Pile head cutting machine for CFG (cement fly-ash gravel) piles

A cutting machine and pile head technology, which is applied in stone processing tools, manufacturing tools, stone processing equipment and other directions, can solve the problems of imperfect performance of the cutting machine and can not meet the requirements of CFG pile head cutting, so as to reduce construction dust pollution, The effect of improving the flatness accuracy of the pile head and improving the work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

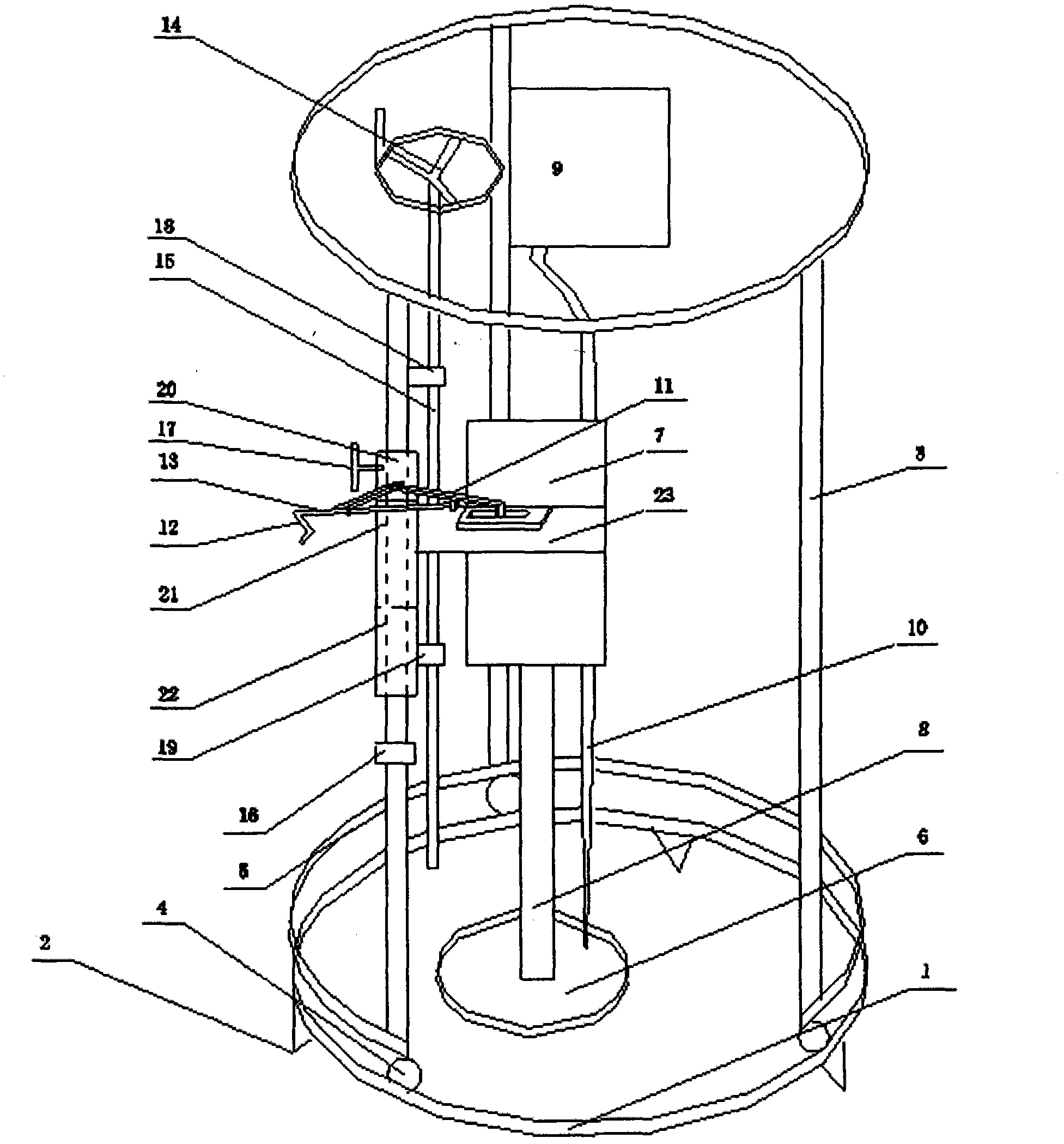

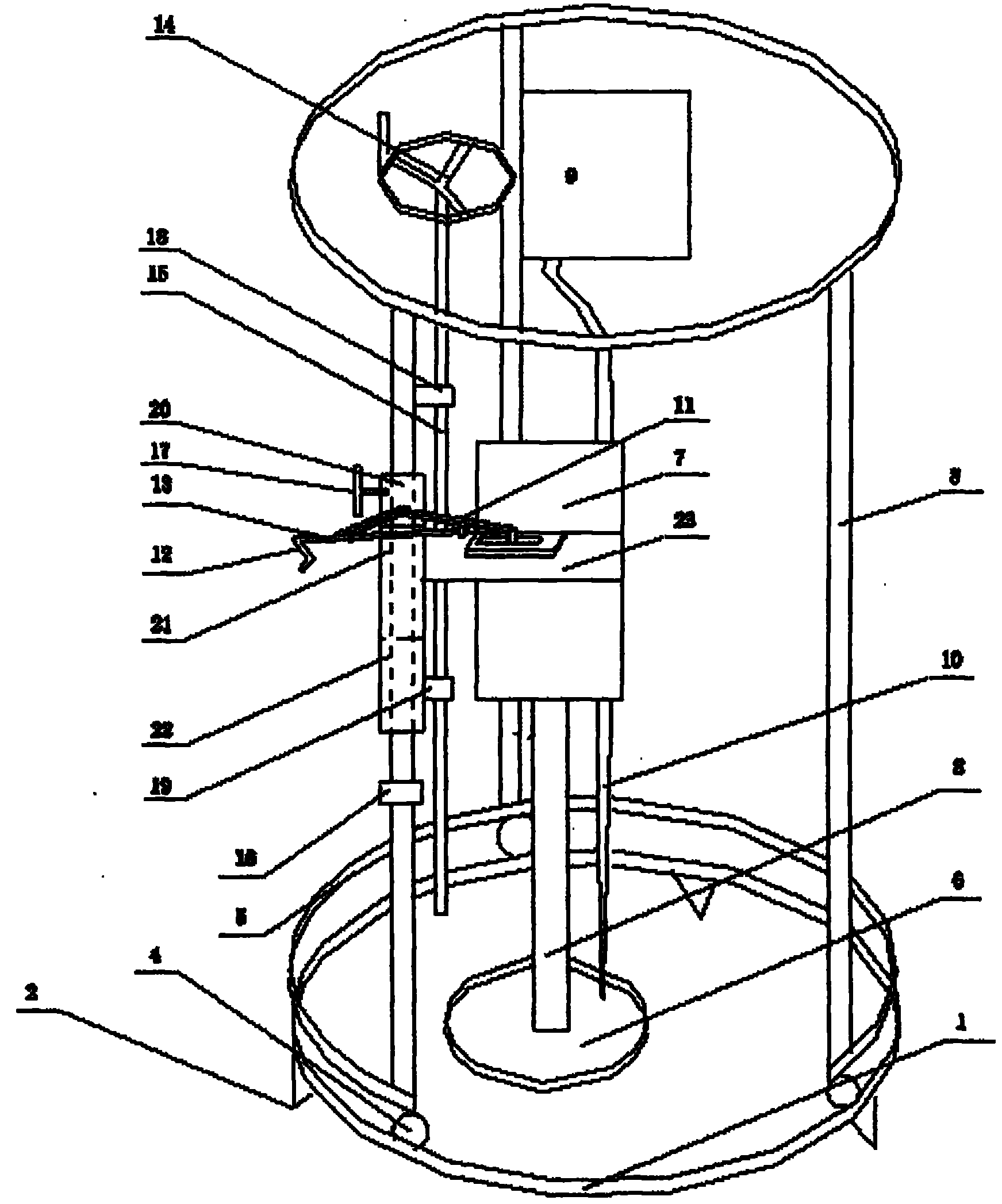

[0019] The specific embodiment of the present invention will be further described in conjunction with the accompanying drawings.

[0020] A pile head cutting machine for CFG piles, including a support system, a cutting system, a cooling system, and a control system. The support system includes a base support made of steel pipes, a triangular blade foot made of steel plates or steel pipes, and a vertical support frame made of steel pipes. , rollers and steel pipe body frame, cutting system includes cutting saw made of hard alloy, three-phase asynchronous motor, motor shaft and power control switch, cooling system includes rectangular tank, water tank, water pipe and control valve, control system includes cutting Saw radial movement control system (including bendable rocker arm, rocker, horizontal transmission screw rod and connecting steel plate with chute), circular rotation (including body bracket, roller) and fine-tuning control system (including handle, Vertical drive screw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com