Liquid-crystalline polyester resin composition and connector using the same

一种树脂组合物、液晶聚酯的技术,应用在液晶材料、化学仪器和方法、底座/外壳等方向,达到工业价值大的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0101] The present invention is illustrated in more detail by means of the following examples, which should not be construed as limiting the scope of the invention.

[0102] The physical properties of mica were measured by methods (1) to (3) shown below, and the prepared liquid crystal polyester resin compositions were evaluated by methods (4) to (6).

[0103] (1) Volume average particle size

[0104] The volume average particle diameter is measured using a master sizer (SYSMEX CORPORATION).

[0105] (2) specific surface area

[0106] The specific surface area was measured using Hmmodel-1208 (Mountech).

[0107] (3) viscous water

[0108] The amount of viscosified water was measured using a heat-dry type moisture meter (A&D Company, Limited).

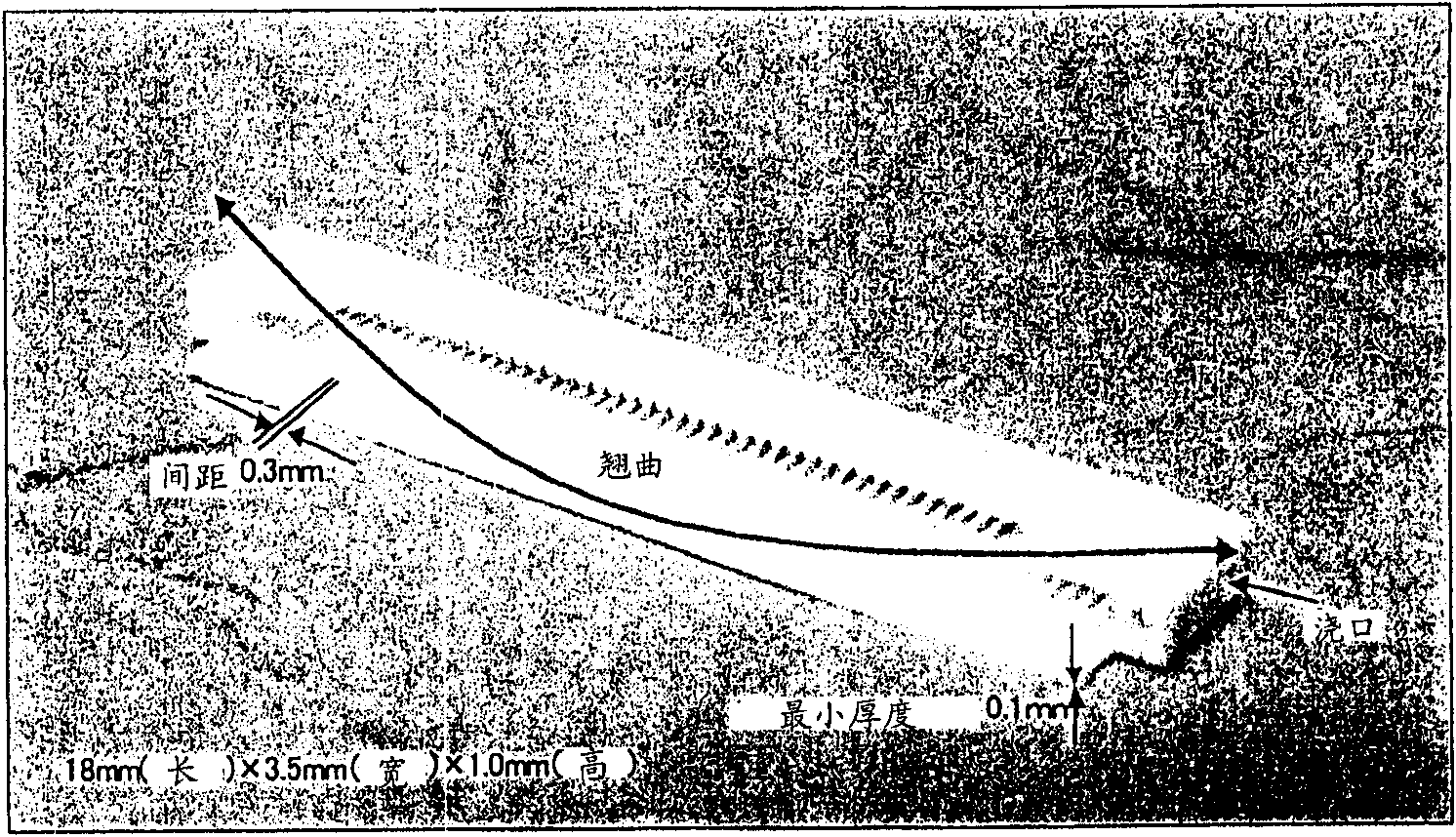

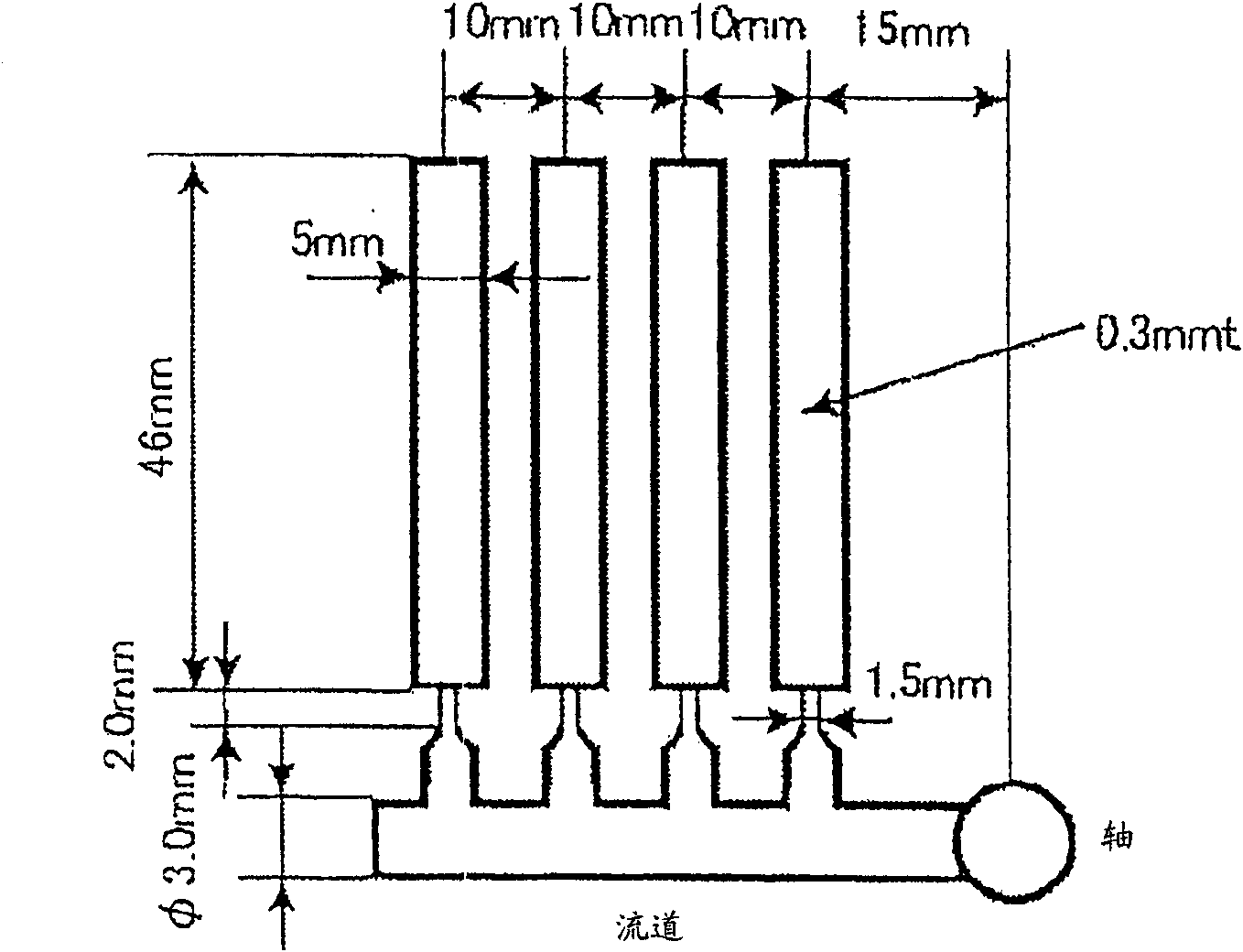

[0109] (4) Thin wall flow length (melt fluidity)

[0110] Use the installed figure 2 Injection molding machine ("PS10E1ASE" manufactured by Nissei Plastic Industrial Co., Ltd.) of the indicated mold (0.3mmt) at a barrel temperatu...

manufacture Embodiment 1

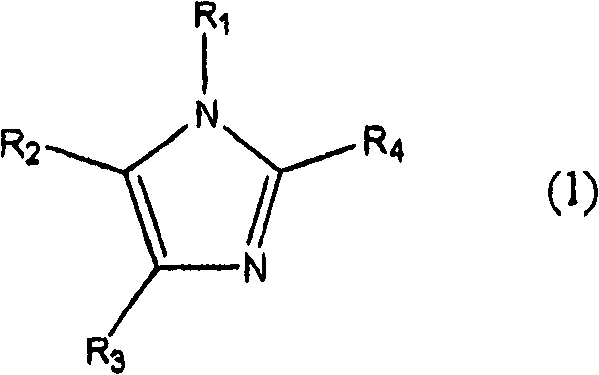

[0116] In a reactor equipped with a stirrer, torque meter, nitrogen conduit, thermometer and reflux condenser, 994.5 g (7.2 mol) of p-hydroxybenzoic acid, 299.0 g (1.8 mol) of terephthalic acid, 99.7 g (0.6 mol) of isophthalic acid, 446.9 g (2.4 mol) of 4,4'-dihydroxybiphenyl and 1347.6 g (13.2 mol) of acetic anhydride. After the atmosphere in the reactor was sufficiently replaced with nitrogen, 0.18 g of 1-methylimidazole was added. The temperature was raised to 150°C over 30 minutes under nitrogen flow, and the mixture was refluxed for 30 minutes by keeping at the same temperature. After adding 2.4 g of 1-methylimidazole, the temperature was raised to 320° C. over a period of 2 hours and 50 minutes while distilling off acetic acid distilled as a by-product and unreacted acetic anhydride. The time at which an increase in torque was recognized was taken as the end of the reaction and the prepolymer was removed. The obtained prepolymer was cooled to room temperature, and then...

manufacture Embodiment 2

[0118] A prepolymer was obtained in the same manner as in Production Example 1 except that 1-methylimidazole was not added. The obtained prepolymer was pulverized by a coarse crusher, and then heated from room temperature to 250° C. in 1 hour, from 250° C. to 285° C. in 5 hours, and kept at 285° C. for 3 hours under a nitrogen atmosphere. for solid phase polymerization. The liquid crystal polyester thus obtained is called LCP2. The resulting LCP2 exhibited a flow onset temperature of 324 °C, (C 1 ) / (A 1 ) molar ratio is 1 / 3, ((B 1 )+(B 2 ))(C 1 ) molar ratio is 1 / 1, (B 2 ) / (B 1 ) molar ratio is 1 / 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com