A cutting device for civil engineering components

A cutting device and civil engineering technology, applied in positioning devices, metal processing machinery parts, manufacturing tools, etc., can solve the problems of large labor consumption, poor cutting effect, low efficiency, etc., to reduce labor intensity, improve accuracy and stability Sex-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

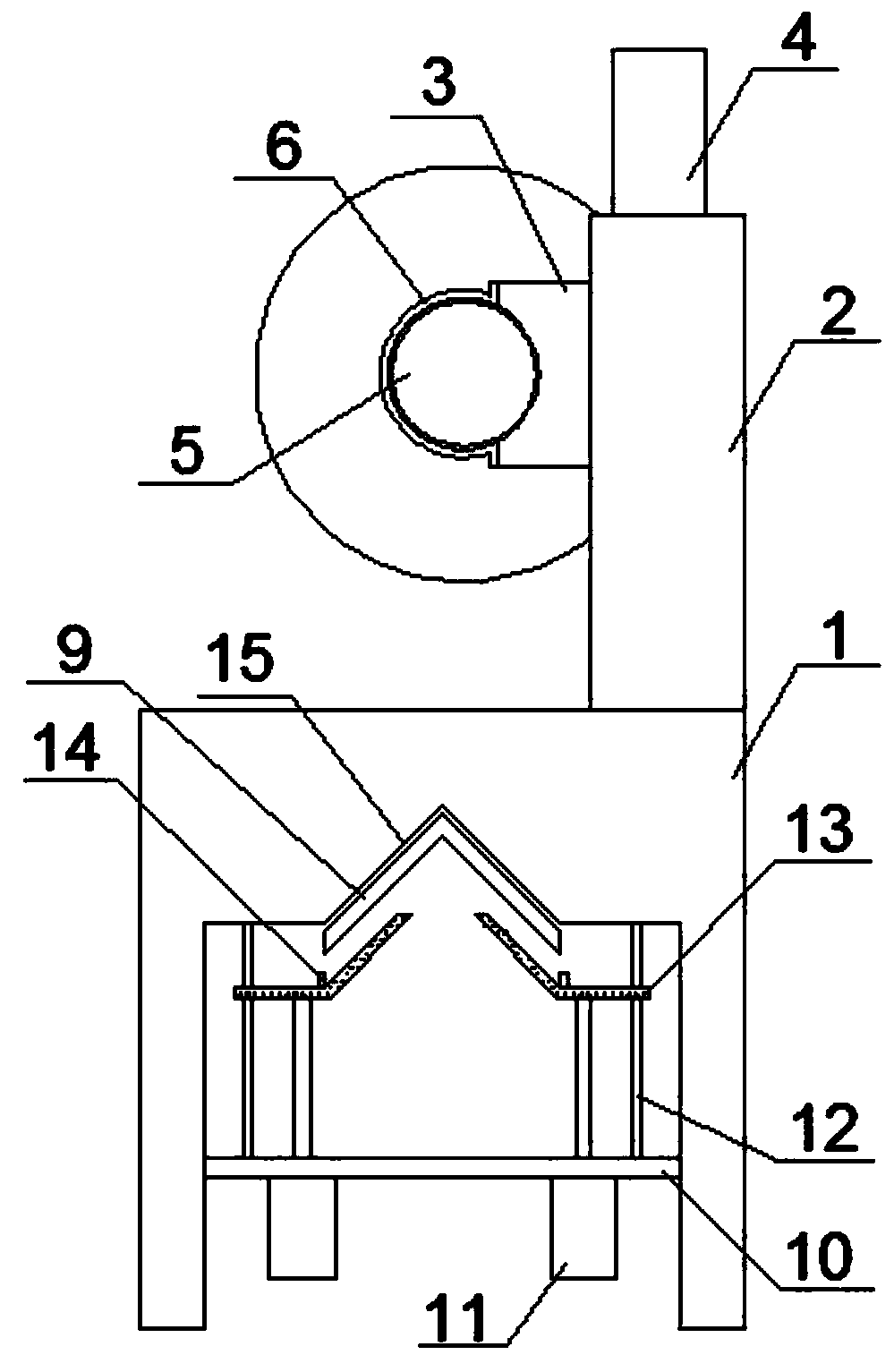

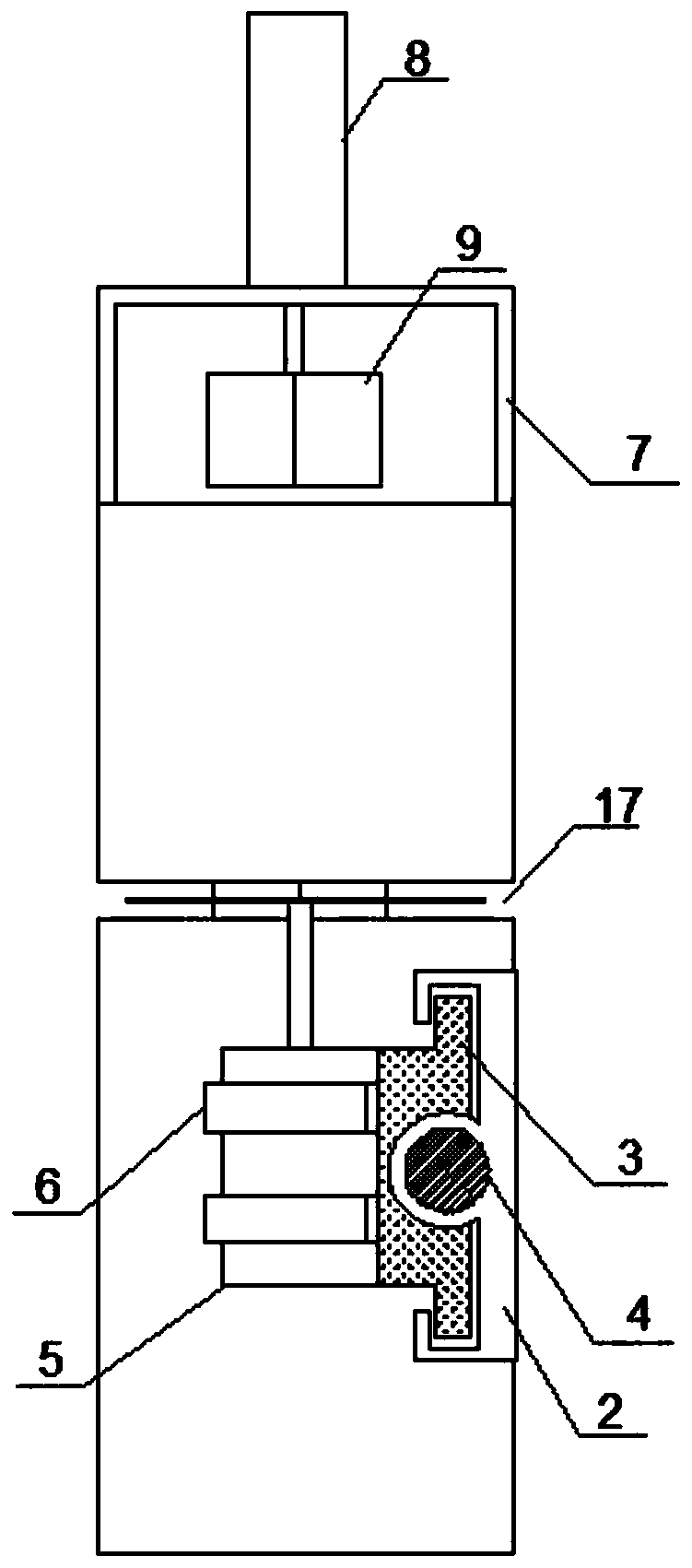

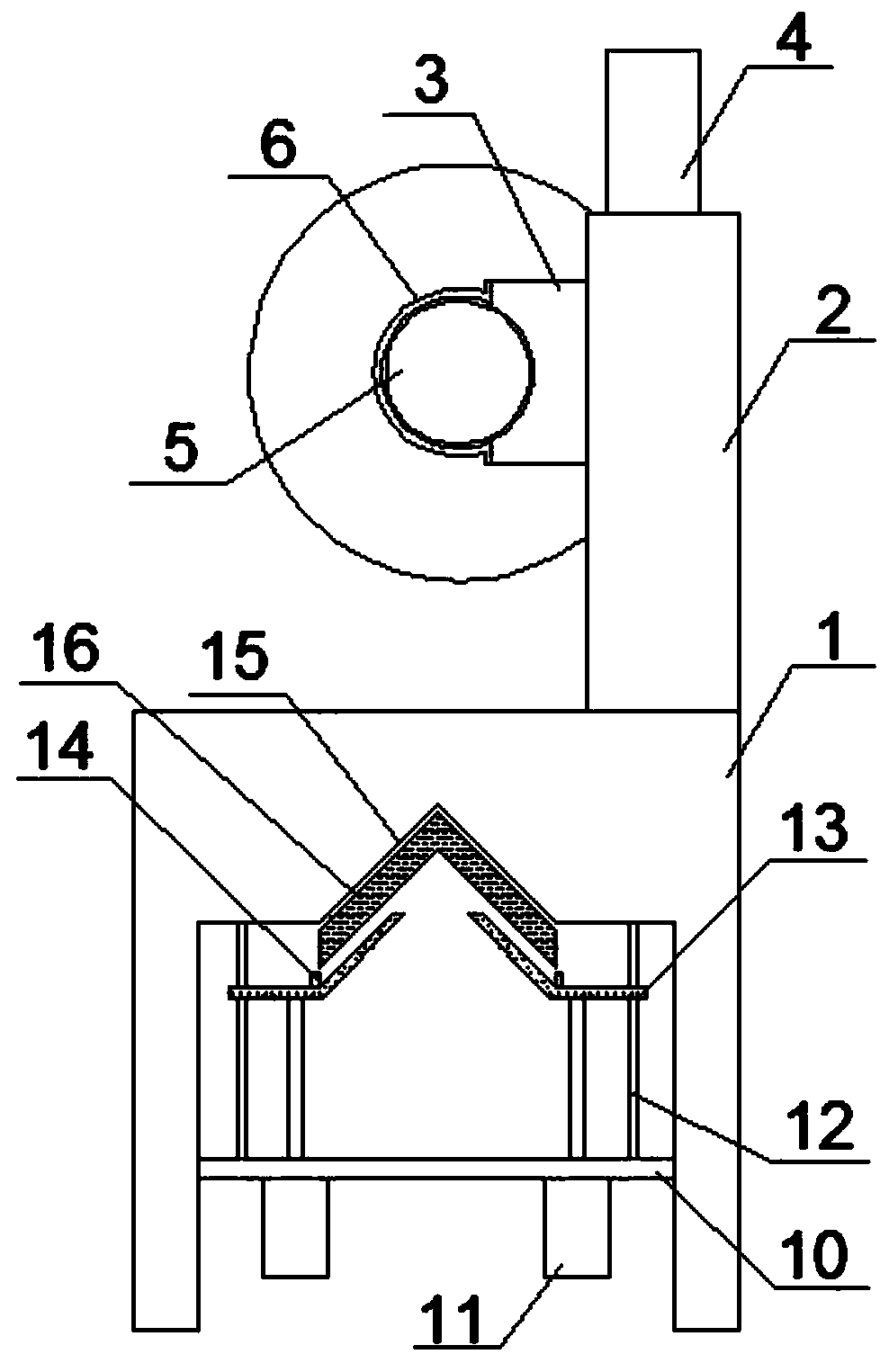

[0020] Such as Figure 1-3 As shown, the present invention discloses a cutting device for civil engineering components, including a frame 1, a clamping and pushing device, and the clamping and pushing device includes a support frame 7 and a beam plate 10, and the support frame 7 is fixedly connected to the frame 1 rear plane, the frame 7 is fixedly connected with a hydraulic cylinder 2 8, the piston rod of the hydraulic cylinder 2 8 is fixedly connected with a push plate 9, and the push plate 9 is facing the chute 15, and the beam plate 10 Fixedly connected to the inner wall of the lower end of the frame 1, the left and right ends of the beam plate 10 are respectively fixedly connected with a hydraulic cylinder group 11 and a guide rod 12, and each guide rod 12 is vertically slidably connected with a top plate 13, The two top plates 13 are fixedly connected to the two hydraulic cylinder groups 11 respectively, and a baffle plate 14 is fixedly connected to the top plate 13. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com