Preparation method of Al/NiO flaky aluminothermic agent

A kind of thermite and sheet-like technology, which is applied in the field of preparation of composite films of nano energetic materials, can solve the problems of mass transfer rate of thermite reaction, environmental friendliness of process design, convenience of use and unsatisfactory industrial production, aluminum The problems of slow reaction rate and high ignition temperature on the hot surface achieve the effect of low preparation cost, excellent heat release performance and combustion performance, and uniform surface distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

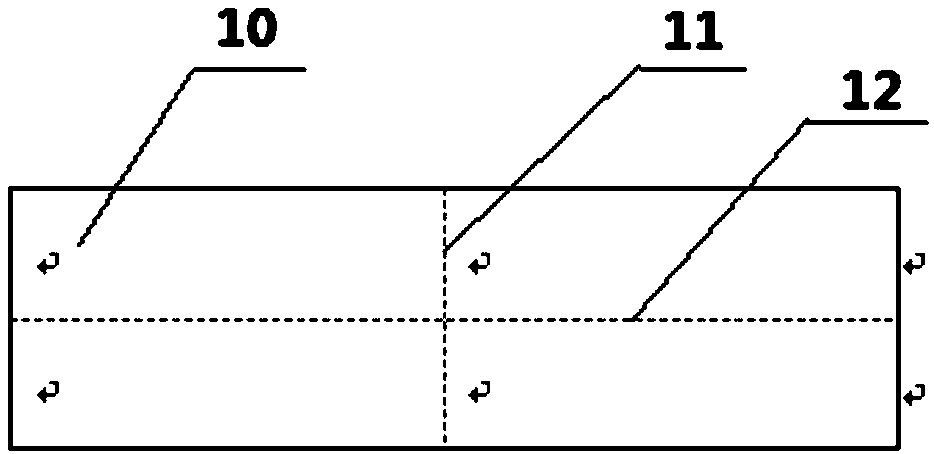

Method used

Image

Examples

Embodiment 1

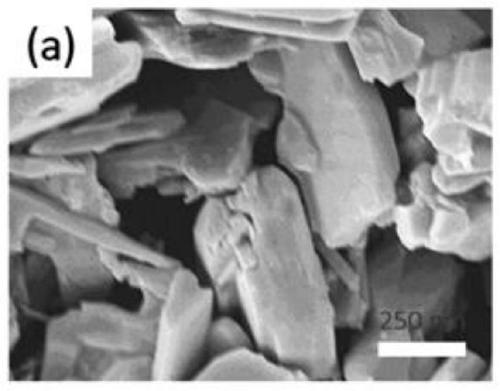

[0043] PEG2000 was used for PEG; the hydrothermal reaction temperature was maintained at 160°C, the reaction time was 12h, and the pH was adjusted to 7; the calcination temperature was 350°C; the sputtering plating time was 0.2h.

[0044] Field emission scanning electron microscope (FESEM), differential scanning calorimeter (DSC), high-speed camera, etc. were used to analyze and characterize the surface morphology and performance of the composite film product. Fig. 2 (a) and Fig. 2 (b) are the scanning electron micrograph and the transmission electron micrograph of the Al / NiO flake thermite prepared according to embodiment 1 respectively; image 3 is the corresponding DSC heat release curve, the heat release is as high as 1.5MJ Kg -1 ; Figure 4 is the combustion flame diagram of the thermite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com