Whole-thermal reclaiming type thermal-drive solution ventilation processor set by using evaporative cooling of return air

A technology of evaporative cooling and total heat recovery, applied in the energy field, can solve problems such as the inability to completely solve the problem of air leakage between the new and return air

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

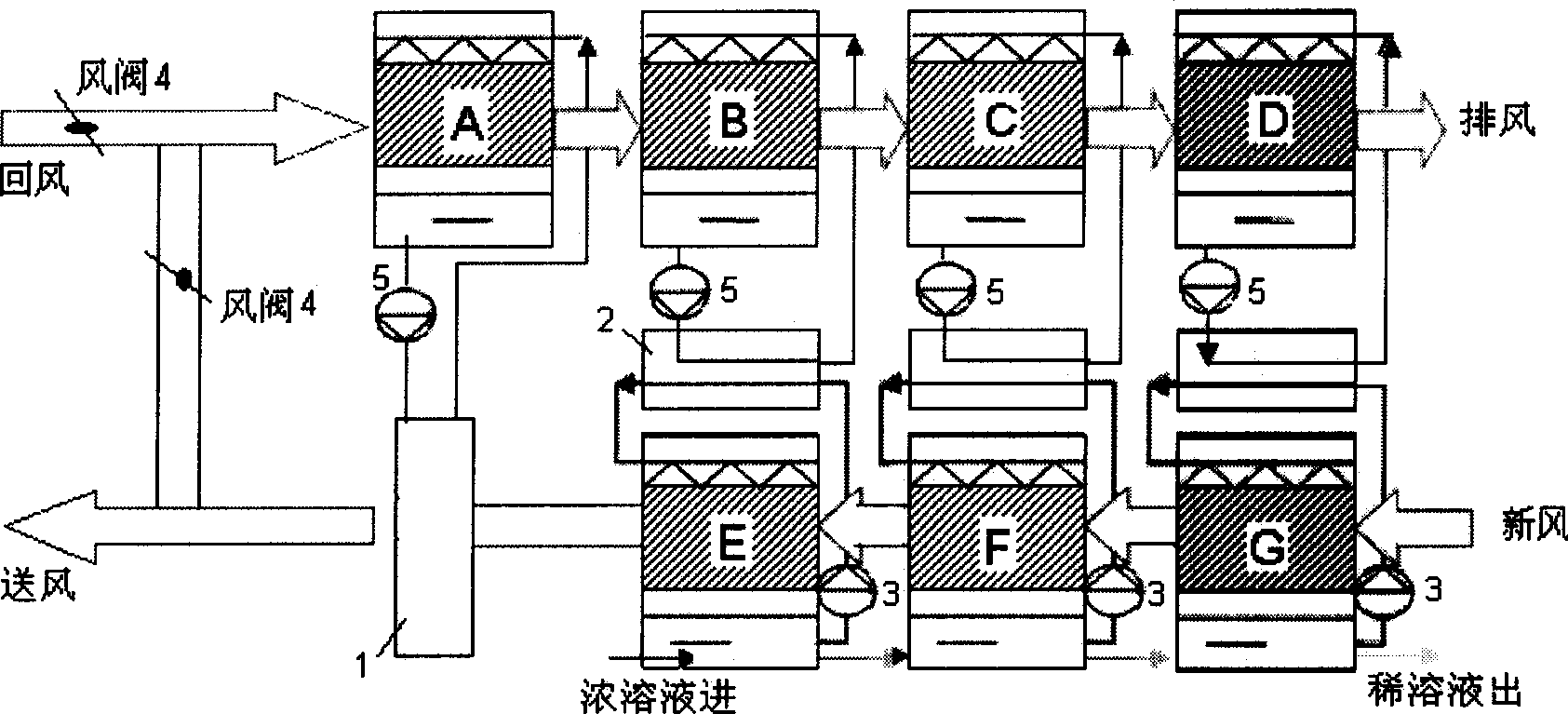

[0007] Below in conjunction with accompanying drawing, technical scheme of the present invention is described further:

[0008] see figure 1 , The fresh air processor includes: gas-liquid direct contact modules A~G, plate heat exchanger 2, solution self-circulation pump 3, air valve 4, water pump 5 and other components. The fresh air fan is divided into upper and lower channels, the upper channel is the return air processing channel, and the lower layer is the fresh air processing channel. The upper channel is composed of gas-liquid direct contact modules A, B, C, and D, and the lower channel is composed of gas-liquid direct contact modules E, F, and G. The upper gas-liquid direct contact modules B, C, and D correspond to the lower modules E, F, and G respectively to form three-stage total heat recovery, and the upper and lower modules of each stage are connected by a plate heat exchanger 2 . Inside the modules B, C, and D, the return air is used for evaporative cooling to g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com