High-temperature-resistant methanation catalyst as well as preparation method thereof

A methanation catalyst, high temperature resistant technology, applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of reducing catalyst surface area, shortening catalyst life, reducing Catalyst activity and other issues, to achieve the effect of reducing interaction, reducing carbon deposition reaction, and improving selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

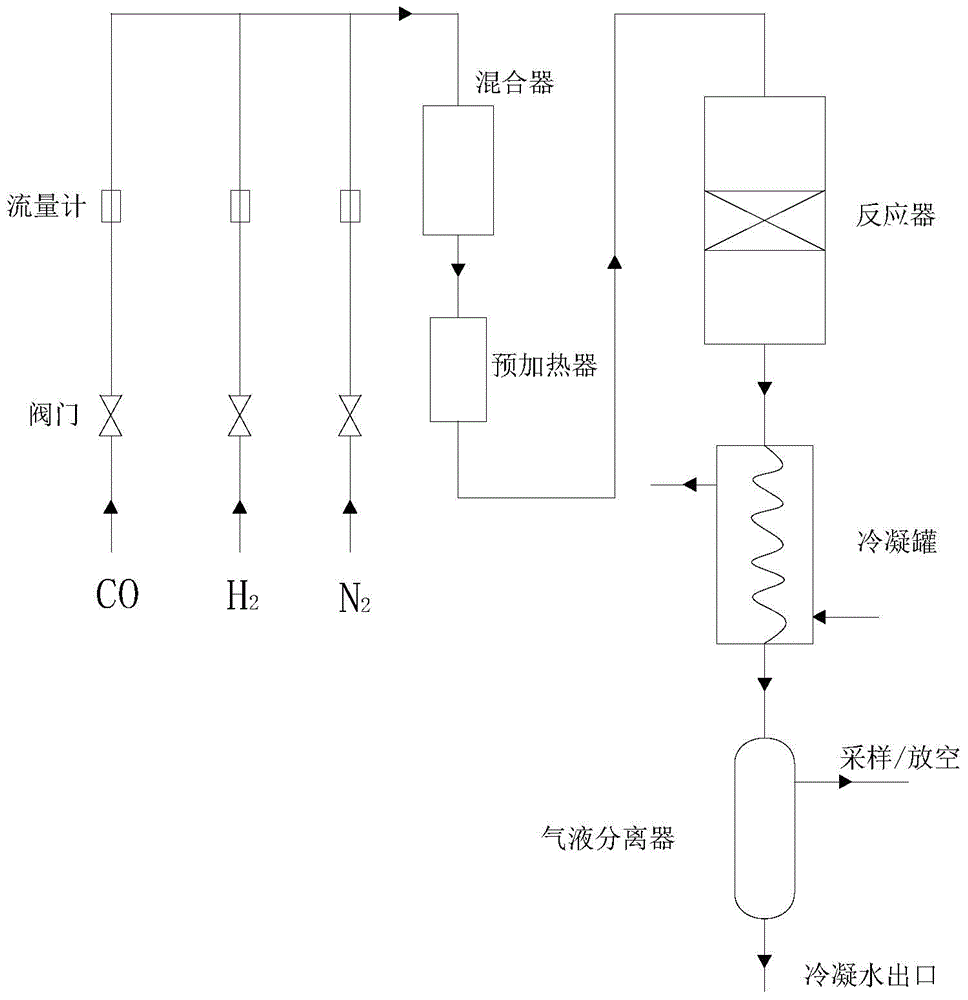

Method used

Image

Examples

Embodiment 1

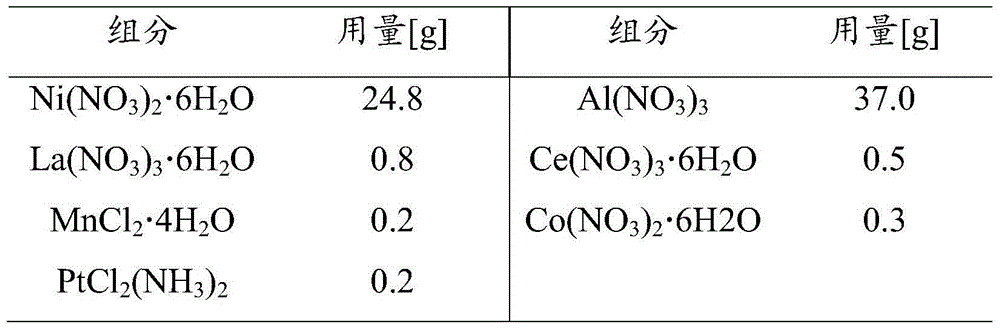

[0040] The high temperature resistant methanation catalyst described in this example is mainly prepared from the raw materials described in Table 1:

[0041] Table 1

[0042]

[0043] The methanation catalyst described in this example is prepared by co-precipitation-equal volume impregnation method, and the specific steps are as follows:

[0044] Weigh 24.8g Ni(NO 3 ) 2 ·6H 2 O, 37.0g Al(NO 3 ) 3 , 0.2g PtCl 2 (NH 3 ) 2 , 100mL of deionized water was prepared as an aqueous solution, and 4 g of PEG 400 was added and stirred evenly. Add ammonia water drop by drop to the above solution, adjust the pH to 11, continue ultrasonication for 2 hours, let it stand for 12 hours, centrifuge, filter, and wash to obtain a solid precipitate, dry at 120°C, and then roast at 800°C to obtain NiO-Al 2 o 3 catalyst.

[0045] Weigh 0.8g La(NO 3 ) 3 ·6H 2 O, 0.5g Ce(NO 3 ) 3 ·6H 2 O, 0.2g MnCl 2 4H 2 O and 0.3gCo(NO 3 ) 2 ·6H 2 O add 10mL deionized water to prepare a soluti...

Embodiment 2

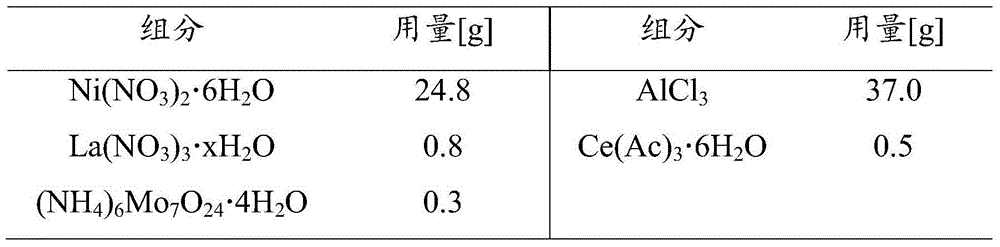

[0047] The high temperature resistant methanation catalyst described in this example is mainly prepared from the raw materials described in Table 2:

[0048] Table 2

[0049]

[0050] The methanation catalyst described in this example is prepared by co-precipitation-equal volume impregnation method, and the specific steps are as follows:

[0051] Weigh 24.8g Ni(NO 3 ) 2 ·6H 2 O, 37.0g AlCl 3 , add 100mL deionized water to prepare an aqueous solution, add 5g PEG 400, and stir well. Add ammonia water drop by drop to the above solution, adjust the pH to 11, continue ultrasonication for 2 hours, let it stand for 12 hours, centrifuge, filter, and wash to obtain a solid precipitate, dry at 120°C, and then roast at 800°C to obtain NiO-Al 2 o 3 catalyst.

[0052] Weigh 0.8g La(NO 3 ) 3 ·6H 2 O, 0.5g Ce(Ac) 3 ·6H 2 O and 0.3g (NH 4 ) 6 Mo 7 o 24 4H 2 O, added with NiO-Al in this example 2 o 3 Prepare a solution with 10mL deionized water with equivalent catalyst volu...

Embodiment 3

[0054] A kind of high temperature resistant methanation catalyst of this embodiment is mainly prepared from the raw materials described in Table 3:

[0055] table 3

[0056]

[0057] The methanation catalyst described in this example is prepared by co-precipitation-equal volume impregnation method, and the specific steps are as follows: Weigh 14.8g Ni(NO 3 ) 2 ·6H 2 O,68.1g Al(NO 3 ) 3 , 0.04g PtCl 2 (NH 3 ) 2 , add 100mL deionized water to prepare an aqueous solution, add 1 g PEG 600, and stir well. Add ammonia water drop by drop to the above solution, adjust the pH to 11, continue ultrasonication for 1 hour, and continue ultrasonication for 4 hours, protect the temperature in an ice-salt bath at 0-2°C, let stand for 10 hours, centrifuge, filter, and wash to obtain a solid precipitate material, dried at 110°C, and then calcined at 700°C to obtain NiO-Al 2 o 3 catalyst.

[0058] Weigh 0.8g La(NO 3 ) 3 ·6H 2 O, 0.8g Ce(Ac) 3 ·H 2 O and 0.5g Co(NO 3 ) 2 ·6H ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com