Sintering flue gas dioxin and particulate matter synergism purification equipment and method

A technology for sintering flue gas and particulate matter, applied in chemical instruments and methods, separation methods, dispersed particle filtration, etc., can solve problems such as unfavorable dioxin purification operation, low dust removal efficiency of electrostatic precipitator, high absolute value of emission, and achieve operation and maintenance Low cost, reduced device consumables and floor space, and small investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. It should be understood that the preferred embodiments are only for illustrating the present invention, but not for limiting the protection scope of the present invention.

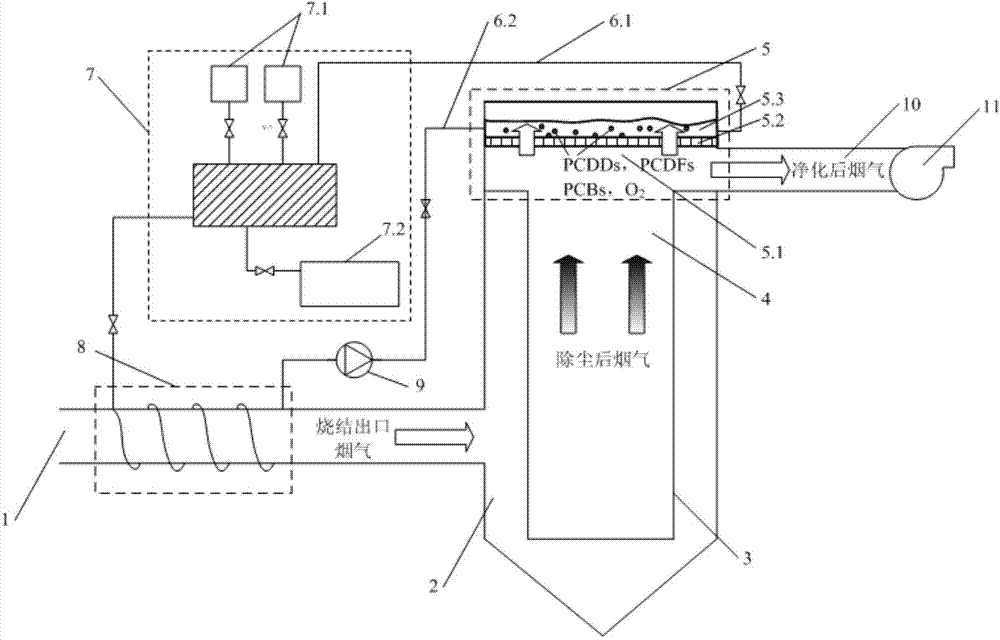

[0030] As shown in the figure, a device for synergistic purification of dioxin and particulate matter in sintering flue gas includes a filter device. The filter device is provided with a dust-laden flue gas inlet 1 and a clean gas outlet 10. The filter device is also provided with A flat membrane reactor 5, the flat membrane reactor is provided with a selective permeable membrane 5.2 that can only pass through dioxin and oxygen, and the selective permeable membrane separates the flat membrane reactor to form the gas permeation chamber 5.1 and the gas permeation chamber located at the lower part The upper liquid permeable cavity 5.3 is provided with a dioxin degradation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| dust removal efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com