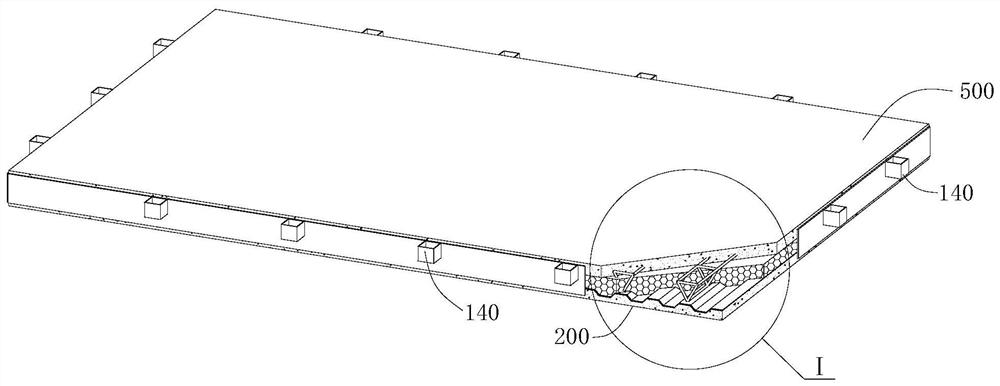

Prefabricated composite floor slab and its construction method

A construction method and prefabricated technology, applied to floors, buildings, building components, etc., can solve problems such as low construction efficiency, heavy weight, and large energy consumption, and achieve the goals of improving construction efficiency, ensuring load-bearing strength, and reducing overall weight Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

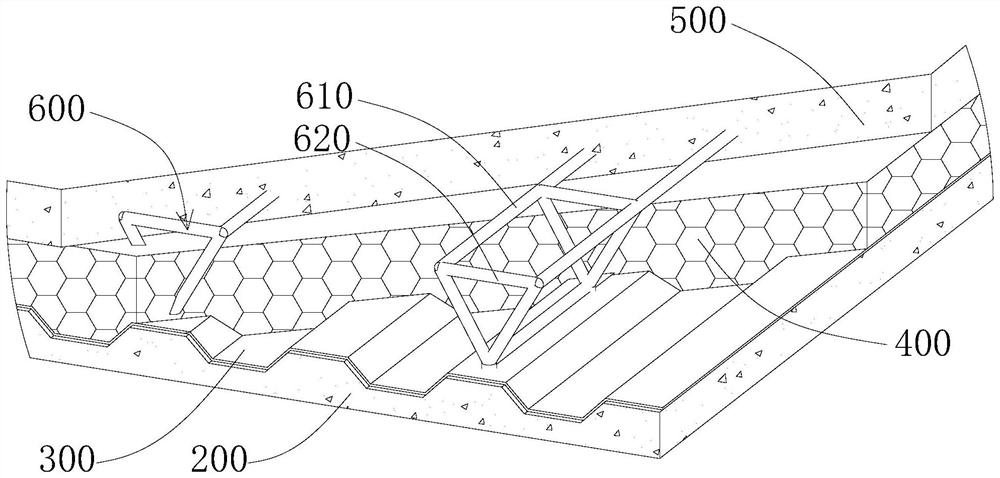

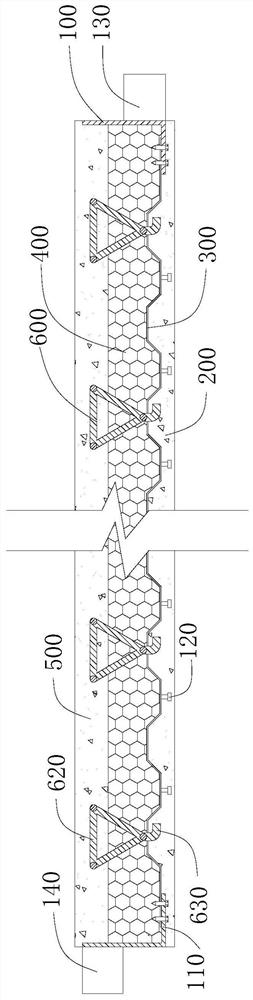

[0040] As a specific embodiment of the assembled composite floor provided by the present invention, the construction method of the assembled composite floor includes the following steps:

[0041] The manufacture of the truss 600 and the frame 100 is to manufacture the truss 600, and install two side panels of the frame 100 at both ends of the truss 600, and install the other two side panels of the frame 100 at both ends of the two side panels, which are the above four side panels. The plate forms the frame 100, and the manufacture of the truss 600 and the frame 100 is completed;

[0042] For the pouring of the first concrete layer 500, the whole of the frame 100 and the truss 600 is placed upside down on the pouring formwork, and the first concrete layer 500 is poured until part of the truss 600 is covered;

[0043] For the installation of the profiled steel plate 300, several holes are provided on the profiled steel plate 300, and the vertices of the several openings correspo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com