A method for installing a sliding door leaf and hanging wheels

An installation method and hanging wheel technology, applied in the field of sliding doors, can solve the problems of large gap between guide rail and door frame, inconvenient disassembly, unreliable fixing method, etc., and achieve the effect of improving aesthetics, reducing operating space, and facilitating disassembly and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further illustrated below in conjunction with the accompanying drawings and specific embodiments. This embodiment is implemented on the premise of the technical solution of the present invention. It should be understood that these embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

[0029] The invention discloses a method for installing a sliding door leaf and a hanging wheel, which comprises the following steps:

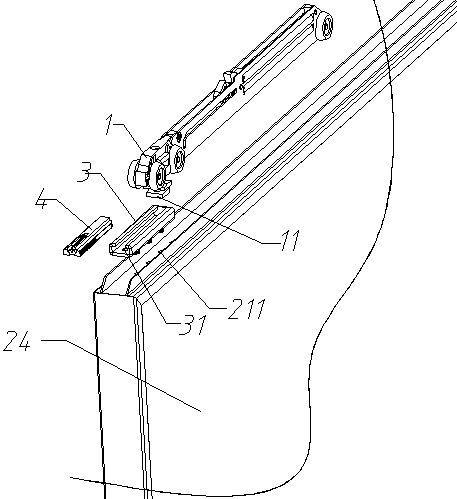

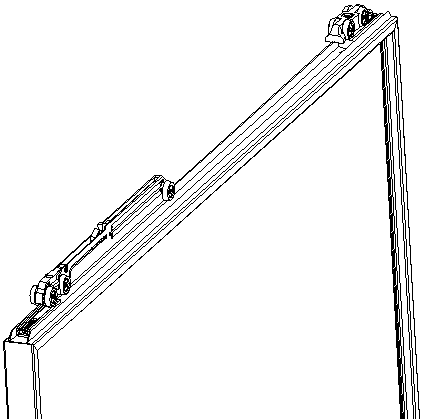

[0030] (1) Install the suspension wheel 1 into the guide rail from the reserved inspection port, and the suspension wheel is connected with the suspension wheel installation block 11 through the connecting rod;

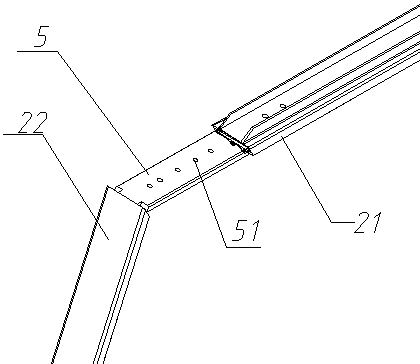

[0031] (2) Assemble the upper frame profile 21, side profile 22, lower frame profile 23 and glass 24 of the sliding door leaf; fix the two hanging wheel load-bearing grooves 3 on the assembled sliding door leaf with screws At the left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com