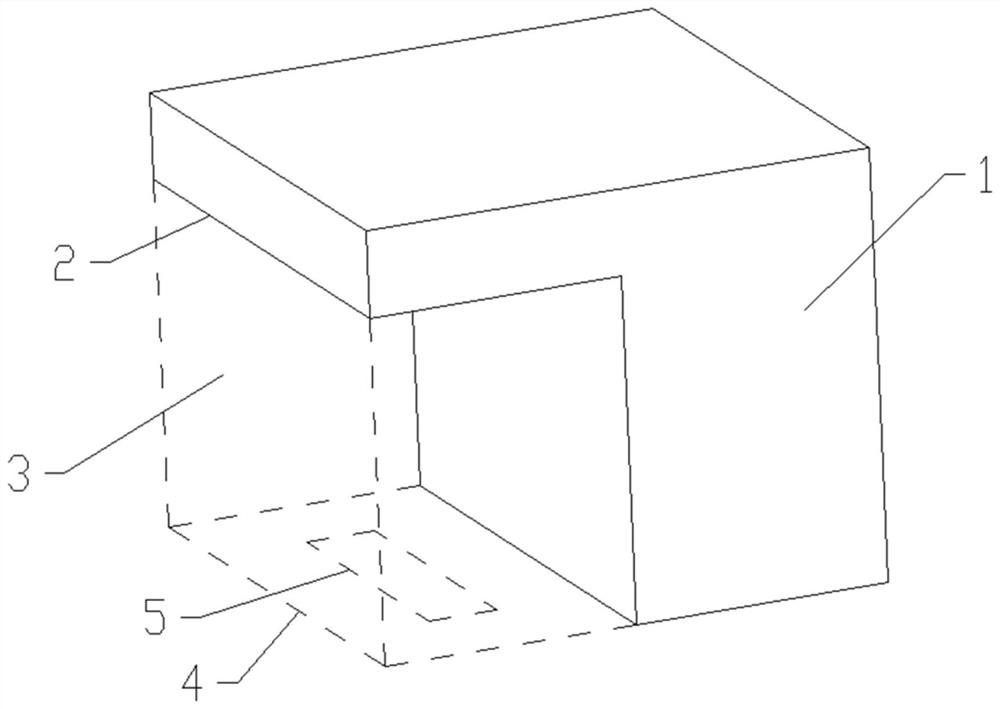

[0095] Figure 3B It is a schematic structural diagram of a 3D printing support structure provided by Embodiment 3 of the present invention. Such as Figure 3B As shown, the 3D printing support structure provided by the embodiment of the present invention includes a support bottom 10 and a support top 20 connected to each other, wherein the support top 10 includes a first hollow area 11 with a gradually changing cross-sectional area, and the support bottom 20 includes a first hollow area 11 with a fixed cross-sectional area. The cross-sectional area of the second hollow area 21. The peripheral dimensions of the support bottom 10 and the support top 20 are the same, and are smaller than or equal to the size of the support surface of the model to be printed.

[0096] In this embodiment, the inside of the support top 10 is a first hollow area 11 with a gradually changing cross-sectional area formed by a stepped structure, and the width of the stepped structure gradually decre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com