Photovoltaic thin film backboard

A photovoltaic thin film and photovoltaic backplane technology, applied in photovoltaic power generation, electrical components, circuits, etc., can solve the problems of heavy weight, thick thickness, low photoelectric conversion efficiency, etc., achieve weight reduction, lower wall thickness uniformity, and improve photoelectricity The effect of conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

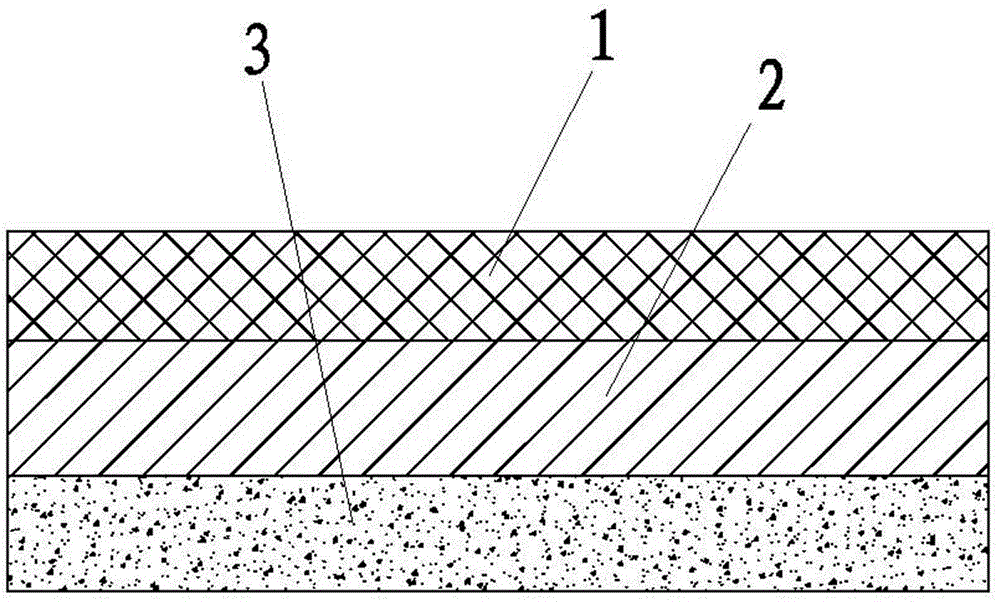

[0031] Embodiment 1: as figure 1 As shown, a photovoltaic thin film backboard includes a multi-microbubble polymer film layer 1, a PET film layer 2, and a fluorine-containing film layer 3 from top to bottom; The surface of the backsheet away from the cells is down.

[0032] Such as Figure 5 As shown in the figure, the abscissa is the wavelength, and the ordinate is the reflectivity. The a curve represents the diffuse reflection of sunlight on the surface of the tiny bubbles; the b curve represents the non-vertical reflection of sunlight on the surface of the tiny bubbles; the c curve Represents the vertical reflection of sunlight on the surface of tiny bubbles; it can be seen from the figure that the diffuse reflectance occurs between 95% and 97% in the wavelength range of 390-770 nanometers. It can be seen from the data that this embodiment has high diffuse reflectance performance.

[0033] Such as Figure 4 As shown, the top view of the surface topography of the multi-m...

Embodiment 2

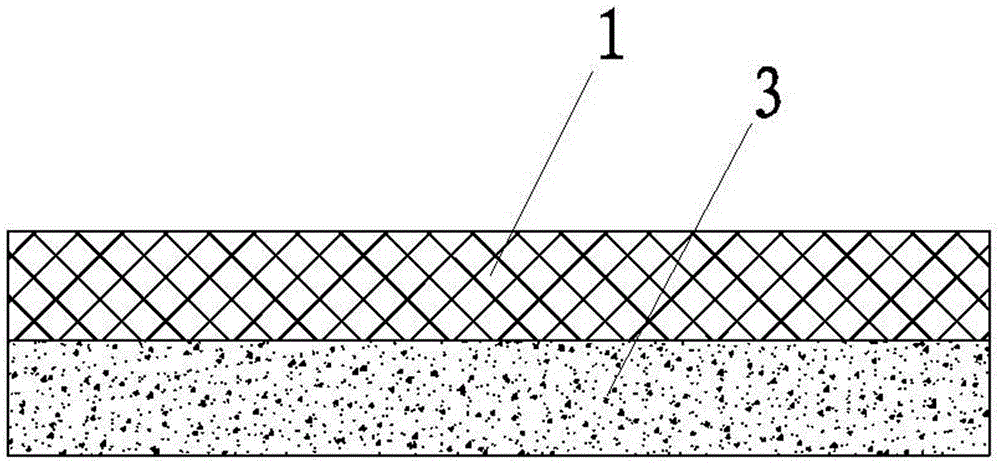

[0041] Embodiment 2: as figure 2As shown in the figure, a photovoltaic thin film backboard includes a multi-microbubble polymer film layer 1 and a fluorine-containing thin film layer 3 from top to bottom; when installed, the backplane surface close to the cell unit is on the top, and the backplane away from the cell unit is The plate surface is down.

[0042] Because the multi-microbubble polymer film layer 1 has a certain supporting effect, which realizes the supporting function of the current PET film in the back sheet, it can replace the PET film commonly used in the existing photovoltaic back sheet matrix materials, thereby realizing the photovoltaic thin film back sheet The two-layer structure not only saves costs and reduces consumables, but also makes the photovoltaic film backplane lighter and thinner, further reducing the consumables and weight ratio of the photovoltaic backplane.

[0043] The thickness of this embodiment is 1.2mm.

[0044] The preparation steps of...

Embodiment 3

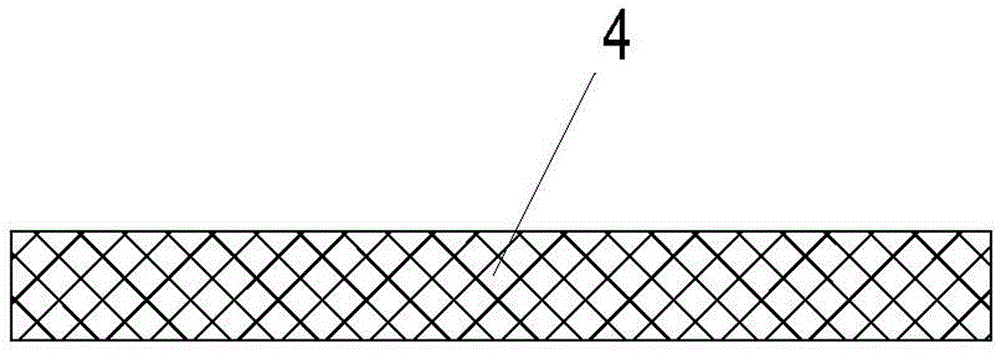

[0049] Embodiment 3: as image 3 As shown, a photovoltaic thin film backsheet is composed of a fluorine-containing multi-microbubble polymer film layer 4, which is made by foaming a fluorine-containing polymer, and has good anti-ultraviolet, waterproof, insulation, weather resistance and aging resistance, etc. performance, and also has a certain supporting effect, which can replace PET film, fluorine-containing film and other backsheet materials in the prior art at the same time, and realize a one-layer structure of photovoltaic thin film backsheet; this not only saves costs, but also makes the photovoltaic thin film backsheet more efficient. Light and thin, effectively reducing the consumables and weight ratio of photovoltaic backplanes.

[0050] The thickness of this embodiment is 0.3 mm.

[0051] The preparation steps of the fluorine-containing multi-microbubble polymer film layer 1 of the present embodiment are as follows in sequence:

[0052] (1) Place the fluorine-cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com