An online ring cutting device for continuous casting and rolling copper pipes

A technology of copper tube and ring cutting, which is applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of complex cutting process, high cutting cost, and complexity, and achieve low labor intensity for operators, simplified cutting process, and simple cutting process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

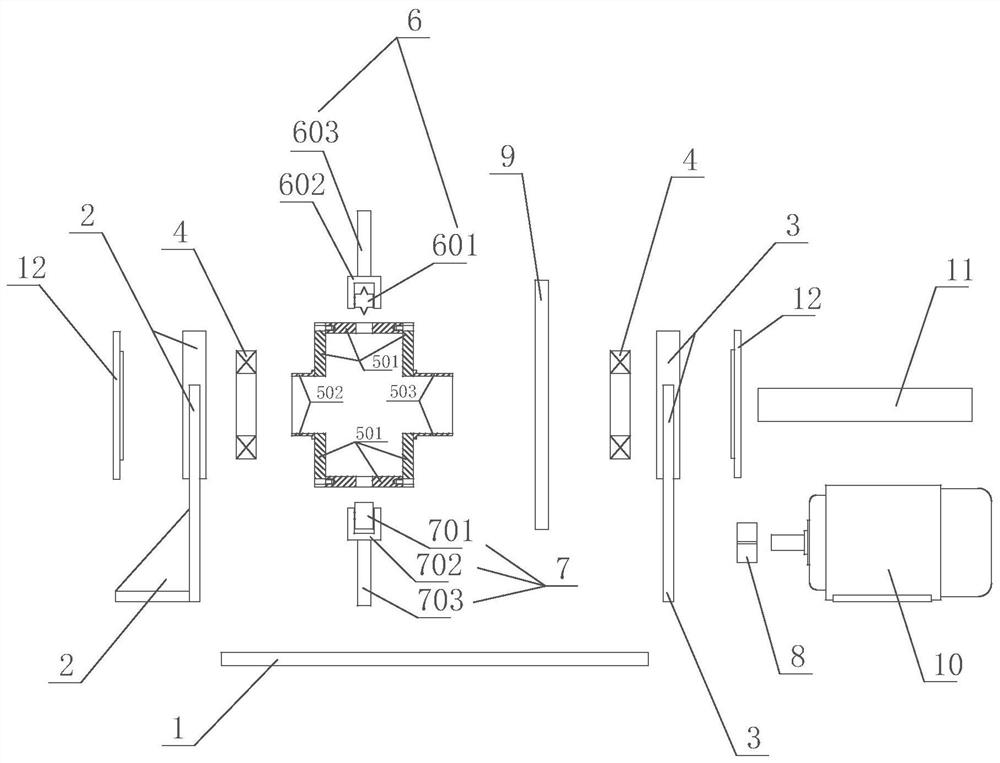

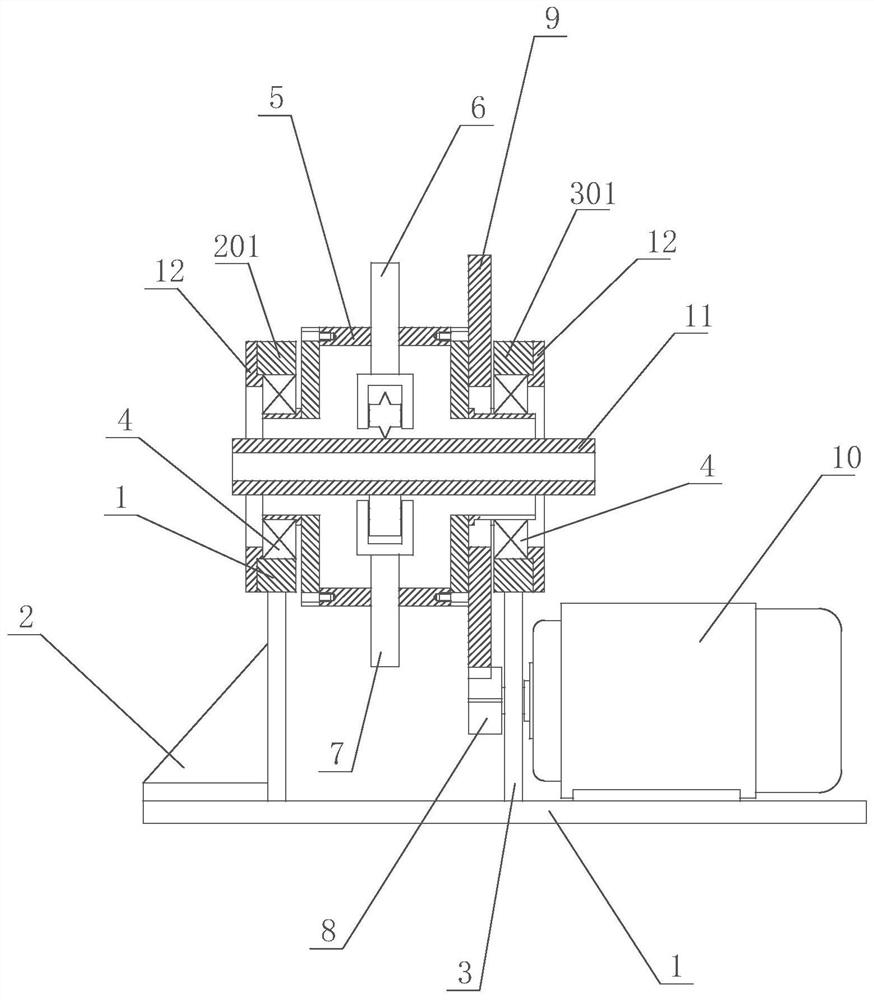

[0029] The application provides an online circular cutting device for continuous casting and rolling copper pipes, including a base, a motor 10, a driving gear 8, a driven gear 9, a revolving box 5, a left bracket 2, and a right bracket 3, which are used for cutting while revolving A ring cutter 6 for the copper pipe 11, an idler assembly 7 for supporting the copper pipe 11;

[0030] The base includes a base plate 1 and a linear sliding guide rail, the linear sliding guide rail is fixed on the ground, a chute is provided on the lower surface of the base plate 1, and the chute on the base plate 1 is sleeved on the linear sliding guide rail A linear sliding pair is formed to move the online circumcision device axially and linearly;

[0031] The left bracket 2 and the right bracket 3 are arranged on the upper surface of the base plate 1, and the left bracket 2 and the right bracket 3 are provided with bearings 4;

[0032] The rotary box 5 includes a rotary box main body 501 in the...

Embodiment 2

[0039] In this embodiment 2, on the basis of the technical solution of embodiment 1, it is further preferred that the main body 501 of the revolving box is a cuboid box;

[0040] The elastic telescopic rod 603 and the support rod 703 are respectively arranged on two mutually symmetrical side walls of the cuboid box.

Embodiment 3

[0042] In this embodiment 3, on the basis of the technical solution of embodiment 1, it is further preferred that the support rod 703 is provided with an external thread, and the outer wall surface of the side wall of the rotary box main body 501 is provided with a hand screw. The hand wheel is arranged on the outer wall surface of the side wall of the rotary box main body 501 through bearings, the central through hole of the hand wheel is an internal thread hole, and the support rod 703 is sequentially connected from the rotary box main body. 501 through the through hole on the side box wall and the internal thread hole in the hand wheel, the external thread on the support rod 703 and the internal thread in the internal thread hole form a threaded connection for passing through Turn the hand wheel to lift and lower the idler roller 701. In embodiment 3, the supporting roller 701 is adjusted and lifted by screw connection, so as to adapt to the outer diameter range of the copp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com