Glass polishing agent

A technology of polishing agent and glass, which is applied in the direction of polishing composition containing abrasives, etc., which can solve the problems of scratches on abrasive particles, decrease in polishing effect, and increase in the probability of abrasive particles scratching scratches, so as to prevent scratches and improve The effect of surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

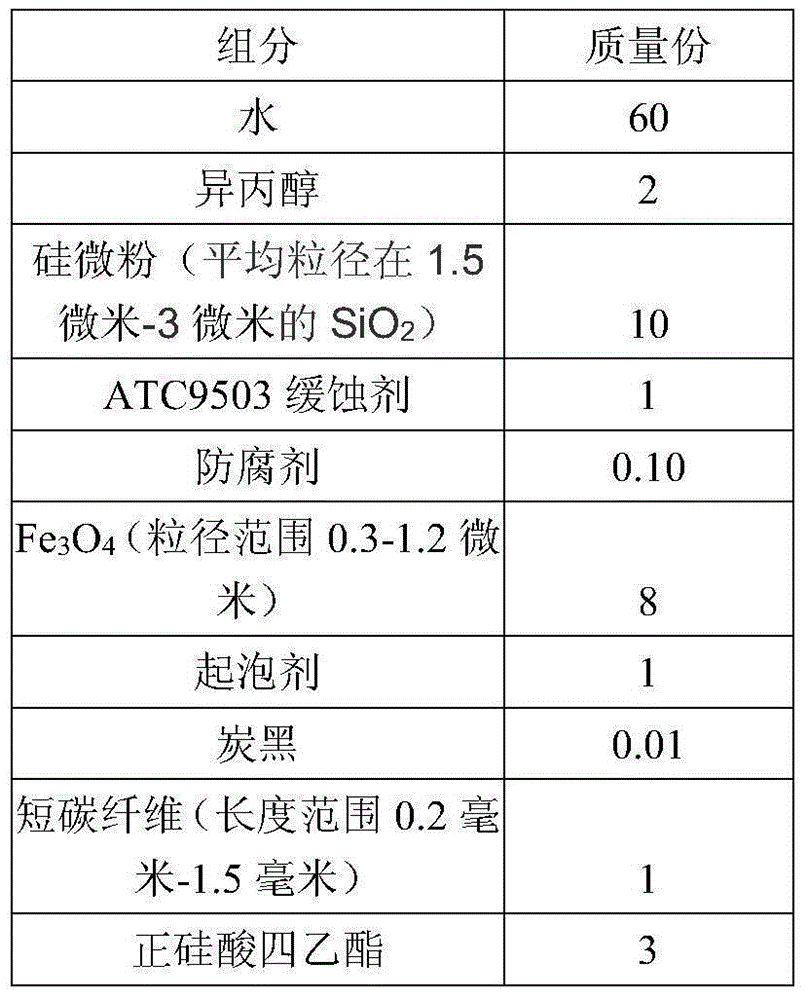

[0018] The formula of the glass polishing agent of the present embodiment is shown in Table 1.

[0019] Table 1. The formula of the glass polishing agent of embodiment 1

[0020]

[0021] As grinding progresses, tetraethyl orthosilicate gradually decomposes to form SiO 2 , SiO 2 with Fe 3 o 4 And the microstructure on the surface of the carbon fiber is a crystallization nucleus, forming a large number of microcrystals, thereby forming more refined abrasive particles, so as to effectively prevent the possibility of causing larger scratches on the previously ground flat surface, and because the microcrystals are finer, Therefore, the surface finish can be further improved to achieve the effect of killing two birds with one stone.

[0022] Fe 3 o 4 It is magnetic in itself, it will not be dispersed due to centrifugal action during the grinding process, and it will be more evenly distributed on the surface under the promotion of external force.

[0023] Short carbon fibe...

Embodiment 2

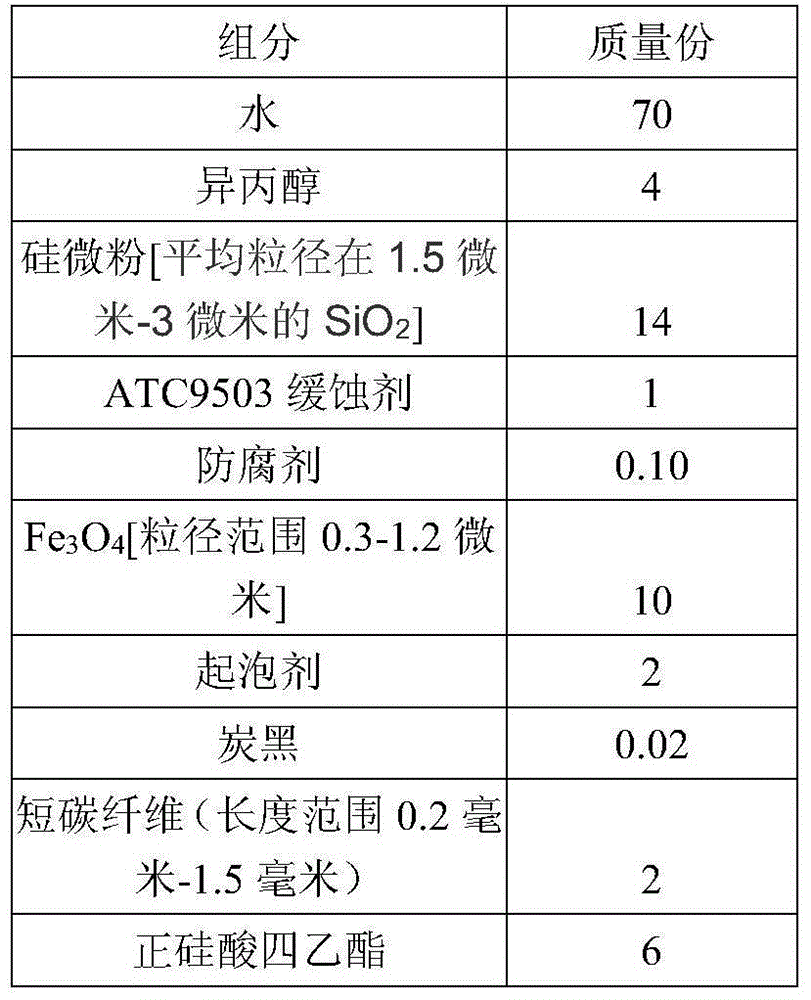

[0026] The formula of the glass polishing agent of the present embodiment is shown in Table 2.

[0027] Table 2. The formula of the glass polishing agent of embodiment 2

[0028]

Embodiment 3

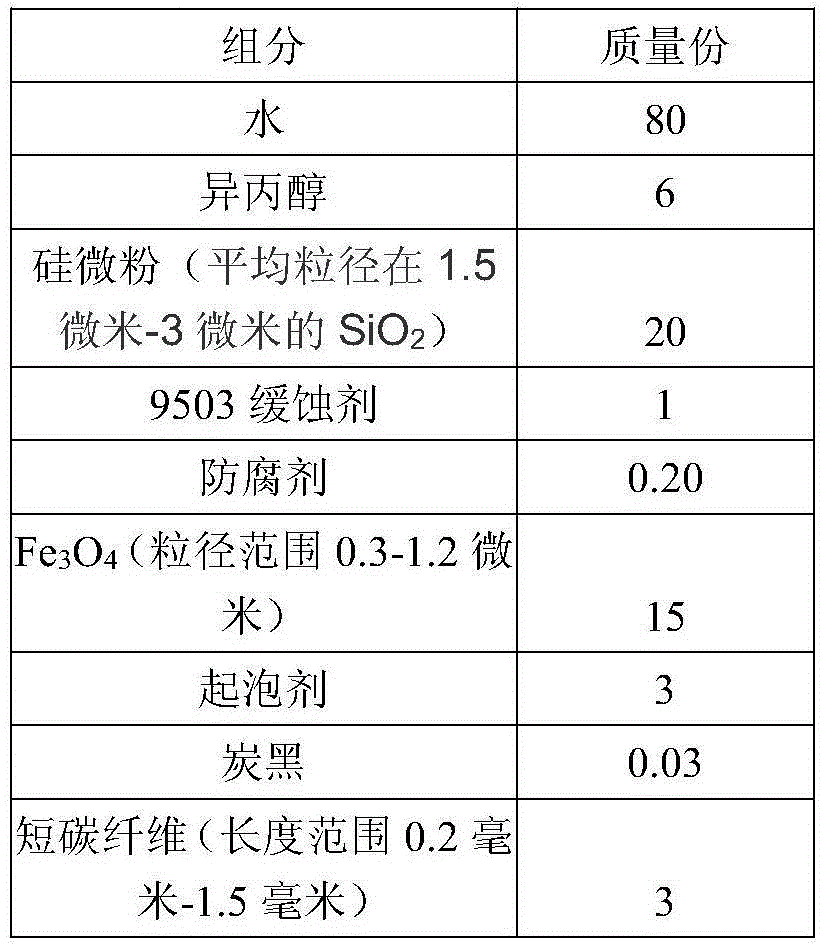

[0030] The formula of the glass polishing agent of the present embodiment is shown in Table 3.

[0031] Table 3. The formula of the glass polishing agent of embodiment 3

[0032]

[0033]

[0034] Corrosion inhibitors and preservatives can be added according to actual needs. The amount added is not limited to the ranges provided in the above examples.

[0035] In order to achieve better results, tetraethyl orthosilicate can be mixed with other components before use to prevent hydrolysis after long-term storage.

[0036] After half an hour of polishing, the probability of scratches with a length of more than 1 mm per square meter is reduced by half compared with traditional glass polishes (such as German SONAX glass polishes).

[0037] Get four groups of automobile glass, get respectively the polishing agent that the formula of embodiment 1, embodiment 2, embodiment 3 makes and the polishing agent of control group carry out half an hour polishing treatment to automobile...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com