Fireproof flexible cable production process and flexible fireproof cable produced thereby

A production process and flexible cable technology, applied in the field of transmission lines, can solve the problems of increased copper core cross-sectional area, large cable diameter, troublesome use, etc., and achieve the effects of reduced weight, reduced consumables, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

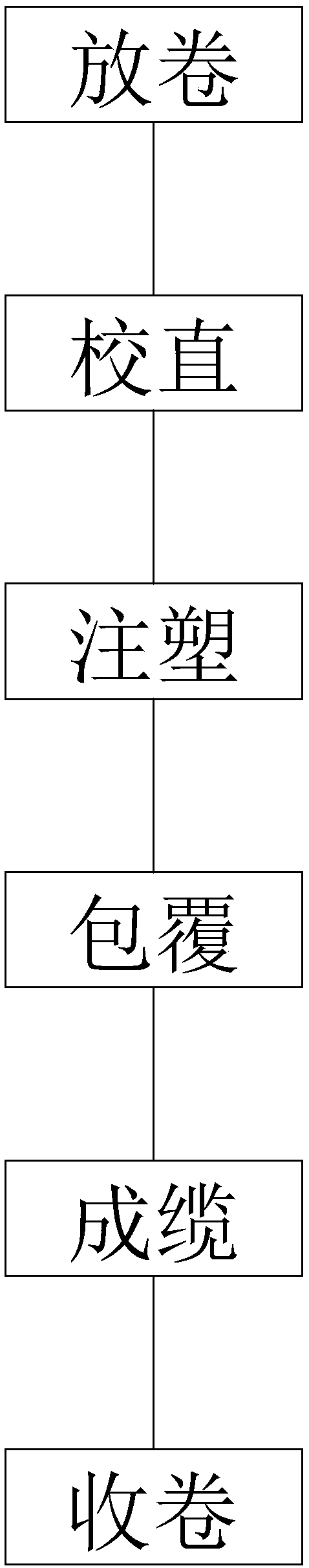

[0050] A fireproof flexible cable production process, which comprises the following steps,

[0051] S1, unwinding, the single copper core 81 is released from the copper core reel; the single copper core 81 is slowly released from the copper core reel by the unwinder;

[0052]S2, straightening, straightening the single copper core 81, and at the same time, performing frosting treatment on the single copper core 81; while straightening, grinding, through the grinding process, the surface of the single copper core 81 can be made It becomes rougher, and at the same time, in the process of frosting, it can straighten the single copper core, so that it can further improve its straightening degree;

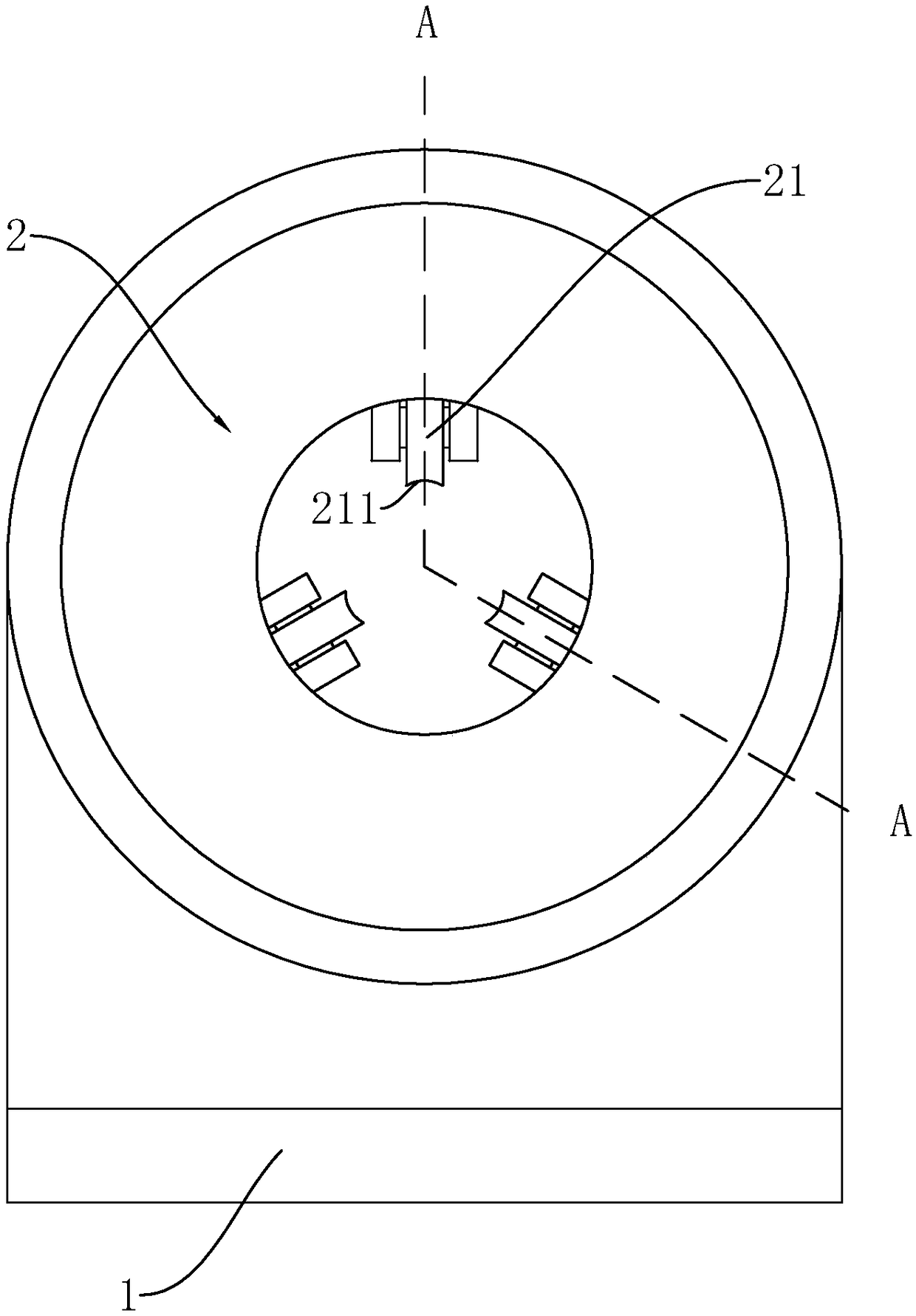

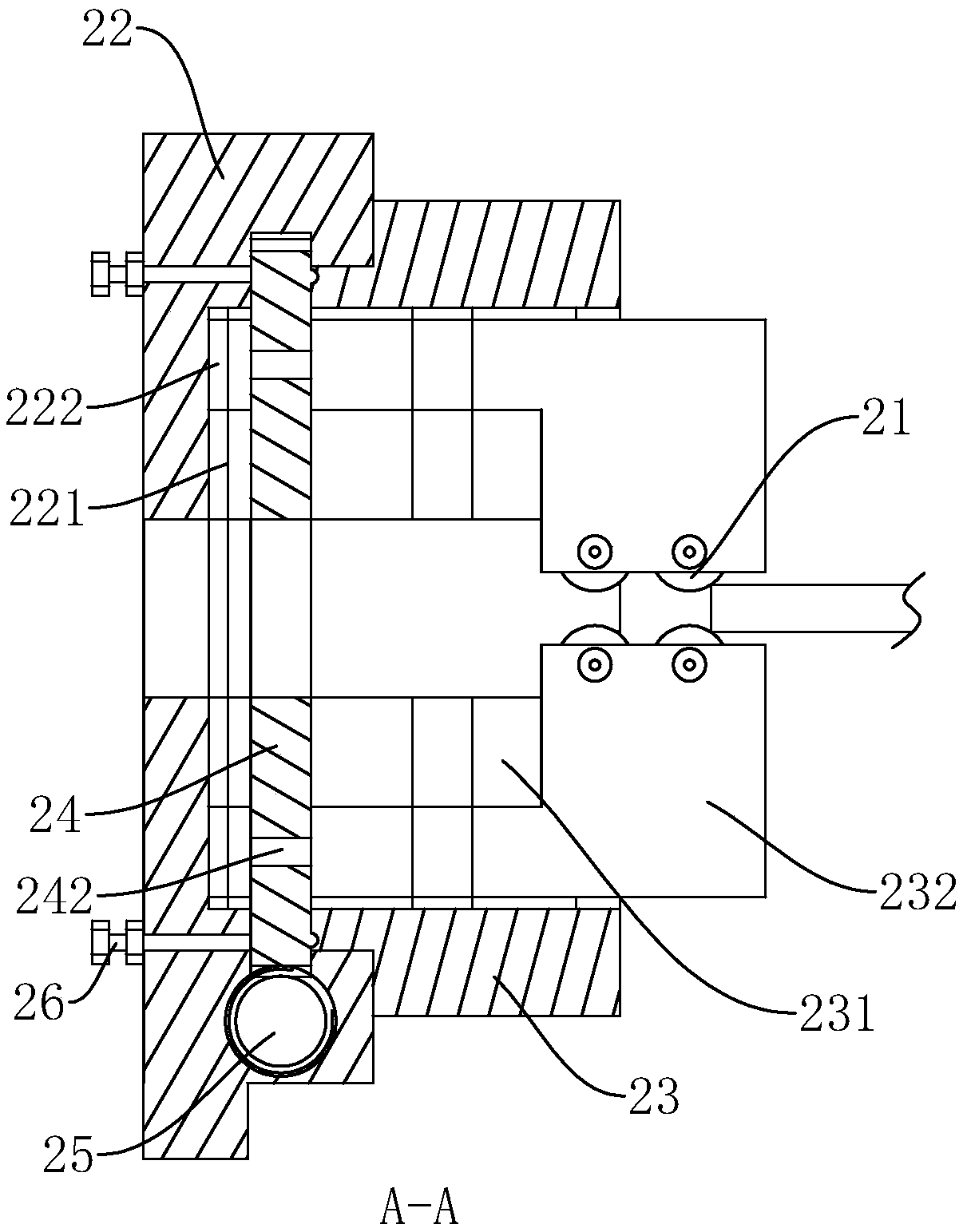

[0053] S3, injection molding, coating the surface of the single copper core 81 with a layer of fireproof insulating layer; the insulating material is processed by an injection molding machine, and then the insulating layer is coated on the single copper core by installing an injection mo...

Embodiment 2

[0066] A flexible fireproof cable produced by the production process as described in Example 1, comprising a single copper core 81 with a large diameter, a mica insulating layer 82, a copper sheath 83 and an insulating sheath, wherein the surface of the cable is provided with several The anti-skid pattern, the anti-skid pattern can be set as a spiral structure or a ring structure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com