A kind of low-carbon alkane dehydrogenation catalyst and preparation method thereof

A technology for dehydrogenation catalysts and low-carbon alkanes, applied in the direction of carbon compound catalysts, catalysts, hydrocarbons, etc., to achieve the effect of increasing active sites, promoting uniform dispersion and reducing deactivation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

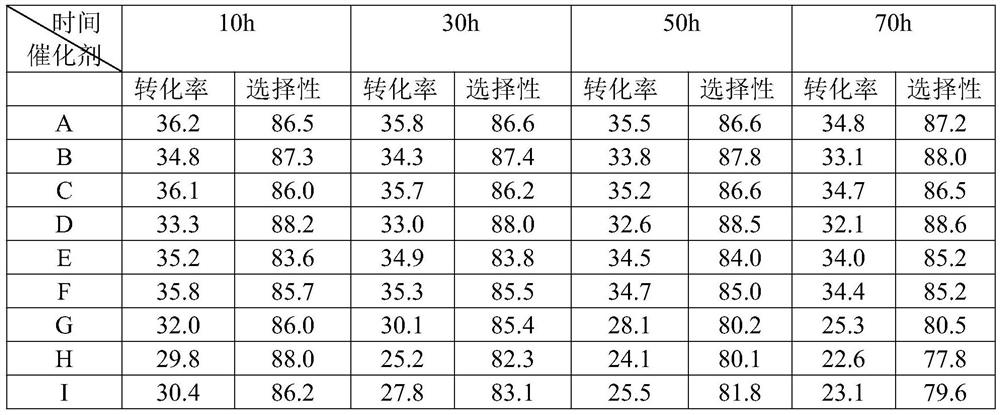

Examples

Embodiment 1

[0031] Weigh 1.0g SnCl 2 Dissolve in 5ml hydrochloric acid, add 0.6g CeCl under stirring 3 , stirred for 30 minutes to make the solution uniform, and then slowly added dropwise ammonia water until the pH was 8, while stirring. After the dropwise addition of ammonia water, stirred for 30 minutes, then stood still for 30 minutes. The precipitate was filtered, dried at 120°C for 2 hours, calcined at 550°C for 3 hours, and then the obtained solid solution was ground into a fine powder below 40 μm. Weigh 30.0g of pseudo-boehmite and pour it into 30.0g of deionized water and stir, then add Sn-Ce-O solid solution fine powder and stir, slowly add 5.8g of hydrochloric acid solution dropwise to make the solution into a sol state, prepared by the oil ammonia column method spherical shape, then dried at 100°C for 3h, and then calcined at 600°C for 4h to prepare a composite alumina carrier containing Sn-Ce-O solid solution. Dissolve 0.3g of chloroplatinic acid in 10g of dilute hydrochlor...

Embodiment 2

[0033] Weigh 1.2g SnCl 2 Dissolve in 5ml hydrochloric acid, add 0.4g TiCl under stirring 4 , stirred for 60 minutes to make the solution uniform, and then slowly added dropwise ammonia water until the pH was 7.0 while stirring. The precipitate was filtered, dried at 100°C for 2 hours, calcined at 620°C for 3 hours, and then the obtained solid solution was ground into a fine powder below 40 μm. Weigh 32.0g of aluminum hydroxide, add Sn-Ti-O solid solution fine powder, pour into 15.0g of deionized water and knead, use extruder to make strips, then dry at 130°C for 3h, and roast at 700°C for 4h to prepare Sn-Ti-containing Composite alumina support for -O solid solution. Dissolve 1.2g of chloroplatinic acid and 0.5g of KCl in 10g of dilute hydrochloric acid, add a composite alumina carrier containing Sn-Ti-O solid solution under stirring, mix well, then dry at 120°C for 2h, and roast at 750°C for 2h to obtain low-carbon Alkane dehydrogenation catalyst B. Evaluation conditions ...

Embodiment 3

[0035] Weigh 0.8g SnCl 2 Dissolve in 5ml hydrochloric acid, add 0.6g FeCl under stirring 3 , stirred for 60 minutes to make the solution uniform, and then slowly added dropwise ammonia water until the pH was 7.0 while stirring. The precipitate was filtered, dried at 100°C for 2 hours, calcined at 620°C for 3 hours, and then the obtained solid solution was ground into a fine powder below 40 μm. Weigh 35.0g macroporous pseudo-boehmite, add Sn-Fe-O solid solution fine powder, pour 15.0g deionized water and knead, use extruder to make strips, then dry at 130°C for 3h, and roast at 700°C for 4h to prepare Composite alumina support containing Sn-Fe-O solid solution. Dissolve 0.08g of chloroplatinic acid and 0.5g of KCl in 10g of dilute hydrochloric acid, add a composite alumina carrier containing Sn-Fe-O solid solution under stirring, mix well, then dry at 150°C for 8h, and roast at 750°C for 2h to obtain low-carbon Alkane dehydrogenation catalyst C. Evaluation conditions are th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com