Balanced type multipurpose valve with cut-off, non-return and adjusting functions

A balanced, multi-purpose valve technology, applied in the direction of lift valve, control valve, valve device, etc., can solve the problems of inconvenient operation, large pipeline space, increase production cost, etc., achieve easy operation, reduce production cost, reduce operation force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

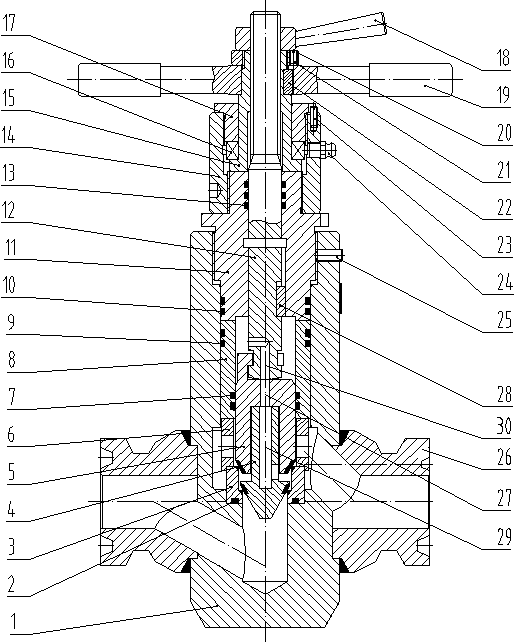

[0017] As shown in the figure, the balanced cut-off check multi-purpose valve includes a valve body 1, an end flange 26 welded to the inlet and outlet of the valve body 1, a valve seat 3 and a valve disc arranged in the valve body 1, The bonnet 11 that is screwed to the upper part of the valve body 1 and fixed by the set screw 25 is threaded to the bracket 14 on the top of the bonnet 11 and the valve stem 12. The bracket 14 is built with a valve stem nut 15 that matches the valve stem 12 and Press against the thrust ball bearing 16 on the valve stem nut 15. The upper part of the thrust ball bearing 16 is pressed by the bearing gland 17 and fixed by the set screw 23. Handle 19, the upper part of the operating handle 19 is limited by a lock nut 20 and a set screw 21, the top of the valve stem 12 is locked and positioned by a lock handle 18, and oil is set on the bracket 14 corresponding to the position of the thrust ball bearing 16. Cup 24. Rotate the operating handle 19, the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com