Metal fiber post-mixing type burner and boiler employing same

A metal fiber and burner technology, which is applied in the direction of burners, gas fuel burners, combustion methods, etc., can solve the problems that the overall volume of the boiler cannot be reduced, cannot be promoted, and has a large shape, so as to reduce the installation area , Small size, evenly distributed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

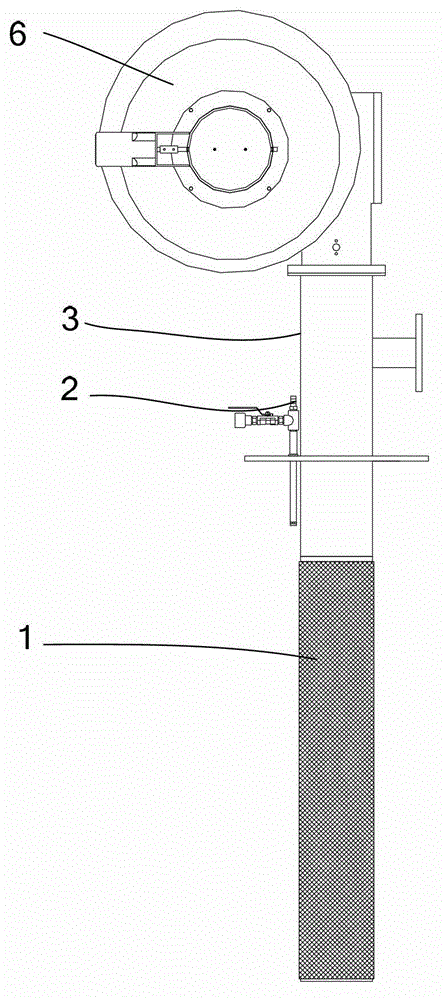

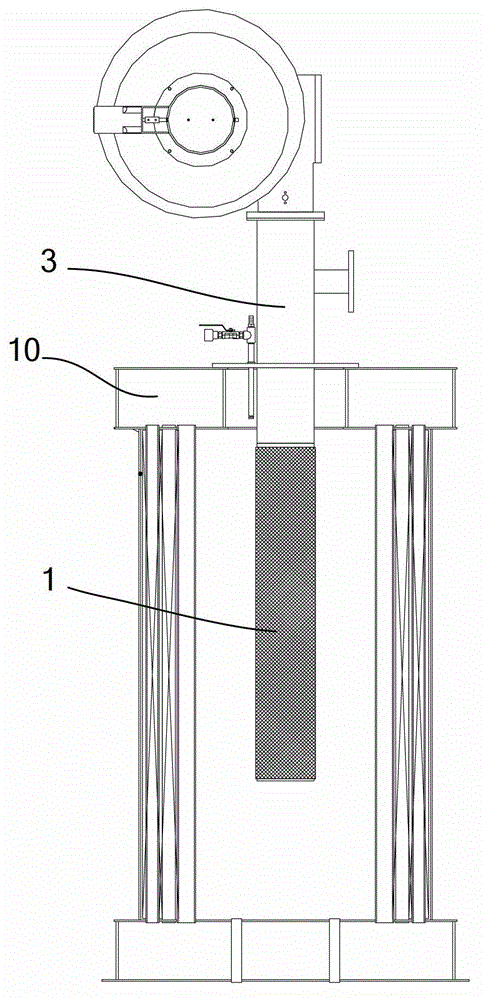

[0033] Such as figure 1 As shown, this embodiment provides a burner that can be used in conjunction with a boiler and has a small size. The gas boiler using this burner has a small appearance and saves costs. The burner uses a new metal fiber post-mixing mixing technology to shorten the mixer length. To enable the flame to burn evenly on a more slender cylinder, the cylindrical metal fiber burner has a larger length to diameter ratio.

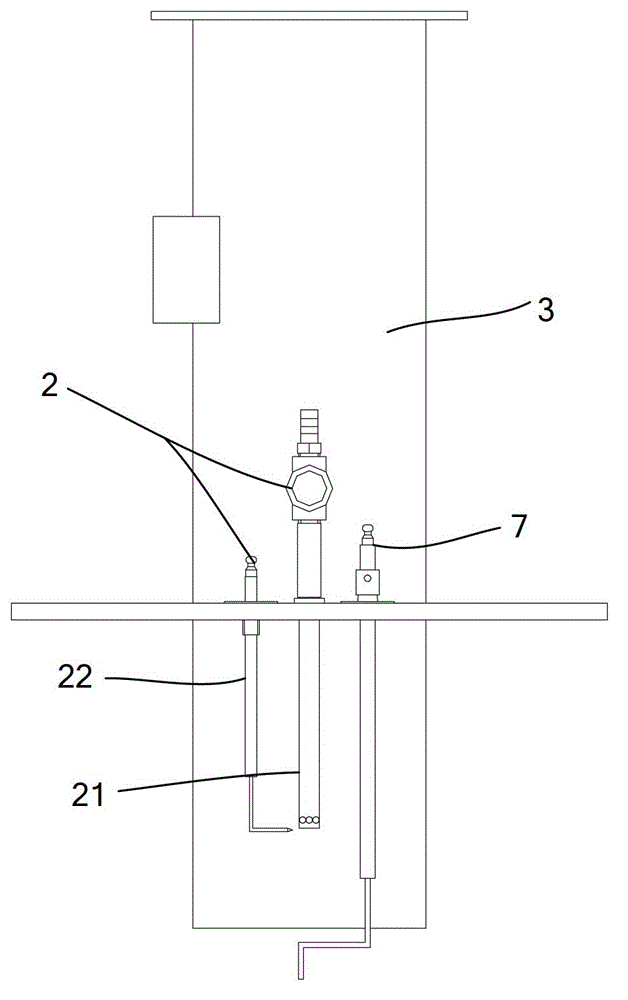

[0034] Specifically, a metal fiber post-mixing burner includes a cylindrical combustion head 1, an ignition device 2, a mixer 3, a fan 6, a gas swirl device and a servo control system. The mixer and fan are devices exposed outside the boiler, and the length of the three parts of the mixer is only 360mm, and the length of the entire burner is slightly shorter or equivalent than that of ordinary b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com