Method and apparatus for manufacturing thermoformed wheel spokes

A technology of thermoforming and spokes, which is applied in wheel manufacturing, metal processing equipment, wheel hubs, etc., to reduce the risk of cracks and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

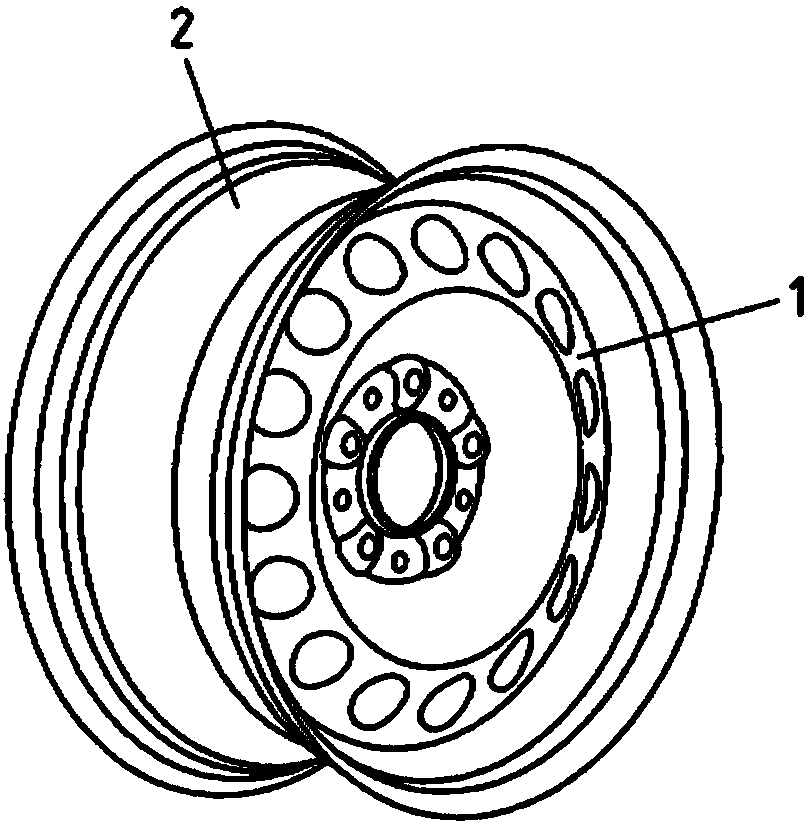

[0026] figure 1 A typical wheel is firstly shown schematically in , which consists of a spoke 1 and a rim 2 . The spokes 1 are connected to the rim 2 in a material fit and transmit the forces of the hub to the rim 2 .

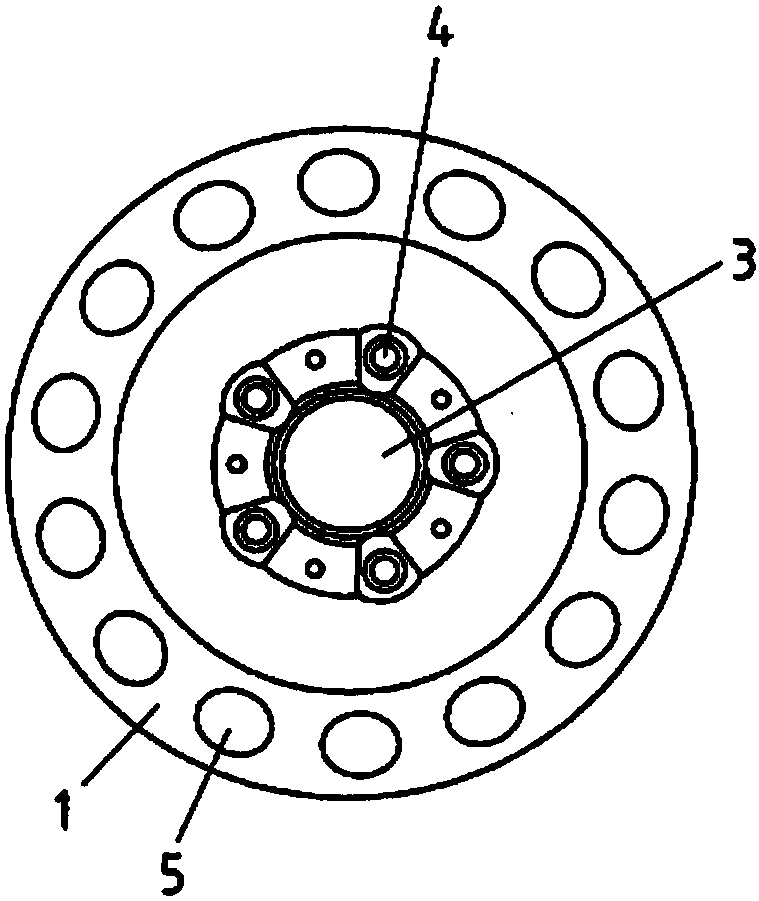

[0027] figure 2 The front view shows the spoke 1 . It can be seen that the spoke 1 has three different holes. Firstly, a hub hole 3 is arranged centrally, which is surrounded by a total of five concentrically arranged wheel bolt holes 4 . Ventilation holes 5 are additionally provided in the outer regions of the spokes, which are required for the ventilation of the brakes. The hub bore 3 , the wheel bolt bore 4 and the vent hole 5 must be inserted into the spoke with extreme precision, because otherwise the spoke 1 would cause problems during installation into the wheel, such as imbalance, if the dimensional tolerances were exceeded.

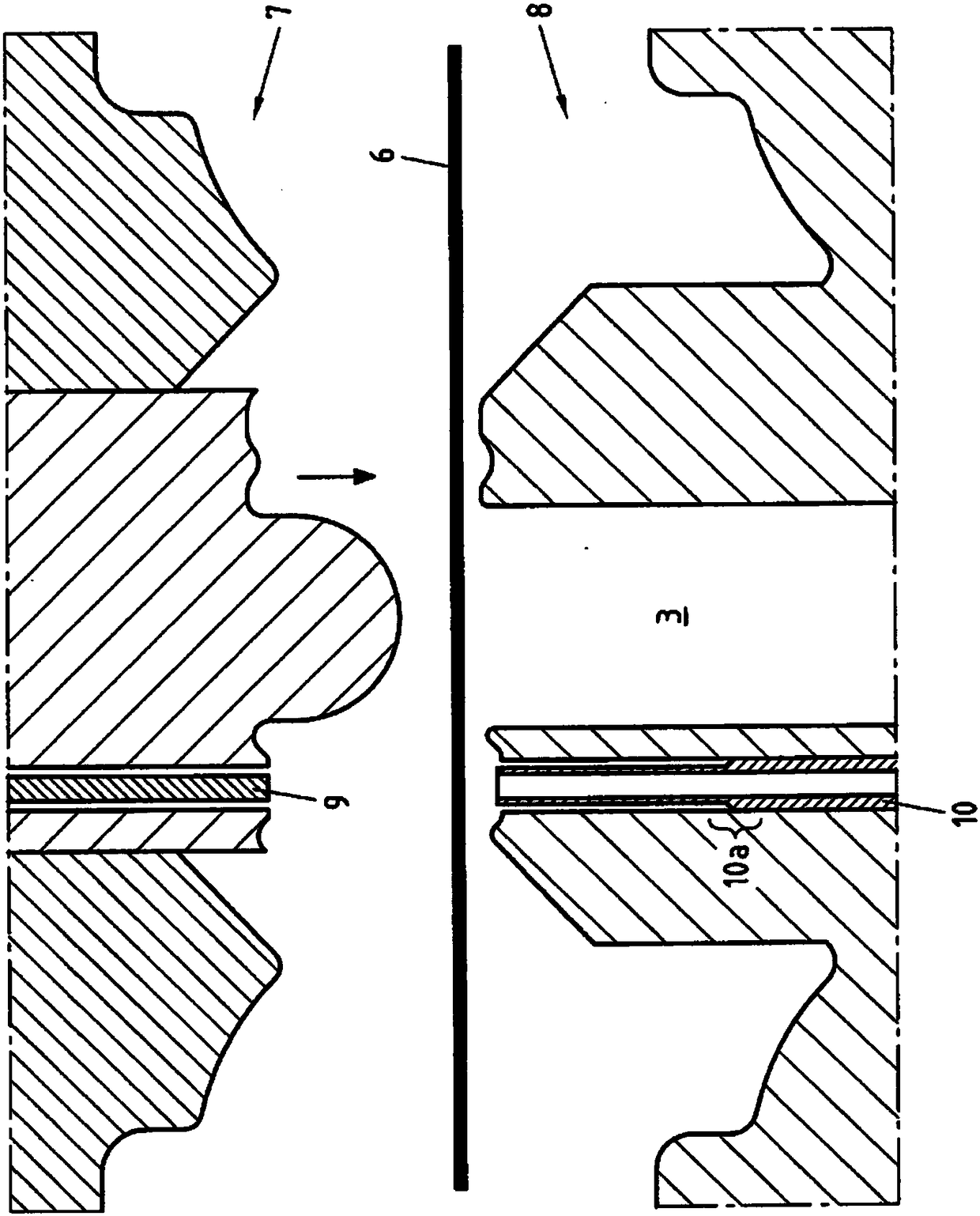

[0028] image 3 , 4 and 5 now show the method for manufacturing wheel spokes at three different points in time, wherein,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com