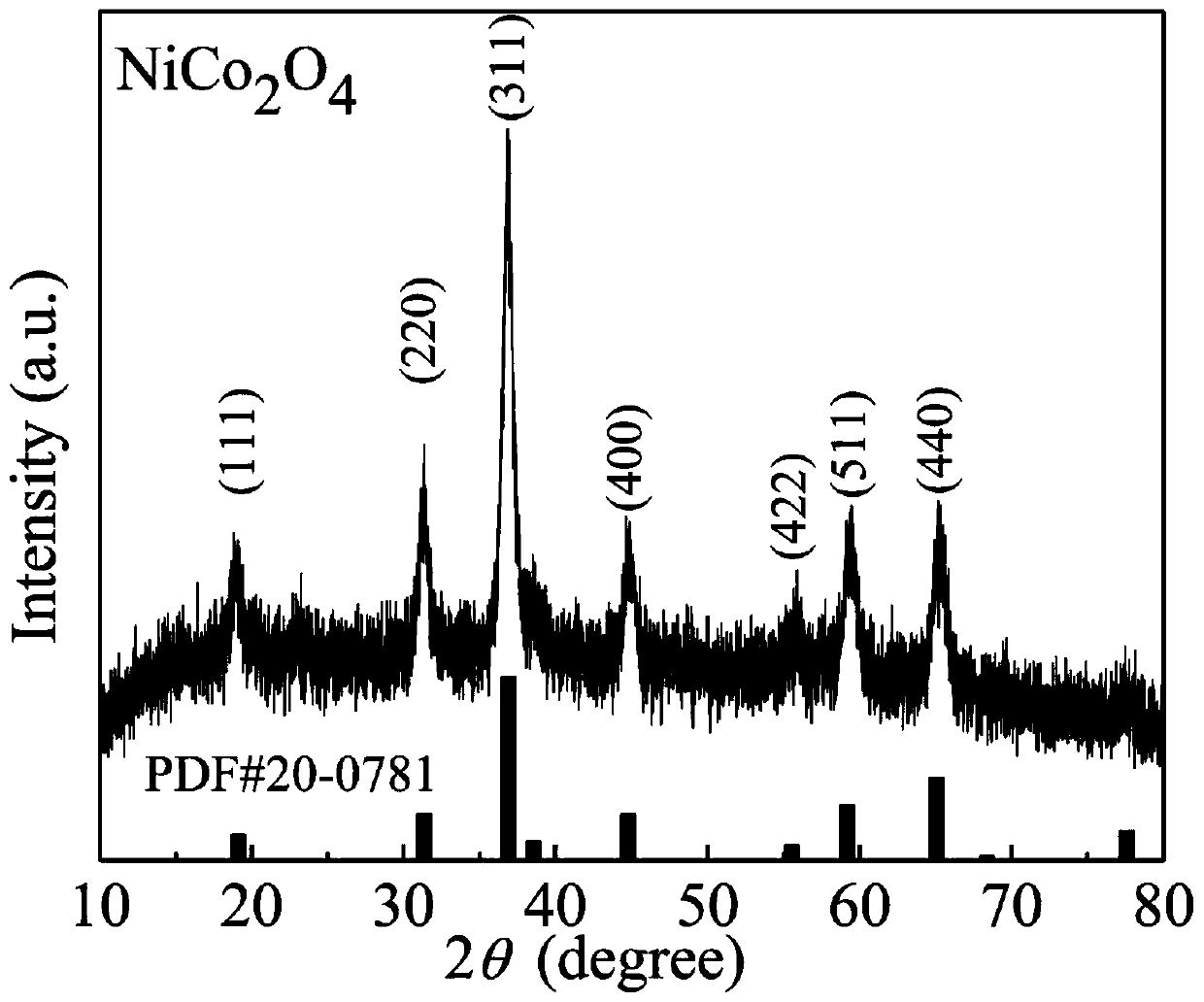

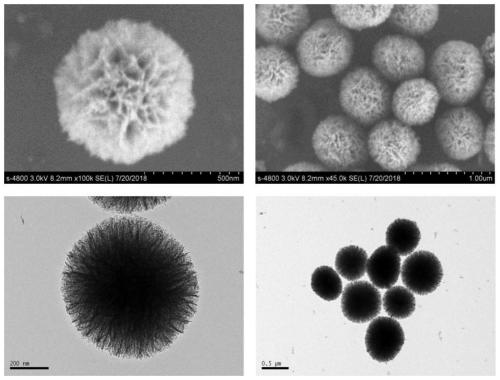

NiCo2O4 nano flower-like composite material and preparation method thereof

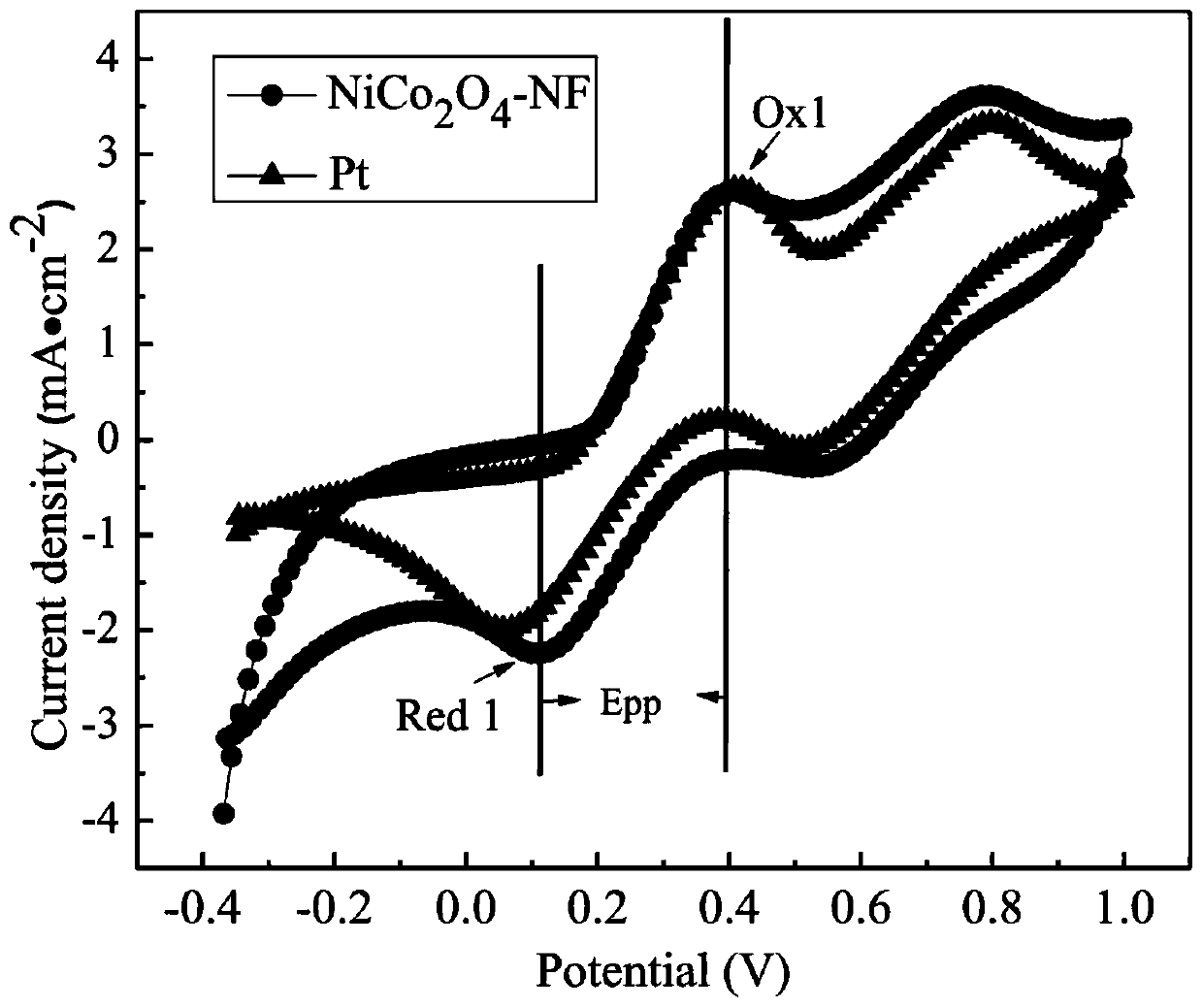

A composite material, nickel cobalt oxide technology, used in nickel compounds, nanotechnology, chemical instruments and methods, etc., to achieve the effect of enhancing the ability to store electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A preparation method of nickel cobaltate nano-flower composite material, comprising the following steps:

[0043] (1) Slowly pour 1,3 propylene glycol and isopropanol into a beaker to prepare a mixed solution, and continue stirring with a magnetic stirrer for 0.4h, so that the mixed solution is evenly mixed; wherein, 1,3 propylene glycol and isopropanol in the mixed solution The volume ratio is 3:1;

[0044] (2) Slowly add nickel acetate tetrahydrate and cobalt acetate tetrahydrate into the mixed solution of step (1) in sequence, and continue to stir for 0.8h with a magnetic stirrer, so that the mixed solution is evenly mixed; wherein, nickel acetate tetrahydrate and nickel acetate tetrahydrate The mass ratio of cobalt acetate is 1:2;

[0045] (3) Transfer the mixed solution of step (2) to a Teflon autoclave lined with polytetrafluoroethylene, put the Teflon autoclave into a blast drying oven, and set 155°C to react for 13h ;

[0046] (4) After being cooled to room t...

Embodiment 2

[0050] A preparation method of nickel cobaltate nano-flower composite material, comprising the following steps:

[0051] (1) Slowly pour 1,3 propylene glycol and isopropanol into a beaker to prepare a mixed solution, and continue stirring with a magnetic stirrer for 0.5h, so that the mixed solution is evenly mixed; wherein, 1,3 propylene glycol and isopropanol in the mixed solution The volume ratio is 3:1;

[0052] (2) Slowly add nickel acetate tetrahydrate and cobalt acetate tetrahydrate into the mixed solution of step (1) in sequence, and continue to stir for 1 hour with a magnetic stirrer, so that the mixed solution is evenly mixed; wherein, nickel acetate tetrahydrate and acetic acid tetrahydrate The mass ratio of cobalt is 1:2;

[0053] (3) Transfer the mixed solution of step (2) to a Teflon autoclave lined with polytetrafluoroethylene, put the Teflon autoclave into a blast drying oven, and set the reaction temperature at 160°C for 12 hours ;

[0054] (4) to be cooled ...

Embodiment 3

[0058] A preparation method of nickel cobaltate nano-flower composite material, comprising the following steps:

[0059](1) Slowly pour 1,3 propylene glycol and isopropanol into a beaker to prepare a mixed solution, and continue stirring with a magnetic stirrer for 0.6h, so that the mixed solution is evenly mixed; wherein, 1,3 propylene glycol and isopropanol in the mixed solution The volume ratio is 3:1;

[0060] (2) Slowly add nickel acetate tetrahydrate and cobalt acetate tetrahydrate into the mixed solution of step (1) successively, and continue stirring with a magnetic stirrer for 0.8-1.2h, so that the mixed solution is evenly mixed; wherein, nickel acetate tetrahydrate and The mass ratio of cobalt acetate tetrahydrate is 1:2;

[0061] (3) Transfer the mixed solution of step (2) to a Teflon autoclave lined with polytetrafluoroethylene, and put the Teflon autoclave into a blast drying oven, set 165°C for 11 hours ;

[0062] (4) to be cooled to room temperature, the solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com