Patents

Literature

89results about How to "Uniform surface distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

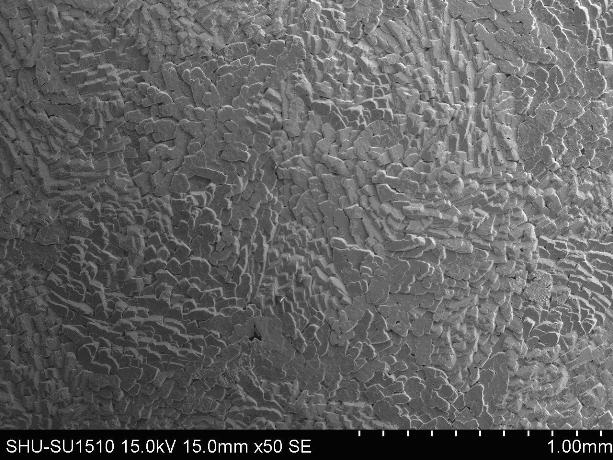

Method for preparing silver-enriched antibacterial film on pyrolytic carbon and TiN film for medical use

InactiveCN1827840AIncrease concentrationImprove antibacterial propertiesVacuum evaporation coatingSputtering coatingSputteringHigh energy

The invention relates the method for preparing rich silver antibiotic film used for medical pyrolytic carbon and TiN film. It solves the antibiosis question. The method comprises the following steps: on the pyrolytic carbon: a buffing and cleaning; b evacuating; c sputtering and cleaning for 5 minutes with 1keV nitrogen ion; d injecting silver ion: 70, 30keV energy, 2-8mA beam current, 2X1014 / cm2-3X1014 / cm2 dosage, and forming rich silver antibiotic film and antibiosis ratio being 100%; on TiN film: a buffing and cleaning; b evacuating; c sputtering and cleaning for 5 minutes with 1keV nitrogen ion; d sputtering Ti target with 3keV, 80mA Ar+ ion, 20-40keV, beam current: bombarding with 2-8mA high-energy N+ ion for 10-20 minutes; 50-350eV, beam current: bombarding with 10-30mA low-energy N+ ion for 60-180 minutes to deposit, N2 air pressure being 8X10 3Pa; e injecting silver ion: 30-80keV, beam current: 2-8mA, 1X1017 / cm2-5X1018 / cm2 dosage, forming rich silver antibiotic film and antibiosis ratio being 90%. The film has the advantages of good abradability, strong adhesive force and anti-corrosion, good cell compatibility and long antibiosis time-effect. The film can be used to prepare artificial heart valve and hard tissue alternate material which is implanted in human.

Owner:TIANJIN NORMAL UNIVERSITY

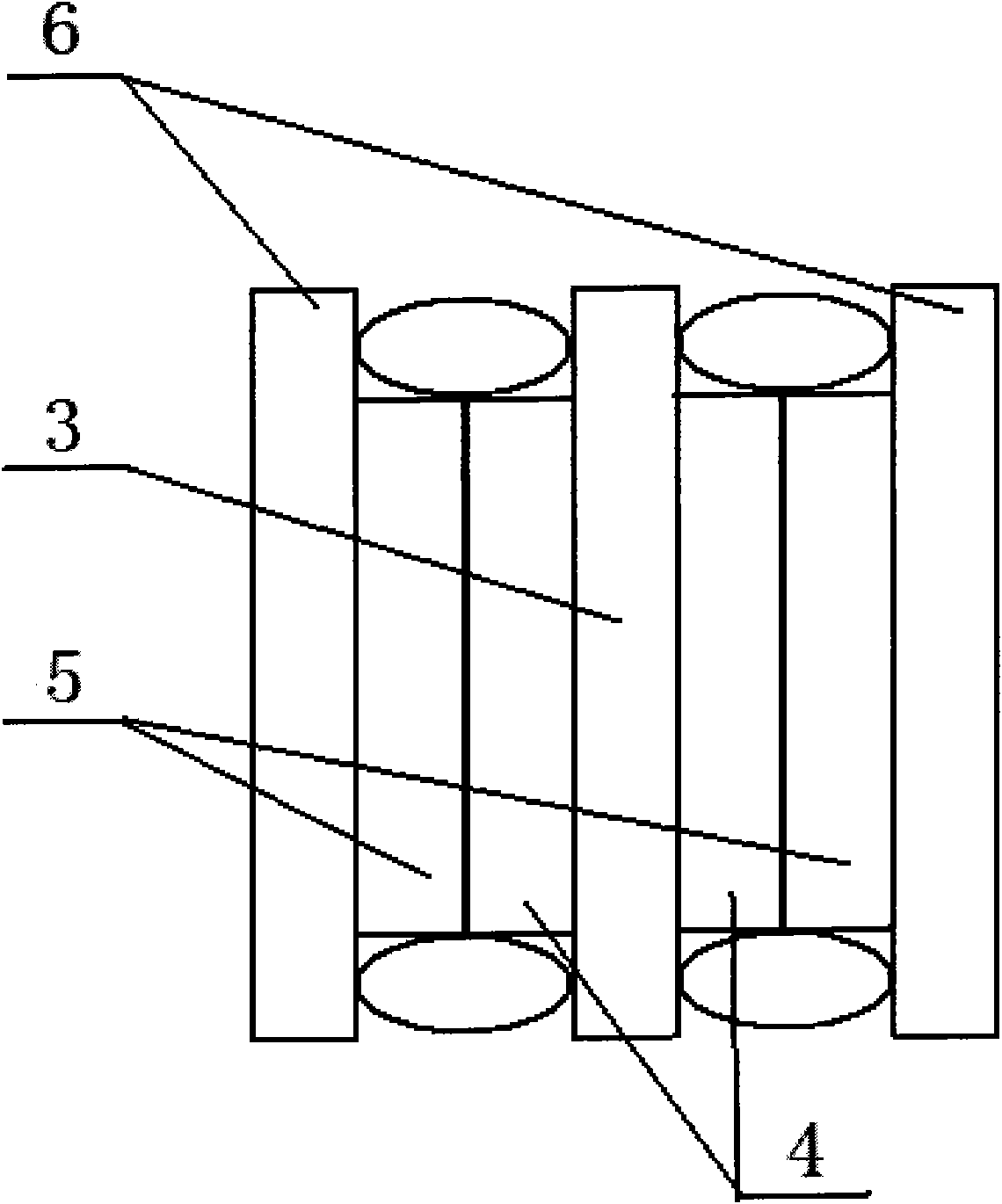

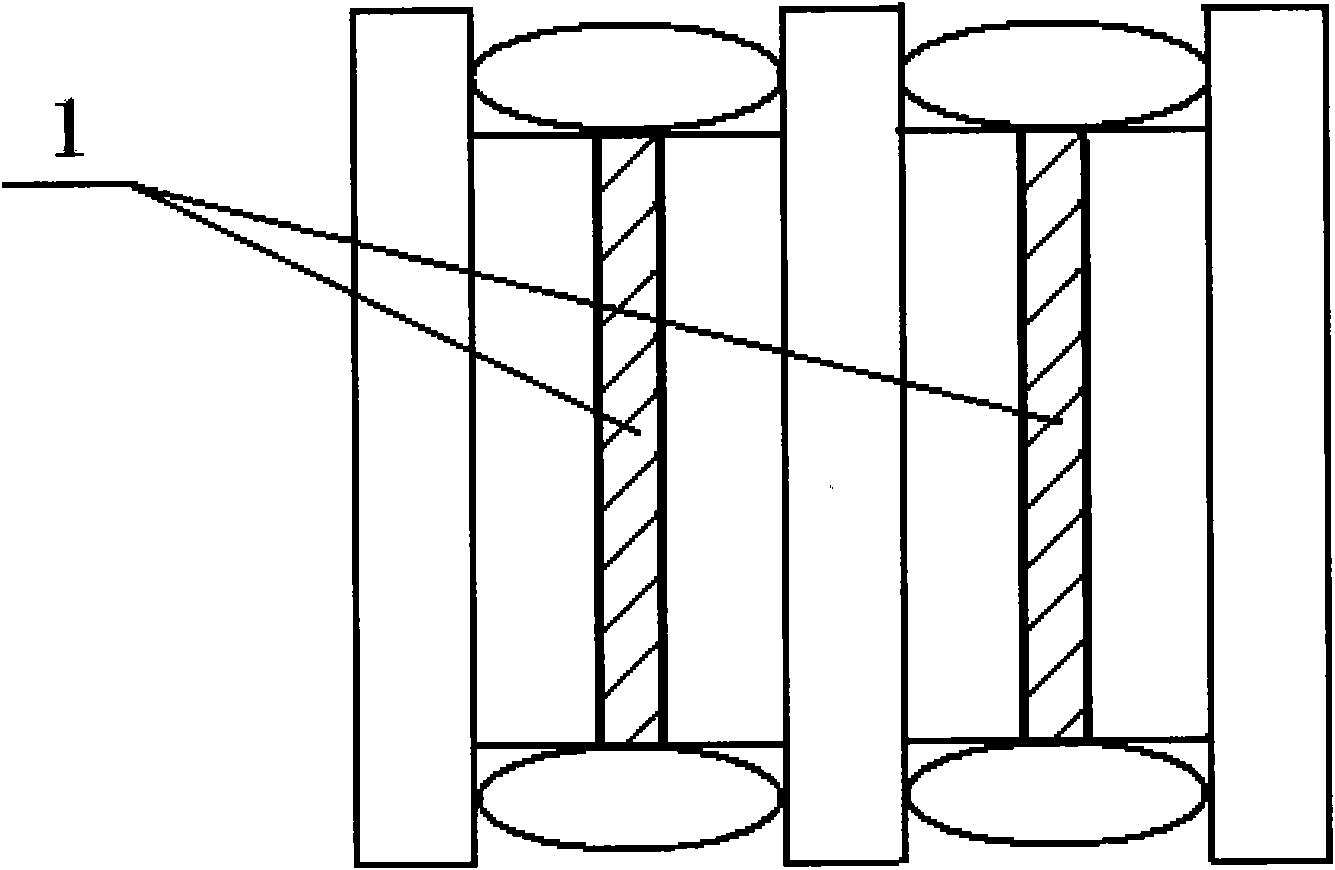

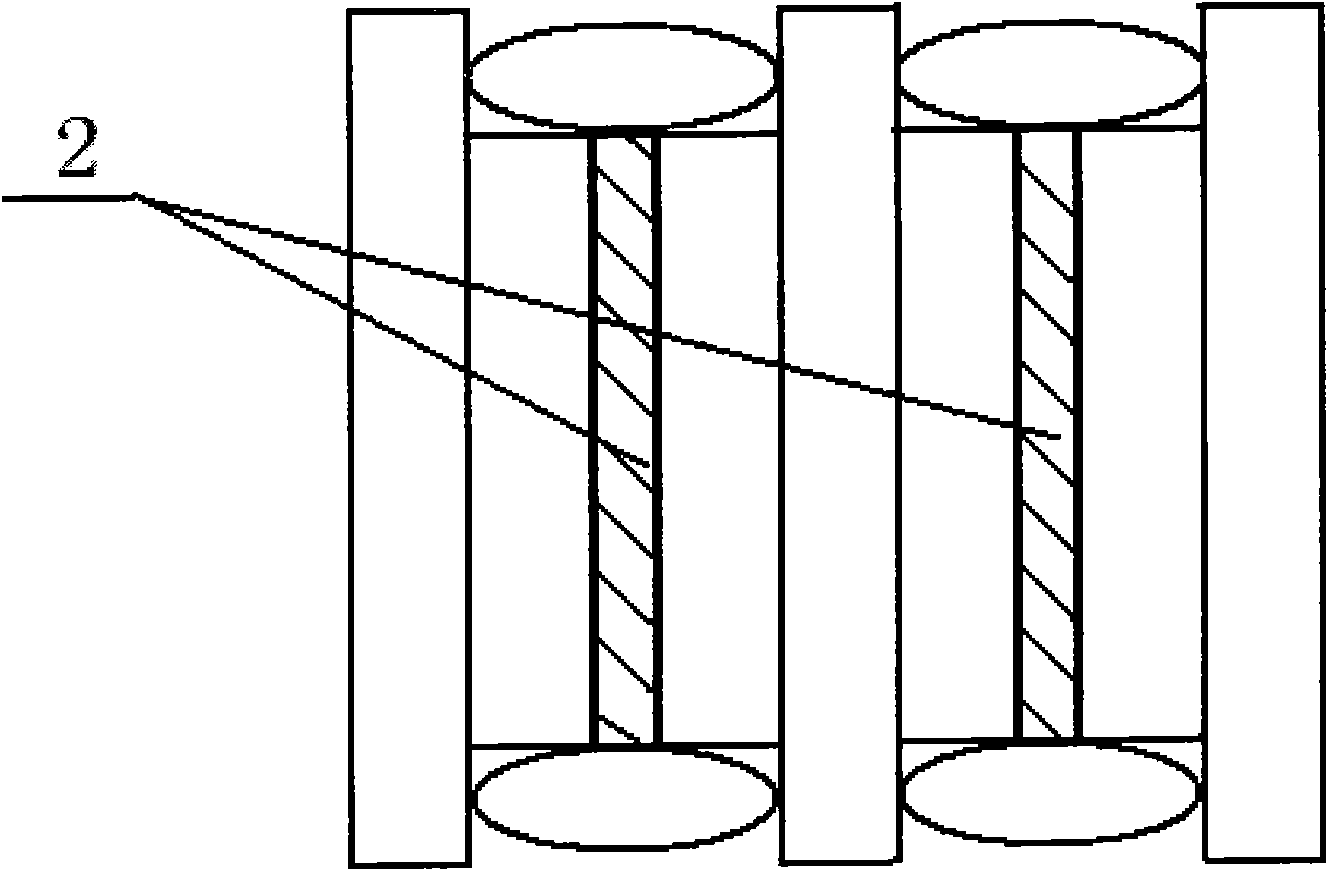

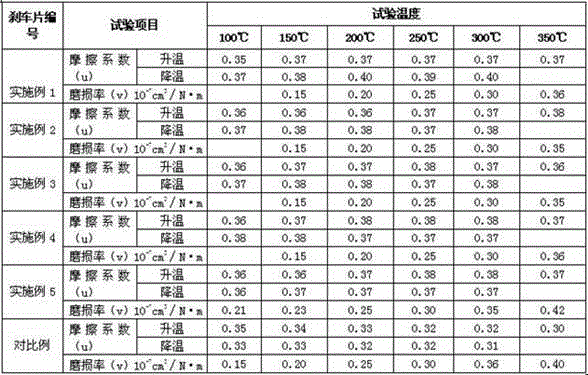

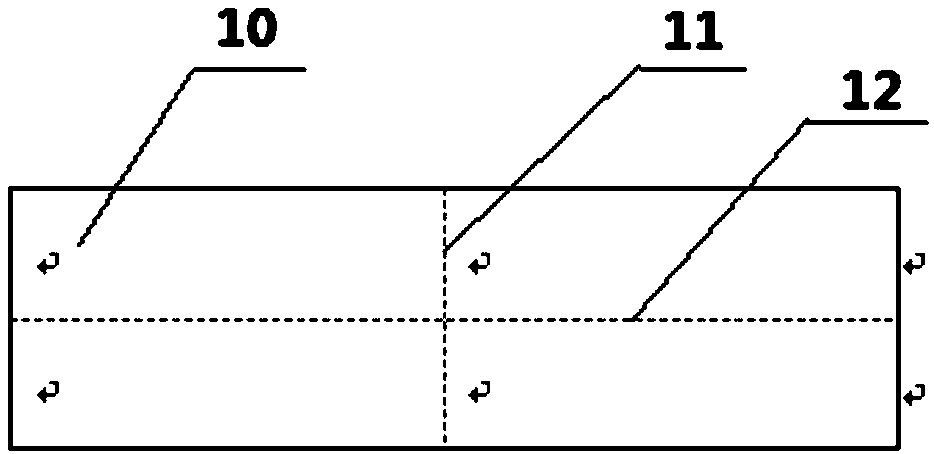

Gas diffusion layer and preparation method and application thereof

InactiveCN102110822AStable structureUniform surface distributionCell electrodesFuel cellsChemical reaction

The invention discloses a gas diffusion layer and a preparation method and application thereof. The gas diffusion layer comprises a carbon black layer (2) with the micropore diameter of 30 to 100 microns and / or a carbon fiber layer (1) with the micropore diameter of 50 to 150 microns. The gas diffusion layer can be widely applied to gas diffusion electrodes in fuel cells, electrolytic cells and ultracapacitor electrochemical reaction devices. The invention simultaneously discloses a preparation method of the gas diffusion layer. The gas diffusion layer has a simple, rational and compact structure, overcomes various defects of the prior art, and has the advantages of high air permeability, high drainage, high conductivity, stable catalyst layers and high catalyst utilization rate.

Owner:NANJING UNIV

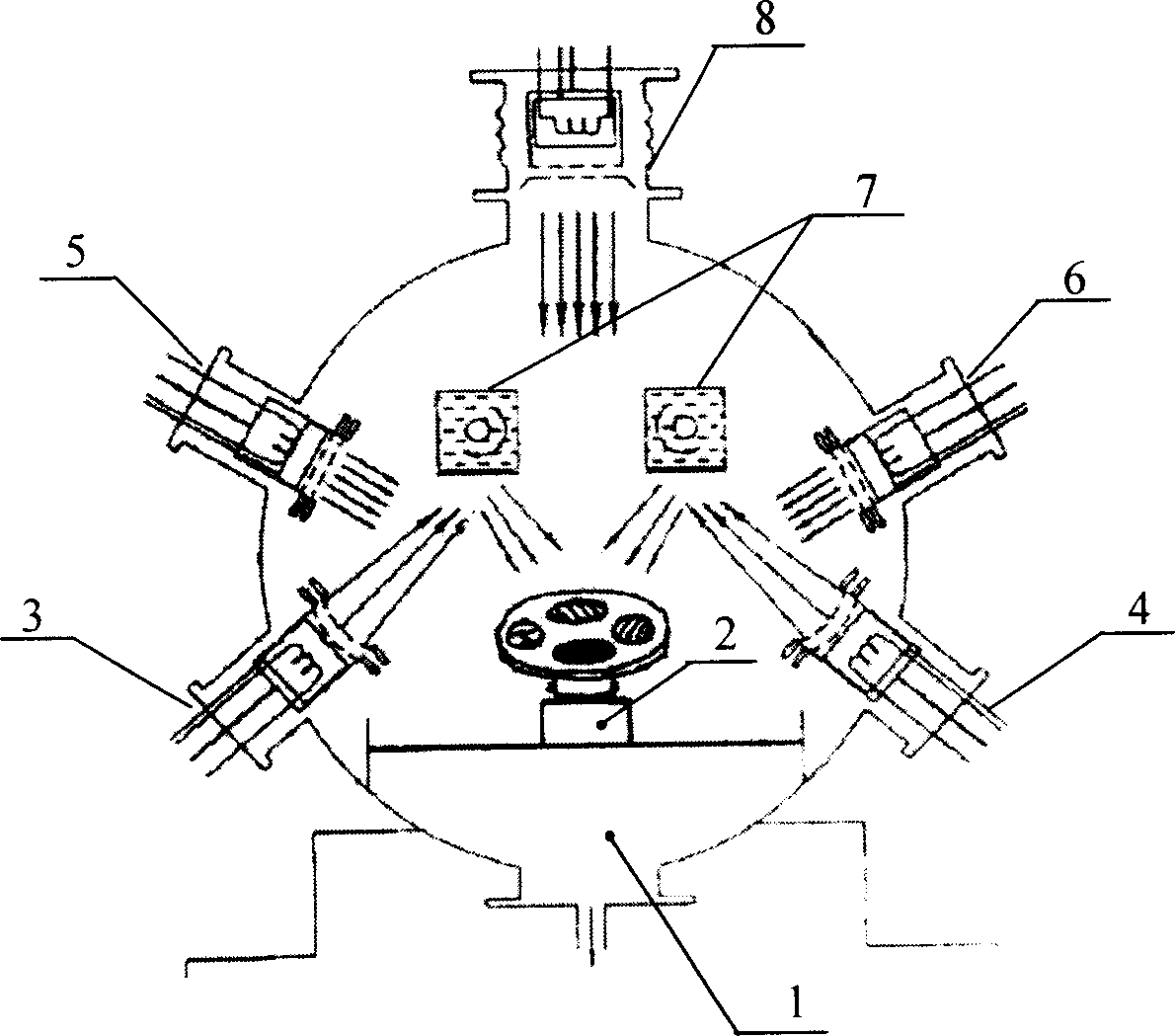

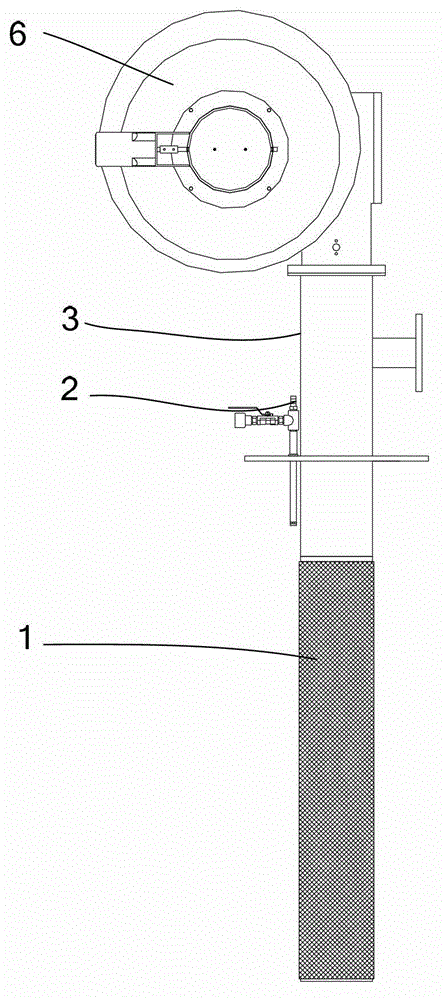

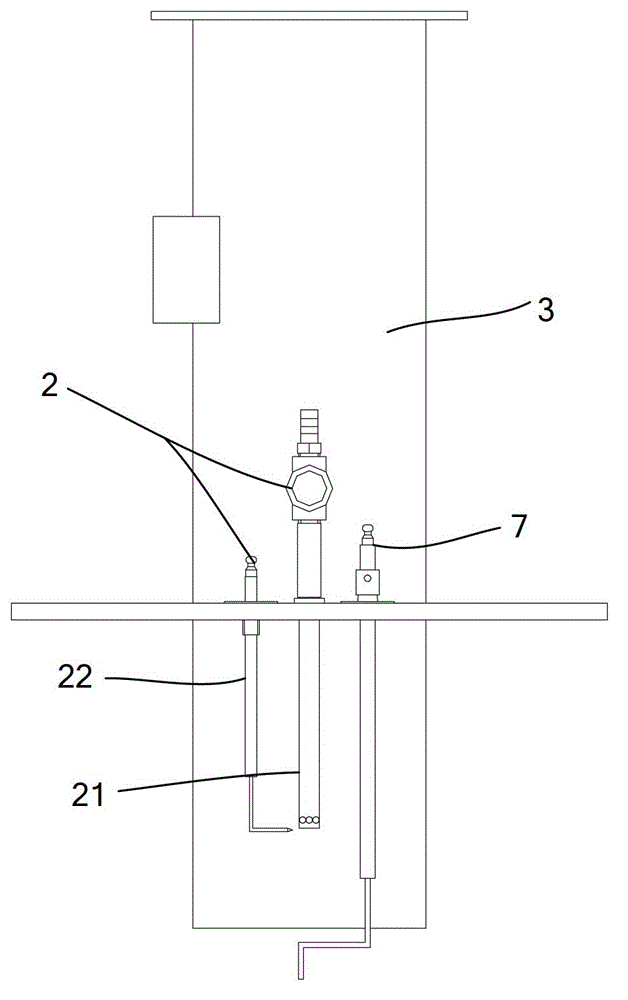

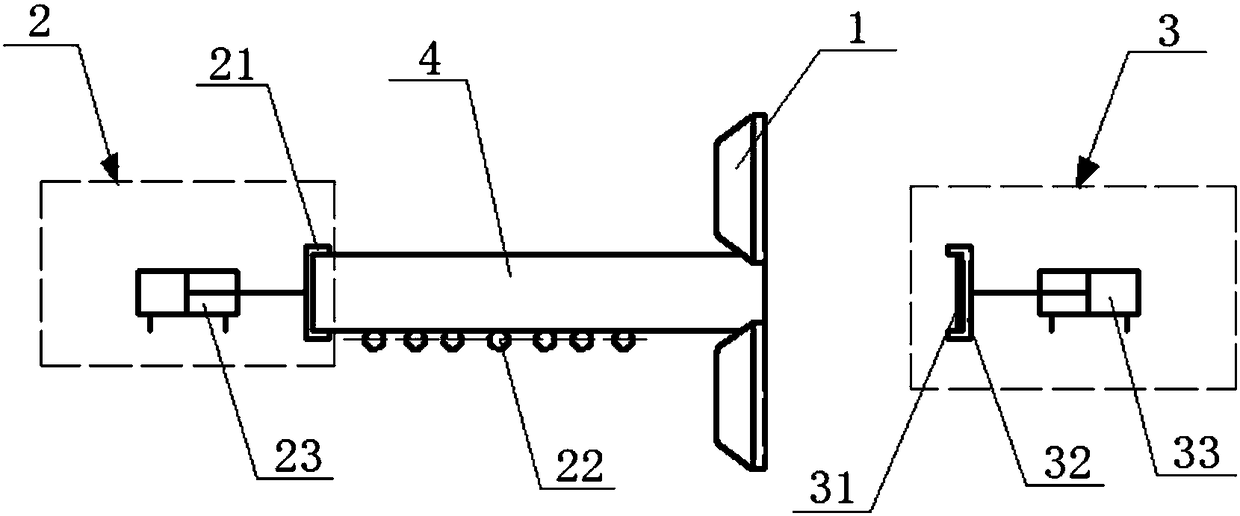

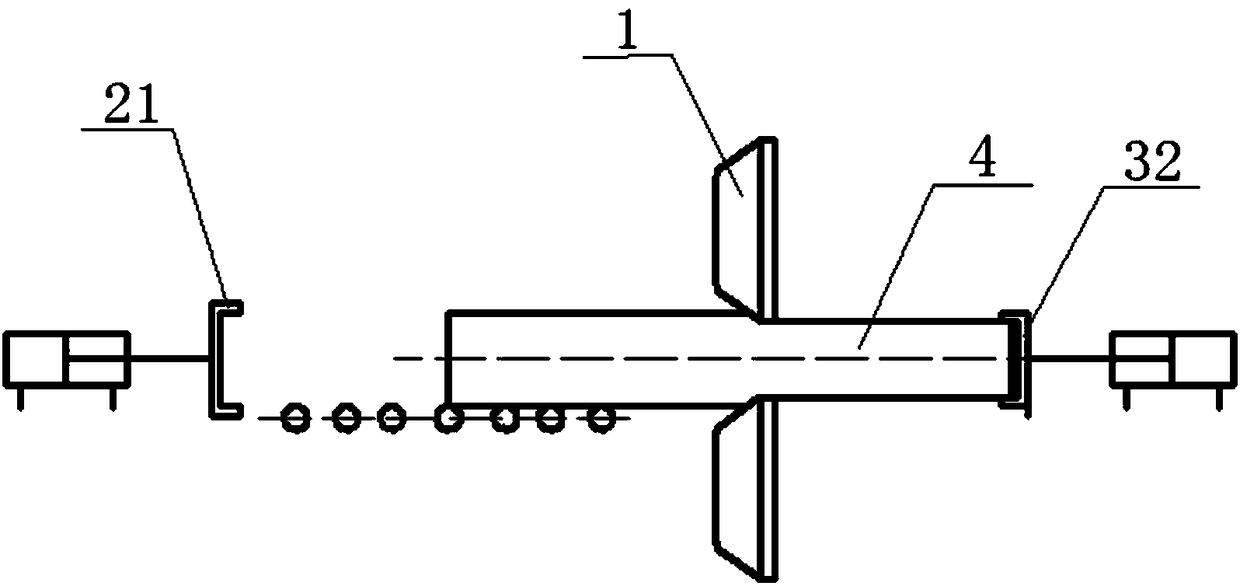

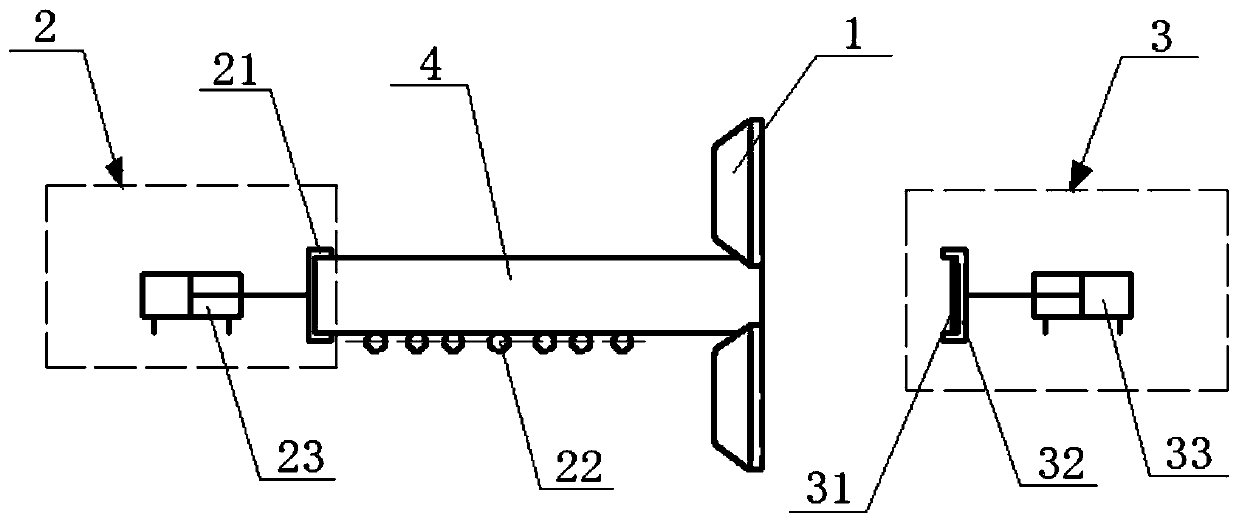

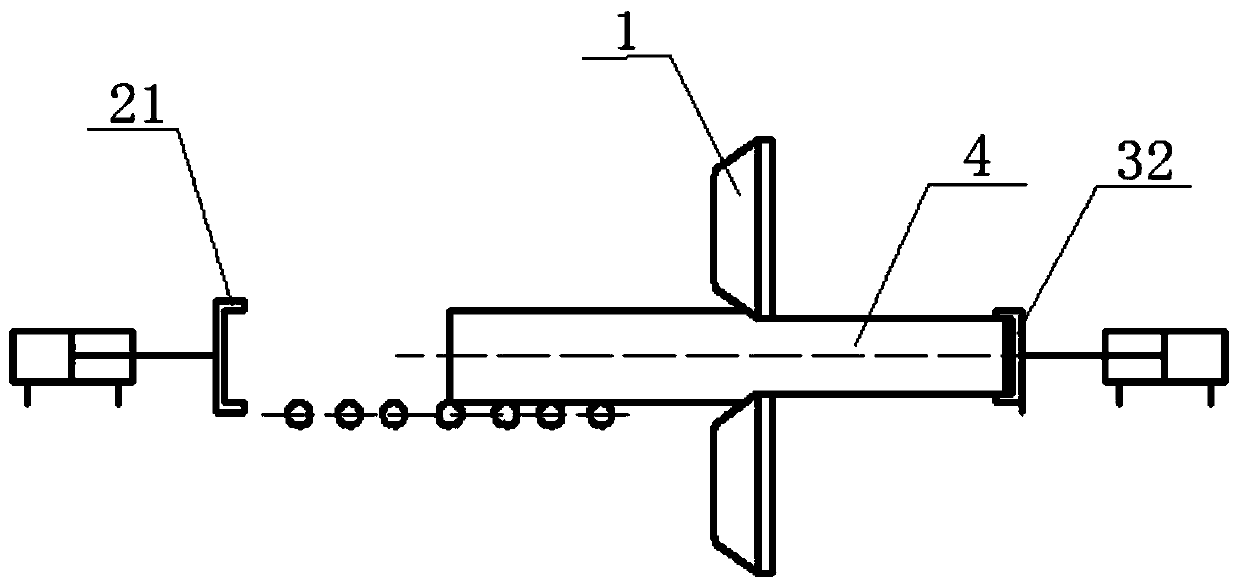

Metal fiber post-mixing type burner and boiler employing same

InactiveCN102913909AReduce volumeUniform surface distributionGaseous fuel burnerDiameter ratioMaterial consumption

The invention relates to the field of gas burners in the boiler industry, in particular to a metal fiber post-mixing type burner and a gas-fired boiler. The burner comprises a combustion head, a blower and a mixer, wherein a gas-fired swirl device is arranged in the mixer. When the burner is in operation, both fuel gas and air fed into the mixer by the blower flow into the mixer and enter the combustion head for burning after being uniformly mixed by the gas-fired swirl device. The boiler employs the above burner. According to the invention, the part of the burner in a metal fiber post-mixing burning mode, which is arranged outside the boiler, is compact in size; flame on the surfaces of the metal fibers is more uniform; the ignition reliability is improved; and the shaft diameter ratio of the combustion head is increased. The boiler is matched with the burner in a compact shape, so that more than half of the steel material consumption of the boiler is reduced and the occupied area for installation of the matched boiler is reduced by more than a half.

Owner:上海钜荷热力技术有限公司

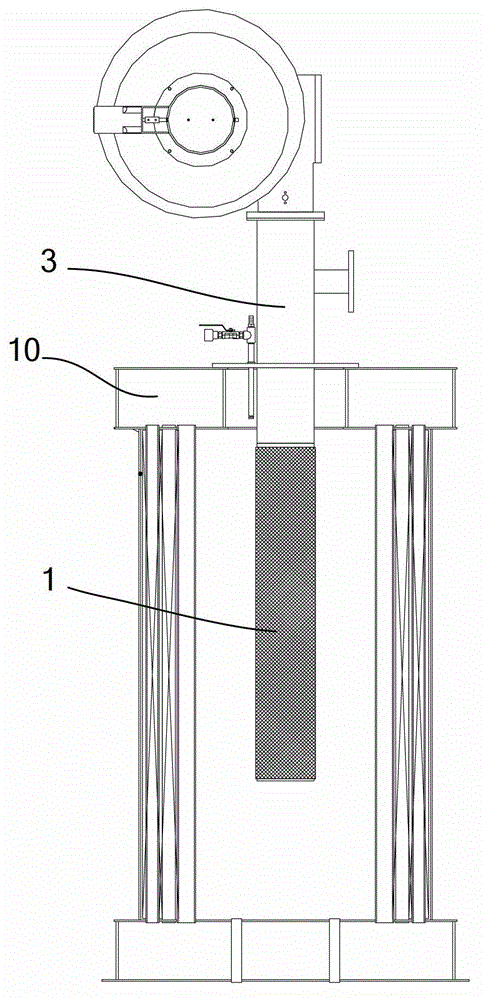

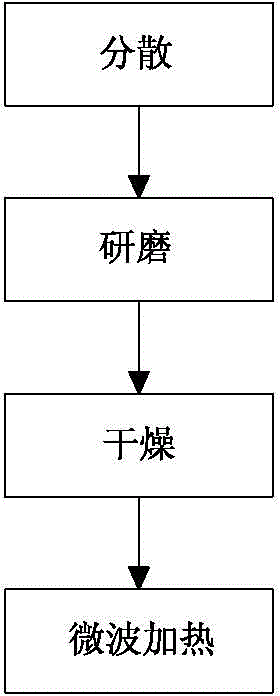

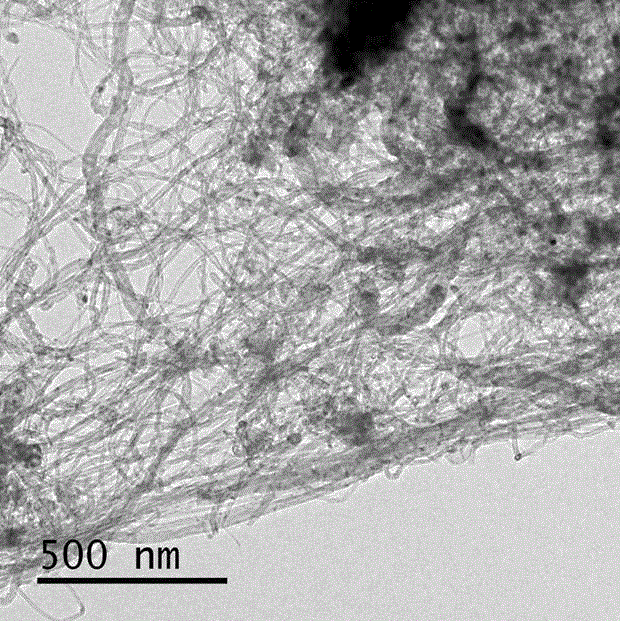

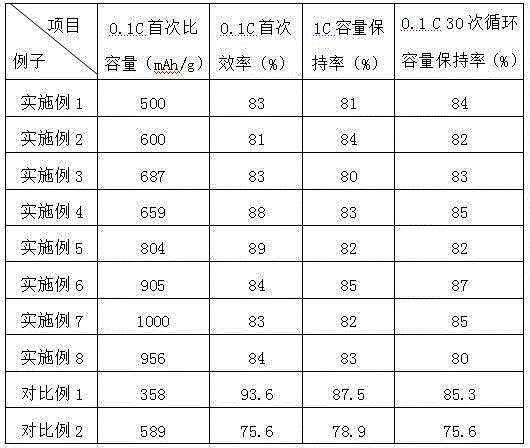

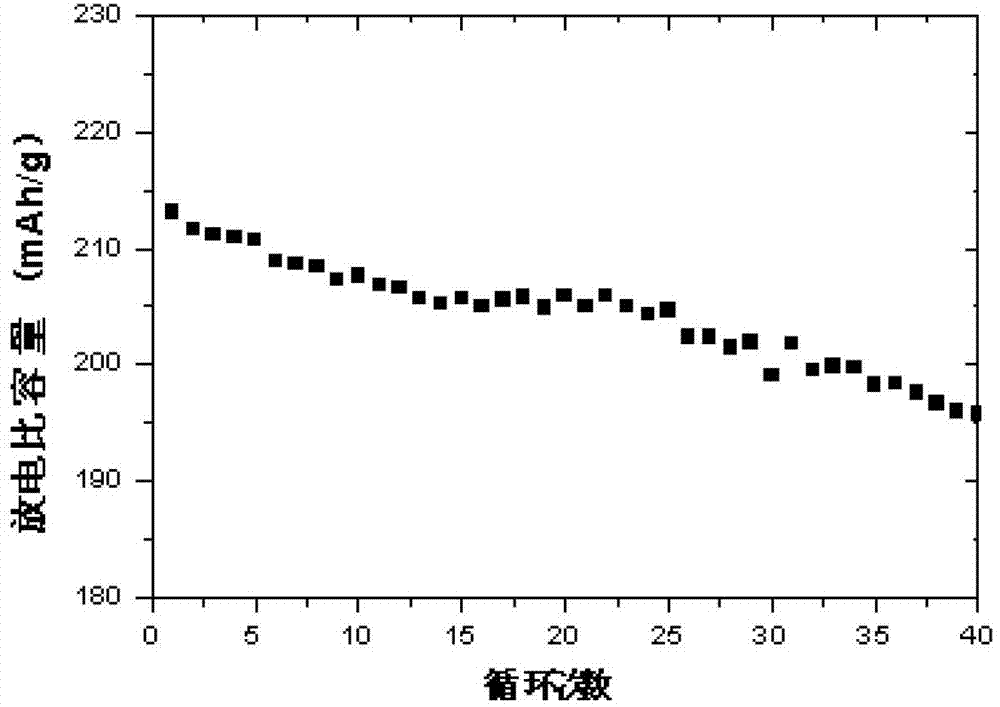

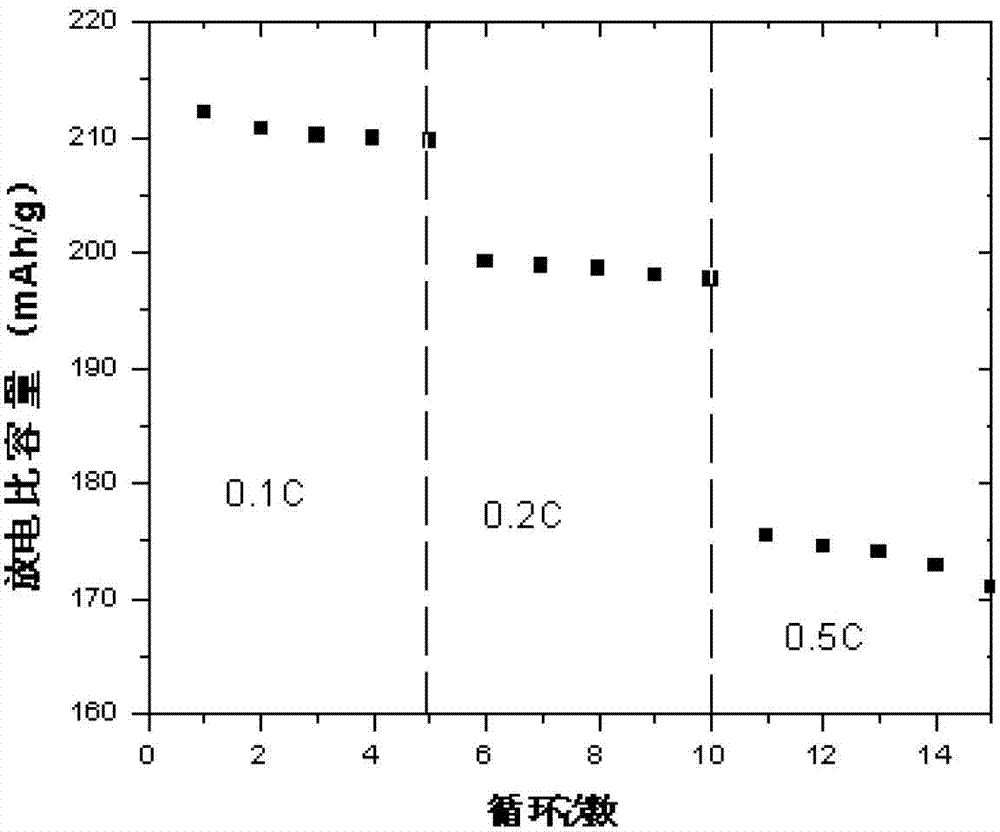

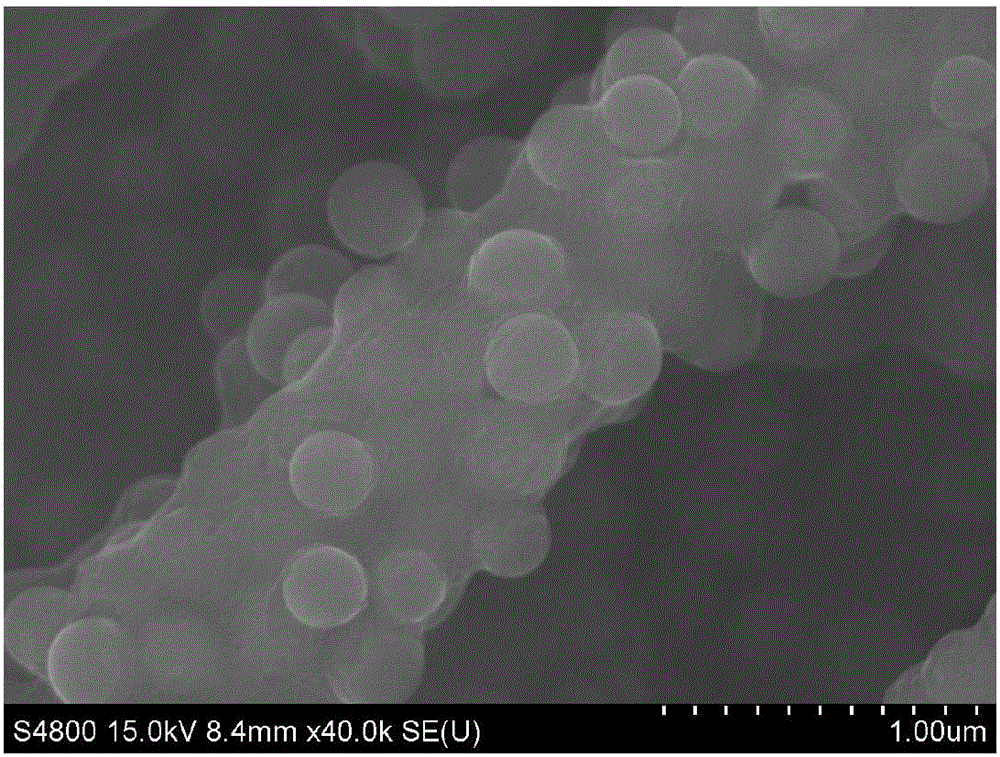

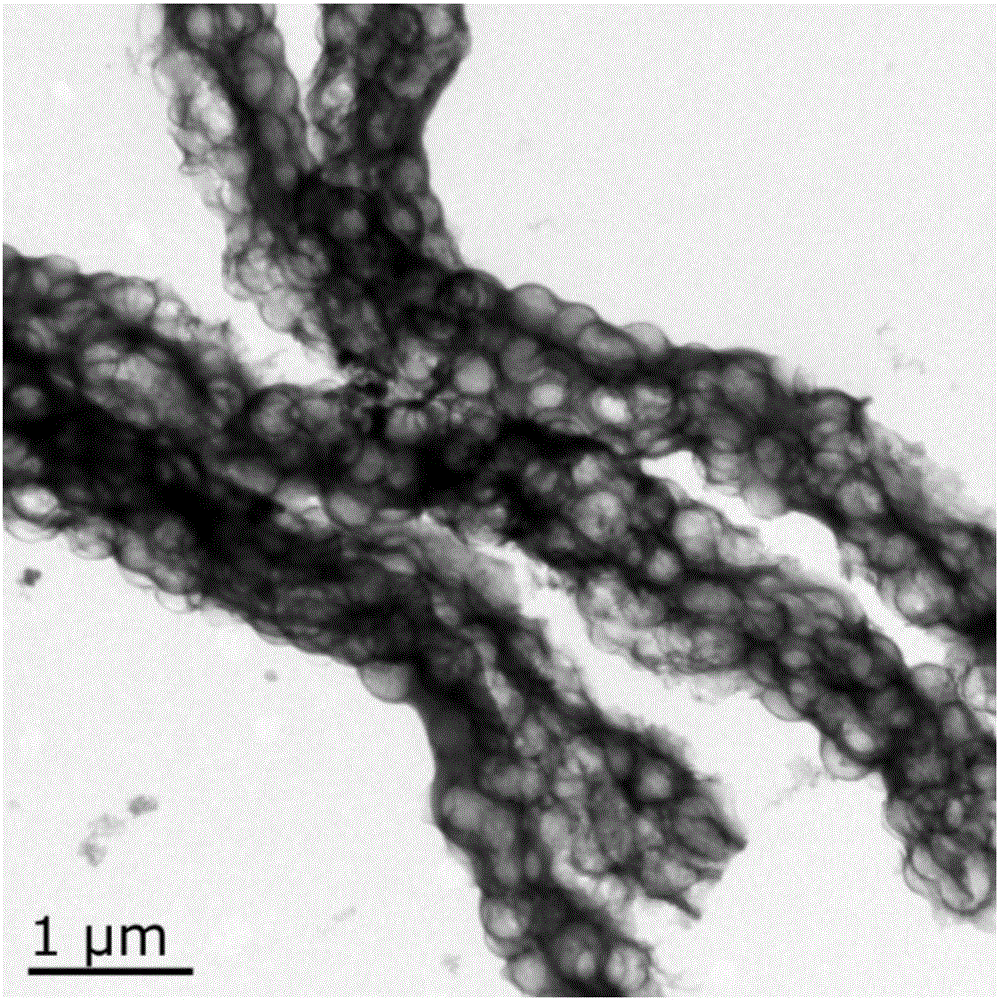

Method for preparing composite cathode material of silicon-carbon nanotube of lithium ion battery

ActiveCN104617261AAlleviate the volume expansion effectImprove conductivityNegative electrodesNanotechnologyDischarge efficiencyCarbon nanotube

The invention discloses a method for preparing a composite cathode material of a silicon-carbon nanotube of a lithium ion battery. According to the method, firstly, the surface of nano silicon is coated with a carbon source, carbon nanotubes are generated in microwave treatment, and furthermore the surface of silicon is also coated with an introduced catalyst, so that the carbon nanotubes which are coated with the carbon source and are generated through catalytic cracking are very uniformly distributed on the surface of nano silicon, the problems that in the prior art the nano silicon is high in volume expansion effect, low in first charge / discharge efficiency and poor in circulation stability are solved, and both the conductivity and the mechanical property of the composite cathode material prepared by using the method disclosed by the invention are greatly improved and the circulation property, the multiplying power charge and discharge performance and the initial charge-discharge efficiency of the composite cathode material as a lithium lion battery cathode material are all greatly improved when being compared with those of a silicon-carbon nanotube cathode material which is mixed in a mechanical ball-milling manner as silicon and carbon nanotubes are compounded in an in-situ manner in the method disclosed by the invention. In addition, the method disclosed by the invention is simple in process, and the energy consumption is greatly reduced due to the adoption of a simple and efficient microwave chemical method.

Owner:FUJIAN XFH NEW ENERGY MATERIALS CO LTD

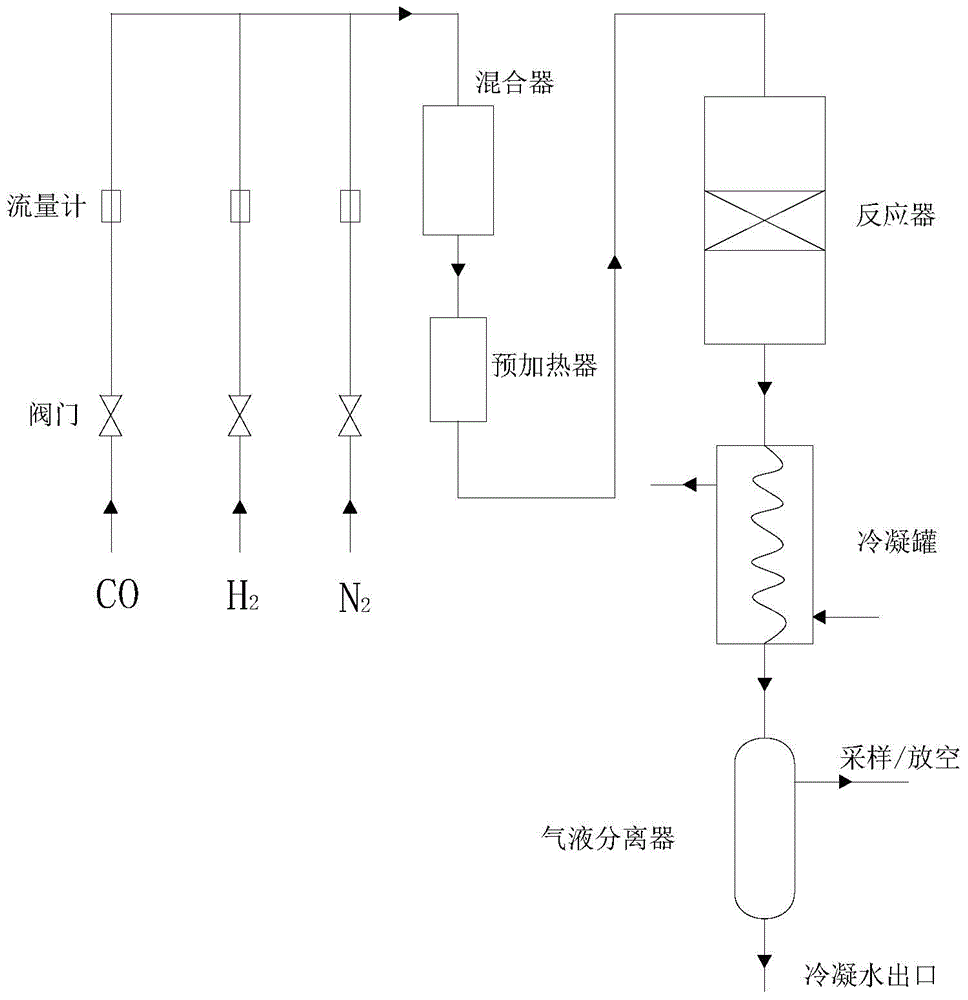

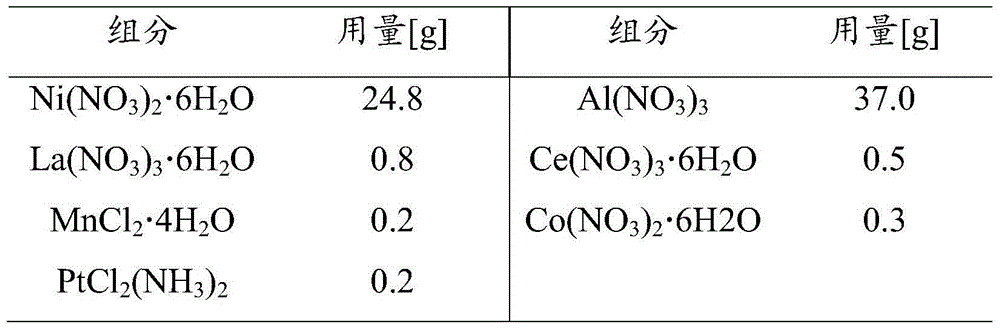

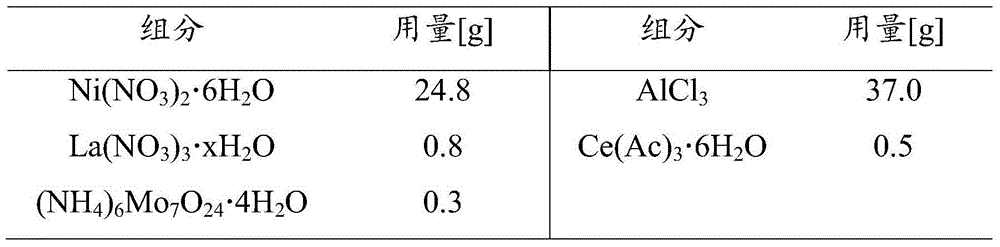

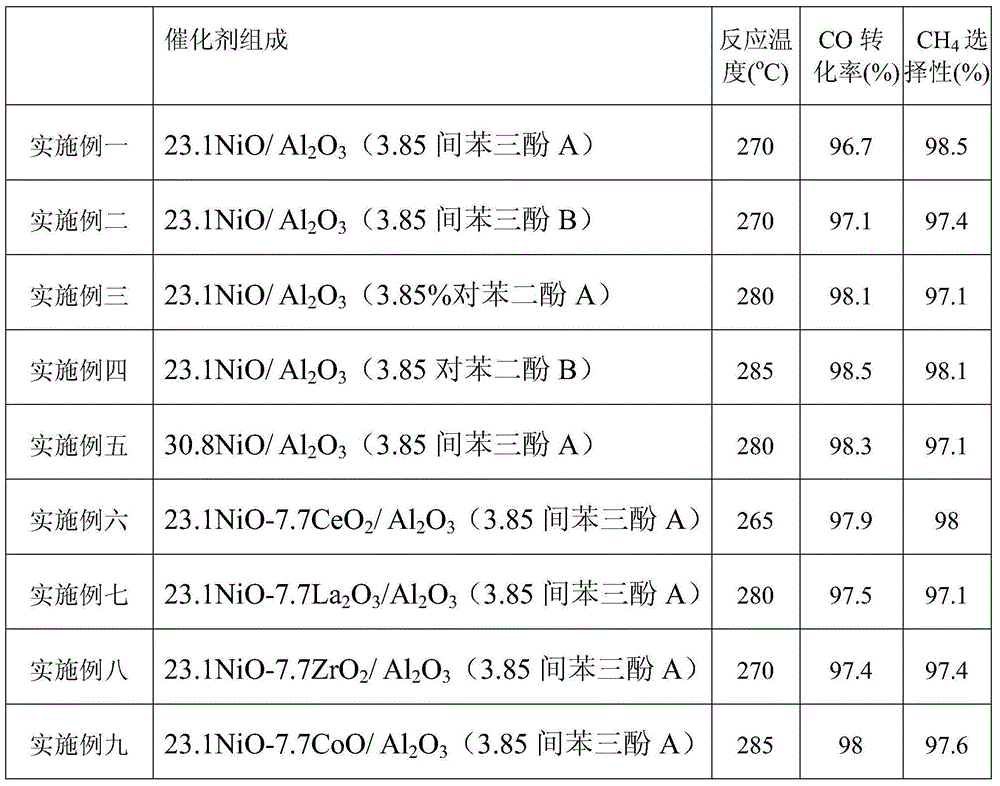

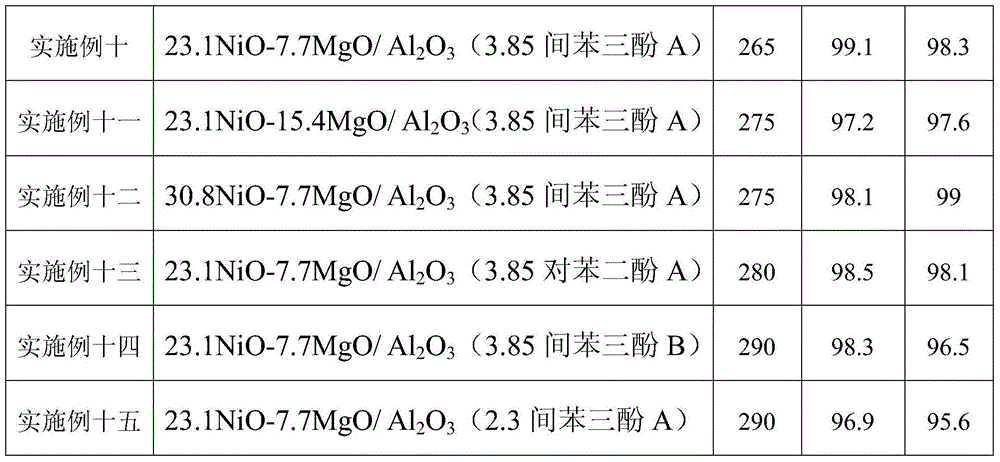

High-temperature-resistant methanation catalyst as well as preparation method thereof

ActiveCN104399491AIncrease active siteLarge specific surface areaHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsIncipient wetness impregnationOxide

The invention discloses a high-temperature-resistant methanation catalyst as well as a preparation method thereof. According to the catalyst, Al2O3 is used as a carrier, Ni is used as a primary active component, La and Ce are used as secondary components, and metallic oxides of Mn, Co, Fe, W or Mg are used as other active auxiliaries; the preparation method of the catalyst comprises the following steps: carrying out ultrasonic dispersion and coprecipitation on the primary active component Ni and a PEG (polyethylene glycol)-aqueous solution of a carrier precursor, and separating, drying and roasting to obtain a NiO-Al2O3 catalyst; then, loading the secondary components La and Ce and precursors of the active auxiliaries to the NiO-Al2O3 catalyst by adopting an incipient-wetness impregnation method; finally, roasting and carrying out reduction activation to obtain the high-temperature-resistant methanation catalyst; the catalyst has high specific surface area, and can reduce carbon deposition reaction and improve the selectivity of methane. The high-temperature-resistant methanation catalyst can maintain relatively high methanation catalytic activity for a long time at high temperatures and can be widely applied to a methanation process under a high-temperature environment.

Owner:广东省瀚思尔科技有限公司

Preparation method of loaded cobalt catalyst

ActiveCN106925274AHighlight substantiveEvenly dopedCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNanofiberReducing atmosphere

The invention provides a preparation method of a loaded cobalt catalyst, and relates to a cobalt-containing catalyst. The preparation method includes the steps that a spinel-type oxide CoAl2O4 is prepared through a sol-gel method; then, the oxide is loaded on the surface of sepiolite ore nanofiber through an impregnation method, and a CoAl2O4 / sepiolite ore nanofiber composite is obtained; then, the composite is reduced in a reducing atmosphere, and a cobalt / CoAl2O4 / sepiolite ore nanofiber composite, namely, the loaded cobalt catalyst formed by the CoAl2O4 / sepiolite ore nanofiber composite loaded with cobalt is obtained. The defects of an existing loaded cobalt catalyst that the preparation process is complex, the reaction energy consumption is high, and a product is poor in high-temperature stability and prone to agglomeration at a high temperature are overcome.

Owner:HEBEI UNIV OF TECH

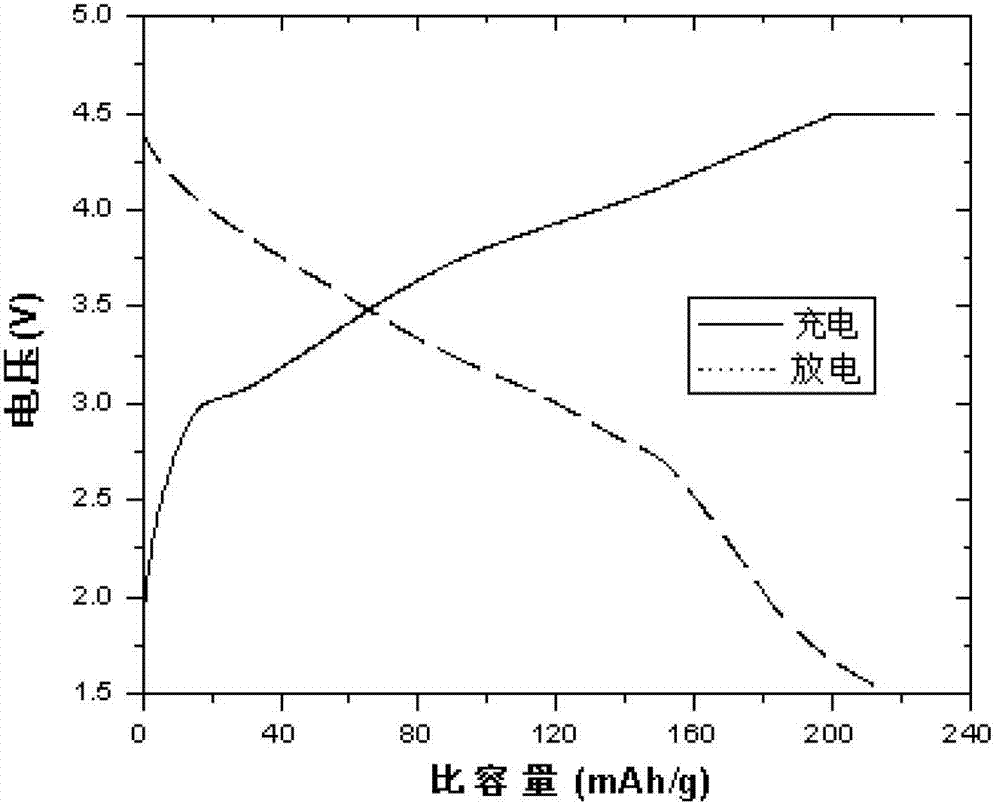

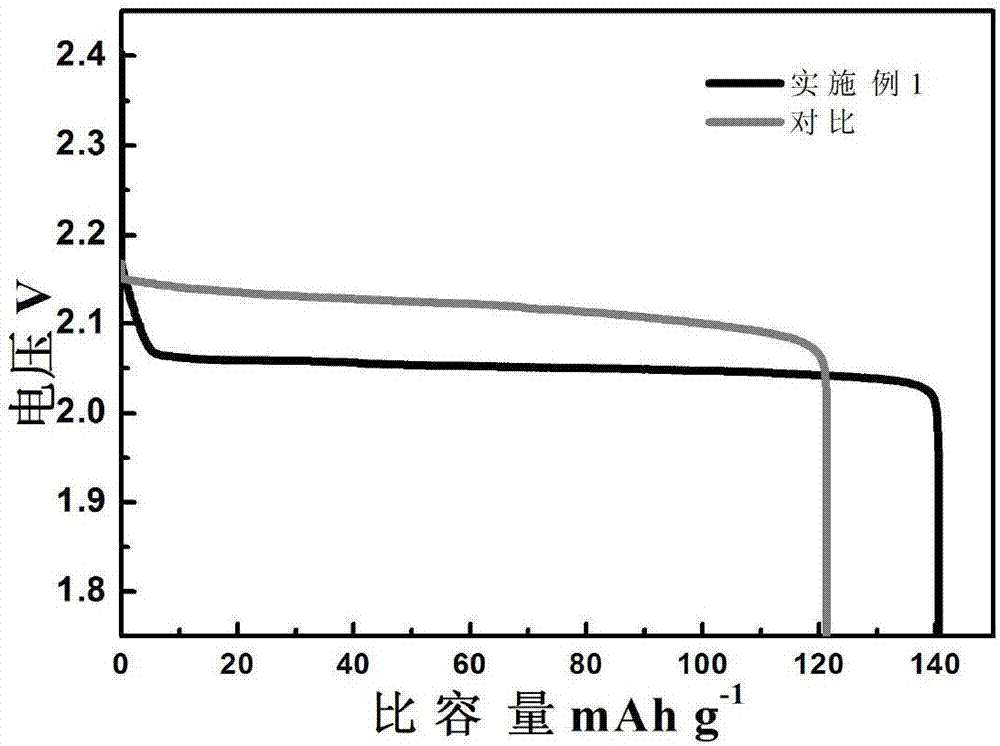

Composite silicate and carbon composite material, preparation method of composite material, and lithium ion battery containing composite material

ActiveCN102969503AUniform surface distributionSimple operation processCell electrodesCarbon compositesManganese

The invention discloses a composite silicate and carbon composite material, a preparation method of the composite material, and a lithium ion battery containing the composite material. The general formula of the composite silicate prepared by using the method is Li2FexMn(1-x)SiO4, wherein x is greater than or equal to 0 and smaller than or equal to 1. The preparation method comprises the following steps: (1) mixing a lithium compound, a ferrum compound, a manganese compound, a silicon compound and a carbon source; and (2) carrying out firing under inert atmosphere, so as to obtain Li2FexMn(1-x)SiO4 and carbon composite material. The preparation method is simple in technology and the cost is low. By using the method, both the surfaces of the composite silicate and the interiors of gaps of the composite silicate can be coated with the carbon. A conductive network can be formed in the way that the carbon is coated on the surface and in the gaps of the composite silicate, so that the conductivity of the composite material of the composite silicate and the carbon is enhanced; in addition, the composite material of the composite silicate and the carbon can be prevented from being dissolved and corroded by electrolyte; and the volume change resulting from a jahnteller effect of Mn<3+> is relieved.

Owner:CHERY AUTOMOBILE CO LTD

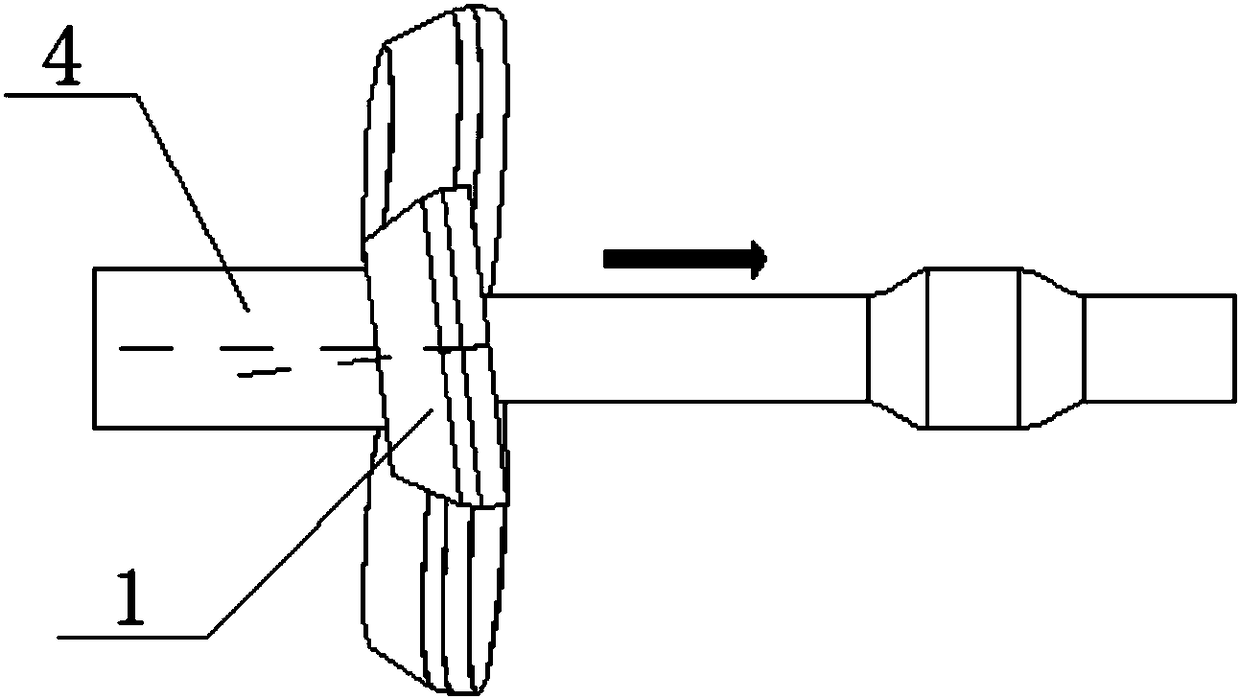

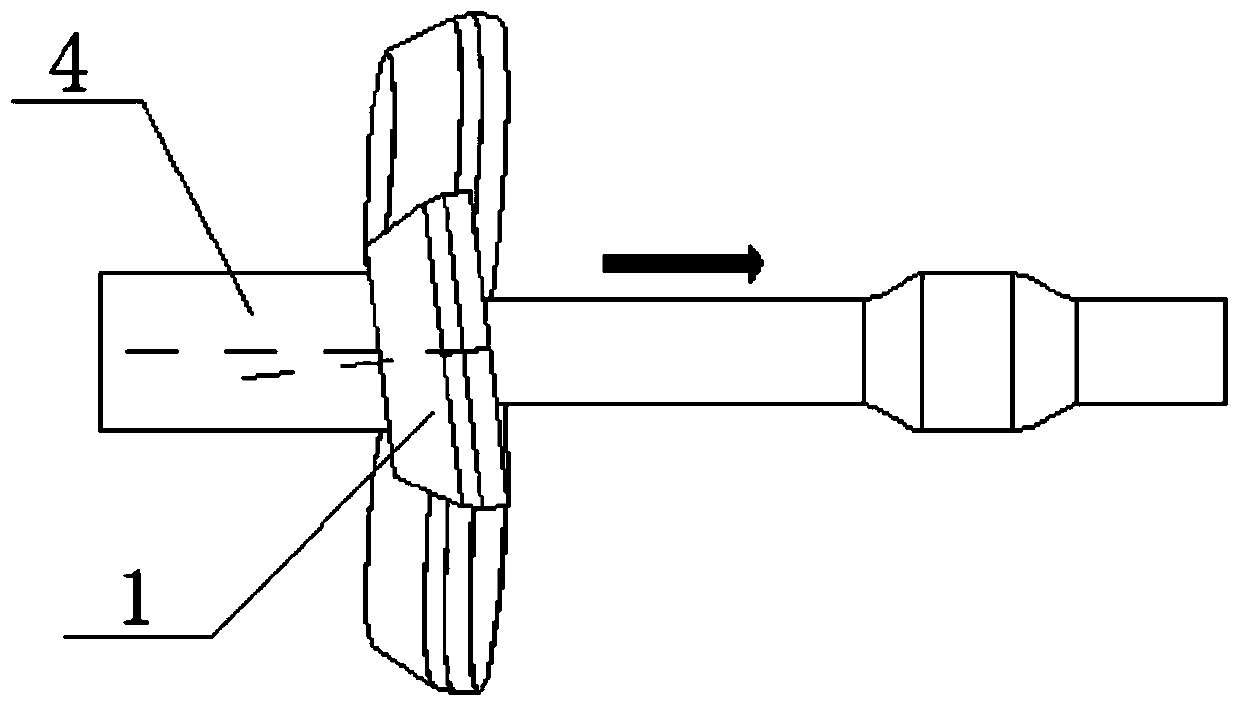

Three-roller inclined rolling forming method of rail vehicle axles

The invention discloses a three-roller inclined rolling forming method of rail vehicle axles. The method is characterized in that rods are heated and fed into a three-roller inclined rolling machine through an axial pushing device; three inclined rollers are engaged with the rods at the same time, and drive the rods to rotate; meanwhile, the axial pushing device pushes the rods to axially move ata constant speed; a radial driving mechanism controls radial movement of the inclined rollers according to diameter requirements of rail vehicle axles needing to be machined; when the rods axially move to contact with an axial guide device, the axial guide device tows the rods to continuously move axially at a constant speed; meanwhile, the rods are deviated from the axial pushing device; and after machining is finished, large-diameter long step shafts-rail vehicle axles are obtained. The method has the advantages of simple mold manufacturing, uniform distribution of force on the surfaces of rolled parts, capability of effectively reducing wear of the rollers in the inclined rolling process, capability of realizing light construction of the rolling machine and effective prolonging of the service life of the rolling machine.

Owner:NINGBO UNIV

Preparation method of magnetic controlled ultra paramagnetism nanometer carbon pipe

InactiveCN100999319AUniform and controllable sizePrecisely control the magneticNanostructure manufactureInorganic material magnetismIron saltsCarbon nanotube

This invention relates to a preparation method of magnetism controllable superparamagnetism nanometer carbon tube, it relates to preparation technique domain of superparamagnetism nanometer carbon tube. Its preparation step is: 1. add nanometer carbon tube in polyalcohol, disperse with super sound; 2. add metallic organic iron compound or inorganic iron salt; 3. heat to boiling; 4. cool to room temperature; 5. add low polar solvent or nonpolar solvent, flocculate and precipitate, adsorb by magnet, dry, and get magnetic nanometer carbon tube. This invention has high reaction efficiency. Size of ferric oxide nanoparticle is uniform and controllable. Diameter is between 4-20 nanometers. Wrapping degree is uniform and controllable. It can exactly control magnetism of prepared magnetic nanometer carbon tube.

Owner:HARBIN INST OF TECH

Short carbon fiber aluminum based composite material and preparation method thereof

ActiveCN108203794AThicker and more uniformUniform thicknessLiquid/solution decomposition chemical coatingFiberDispersity

The invention discloses a short carbon fiber aluminum based composite material and a preparation method thereof. The preparation method comprises the steps of surface processing, chemical copper plating, mixing, sintering, etc.; the prepared short carbon fiber aluminum based composite material comprises the following components in percentage by mass: 8-10% of copper plating short carbon fibers, and 90-92% of aluminum powder, wherein the length of the copper plating short carbon fibers is 2-3mm, and the diameter is less than 20 microns; the thickness of a copper plating layer is 1 micron; the particle size of the aluminum powder is 20-100 microns; the measurement result shows that the density of the short carbon fiber reinforced aluminum based composite material is 98.5%, the hardness is 92.38Mpa, the tensile strength is 202.05Mpa, and the bending resistance is 376.05Mpa. With the adoption of the method, the technical problem of low dispersity of short carbon fibers in the composite material can be solved; the prepared short carbon fiber aluminum based composite material is outstanding in performances and meets the use demands of special situations.

Owner:CENT SOUTH UNIV

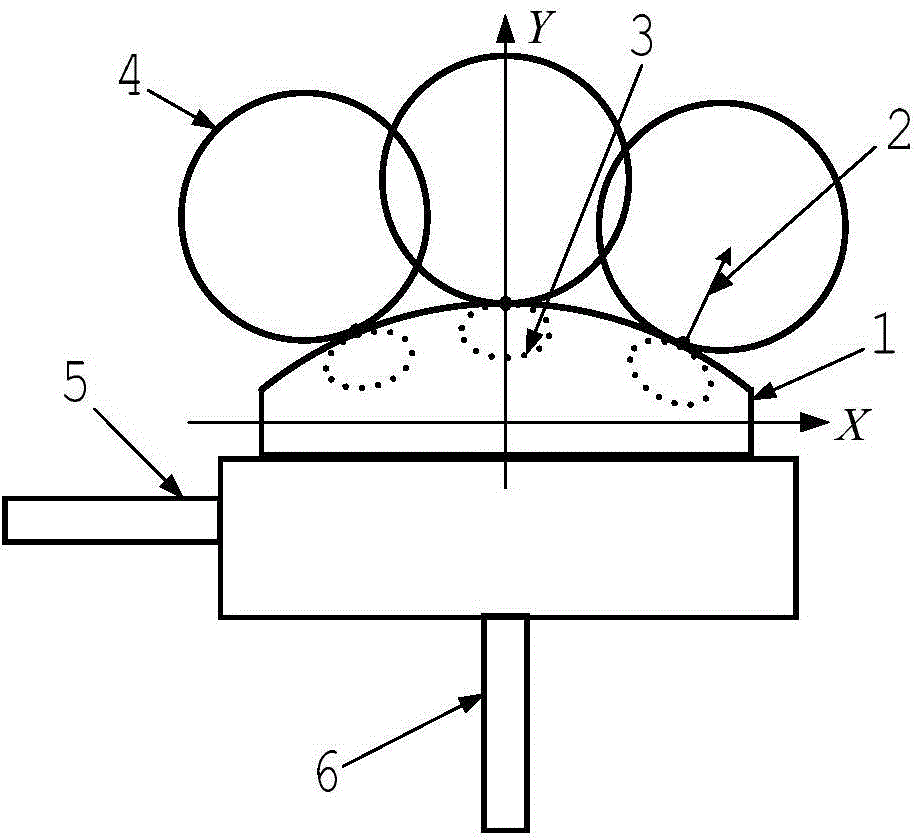

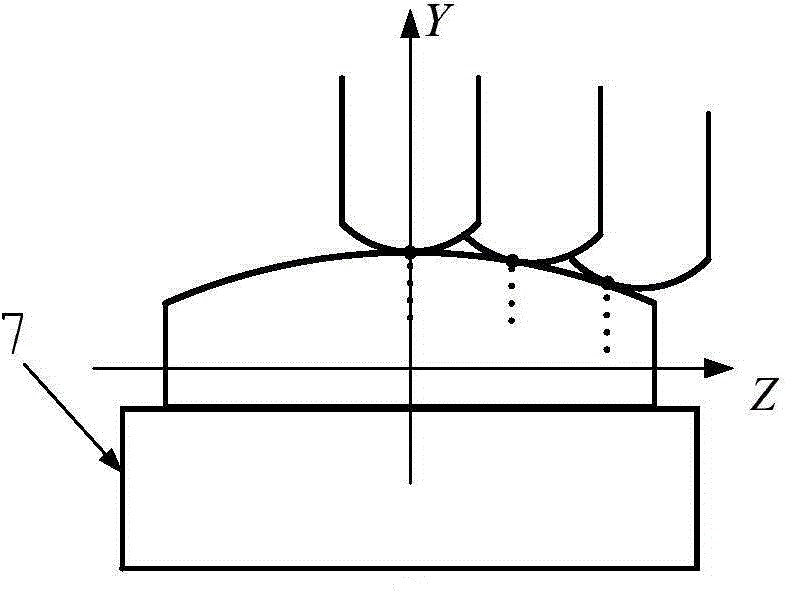

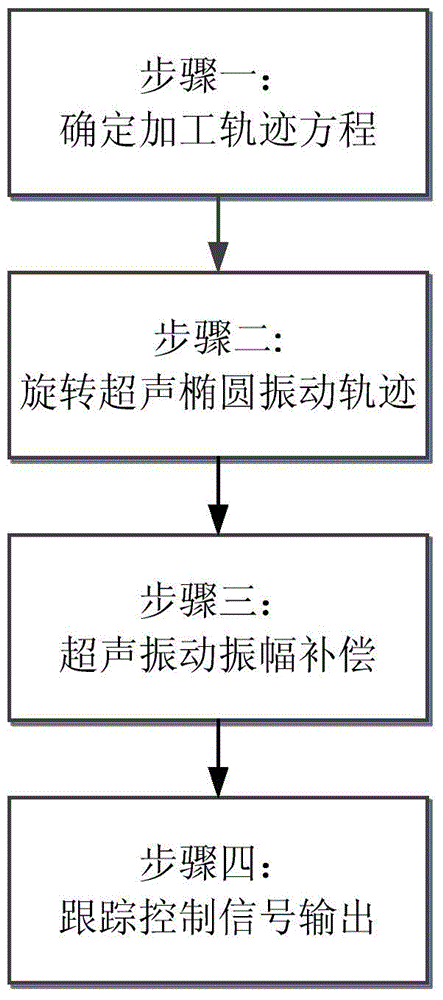

Vibration locus tracking control method for two-dimensional ultrasonically-assisted grinding

ActiveCN104889829AUltrasonic vibrations have the same effectReal-time control of vibration trajectoryAutomatic grinding controlUltrasound attenuationControl signal

The invention relates to a vibration locus tracking control method for two-dimensional ultrasonically-assisted grinding. The method includes the steps that an XOY section machining locus equation is determined according to a machining locus and step length; programming is performed through programming software of a wave function generator, and the ultrasonic elliptical vibration locus is rotated by one angle according to the included angle between tangent lines at machining points of the machining locus equation and the X axis, so that the relative attitude between the elliptical vibration locus and the normal of the machining points is kept unchanged in the machining process; different degrees of amplitude attenuation, generated along with changing of the machining points, of the ultrasonic elliptical vibration locus are compensated for, so that the shape of the ultrasonic elliptical vibration locus is kept unchanged at the machining points; an amplitude transformer outputs ultrasonic vibrations which are controlled by tracking control signals and have corresponding amplitudes, frequencies and phases; finally, the two ultrasonic vibrations are superposed into the ultrasonic elliptical vibration locus at a needed attitude, so that the vibration effects of the machining points are kept uniform, the machining effect of uniform surface distribution of an optical aspherical surface workpiece is achieved, and accordingly surface quality and machining precision of the optical aspherical surface workpiece are improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Preparation method for MnO2/C composite fibres

InactiveCN105926083AUniform surface distributionEasy to prepareElectro-spinningConjugated artificial filamentsCapacitanceCarbon fibers

The invention discloses a preparation method for MnO2 / C composite fibres. The preparation method comprises the following steps: dissolving SiO2 in DMF (Dimethyl Formamide) solution, dispersing the SiO2 uniformly by ultrasound, then, adding PVP (Polyvinyl Pyrrolidone) and PAN (Polyacrylonitrile), stirring uniformly to obtain a spinning solution, and performing electrostatic spinning on the spinning solution to obtain SiO2 / PAN / PVP mixture fibres; calcining the SiO2 / PAN / PVP mixture fibres in a vacuum tube furnace to obtain SiO2 / C fibres; soaking the SiO2 / C fibres in a NaOH solution of, and washing and drying the soaked SiO2 / C fibres to obtain nitrogen-doped porous fibres; adding the nitrogen-doped porous fibres to an acidic KMnO4 solution in an ice bath to obtain MnO2 / C composite fibres. The MnO2 / C composite fibres prepared by the preparation method have the diameters of 1mm and have high specific capacitance, and serve as a super-capacitor electrode material; SiO2-removed hollow structures are formed in the MnO2 / C composite fibres.

Owner:NANJING GUOXUAN BATTERY CO LTD

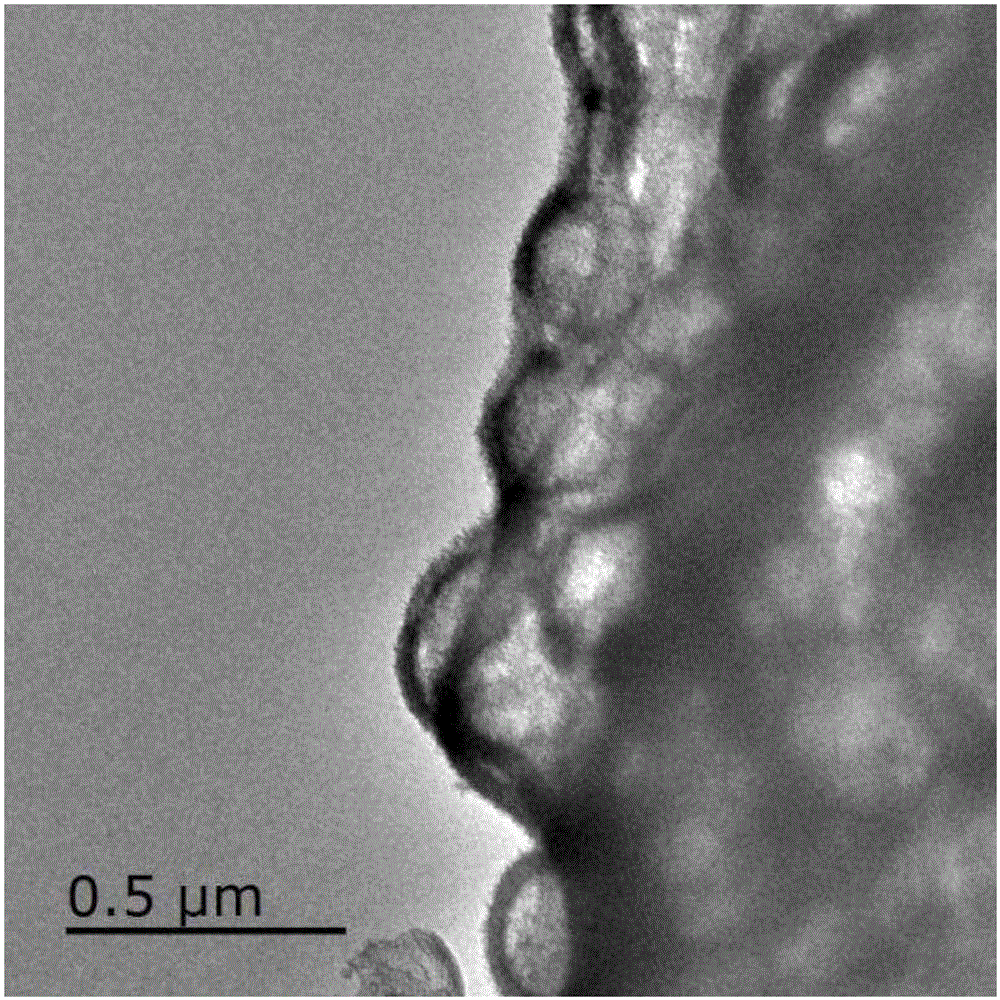

Micro-copper-formulated ceramic brake pad

InactiveCN103821859ALight weightUniform surface distributionOther chemical processesFriction liningSulfideBoron nitride

A micro-copper-formulated ceramic brake pad is made with aramid pulp, carbon fiber, magnesium hydroxide, copper fiber, brown fused alumina, antimony sulfide, ceramic fiber, superfine iron oxide powder, calcium sulfate whisker, potassium titanate, barite, crystalline flake graphite, calcined petroleum coke, nano hollow float beads, flake aluminum powder, nitrile butadiene rubber powder, cashew nut shell oil modified phenolic resin, zirconite, boron nitride, zinc oxide, and benzoxazine resin. The components are reasonably matched, and advantages of the materials can be given to full play in abrasive materials. The novel fiber materials are reasonably composited, performance defects of the materials can be mutually complemented, and high performance is achieved through mutual connective action. The micro-copper-formulated ceramic brake pad has low content of heavy metals and smaller than 0.5% of copper content and therefore, is very environment friendly.

Owner:RUIYANG AUTOMOTIVE MATERIALS XIANTAO

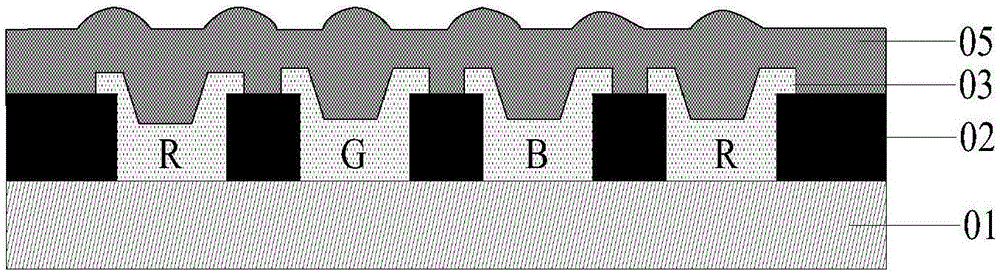

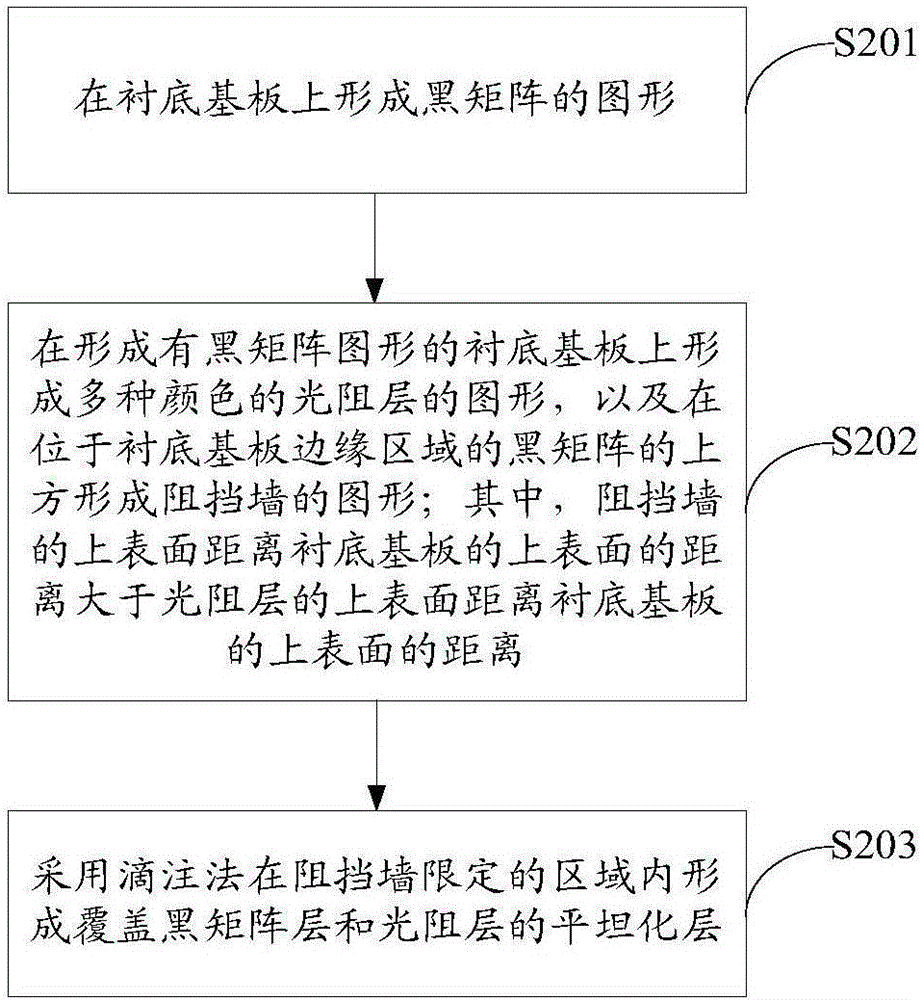

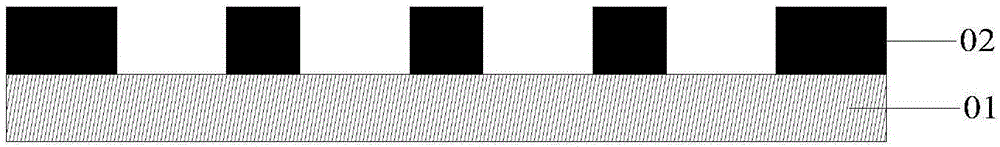

Color film substrate, manufacture method of color film substrate, liquid crystal display and display device

InactiveCN106773215AImprove display uniformityImprove qualityNon-linear opticsLiquid-crystal displayDisplay device

The invention discloses a color film substrate, a manufacture method of the color film substrate, a liquid crystal display and a display device; a barrier wall pattern having a distance from its upper surface to the upper surface of a substrate base plate greater than a distance from the upper surface of a photoresist layer to the upper surface of the substrate base plate is formed above a black matrix in the peripheral area of the substrate base plate, and a flat layer covering the black matrix layer and the photoresist layer is formed in an area defined by a barrier wall by means of dripping method; since material for forming the flat layer by the dripping method has low viscosity, it can be guaranteed that material flows fully in the area defined by the barrier wall, the surface of the flat layer in the display area is distributed evenly, and the flat layer in the display area of the color film substrate is flatter. Therefore, by applying the color film substrate to liquid crystal displays, the liquid crystal display can provide improved displaying uniformity, and the quality of the liquid crystal display is improved accordingly.

Owner:BOE TECH GRP CO LTD +1

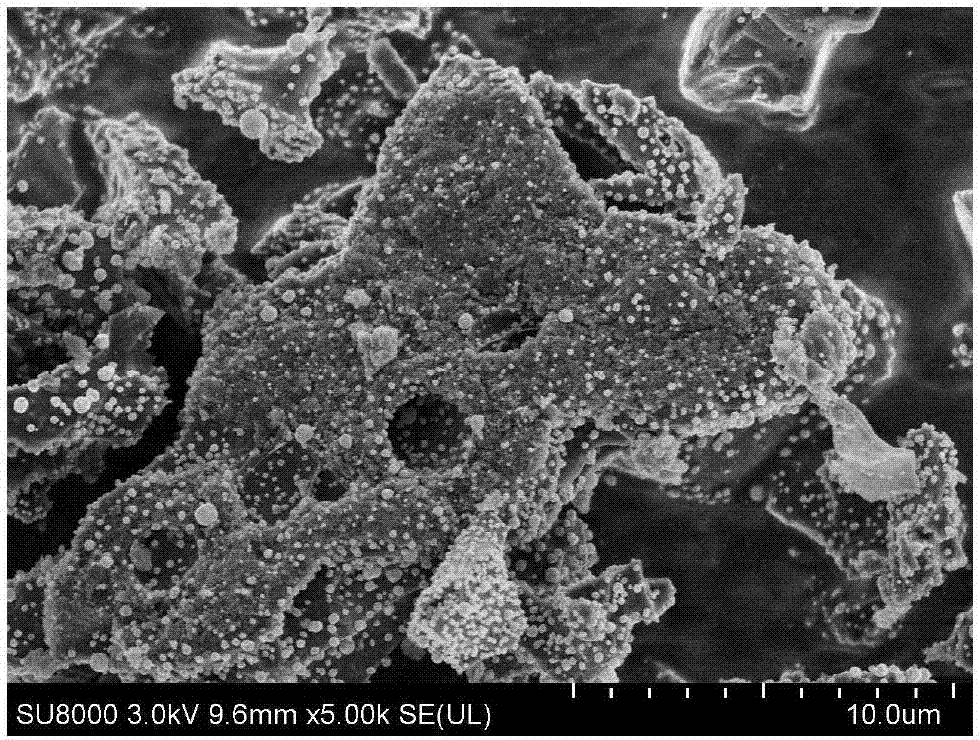

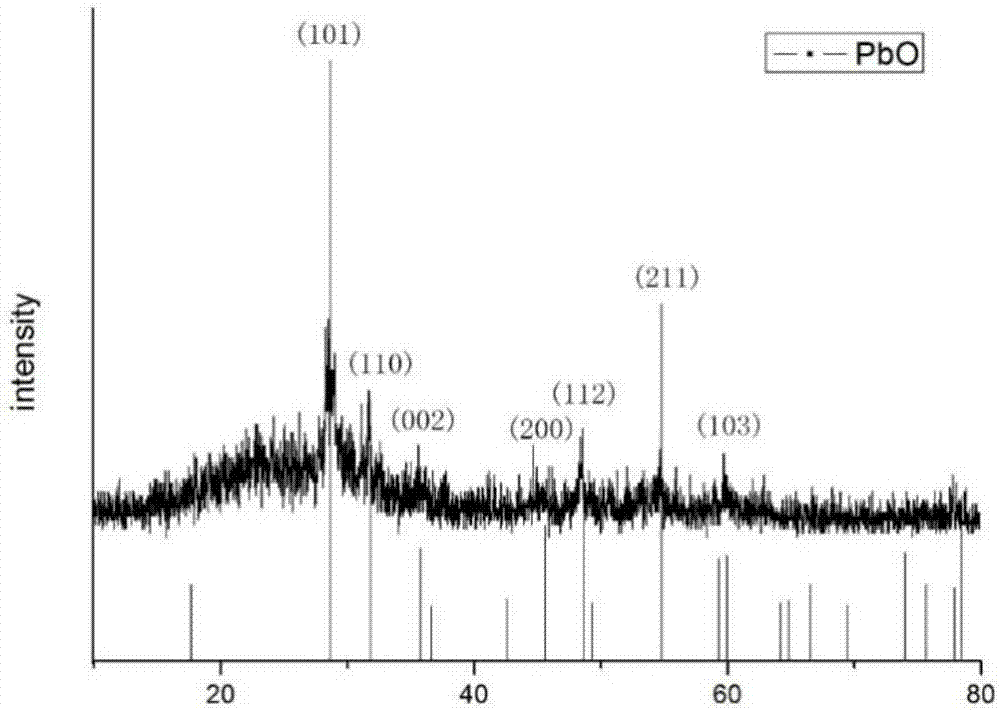

Preparation method of carbon-based composite material for cathode of lead-carbon battery

The invention relates to a preparation method of a carbon-based composite material for a cathode of a lead-carbon battery, which can prepare a carbon-based lead compound composite material with a controllable proportion, wherein the lead compound uniformly distributes on the surface of carbon material and maintains the original structure character of the carbon material. The preparation method isas follows: the carbon material and a lead ion solution are uniformly mixed in a reaction vessel, a precipitant is slowly dropped, the lead ions are completely deposited on the surface of the carbon material, then filtered, washed and dried to obtain a precursor, and the composite material is obtained through high temperature treatment, and mass ratio of lead compounds is between 1% to 90%. The composite material and the active substances of cathode of lead-acid battery can be better combined by the lead oxide particles on the surface, while the cathode capacity of the cathode of the battery prepared by using the composite material additive is obviously increased, the hydrogen evolution of the cathode is reduced, cathode active material utilization rate is also greatly improved, and the cycle life of high-rate charge-discharge of partial charge state of the cathode is significantly prolonged.

Owner:吉林省凯禹电化学储能技术发展有限公司

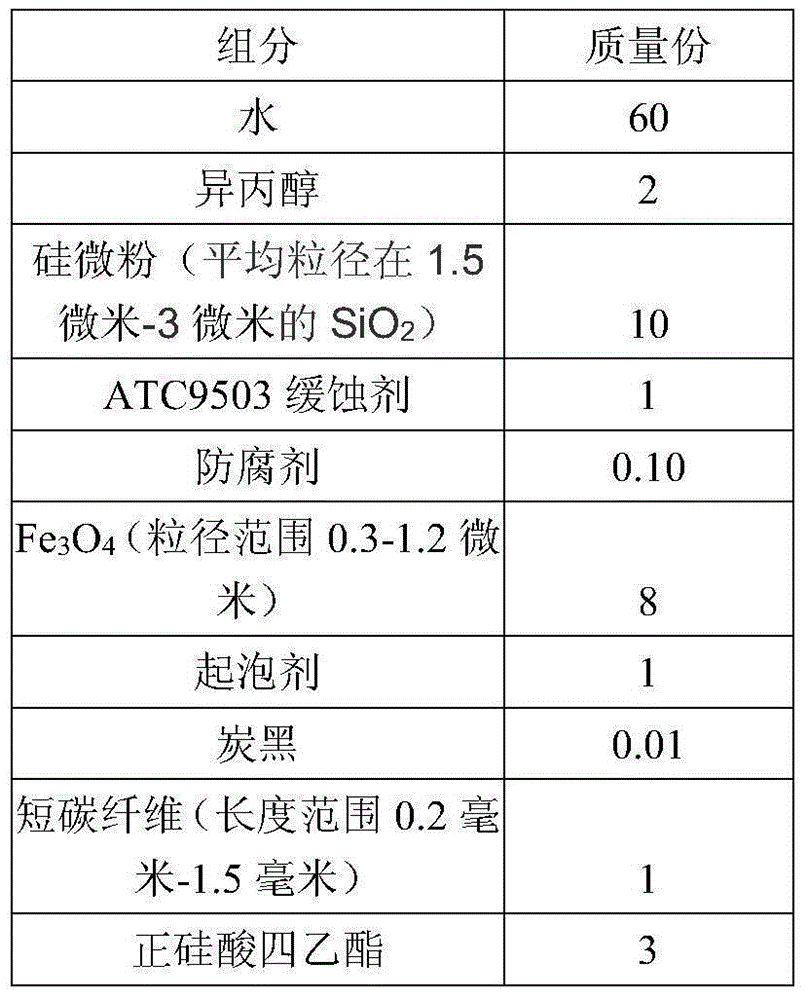

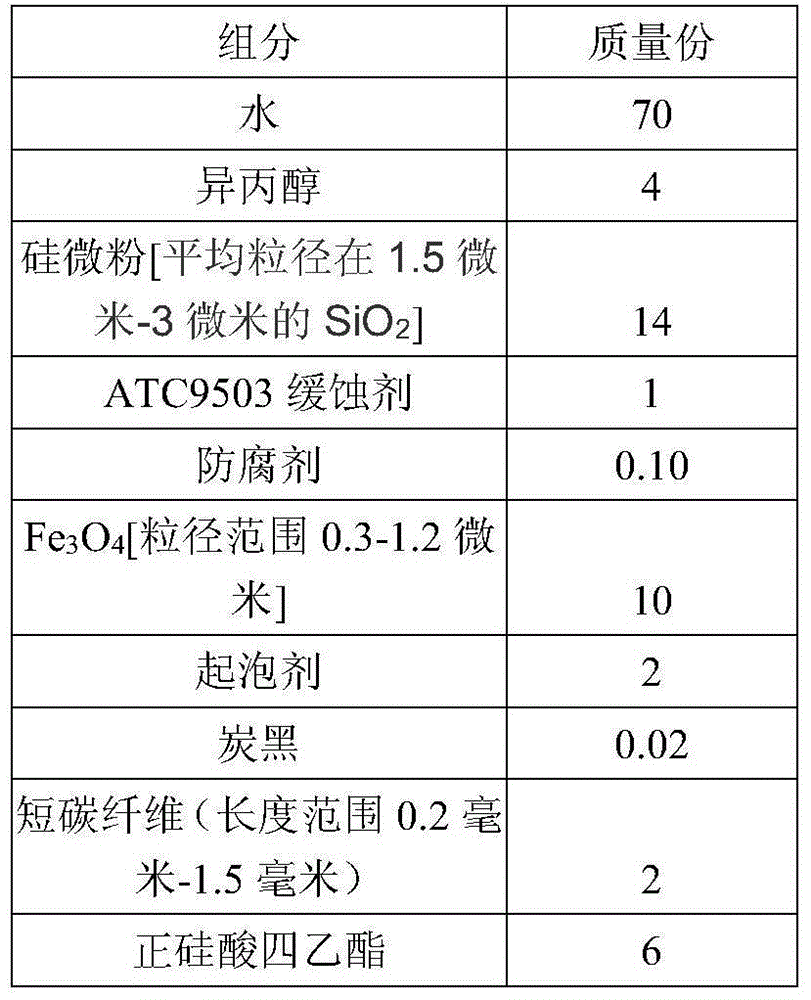

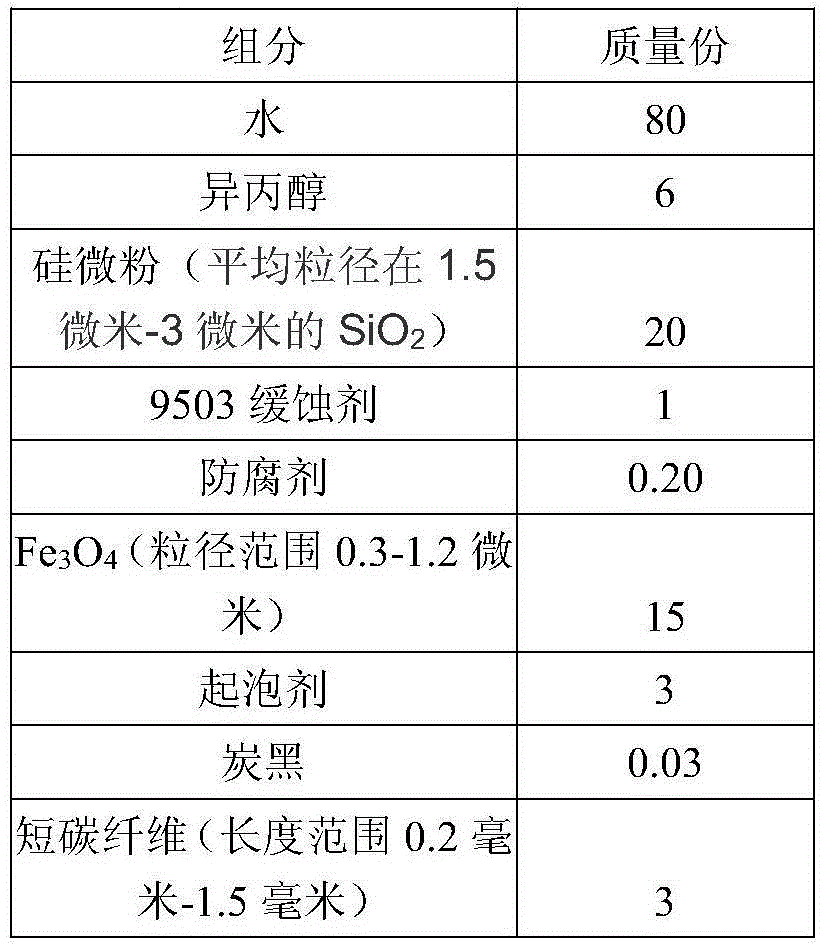

Glass polishing agent

InactiveCN105038608AUniform surface distributionGood dispersionPolishing compositions with abrasivesFiberCentrifugation

The invention provides a glass polishing agent which is characterized by comprising the following components by weight: 60-80 parts of water; 2-6 parts of isopropyl alcohol; 10-20 parts of silica micropowder; 8-15 parts of Fe3O4 powder with the particle diameter range of 0.3-1.2 microns; 1-3 parts of a frothing agent; 0.01-0.03 part of carbon black; 1-3 parts of short carbon fiber with the length range of 0.2-1.5 mm. As Fe3O4 is taken as a grinding agent, and Fe3O4 has magnetic property, during a grinding process, the grinding agent is prevented from dispersing under the action of centrifugation due to own magnetism and can be distributed more evenly on the surface of an object to-be-polished under the action of pushing of an external force.

Owner:SHANGHAI FEIER IND CO LTD

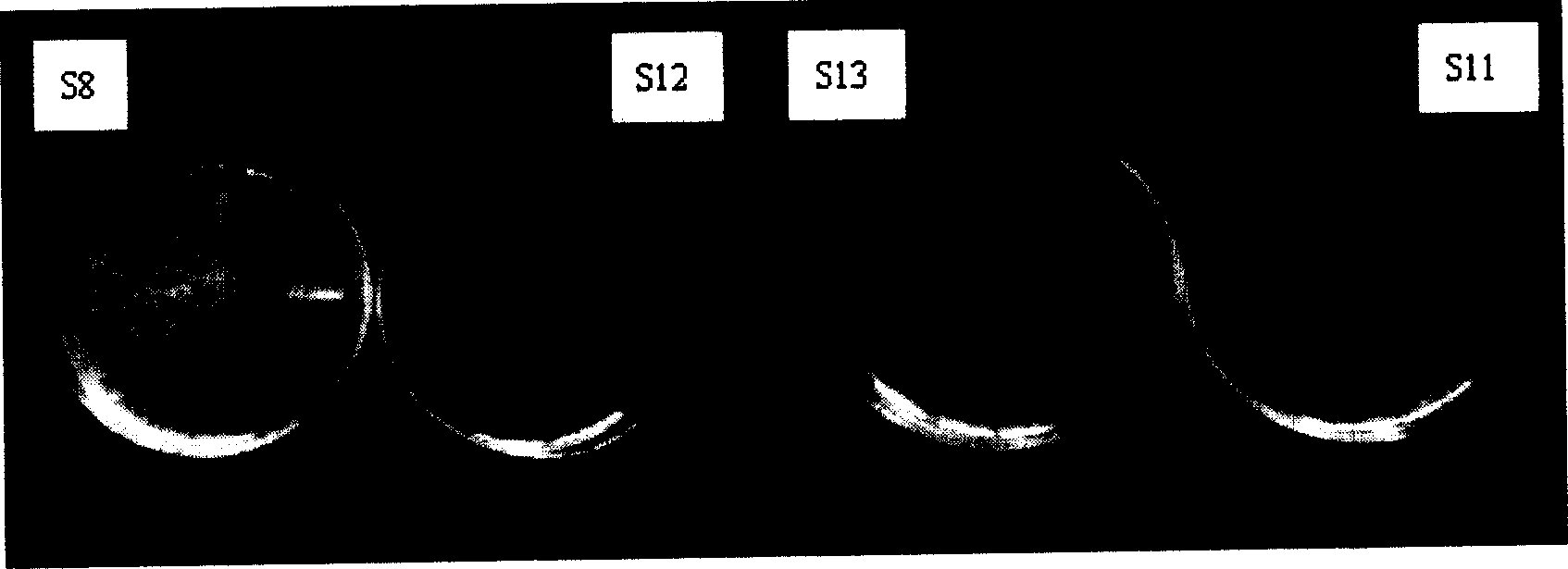

Prepn of porous luminescent material

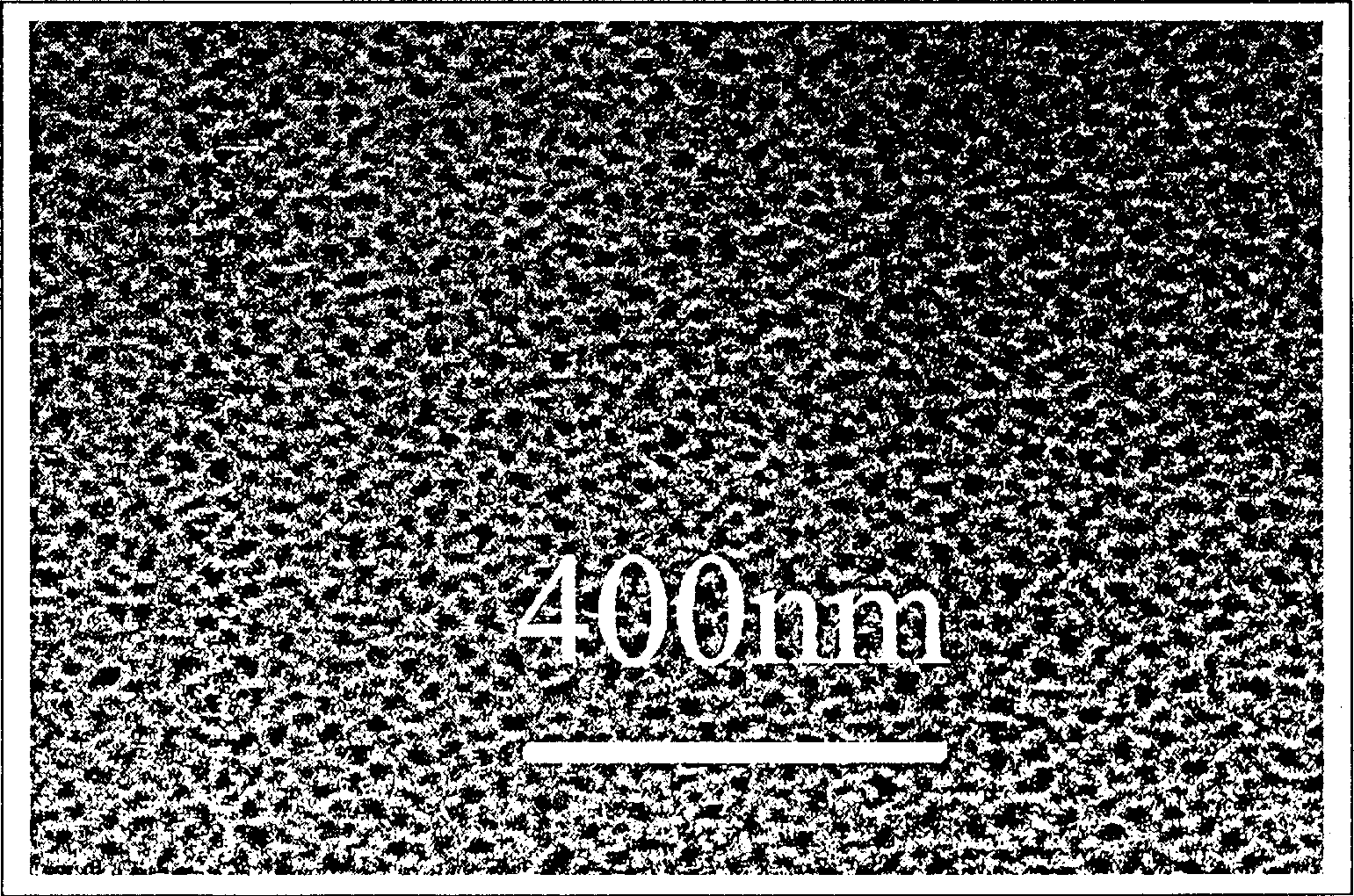

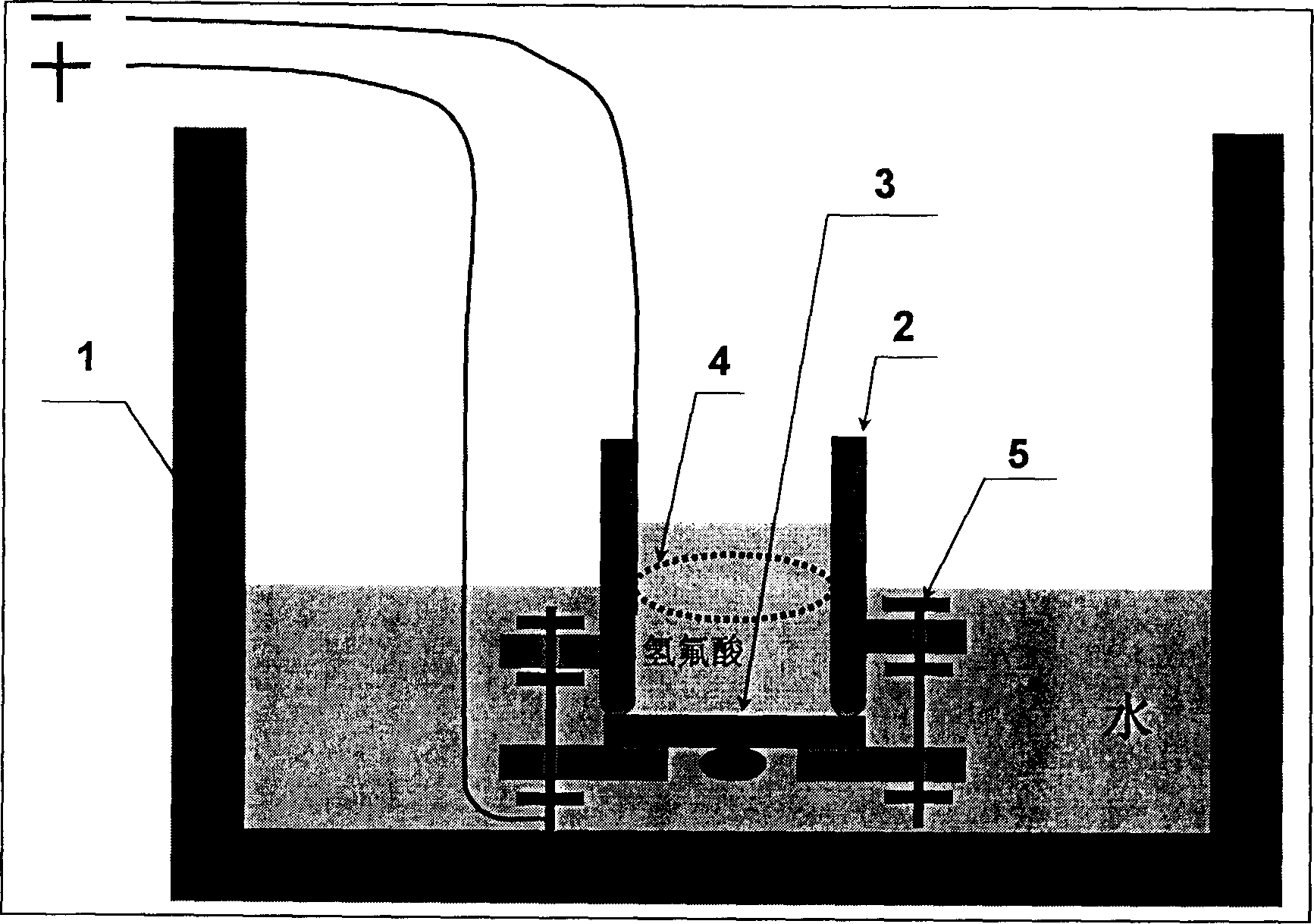

InactiveCN1436878AThe process is simple and convenientGood optical propertiesElectrochemistryOptical properties of carbon nanotubes

The present invention is supersonic electrochemical etching process of preparing porous luminescent silicon material. The traditional porous silicon material preparing electrochemical processes, including DC current process and pulse current process, has some demerits resulting in porous silicon material with imperfect optical characteristics. The supersonic electrochemical etching process of the present invention has optimized etching condition, and can obtain porous silicon material with improved surface interface structure and optical characteristics.

Owner:FUDAN UNIV

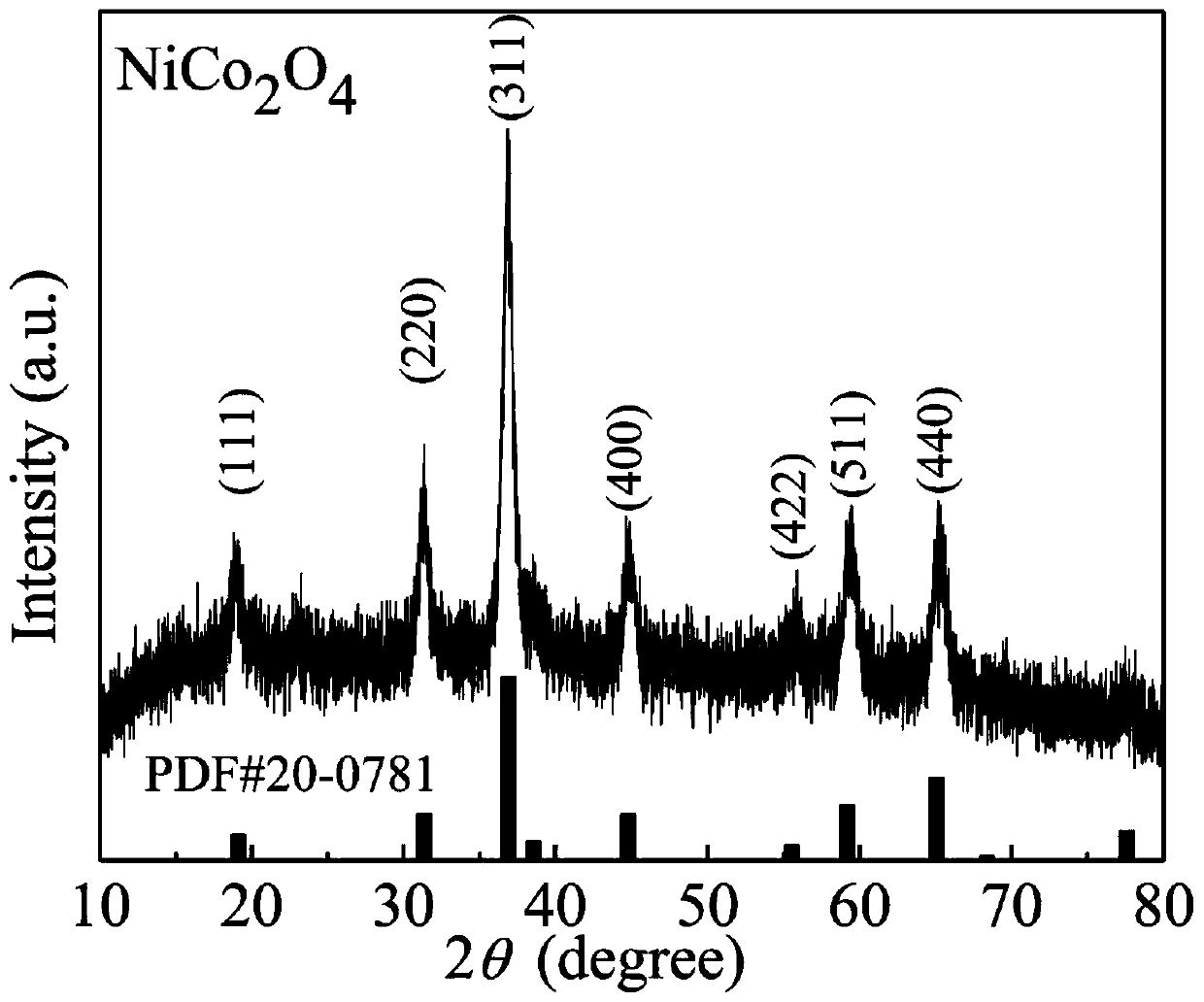

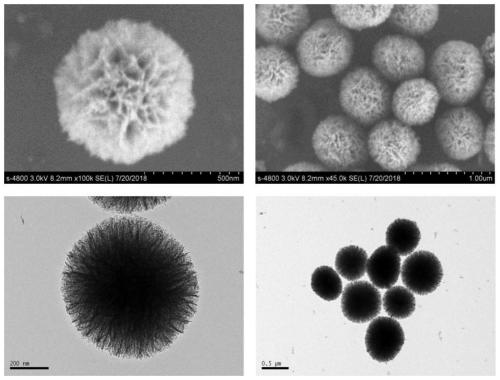

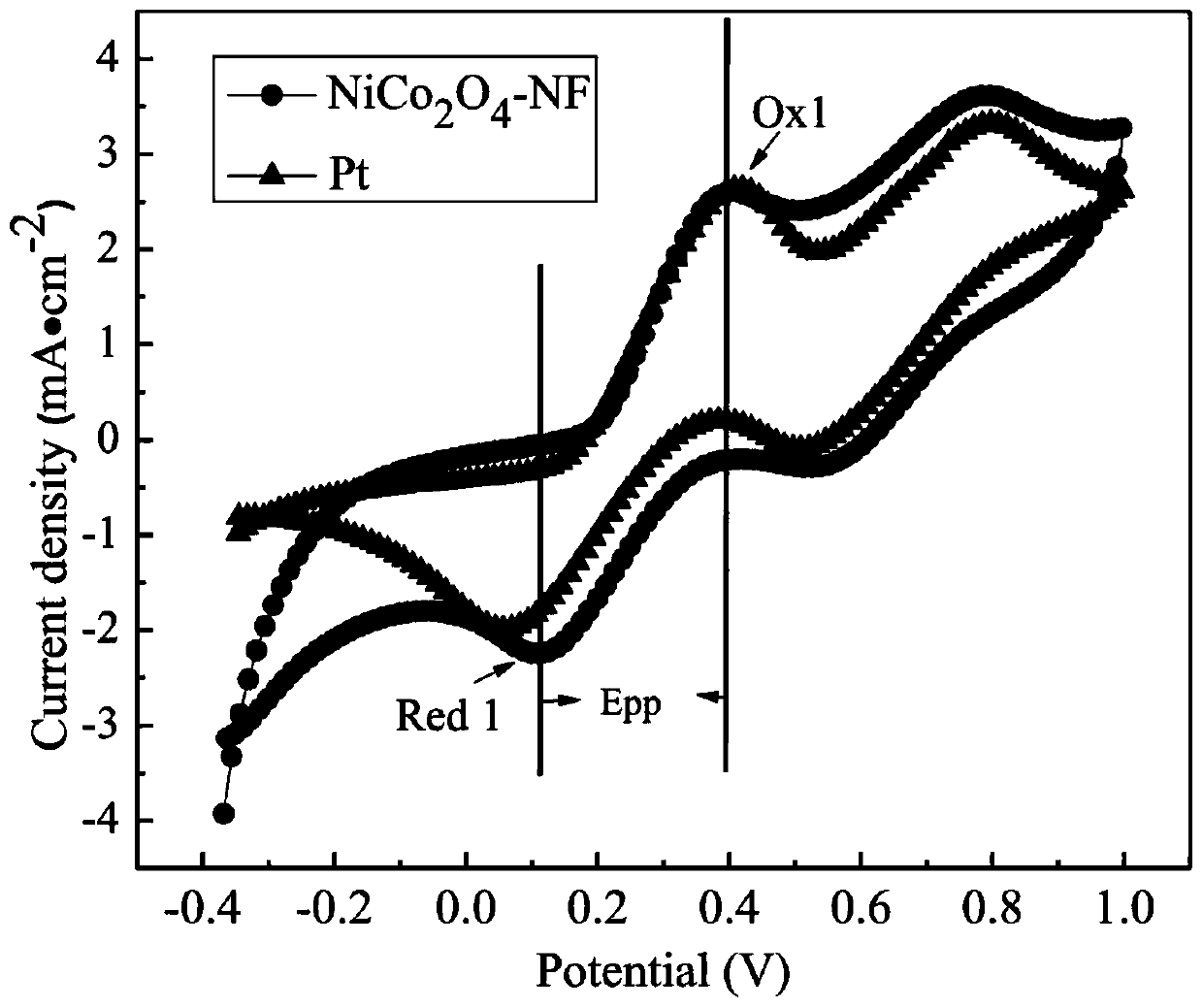

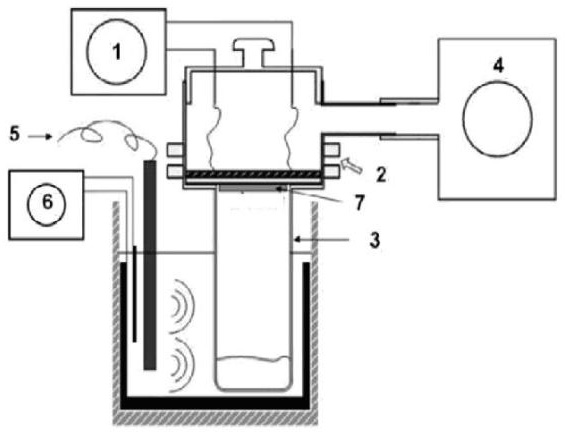

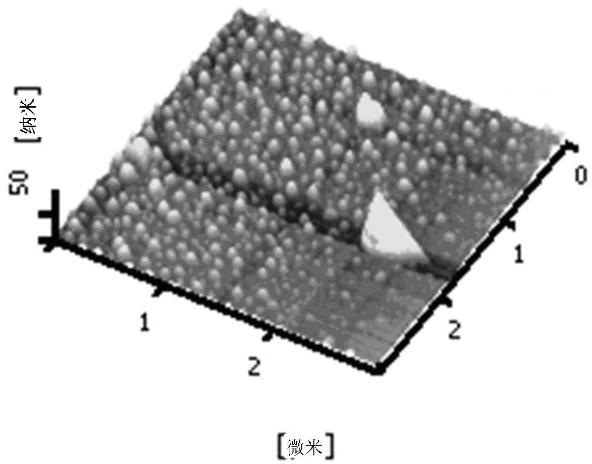

NiCo2O4 nano flower-like composite material and preparation method thereof

InactiveCN110342589AImprove performanceIncreased ability to store electronsNanotechnologyNickel compoundsCapacitancePseudocapacitance

The invention discloses a NiCo2O4 nano flower-like composite material (NiCo2O4-NF). The composite material is a flower-like structural material with loose NiCo2O4 nanosheets uniformly distributed at the surface. A cell assembled by using the composite material as a counter electrode exhibits superior photoelectric conversion performance: under the same conditions, photoelectric conversion efficiency of the dye-sensitized solar cell containing the NiCo2O4-NF counter electrode material is as high as 7.90% and is higher than that of 7.45% of a conventional cell containing commonly-used counter electrode noble metal platinum (Pt); and in addition, the NiCo2O4-NF exhibits better faradaic pseudocapacitance performance when used as an active electrode material: the specific capacitance reaches 817.5 F*g<-1>. The composite material provided by the invention is prepared by the one-step hydrothermal method, and has a simple preparation process, a low price and no pollution, can replace the Pt asa counter electrode to be used in the dye-sensitized solar cell and be used as an excellent active electrode to be used for supercapacitors, and has great application prospects in terms of energy storage.

Owner:ANHUI UNIVERSITY

Method for producing polycrystal mercuric iodide thick films by vacuum evaporation and vapor phase deposition under action of ultrasonic wave

InactiveCN102517544AImprove compactnessFine grainPolycrystalline material growthVacuum evaporation coatingPolymer scienceUltrasound - action

The invention relates to a production method, which utilizes vertical deposition technology excited by magnetic force mixing to produce polycrystal mercuric iodide thin films and belongs to the technical field of semi-conductor thick film production, wherein the mercuric iodide films are used as seed crystal layers, and high-quality polycrystal mercuric iodide thick films are produced by deposition on the seed crystal layers by of the process of vacuum evaporation and physical vapor phase deposition under the action of ultrasonic wave. The produced polycrystal mercuric iodide thick films are particularly applicable to production of X-ray and Gama-ray polycrystal mercuric iodide thick film detectors. 2,7-di-bromo-4-hydroxyl mercuric fluoresce red di-sodium salt (also called merbromin) and iodine tincture are utilized precursor reaction solution, absolute alcohol is used as solvent, and finally the polycrystal mercuric iodide thin films are produced. The mercuric iodide thin films are used as the seed crystal layers, and the polycrystal mercuric iodide thick films are produced by means of vacuum evaporation and physical vapour phase deposition, and finally, high-quality polycrystal mercuric iodide thick films with columnar grains are obtained on lining substrates.

Owner:SHANGHAI UNIV

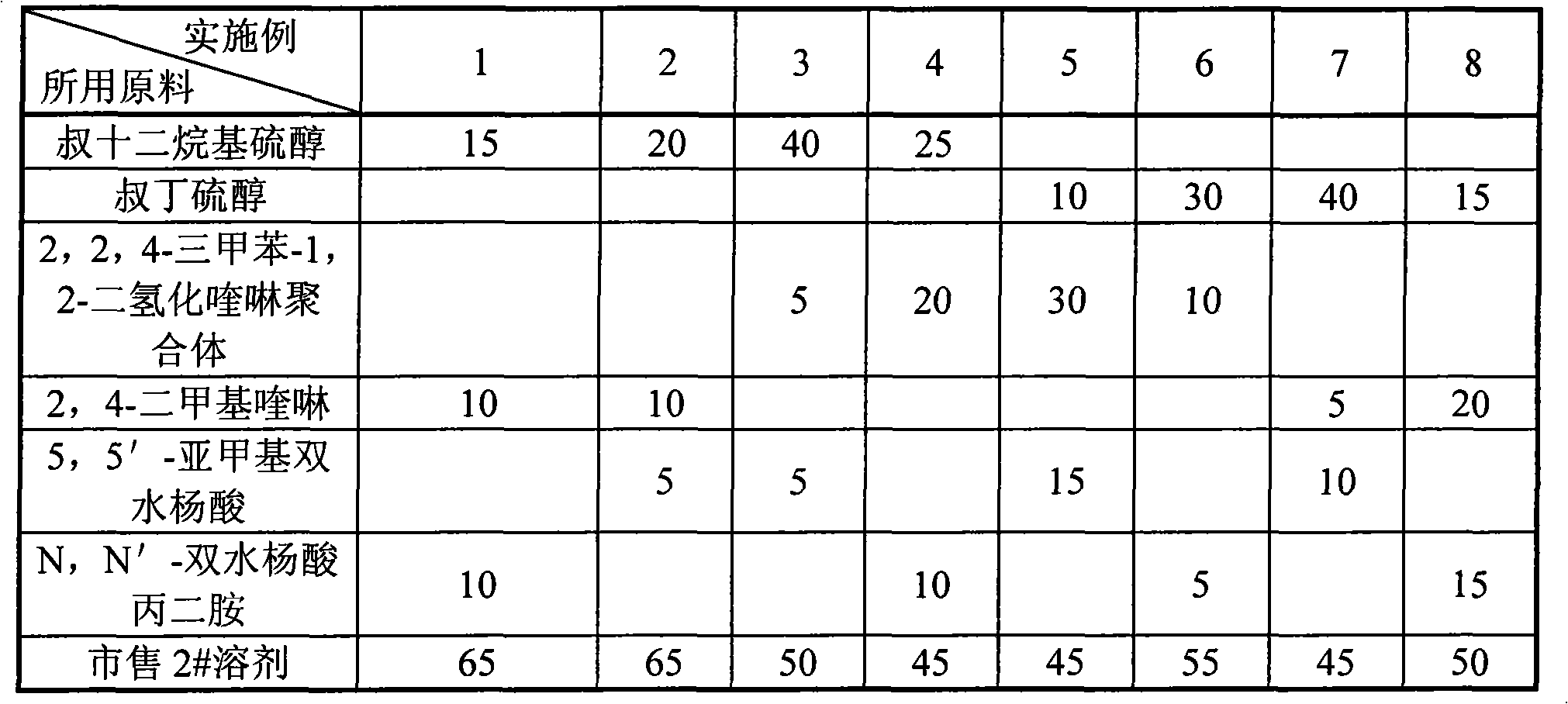

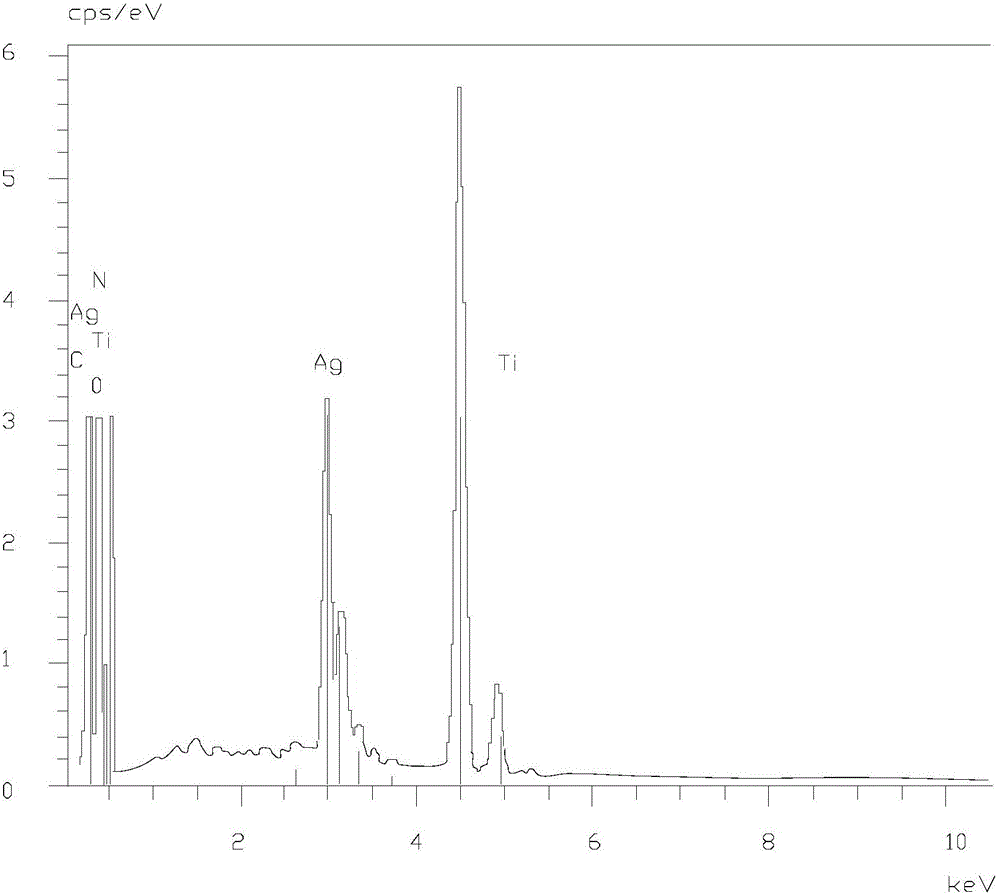

Ethylene cracking furnace coking restrainer and its use method

InactiveCN101318872APassivation of metal surfacesExtended service lifeThermal non-catalytic crackingHydrocarbon by hydrocarbon crackingThiolOrganic solvent

The present invention relates to a coking depressor for an ethylene cracking furnace, and a method for using the same. The depressor consists of a thiol compound, a quinoline compound, a disalicylic acid compound and an organic solvent. The coking depressor not only overcomes the shortcomings in the prior depressor that the manufacturing cost is high, the injection operation is difficult, the distribution in the cracking furnace tube is uneven, and the depressor erodes the inner wall of the furnace tube, etc., but also effectively prolongs the service life of the cracking furnace and improves the yield of ethylene, the usage of the material and the load of an ethylene device. The producing amount of CO and CO2 is largely reduced, and thus the depressor is safe and environment-friendly.

Owner:北京斯伯乐科学技术研究院

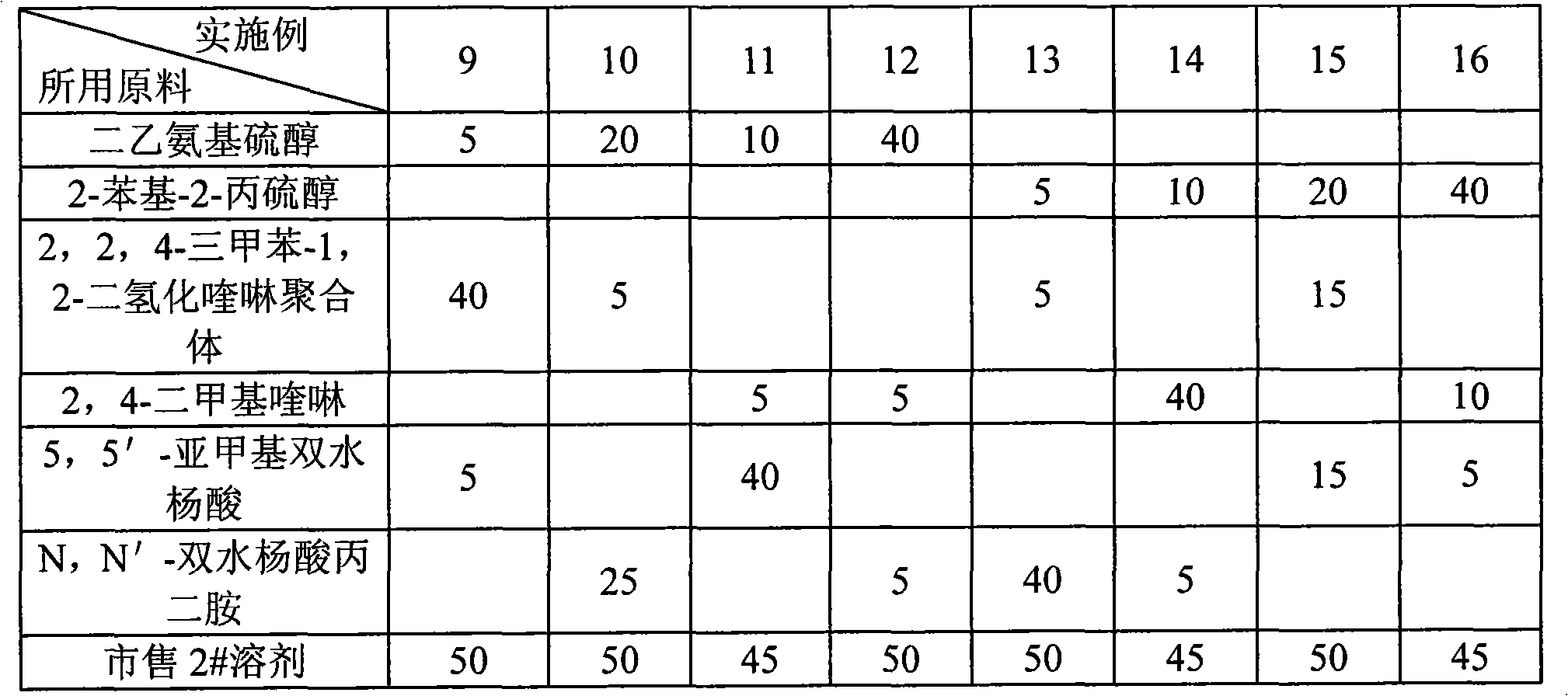

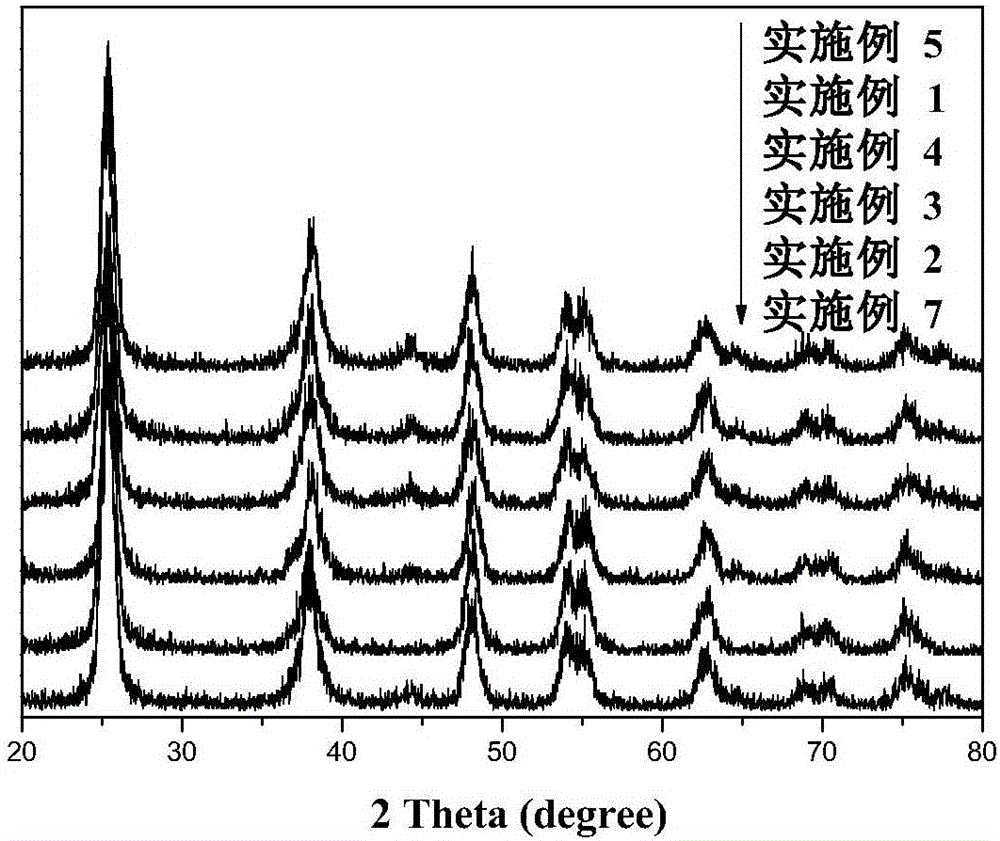

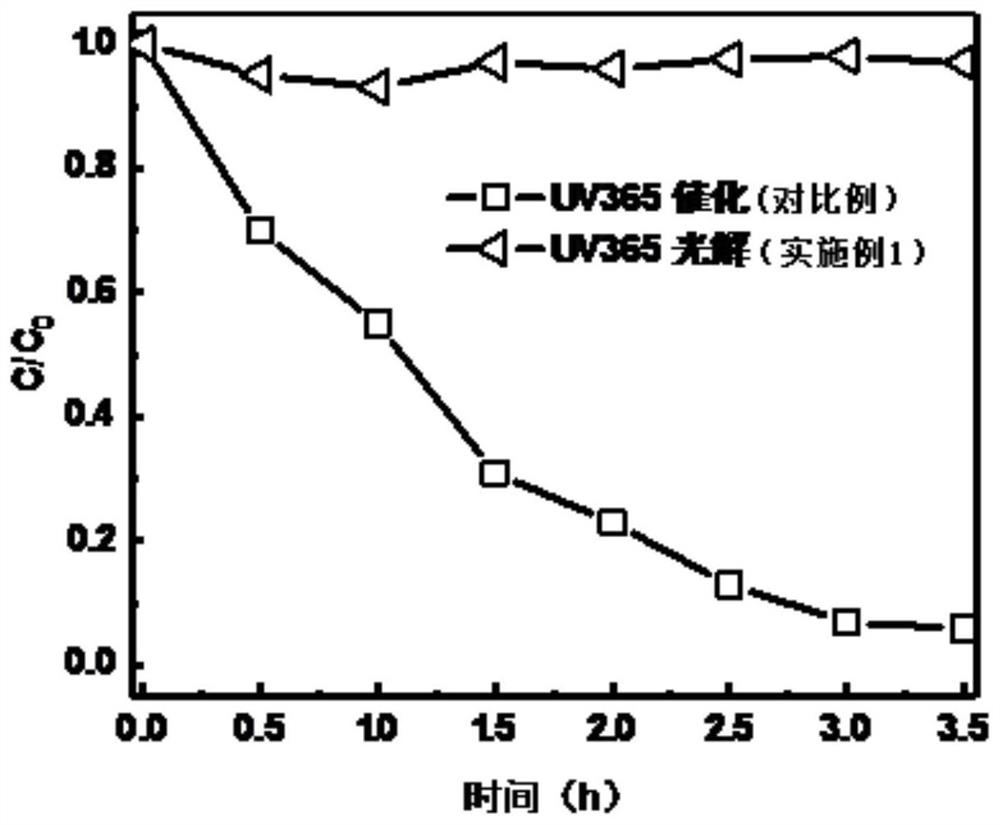

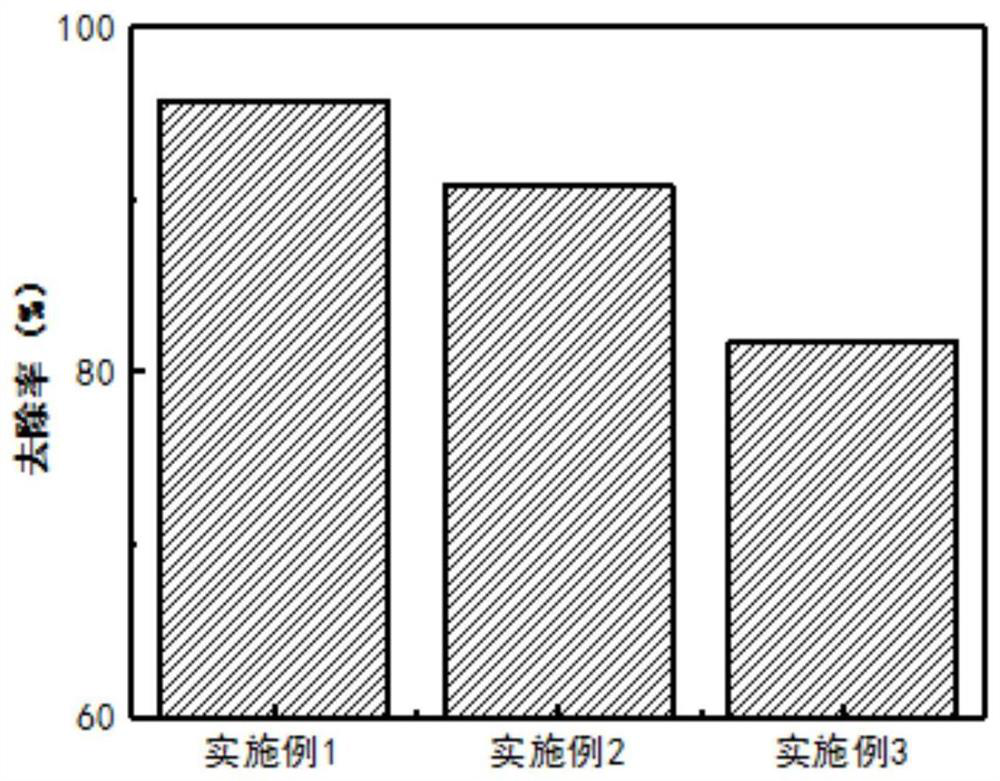

Ag/TiO2-N visible-light catalyst, and supercritical alcohol-heating preparation method and application thereof

ActiveCN105080585AReduce recombination rateAvoid it happening againBiocideMaterial nanotechnologyAntibacterial agentReducing agent

The invention discloses an Ag / TiO2-N visible-light catalyst. A titanium dioxide crystal form is of a pure anatase phase; a particle size is 2.0 [mu]m to 3.0 [mu]m; and a specific surface area is 140 to 169 m2 / g. The invention also discloses a preparation method for the Ag / TiO2-N visible-light catalyst. The method comprises the following steps: (1) preparation of TiO2 nanometer particles; and (2) preparation of the Ag / TiO2-N visible-light catalyst. The invention also provides application of a visible light responding photocatalyst in preparation of a photocatalytic organic-pollutant degradation agent and an antibacterial agent. Compared with the prior art, the invention has the following beneficial effects: raw materials used in the preparation method are simple and easily available; the preparation method is simple, convenient and easily implementable; the prepared micron spherical Ag / TiO2-N visible light responding photocatalyst has the advantages of uniform distribution of Ag nanometer particles on the surface of TiO2, low carrier recombination rate, high photocatalytic activity and good stability; meanwhile, the preparation process does not need any reducing agent, so generation of pollutant by-products is avoided, and cost is reduced.

Owner:SHANGHAI NORMAL UNIVERSITY

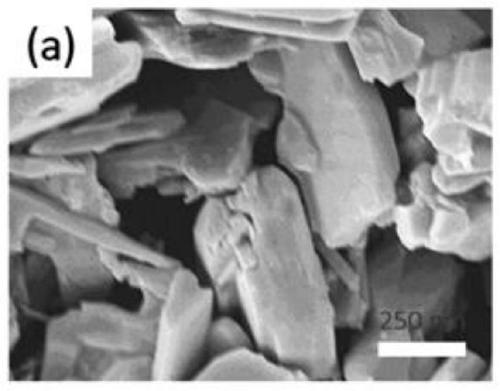

Preparation method of Al/NiO flaky aluminothermic agent

ActiveCN109678630AUniform surface distributionIncrease contact areaVacuum evaporation coatingSputtering coatingSputteringComposite film

A preparation method of an Al / NiO flaky aluminothermic agent comprises the following steps: providing a flaky peelable metal substrate; preparing hydrothermal synthesis reaction liquid; performing a hydrothermal synthesis reaction to obtain a precursor on the substrate; calcinating the precursor to form an NiO flaky layer on the substrate; finally, forming a nanometer aluminum film on the NiO flaky layer through magnetron sputtering so as to obtain a flaky Al / NiO nanometer energetic composite film. The aluminothermic agent is convenient to store and carry, low in production cost, environmentally friendly and excellent in combustion heat release performance.

Owner:CHONGQING UNIV

MXene doping-based composite material and preparation method thereof

InactiveCN113000056AImprove photocatalytic activitySimple preparation processPhysical/chemical process catalystsWater/sewage treatment by irradiationPtru catalystHeat treated

The invention provides an MXene doping-based composite material and a preparation method thereof, and the preparation method comprises the following steps: taking an MAX phase material as a raw material, and preparing an MXene colloidal solution through etching and stripping; performing centrifuging, washing and ultrasonic resuspension on the MXene colloidal solution for multiple times, then carrying out self-assembly under vacuum filtration, and carrying out vacuum drying on an obtained filter cake to obtain MXene paper; dissolving the MXene paper in an isopropanol solution, adding tetrabutyl titanate, uniformly mixing, dropwise adding a hydrofluoric acid solution, carrying out sealed hydrothermal treatment after dropwise adding, and performing cooling, washing and drying to obtain a target product. According to the MXene doping-based composite material and the preparation method thereof, the preparation process is simple, the requirements on instruments and equipment are low, the recombination efficiency of photon-generated carriers can be effectively improved, and the photocatalytic activity of a TiO2-based composite catalyst is improved.

Owner:TIANJIN UNIV

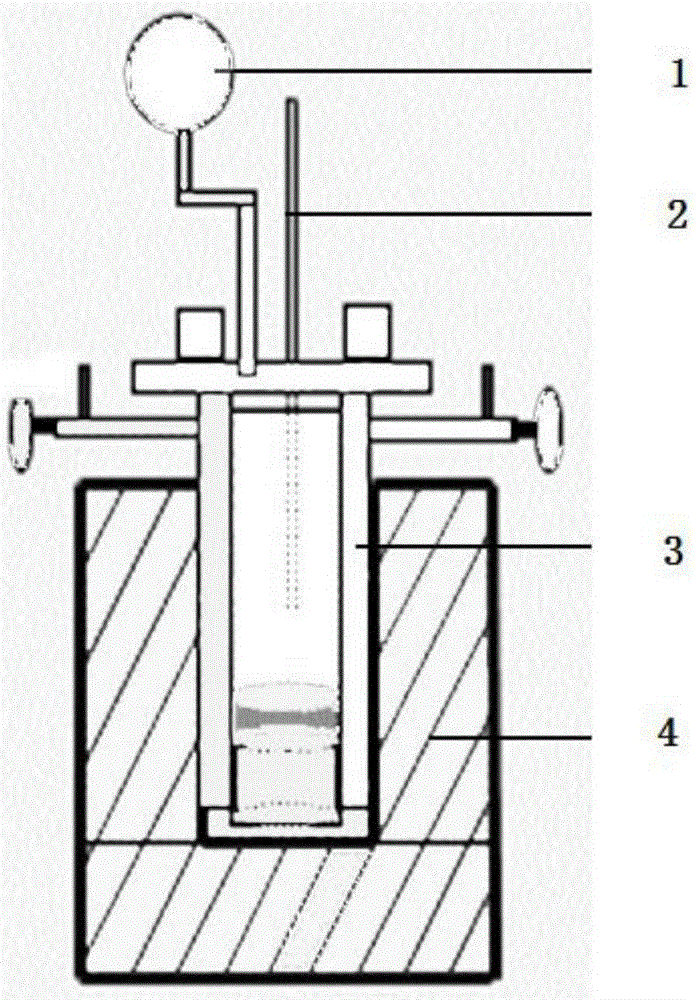

Method for manufacturing grapheme composite selenium and cobalt element counter electrode used in dye sensitized solar cell

InactiveCN105977034AEasy to operateLow costLight-sensitive devicesFinal product manufactureHydration reactionPtru catalyst

The invention discloses a method for manufacturing a counter electrode used in a dye sensitized solar cell (DSSC) with a composite selenium and cobalt ion which has a graphene film as a carrier. The method including the following steps: using a graphene, an element selenium, and a cobalt nitrate hexahydrate as raw materials, adding a reductant glucose, a hydrazine hydrate, and a catalyst polyvinylpyrrolidone (PVP), reacting the raw materials with the reductant glucose, the hydrazine hydrate, and the catalyst polyvinylpyrrolidone (PVP) for 12 hours under 100 degrees so as to obtain a graphene film counter electrodethat contains selenium and cobalt, cleaning a reaction product with an absolute ethyl alcohol for three times, and drying the reaction product at room temperature. A reaction container is a stainless steel reaction vessel which has a polytetrafluoroethylene as an inner container, and a solution has a concentration of 5 mmo1 / L. According to the invention, the method is easy to operate, has short reaction time, excellent repeatability, and low cost. The manufactured film has tight structure and even element distribution. The method can be applied to industrial production and technology promotion of DDSC counter electrodes.

Owner:XUCHANG UNIV

A titanium-containing aluminum hydroxide and preparation method thereof

ActiveCN1951555AUniform surface distributionEasy to prepareCatalyst activation/preparationRefining to eliminate hetero atomsHydrogenAluminium hydroxide

The invention relates to a method for preparing aluminum hydroxide with titanium. Wherein, it leads titanium into aluminum hydroxide paste process, to confirm the uniform disperse of titanium on the surface of aluminum hydroxide; and it uses secondary aging process to make the hole capacity of aluminum hydroxide particles larger than specific surface area. The invention can be used as catalyst carrier and hydrogen catalyst, with better physical property and application property.

Owner:CHINA PETROLEUM & CHEM CORP +1

A three-roll skew rolling forming method for a railway vehicle axle

The invention discloses a three-roll cross-rolling forming method for railway vehicle axles, which is characterized in that the bar is heated, and the bar is sent into a three-roll cross-rolling machine through an axial pushing device, and three cross-rollers are simultaneously engaged with the bar , and drive the bar to rotate. At the same time, the axial pusher pushes the bar to move axially at a constant speed. The radial drive mechanism controls the radial movement of the skew roll according to the diameter of the railway vehicle axle to be processed. When it moves to contact with the axial feeding device, the axial feeding device pulls the bar and continues to move axially at a constant speed, and at the same time the bar is separated from the axial pushing device, and a long step with a large diameter is obtained after processing Axle—the railway vehicle axle; the advantage is that the mold is simple to manufacture, and the force is evenly distributed on the surface of the rolled piece, which can effectively reduce the wear of the roll during the skew rolling process, enable the rolling mill to carry out lightweight construction, and effectively increase the service life of the rolling mill.

Owner:NINGBO UNIV

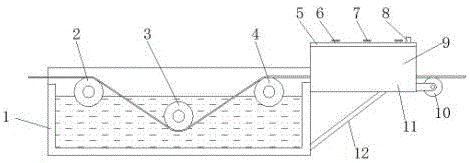

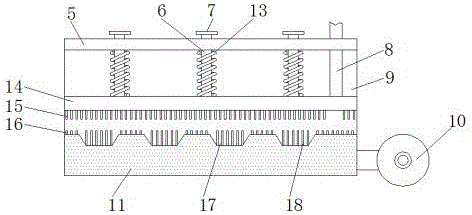

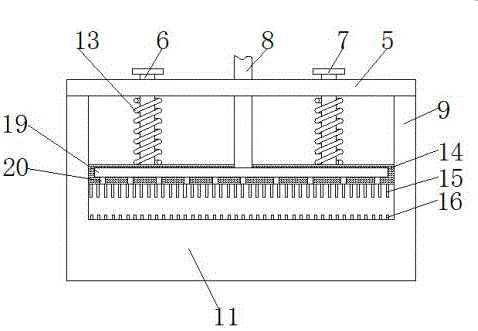

Cleaning device for copper strip machining

PendingCN106733772AWash thoroughlyImprove qualityCleaning using toolsCleaning using liquidsBristlePulp and paper industry

The invention discloses a cleaning device for copper strip machining. The cleaning device comprises a water tank. A first guide roller, a second guide roller and a third guide roller are mounted in the water tank through rotating shafts. The first guide roller and the third guide roller are located on the same horizontal plane. The second guide roller is located between the first guide roller and the third guide roller and meanwhile located below the first guide roller and the third guide roller. A base is welded to the right side face of the water tank. A supporting strip is welded between the bottom face of the base and the right side face of the water tank. A liquid accumulation groove is formed in the upper surface of the base, and third bristles are arranged in the liquid accumulation groove. Second bristles are arranged on the upper surface of the base. A support is welded to the right end of the base. A fourth guide roller is mounted on the support through a rotating shaft. By means of the cleaning device, a cleaning agent can be dispersed to the bottom face and the surface of a copper strip well, the copper strip is cleaned thoroughly, and the quality of the copper strip is improved.

Owner:WUXI DONGHE METAL PROD

Preparation method of polyhydroxy phenyl improved type methanation catalyst

ActiveCN104525205AUniform surface distributionConsistent sizeHydrocarbon from carbon oxidesMetal/metal-oxides/metal-hydroxide catalystsAir atmosphereMethanation

The invention discloses a preparation method of a polyhydroxy phenyl improved type methanation catalyst. The preparation method comprises the following steps: firstly, adding an ethanol dispersant into aluminum oxide or pseudo-boehmite, and performing ball milling on a ball mill to prepare activated aluminum oxide or pseudo-boehmite microsphere particles; secondly, preparing a nickel nitrate-polyhydroxy phenyl solution by using polyhydroxy phenyl and nickel nitrate, or preparing a nickel nitrate / M nitrate-polyhydroxy phenyl solution by using polyhydroxy phenyl, nickel nitrate and nitrate corresponding to an auxiliary agent M, and dipping to an activated aluminum oxide or pseudo-boehmite microsphere particles carrier; and finally, drying overnight at room temperature, and calcining at a nitrogen atmosphere or air atmosphere to prepare a NiO / Al2O3 catalyst or NiO-M / Al2O3 catalyst. By adopting the preparation method disclosed by the invention, the activity, selectivity and thermal stability of the catalyst are improved.

Owner:HUANENG CLEAN ENERGY RES INST +1

Chiral medicine resolution medium based on polypeptide combined chiral recognition base and preparation method thereof

InactiveCN102688750AStrong specificityBroad chiral resolution rangeOther chemical processesBond densitySilica gel

A chiral medicine resolution medium based on a polypeptide combined recognition base is obtained by bonding the polypeptide combined base with different chiral recognition capabilities onto the surface of porous silica gel with its pore size being 8-12nm and particle size being 5-30mm through chemical modification. According to a preparation method of the above chiral medicine resolution medium, one or some medicine-related proteins undergo enzymatic hydrolysis at 25-37 DEG C by the use of trypsin or papain or elastase or one or some enzymes thereof; zymoprotein is removed from the polypeptide combined base obtained after enzymatic hydrolysis by denaturation and adsorption or dialysis, and then the polypeptide combined base is bonded onto the porous silica gel surface by chemical modification so as to obtain the required chiral medicine resolution medium. The prepared chiral medicine resolution medium has wide chiral resolution range and uniform surface distribution, and its bonding density is higher than the bonding density of a protein stationary phase. The chiral medicine resolution medium has the combined chiral recognition base which can be used for resolution and analysis of a plurality of chiral medicines and provides a foundation for developing chiral resolution materials with a wider resolution range and chiral medicines with better specificity.

Owner:WUHAN HUISHITONG BIO ENG

Preparation method of polypyrrole modified activated carbon

ActiveCN111346621AHigh degree of orderHigh crystallinityOther chemical processesPolypyrroleCrystallinity

The invention relates to a preparation method of polypyrrole modified activated carbon. The method comprises the following steps: (1) selecting coconut shell / fruit shell granular activated carbon, washing and drying to constant weight, and carrying out vacuum drying and storage for later use; (2) preparing a pyrrole solution; (3) attaching pyrrole to the activated carbon; (4) adding ferric trichloride hexahydrate; (5) adding benzene sulfonic acid sodium salt; (6) cleaning and drying an obtained modified activated carbon in vacuum; (7) sealing with nitrogen, drying and storing. According to thepreparation method, organic anions ( benzene sulfonic acid sodium salt (BSNa)) are doped, so that laminar growth has a compact and ordered surface form and is highly doped in polypyrrole; the PPy film doped with aromatic sulfonate anions (benzene sulfonic acid sodium salt) has higher degree of order, crystallinity and conductivity, so that the pyrrole film has better stability in an alkaline solution; the ferric trichloride hexahydrate doped polypyrrole modified activated carbon is doped with the surfactant (benzene sulfonic acid sodium salt) at the same time, so that the surface charge distribution is more uniform, and the conductivity is stronger.

Owner:TAIYUAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com