Preparation method of polyhydroxy phenyl improved type methanation catalyst

The technology of a methanation catalyst and polyhydroxy phenol is applied in the field of preparation of an improved polyhydroxy phenol methanation catalyst, which can solve the problems of strong alkalinity of the catalyst, residual precipitant, deactivation and the like, and achieve uniform grain size and distribution. uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A preparation method of polyhydric phenol improved methanation catalyst, comprising the following steps:

[0023] Step 1. Take 100g of alumina and add 20g of ethanol as a dispersant, and mill it on a ball mill for 30 minutes to achieve the effect of surface activation;

[0024] Step 2, take 0.5g phloroglucinol and 11.6g nickel nitrate to configure nickel nitrate-phloroglucinol solution, and impregnate 10g of activated alumina prepared in step 1;

[0025] Step 3. Dry the catalyst precursor prepared in step 2 overnight at room temperature, dry at 105°C for 4h, and calcinate at 550°C for 5h in an air atmosphere. Phloroglucinol is decomposed at high temperature to obtain 23.1NiO / Al 2 o 3 (3.85 Phloroglucinol A) catalyst.

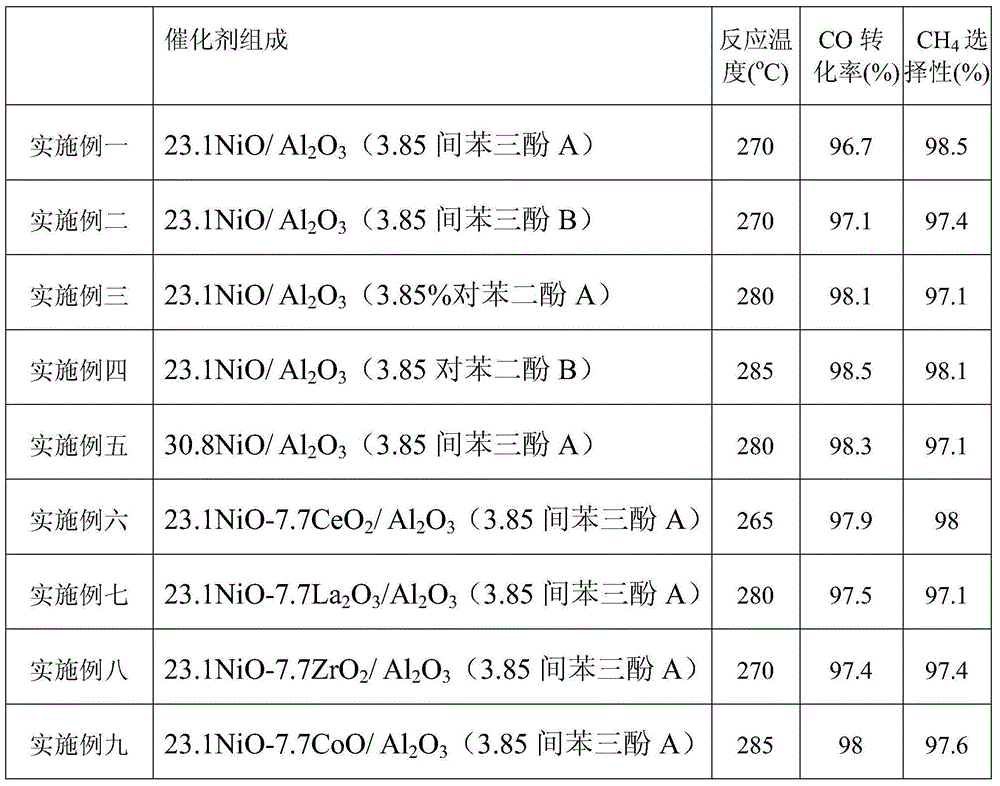

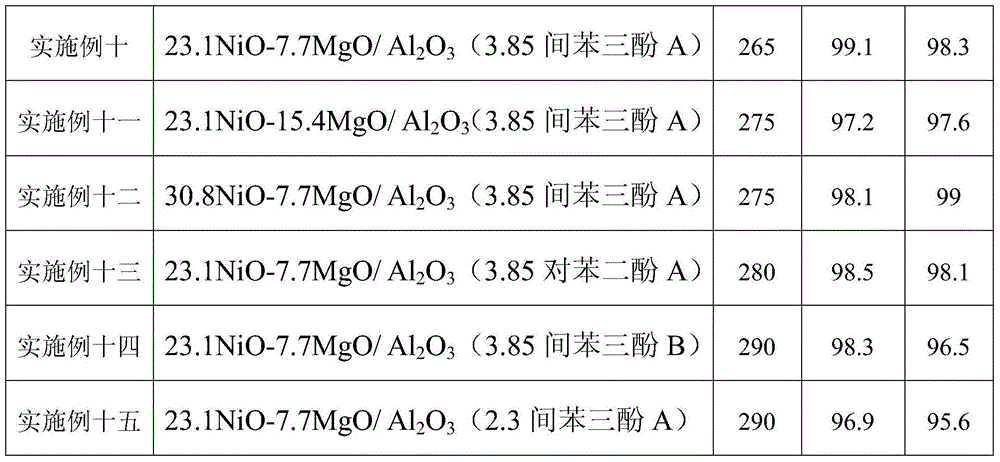

[0026] The composition and activity evaluation results of the catalyst in this example are shown in Table 1.

Embodiment 2

[0028] A preparation method of polyhydric phenol improved methanation catalyst, comprising the following steps:

[0029] Step 1, take 100g of pseudo-boehmite and add 20g of ethanol as a dispersant, and ball mill on a ball mill for 30 minutes to achieve the effect of surface activation;

[0030] Step 2, taking 0.5g phloroglucinol and 11.6g nickel nitrate to configure nickel nitrate-phloroglucinol solution, impregnated into 13.5g activated pseudoboehmite prepared in step 1;

[0031] Step 3. Dry the catalyst precursor prepared in step 2 overnight at room temperature, dry at 105°C for 4h, and calcinate at 550°C for 5h in an air atmosphere. Phloroglucinol is decomposed at high temperature to obtain 23.1NiO / Al 2 o 3 (3.85 Phloroglucinol B) catalyst.

[0032] The composition and activity evaluation results of the catalyst in this example are shown in Table 1.

Embodiment 3

[0034] A preparation method of polyhydric phenol improved methanation catalyst, comprising the following steps:

[0035] Step 1. Take 100g of alumina and add 20g of ethanol as a dispersant, and mill it on a ball mill for 30 minutes to achieve the effect of surface activation;

[0036] Step 2, take 0.5g hydroquinone and 11.6g nickel nitrate to configure nickel nitrate-hydroquinone solution, impregnate 10g activated alumina prepared in step 1;

[0037] Step 3. Dry the catalyst precursor prepared in step 2 overnight at room temperature, dry at 105°C for 4h, and calcinate at 550°C for 5h in an air atmosphere. Hydroquinone is decomposed at high temperature to obtain 23.1NiO / Al 2 o 3 (3.85% Hydroquinone A) catalyst.

[0038] The composition and activity evaluation results of the catalyst in this example are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com