Patents

Literature

98 results about "Nickel acetate tetrahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

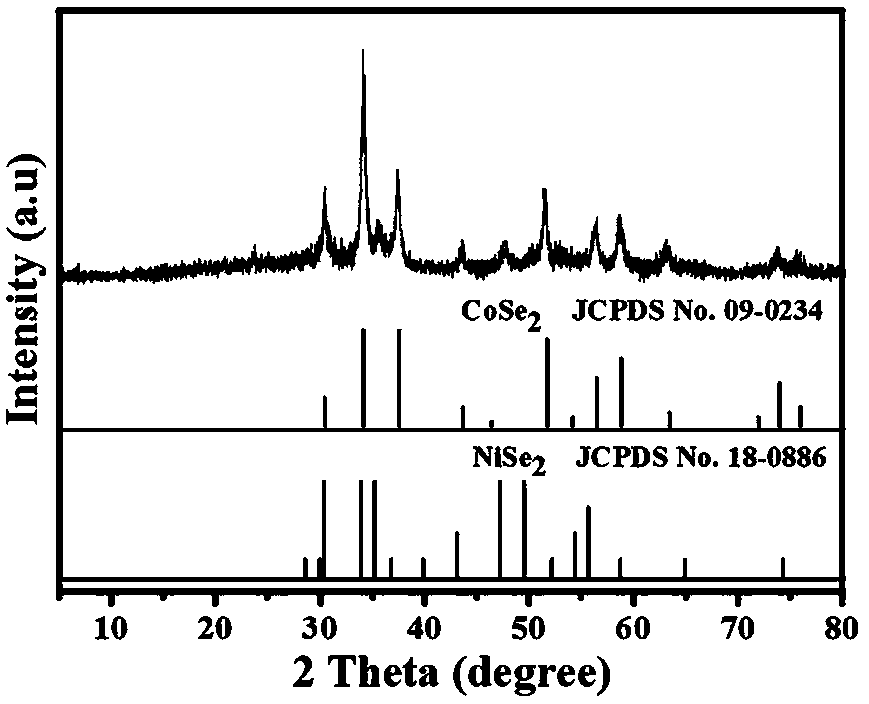

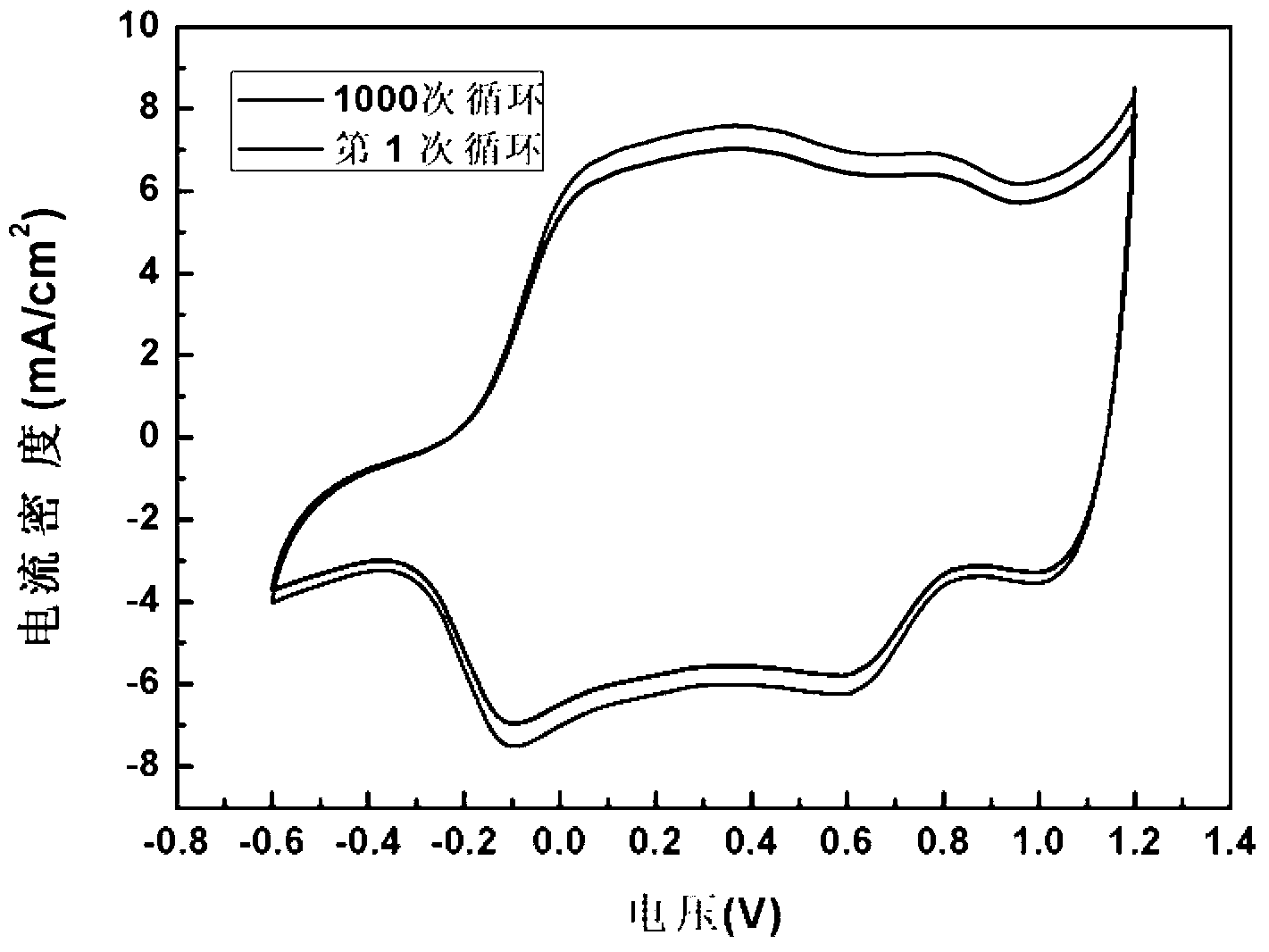

Co-Ni bimetallic selenide/graphene composite electrode material

InactiveCN109243852AAvoid residueHigh purityHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceNickel acetate tetrahydrate

The invention discloses a cobalt-nickel bimetallic selenide / graphene composite electrode material, and belongs to the preparation field of electrode material for supercapacitors. A manufacture methodcomprises that follow steps: adding graphene oxide (GO) into ethylene glycol solution, ultrasonic dispersing, and uniformly dispersing GO in the ethylene glycol solution; Adding polyvinylpyrrolidone(PVP), cobalt acetate tetrahydrate and nickel acetate tetrahydrate into the GO dispersion, ultrasonic dispersing and dissolving, transferring it to a round bottom flask for oil bath reaction and centrifugal washing and drying; After centrifugal washing and drying after oil bath, the product was hydrothermally selenized with sodium selenite and hydrazine hydrate to obtain Co-Ni bimetallic selenide / graphene composite electrode material. A large number of uniform size Co-Ni-Se nanosheets were uniformly loaded on graphene substrate, and the prepared electrode materials had high specific capacitance and excellent rate performance.

Owner:FUZHOU UNIV

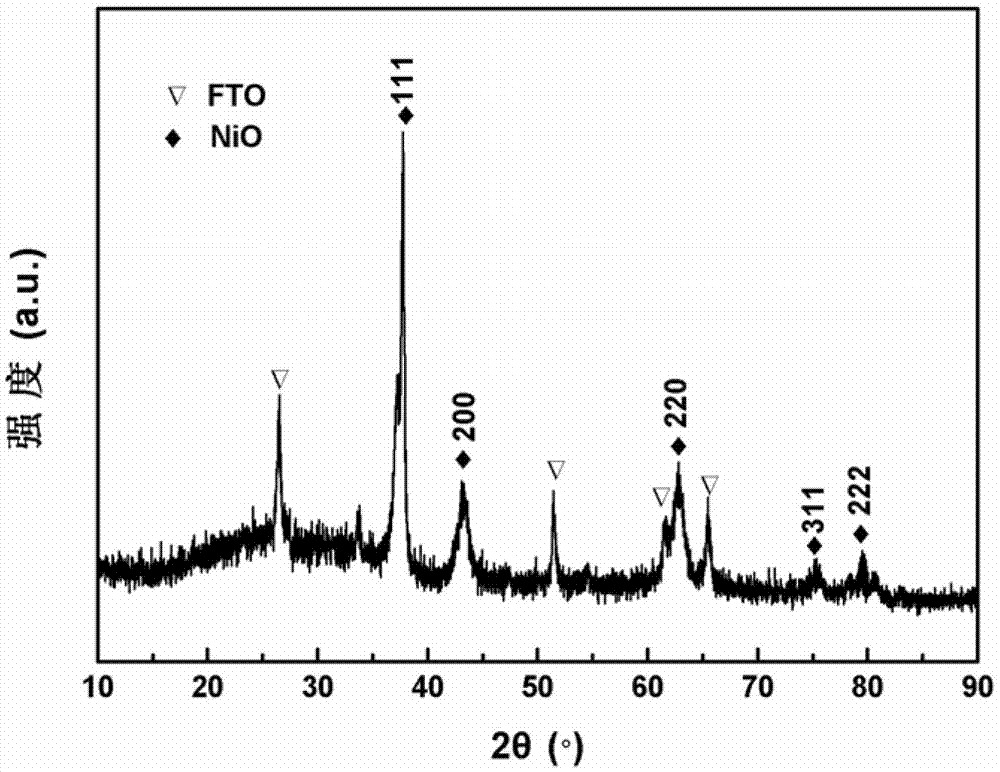

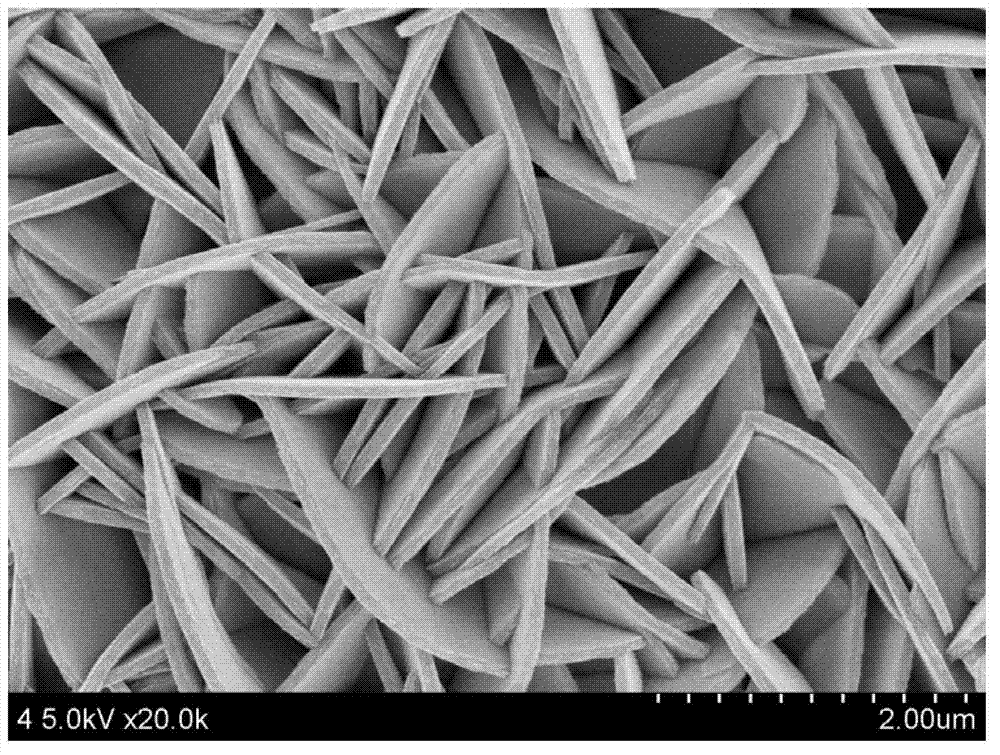

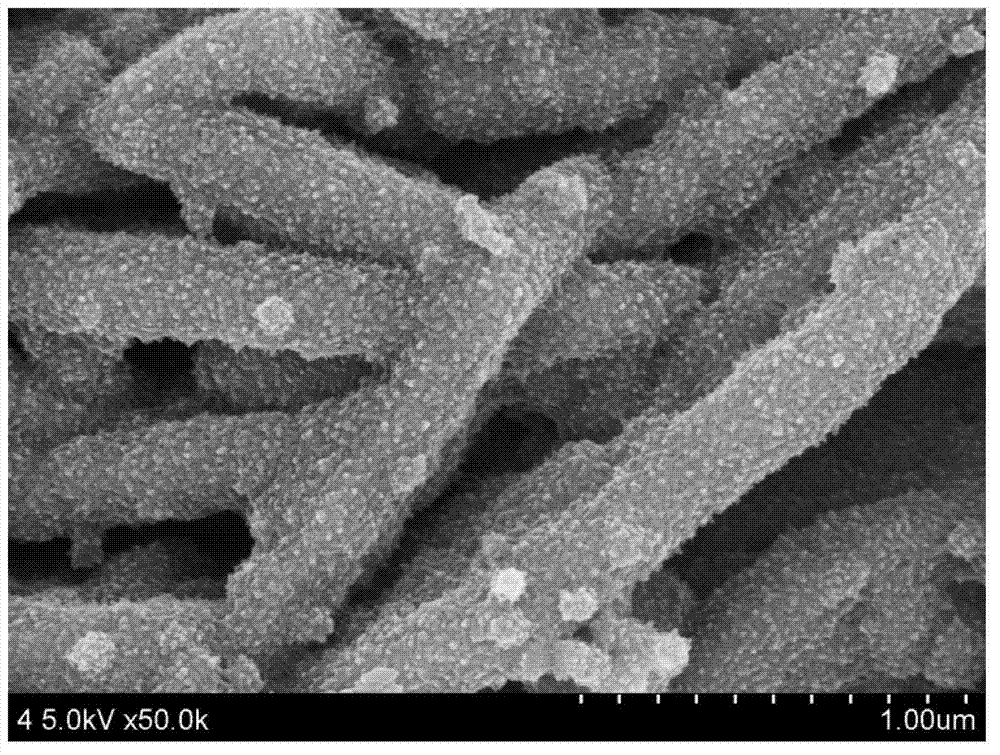

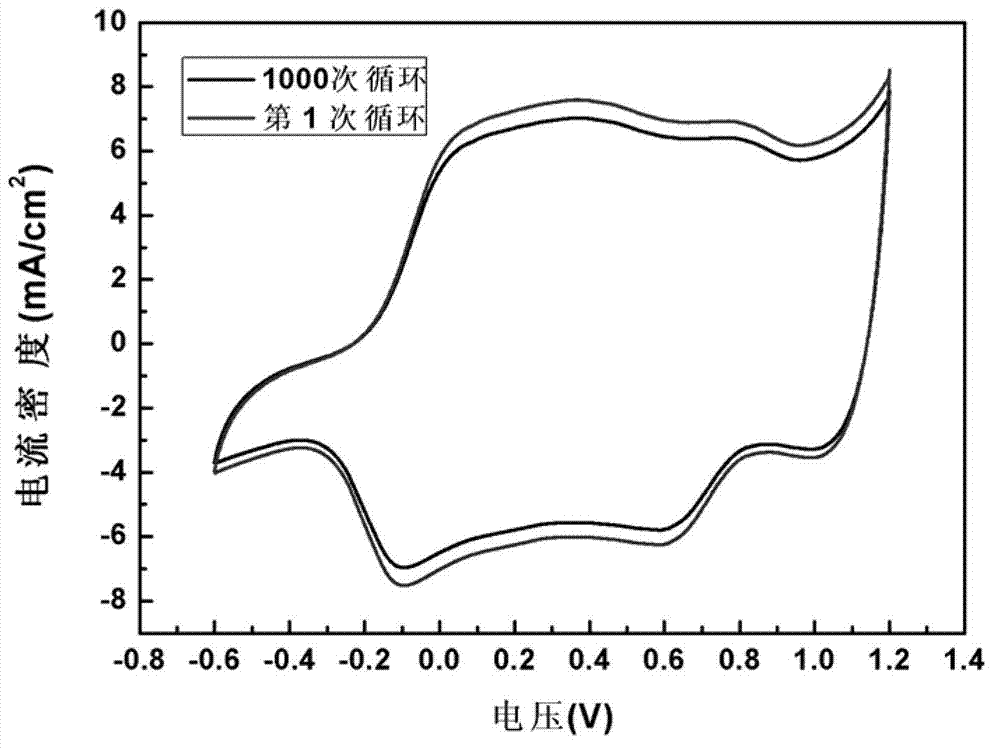

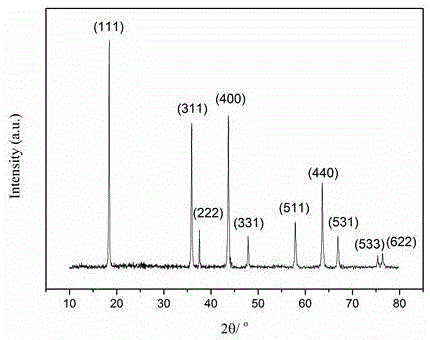

Method for preparing nickel oxide electrochromic film by hydrothermal method

ActiveCN103172273ALarge specific surface areaReduce path lengthNickel oxides/hydroxidesNickel acetate tetrahydrateSolvent

The invention relates to a method for preparing a nickel oxide electrochromic film by a hydrothermal method. The method comprises the following steps of: dissolving nickel acetate tetrahydrate in a mixed solution of alcohol and n-butyl alcohol, dropwise adding ammonia water to the mixed solution after the nickel acetate tetrahydrate is dissolved to obtain sol; coating the sol to the surface of FTO (Fluorine-doped Tin Oxide) conductive glass in a rotary manner, drying the sol to obtain the FTO conductive glass with a crystal seed layer; mixing the nickel acetate tetrahydrate, urea and a solvent to obtain a reaction solution; immersing the FTO conductive glass with the crystal seed layer to the reaction solution for carrying out hydrothermal reaction; keeping the reaction solution for 6 hours to 12 hours under the condition of 160 DEG C to 180 DEG C, cooling the reaction solution to the room temperature, cleaning, drying and roasting to obtain the nickel oxide electrochromic film. The preparation method disclosed by the invention is simple, low in cost and likely applied to the glass surface film-making industry. The nanometer structure nickel oxide film directly grows on the surface of the FTO conductive glass by a hydrothermal method, so that the nickel oxide and the substrate have better binding force for being beneficial to electron conduction. Meanwhile, the electrochemical stability of the film is also improved.

Owner:DONGHUA UNIV

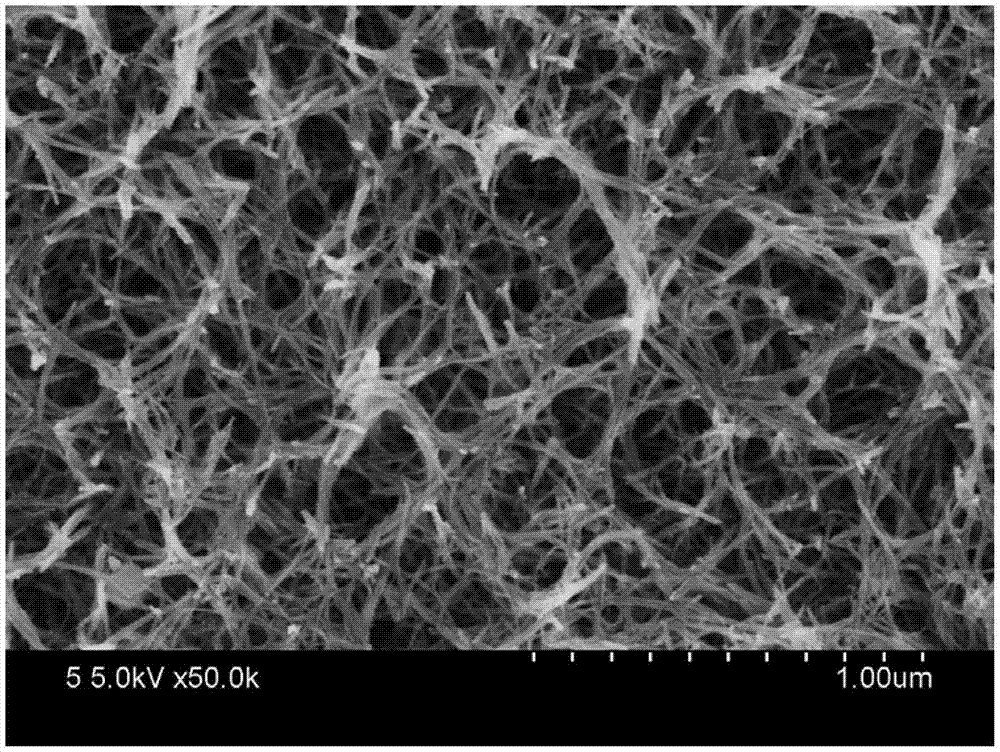

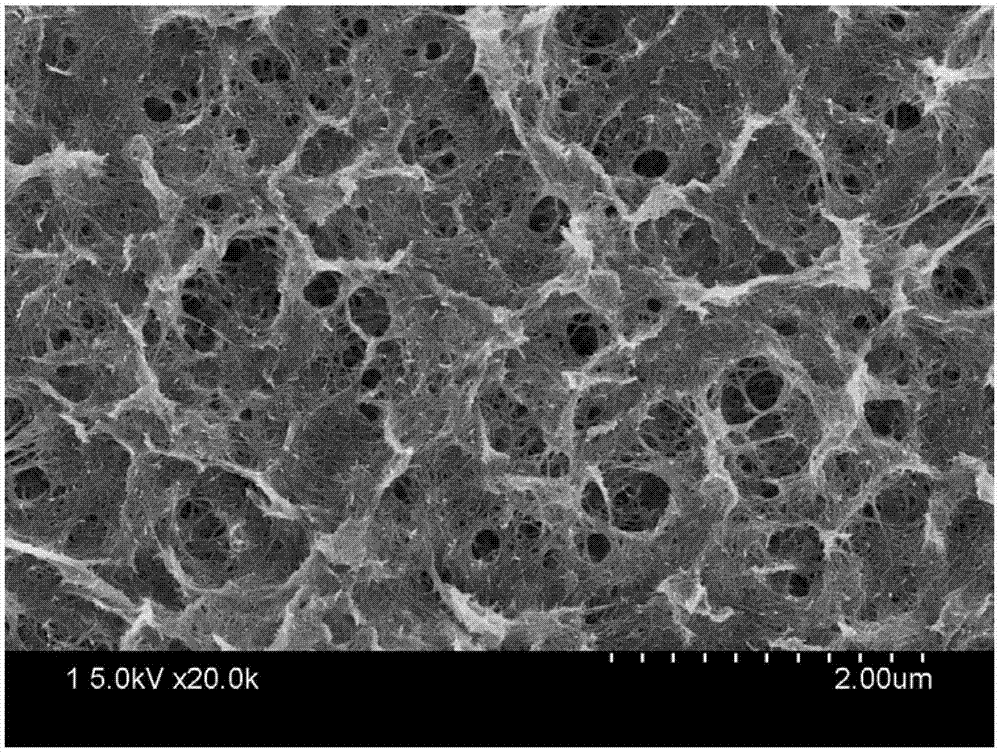

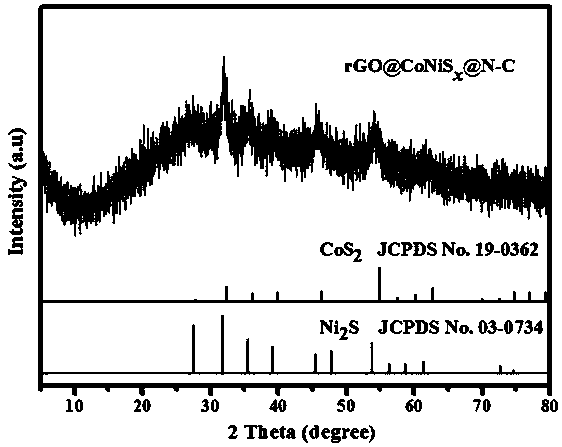

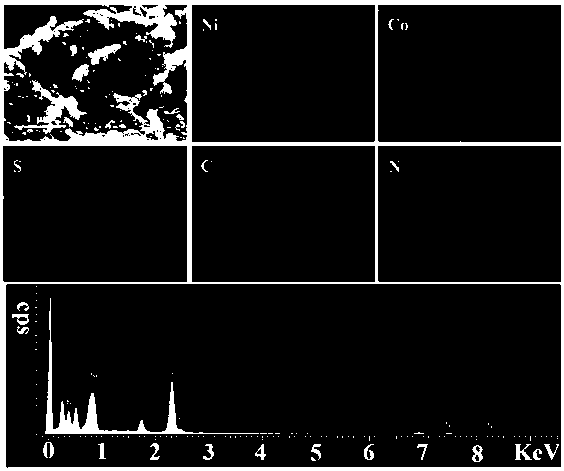

N-doped carbon-coated cobalt-nickel sulfide/graphene composite electrode material

InactiveCN108075128ASimple preparation processImprove controllabilityHybrid capacitor electrodesCell electrodesCapacitanceThiourea

The invention discloses an N-doped carbon-coated cobalt-nickel sulfide / graphene composite electrode material and a preparation method thereof, belonging to the field of preparation of an electrode material for super capacitors. The preparation method comprises the following processes: adding graphene oxide (GO) into an ethylene glycol solution, and performing ultrasonic dispersion to enable the GOto be uniformly dispersed in the ethylene glycol solution; adding polyvinylpyrrolidone (PVP), cobaltous acetate tetrahydrate and nickel acetate into a GO dispersion solution prepared above, after ultrasonic dispersion and dissolution, transferring to a round bottom flask to perform oil bath reaction and performing centrifugal washing and drying; enabling a product, which is dried via centrifugalwashing after oil bath, to calcine with thiourea to obtain the N-doped carbon-coated cobalt-nickel sulfide / graphene composite electrode material. According to the prepared electrode material, N-dopedcarbon is coated outside cobalt-nickel sulfide particles which have uniform sizes in microstructure, the electrode material is uniformly loaded on the substrate of graphene, and meanwhile, the electrode material has relatively high specific capacitance, excellent rate capability and cycling stability.

Owner:FUZHOU UNIV

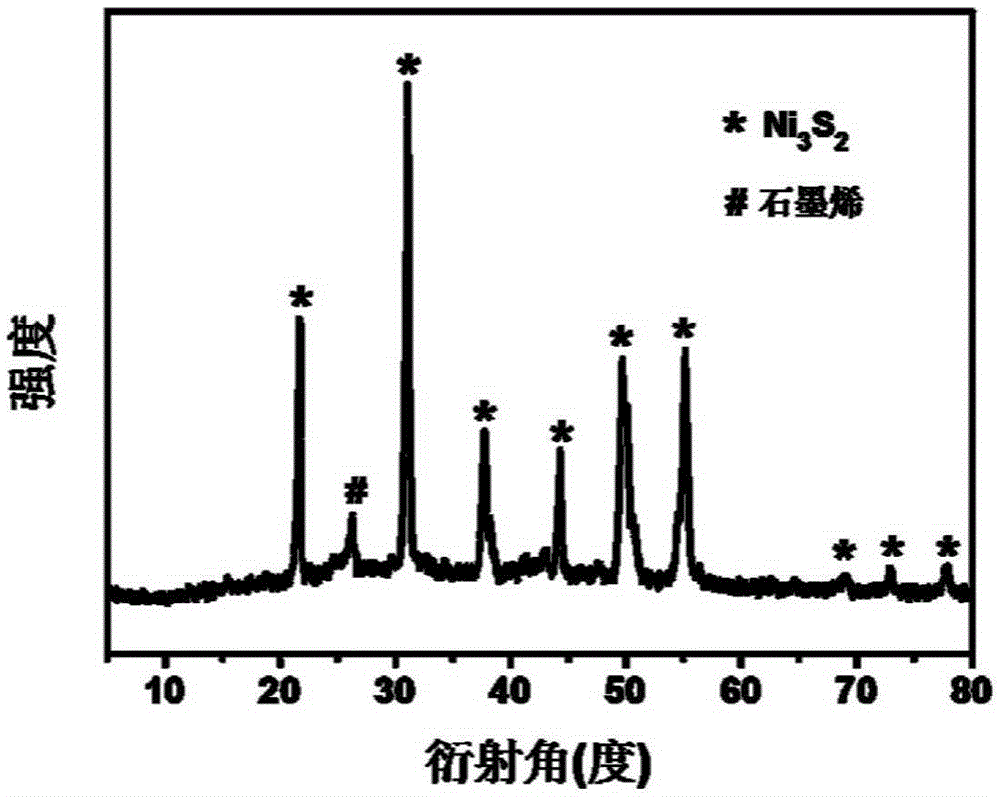

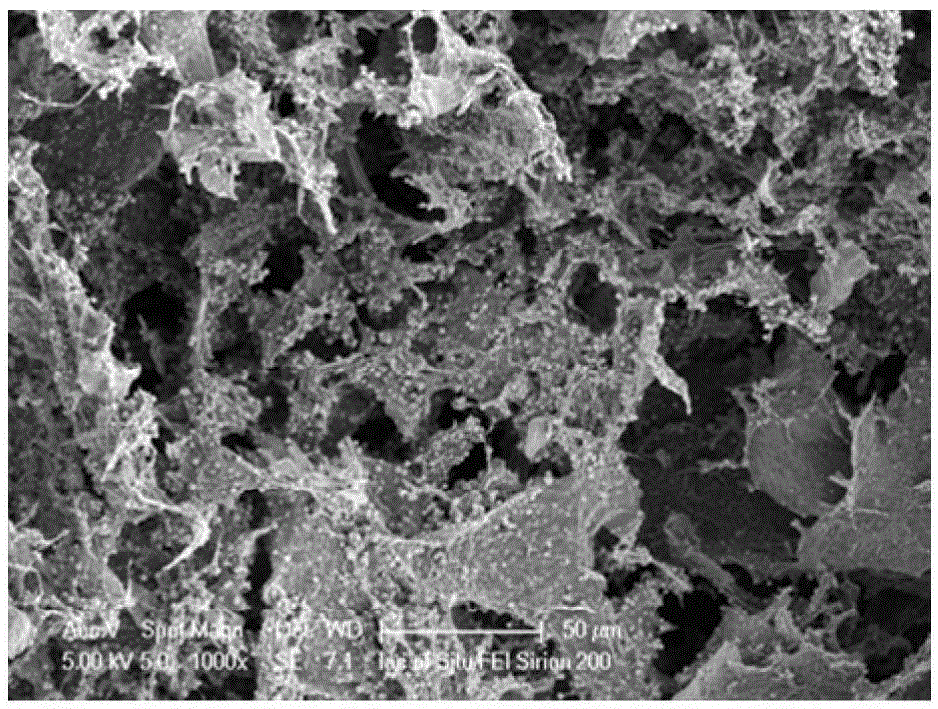

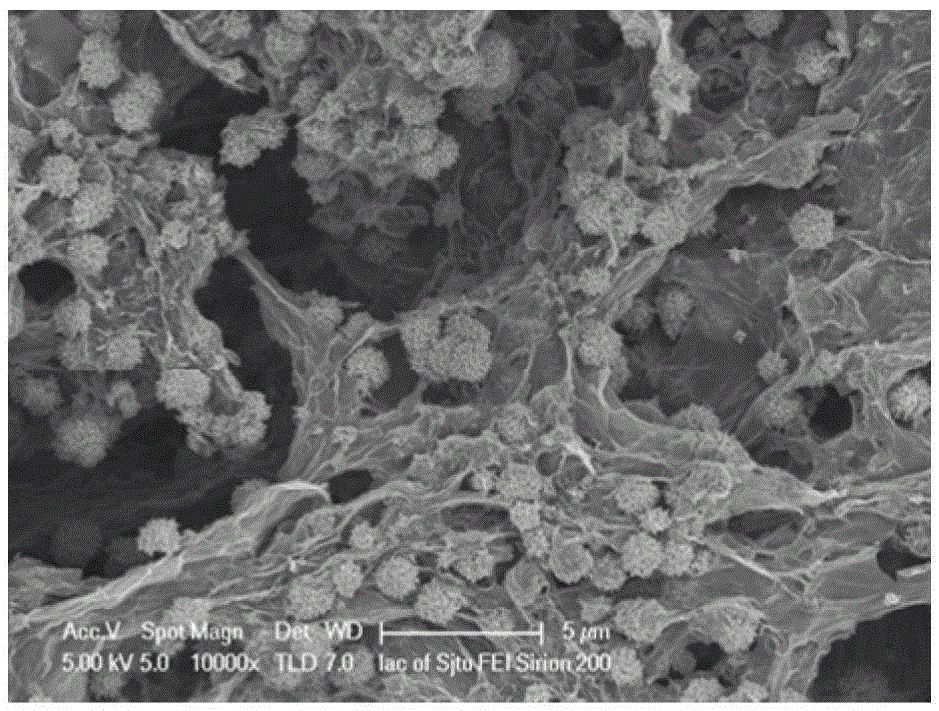

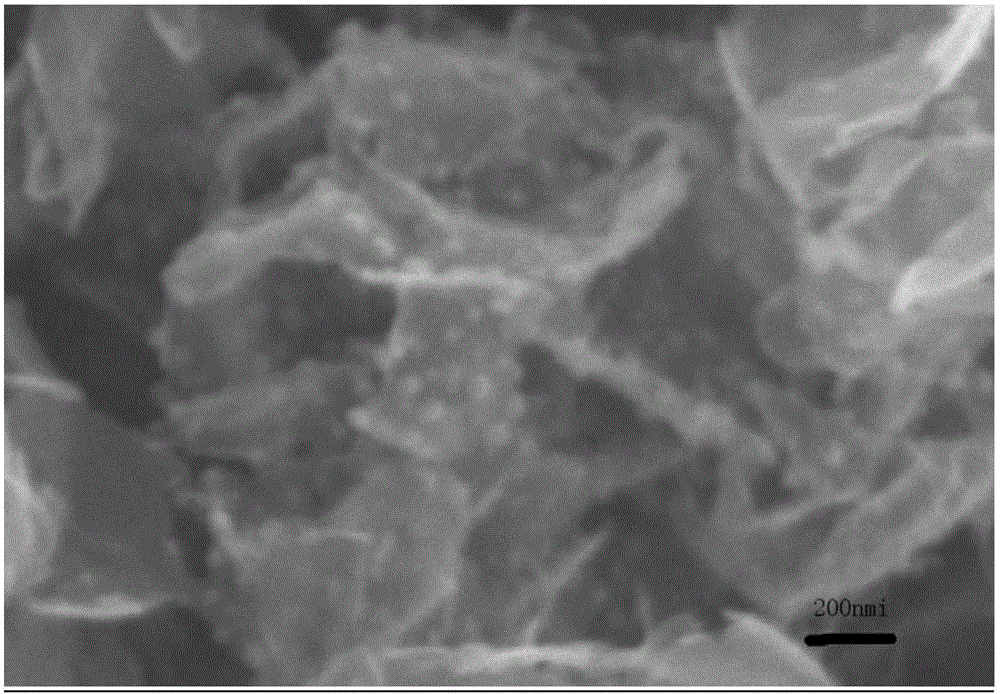

Flower type Ni<3>S<2>/graphene three-dimensional composite electrode material and preparation method thereof

ActiveCN105244176AImprove conductivityNo agglomerationHybrid capacitor electrodesHybrid/EDL manufactureComposite electrodeThiourea

The invention discloses a flower type Ni<3>S<2> / graphene three-dimensional composite electrode material and a preparation method thereof. In the flower type Ni<3>S<2> / graphene three-dimensional composite electrode material, graphene is taken as a substrate, and flower type Ni<3>S<2> particles are uniformly grown on the surface of the graphene. The preparation method of the flower type Ni<3>S<2> / graphene three-dimensional composite electrode material comprises the following steps of uniformly dispersing the graphene, thiourea, nickel acetate tetrahydrate and a three-block polymer F127 in distilled water with ultrasound; carrying out hydrothermal reaction on the obtained solution at 160-200 DEG C; dialyzing the gel-like mixture in the distilled water and then drying the gel-like mixture; and calcining the obtained gel-like solid at a controlled temperature of 750-850 DEG C under the protection of N2, thereby obtaining the black gel-like flower type Ni<3>S<2> / graphene three-dimensional composite electrode material which has high specific capacitance, charging and discharging stability, favorable conductivity and large specific surface area. The flower type Ni<3>S<2> / graphene three-dimensional composite electrode material can be used as an electrode material of a supercapacitor, and the preparation process is simple, and is convenience in operation and high in repeatability.

Owner:SHANGHAI INST OF TECH

Preparation method of nickel oxide/polyaniline composite electrochromic film

The invention relates to a preparation method of a nickel oxide / polyaniline composite electrochromic film. The preparation method comprises the following steps of: soaking FTO (Fluorine-doped Tin Oxide) conductive glass into a mixed solution, keeping the temperature of 160-180 DEG C for 6-12hours, naturally cooling to the room temperature, cleaning and calcining to obtain FTO conductive glass with a NiO layer, wherein the mixed solution is prepared from nickel acetate tetrahydrate, potassium persulfate, ammonia water and water; and dissolving an aniline monomer into a sulfuric acid solution to obtain a deposition liquid, then, soaking the FTO conductive glass with the NiO layer into the deposition liquid to be used as a working electrode, and carrying out electrolytic deposition on the electrode by using a platinum sheet to obtain the nickel oxide / polyaniline composite electrochromic film. By the preparation method, organic and inorganic electrochromic materials are compounded on the micro-nano level; and the prepared film has favorable electrochromic performance and a wide application prospect in the fields such as intelligent windows and large screen display.

Owner:DONGHUA UNIV

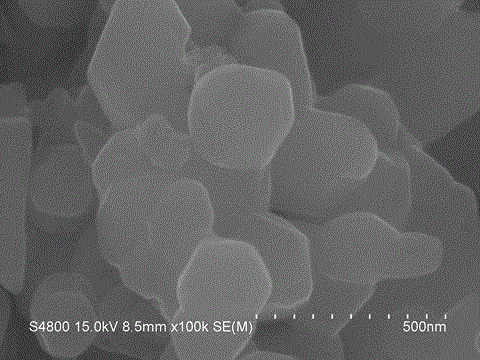

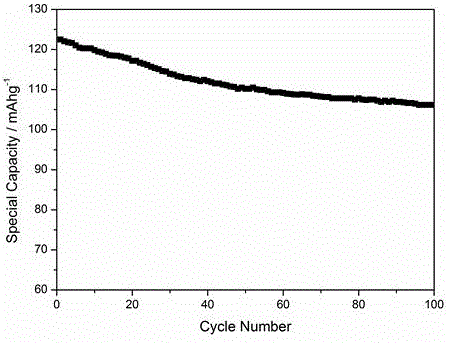

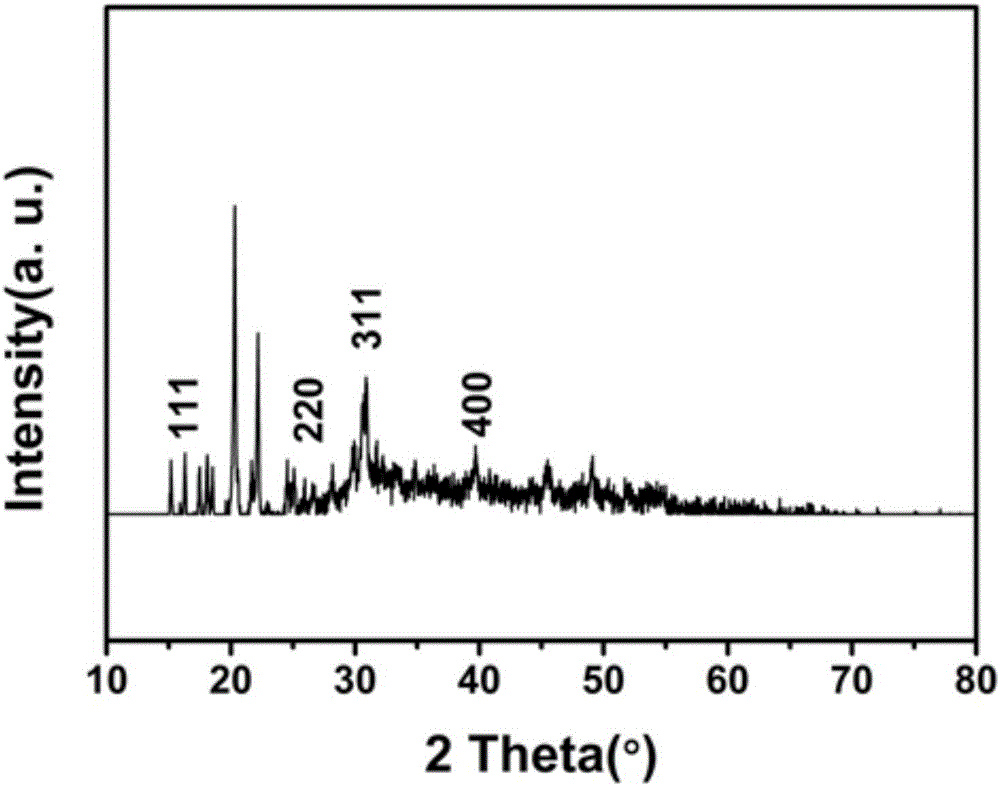

Cobaltosic oxide coated and modified nickel-doped lithium manganate and preparation method thereof

InactiveCN106356509AInhibition of dissolutionIncrease contentCell electrodesSecondary cellsMANGANESE ACETATE TETRAHYDRATENickel acetate tetrahydrate

The embodiment of the invention discloses modified lithium manganate coated based on a sol-gel method, and a preparation method thereof. The preparation method comprises the steps of preparing a nickel-doped lithium manganate material with the sol-gel method by firstly, weighing lithium hydroxide monohydrate, nickel acetate tetrahydrate, manganese acetate tetrahydrate and citric acid according to a certain stoichiometric ratio, adding deionized water, and uniformly mixing, wherein the citric acid is used as a chelating agent; mixing the prepared nickel-doped lithium manganate with cobalt acetate tetrahydrate; grinding, and calcining in a tube furnace to obtain a cobaltosic oxide coated and modified nickel-doped lithium manganate composite material. The composite material prepared by using the technical scheme has excellent cycling stability, rate capability and high-temperature performance.

Owner:EAST CHINA UNIV OF SCI & TECH

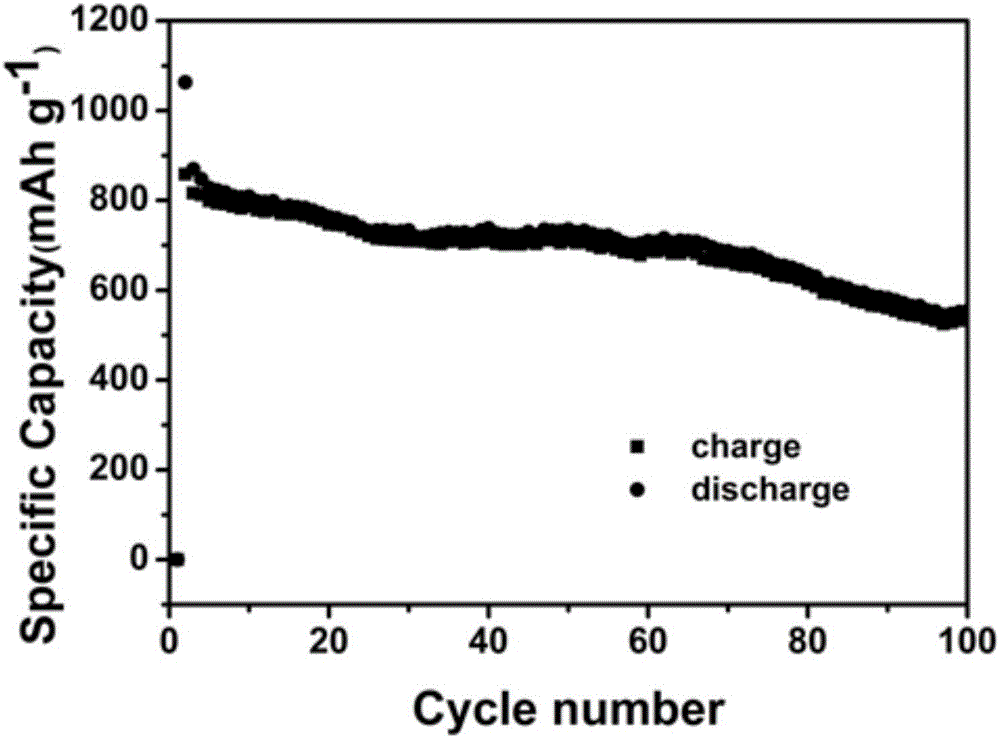

Preparation method of lithium ion battery cathode GO-PANI-Ni3S2 composite material

InactiveCN106207111AImprove cycle performanceGood rate charge and discharge capacityCell electrodesSecondary cellsIce waterFreeze-drying

The invention relates to a preparation method of a lithium ion battery cathode GO-PANI-Ni3S2 composite material. The preparation method comprises the following steps of: carrying out uniform ultrasonic dispersion on graphene oxide; respectively adding lauryl sodium sulfate water solution and aniline to carry out mixing; carrying out ultrasonic treatment to form stable and uniform mixed liquid; carrying out ice-water bath stirring and adding, drop by drop, ammonium persulfate which is acidized by hydrochloric acid; and carrying out ice-water bath stirring for 12 hours to obtain deep green solution; centrifuging and washing the deep green solution to obtain a gelatinous substance; ultrasonically dispersing the gelatinous substance in hydrochloric acid solution; dropwise adding nickel acetate tetrahydrate water solution into the hydrochloric acid solution and carrying out uniform ultrasonic processing; stirring the mixture at room temperature for 1 hour; carrying out hydrothermal treatment at 180 DEG C for 12 hours; adding sodium sulfide nonahydrate water solution; and carrying out centrifugation, washing and freeze-drying to obtain the lithium ion battery cathode material. Compared with the prior art, the composite cathode material has good cycle performance and high-magnification charging-discharging capacity, so that the performance of lithium ion batteries which take the material as a cathode material is improved.

Owner:上海德朗能动力电池有限公司 +2

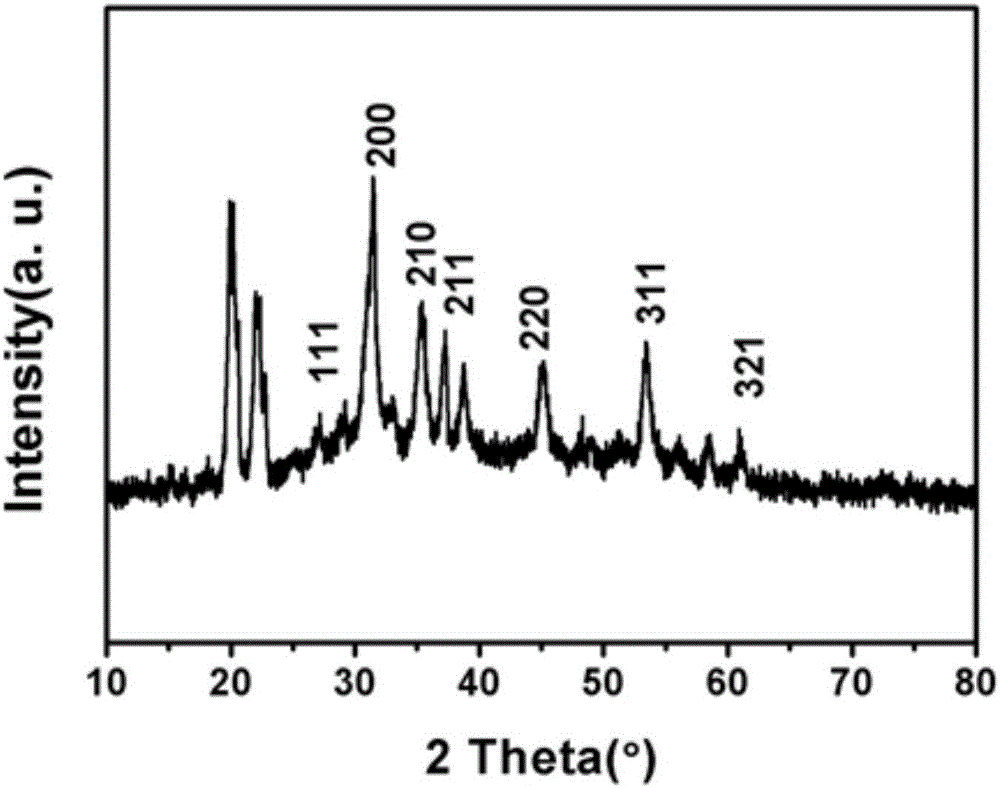

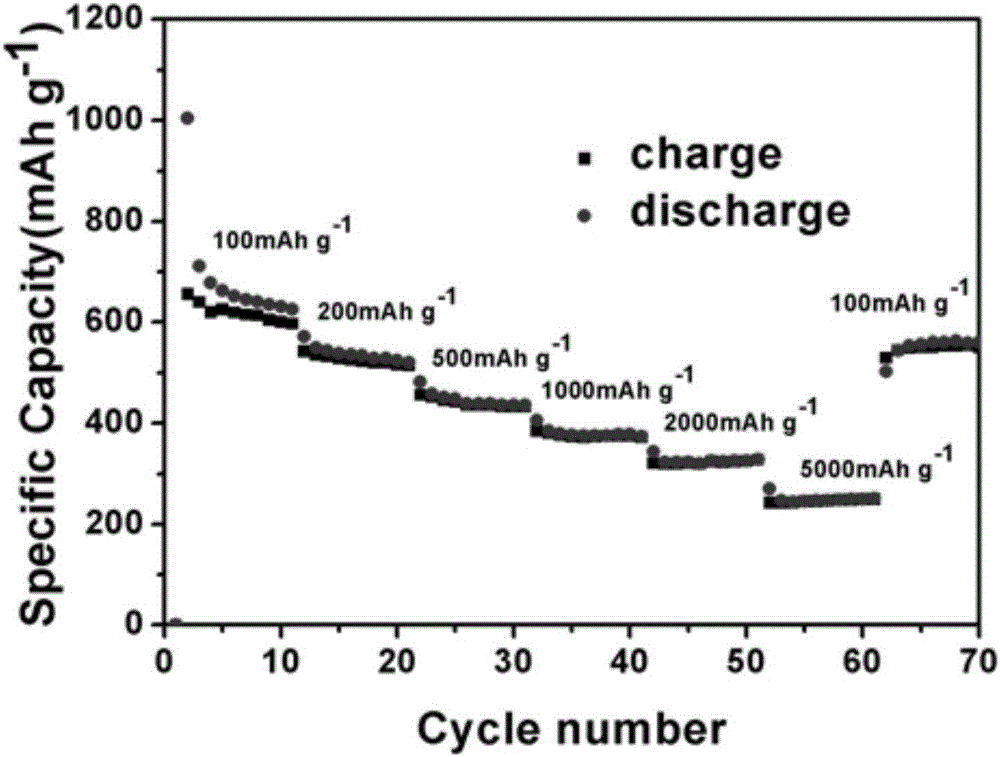

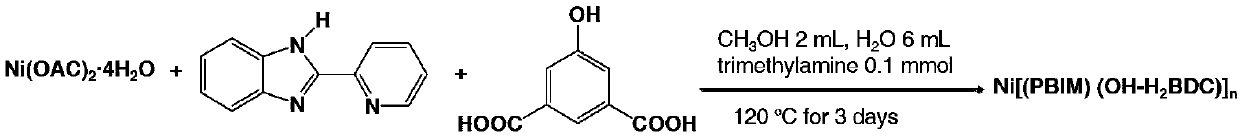

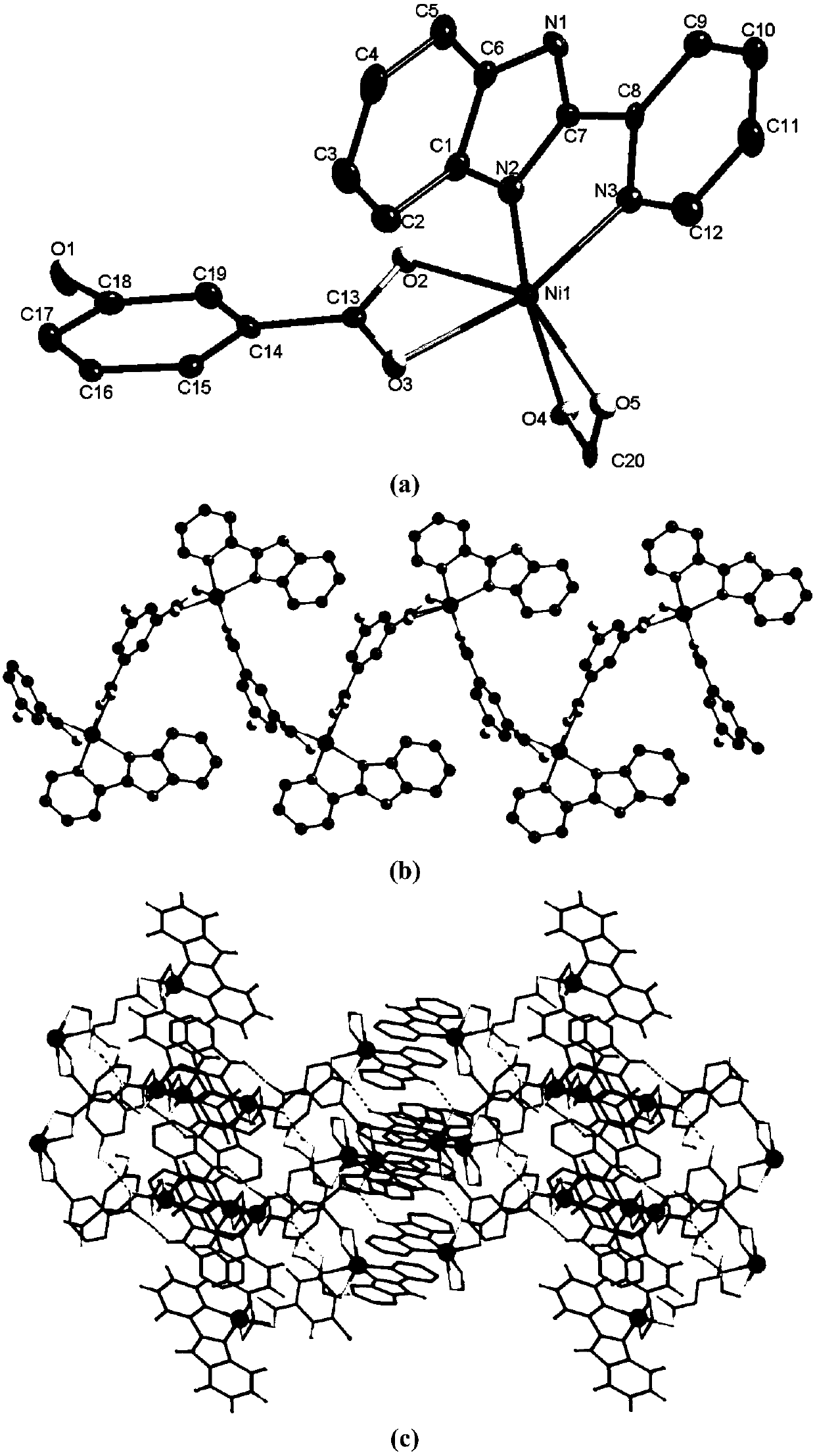

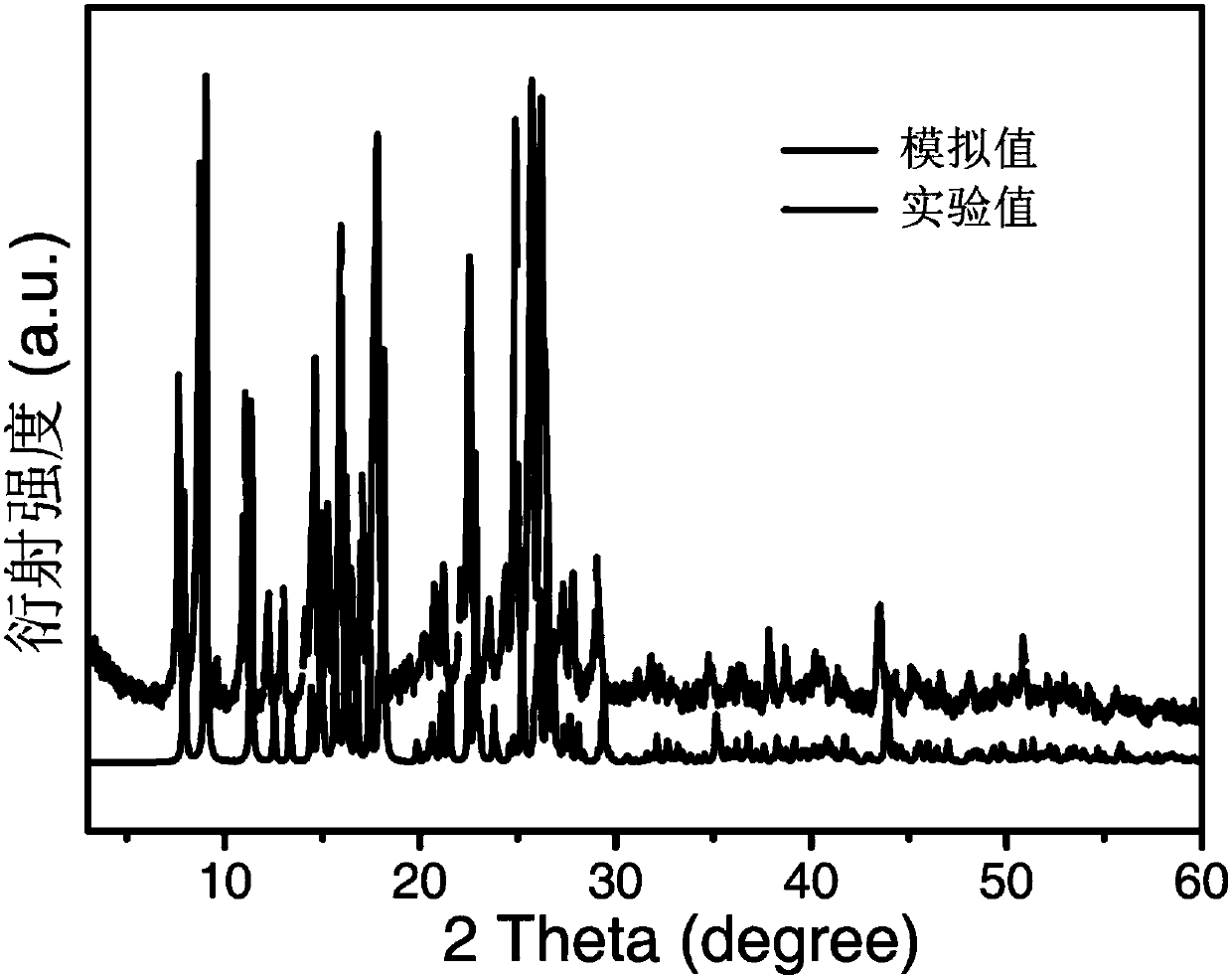

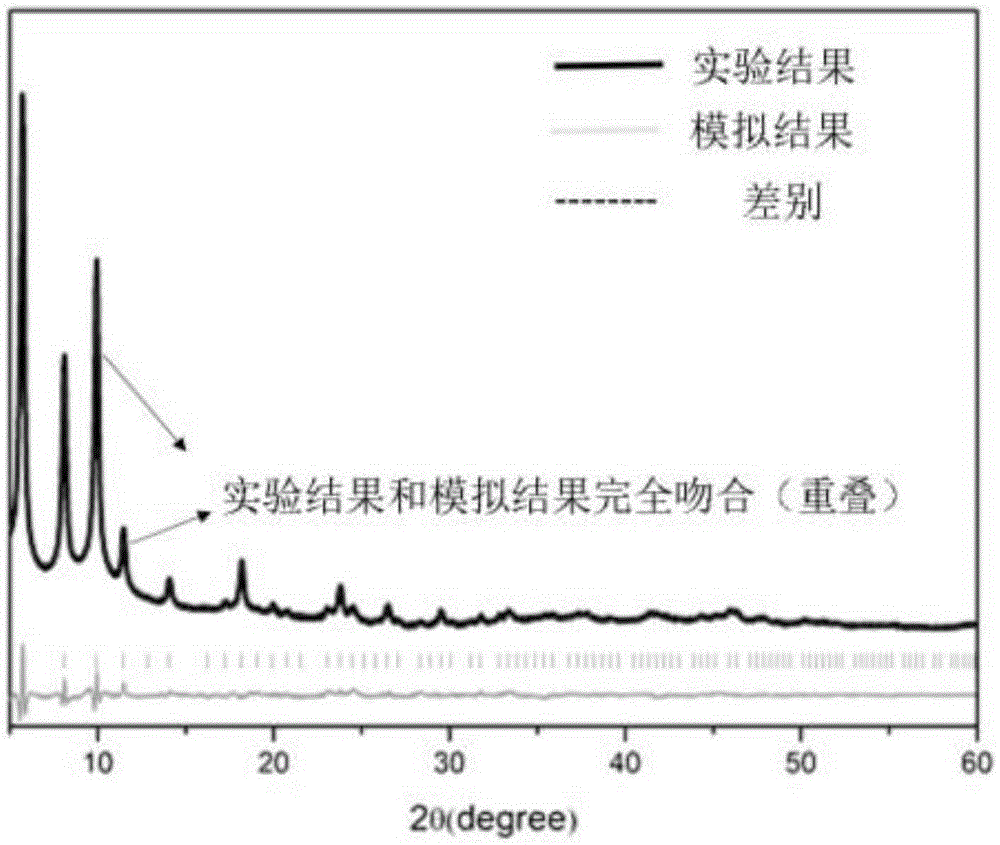

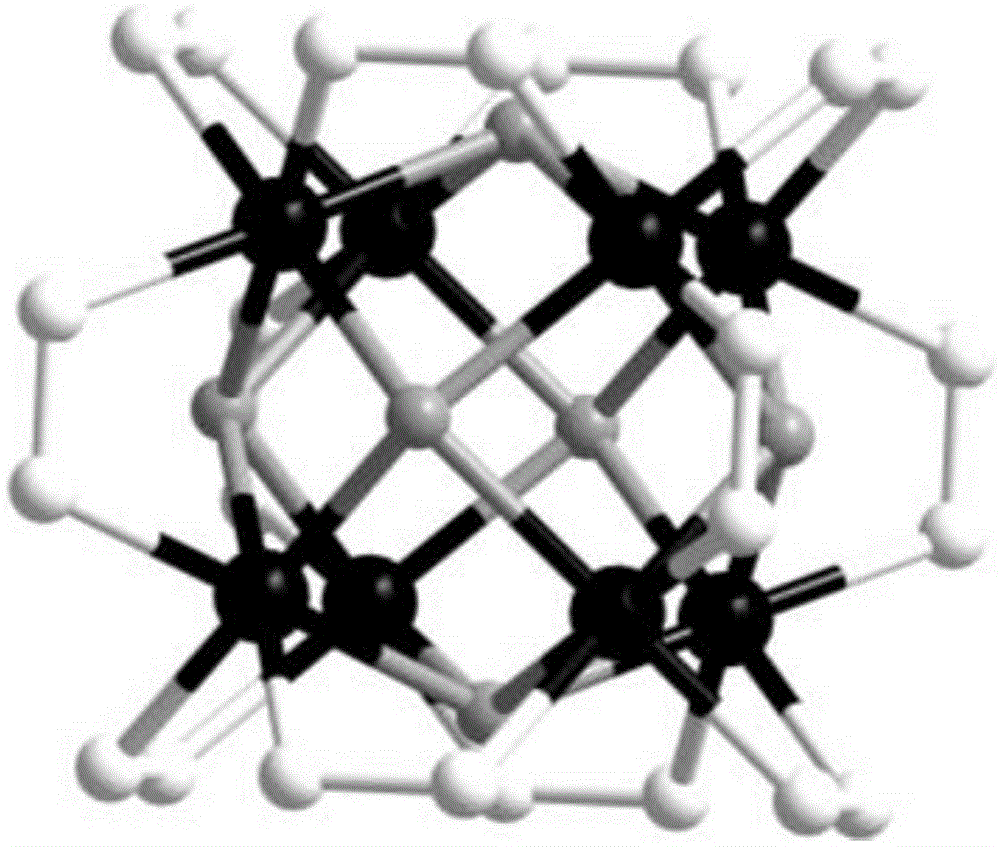

Synthesis of coordination polymer and application of coordination polymer to cathode material for lithium-ion battery

InactiveCN107665993AImprove stabilityImprove electrochemical performanceFinal product manufactureCell electrodesSynthesis methodsNickel acetate tetrahydrate

The invention discloses synthesis of a coordination polymer and application of the coordination polymer to a cathode material for a lithium-ion battery. The chemical formula of a coordination compoundis [Ni(PBIM)(OH-BDC)]n (in the formula, n is a natural number from 1 to positive infinity), wherein PBIM is 2,2'-pyridylbenzimidazole; OH-BDC is 5-hydroxyisophthalic acid. A preparation method of thecoordination compound comprises the following steps of adding a nickel acetate tetrahydrate, the 2,2'-pyridylbenzimidazole, the 5-hydroxyisophthalic acid and triethylamine into a mixed solution of water and methanol, and obtaining the target product complex [Ni(PBIM)(OH-BDC)]n through a hydrothermal reaction; the target product can be applied to the cathode material for the lithium-ion battery. The synthesis has the advantages that a synthesis method of the obtained coordination compound is simple; raw materials are easily obtained; the operation is easy; a reaction condition is mild; the yield is high; the cost is low and the product has better stability, is directly used in the cathode material of the lithium battery and shows favorable electrochemical performance.

Owner:NANKAI UNIV

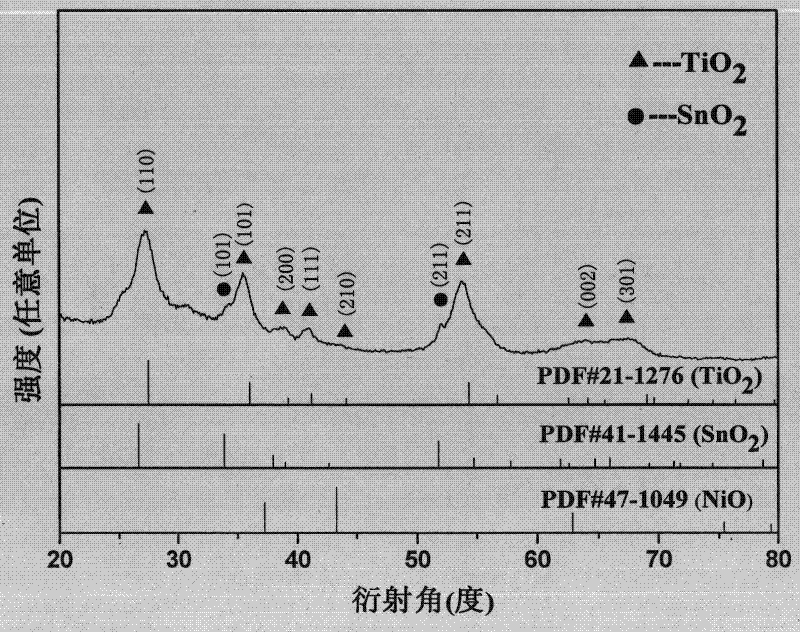

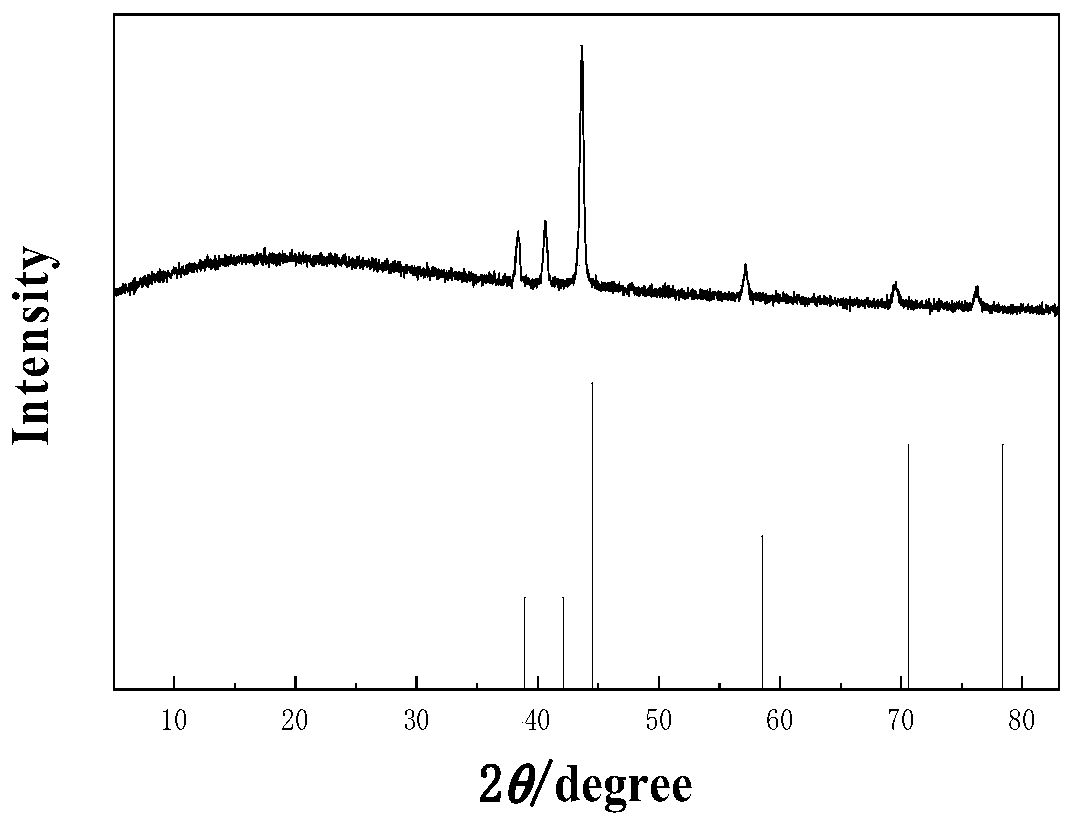

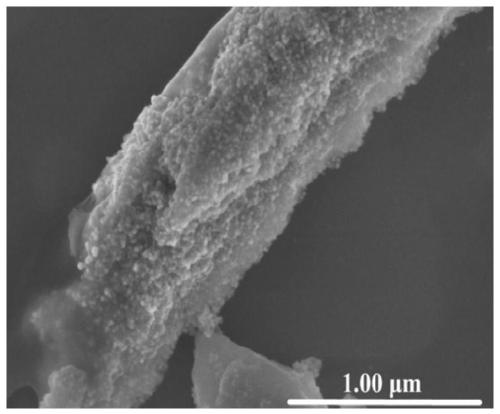

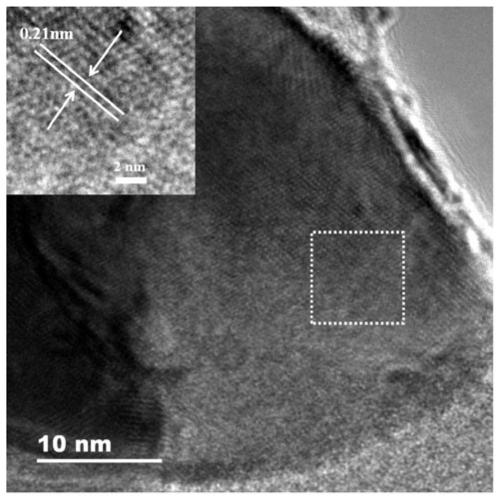

Preparation method of coaxial three-layer nano cable NiO@SnO2@TiO2

InactiveCN102191571AFilament/thread formingConjugated artificial filamentsN dimethylformamideNickel acetate tetrahydrate

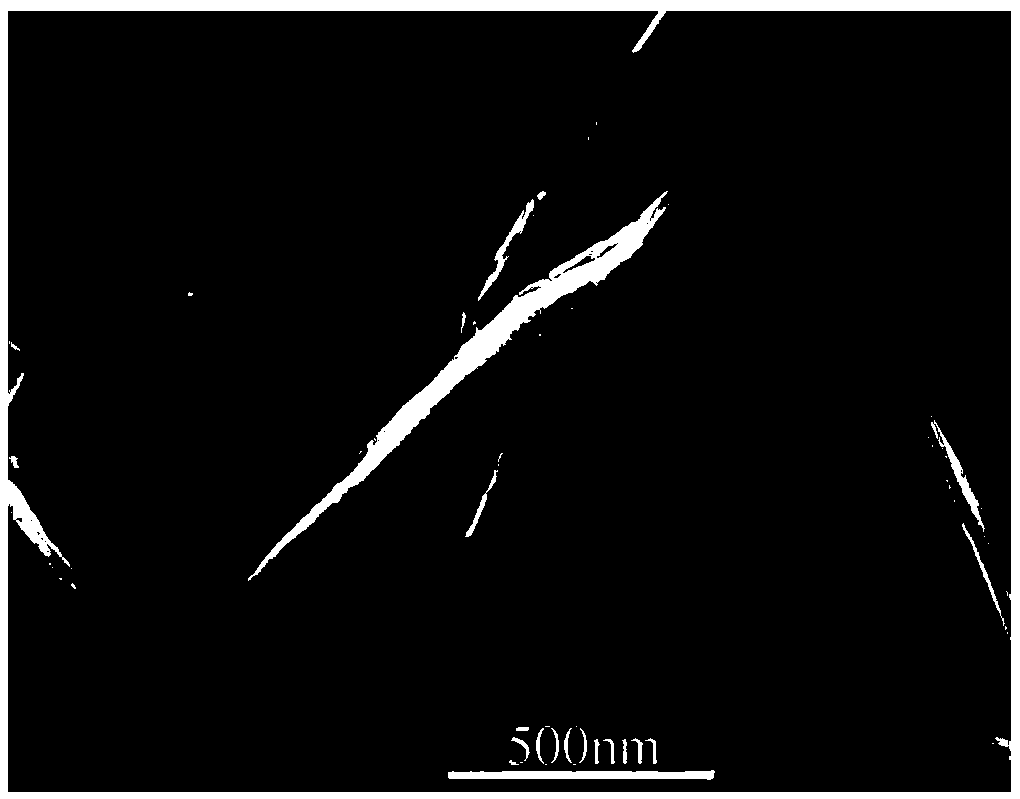

The invention relates to a preparation method of a coaxial three-layer nano cable NiO@SnO2@TiO2, belonging to the technical field of preparation of nano materials. The method comprises the following three steps: (1) preparation of spinning liquids: adding nickel acetate tetrahydrate and polyvinylpyrrolidone (PVP) into N,N-dimethylformamide (DMF) to form a core layer spinning liquid, adding tin tetrachloride pentahydrate and PVP into DMF to form a middle layer spinning liquid, and adding tetrabutyl titanate, PVP and glacial acetic acid into ethanol to form a shell layer spinning liquid; (2) preparation of [Ni(CH3COO)2+PVP]@[SnCl4+PVP]@[Ti(OC4H9)4+CH3COOH+PVP] precursor composite cable: by using a coaxial electrostatic spinning technology and a coaxial three-layer spinning jet, curing at the room temperature of 22-25 DEG C under the voltage of 18kV, wherein the curing distance is 15cm, and the relative humidity 40-50%; and (3) preparation of coaxial three-layer nano cable NiO@SnO2@TiO2:carrying out heat treatment on the precursor composite cable to obtain the NiO (core layer)@SnO2 (middle layer)@TiO2(shell layer) coaxial three-layer nano cable of which the diameter is 340-434 nm and the length is greater than 300 mu m: heating at a rate of 1 DEG C / min, keeping the temperature of 600 DEG C for 8 hours, cooling at a rate of 1 DEG C / min to 200 DEG C, and naturally cooling to room temperature.

Owner:CHANGCHUN UNIV OF SCI & TECH

Multi-element Prussian blue sodium ion battery positive electrode material and preparation method thereof

PendingCN112607748AThe synthesis process is simpleReduce energy consumptionIron cyanidesCell electrodesPeristaltic pumpNickel acetate tetrahydrate

The invention relates to a multi-element Prussian blue sodium ion battery positive electrode material and a preparation method thereof. The preparation method comprises the following steps: mixing nickel acetate tetrahydrate Ni (AC) 2.4 H2O, cobalt acetate tetrahydrate Co (AC) 2.4 H2O, ferrous sulfate heptahydrate FeSO4. 7H2O and trisodium citrate dehydrate C6H5Na3O7. 2H2O to form a chelated solution A, mixing sodium ferrocyanide Na4Fe (CN) 6 and ascorbic acid to form a solution B, dissolving NaCl and PVP in deionized water, slowly dropwise adding the solution A and the solution B into the solution C by using a peristaltic pump, and stirring while dropwise adding; continuously stirring and reacting for 12 hours after dropwise adding to obtain turbid liquid, standing, ageing, centrifugally washing, and drying a filter cake in vacuum to obtain the multi-element Prussian blue sodium ion battery positive electrode material.

Owner:CHINA THREE GORGES UNIV

Method for preparing nickel oxide/zinc oxide heterojunction nanometer materials

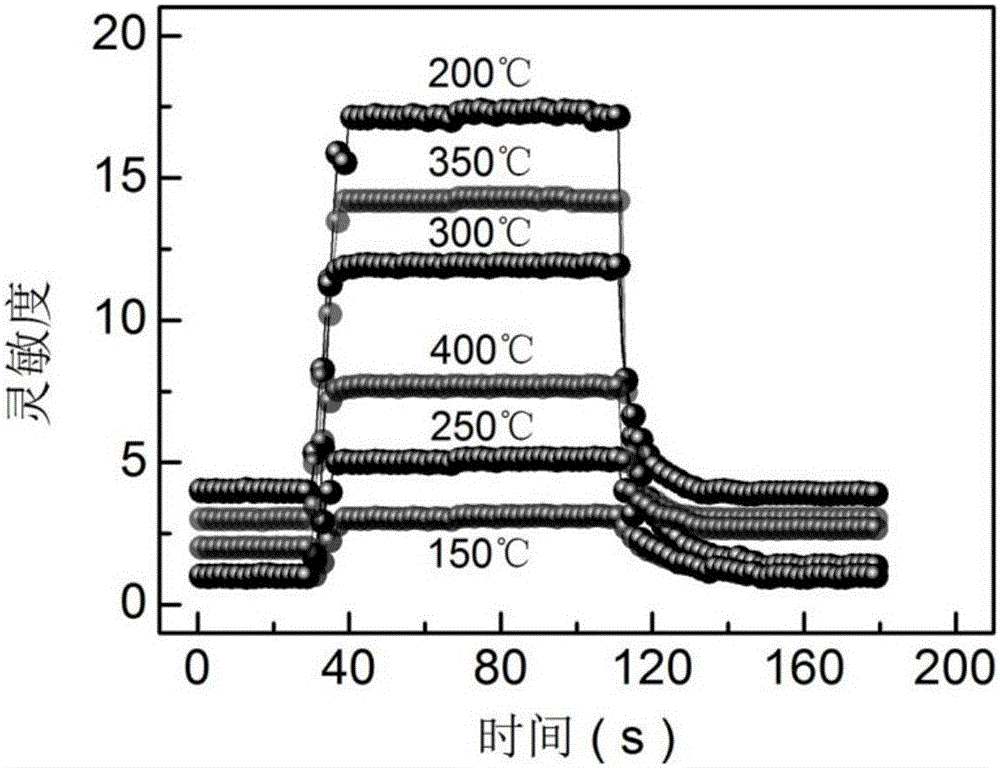

ActiveCN105776357AHigh sensitivityShort reaction timeZinc oxides/hydroxidesMaterial analysis by electric/magnetic meansHeterojunctionWorking temperature

The invention discloses a method for preparing nickel oxide / zinc oxide heterojunction nanometer materials. By the aid of the method, the technical problem of low sensitivity of nickel oxide / zinc oxide heterojunction nanometer materials prepared by the aid of existing methods can be solved. The technical scheme includes that the method comprises synthesizing nickel oxide / zinc oxide heterojunction pre-sintered powder from mixed solution by the aid of a one-step hydrothermal process; calcining the nickel oxide / zinc oxide heterojunction pre-sintered powder to obtain the nickel oxide / zinc oxide heterojunction nanometer materials. The mixed solution is prepared from nickel acetate tetrahydrate, zinc nitrate hexahydrate and sodium hydroxide. The method has the advantages that the method only includes one reaction step instead of two reaction steps in the prior art, and the reaction time is shortened and is 12 h instead of the reaction time of 60 h in the prior art; as shown in gas sensitivity tests, the working temperatures of gas sensors made of the nickel oxide / zinc oxide heterojunction nanometer materials prepared by the aid of the method are lowered and are 200 DEG C instead of the working temperatures of 330 DEG C in the prior art; the sensitivity of the gas sensors for 100 ppm acetone gas is improved and reaches 15-17 instead of the sensitivity of 12 in the prior art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

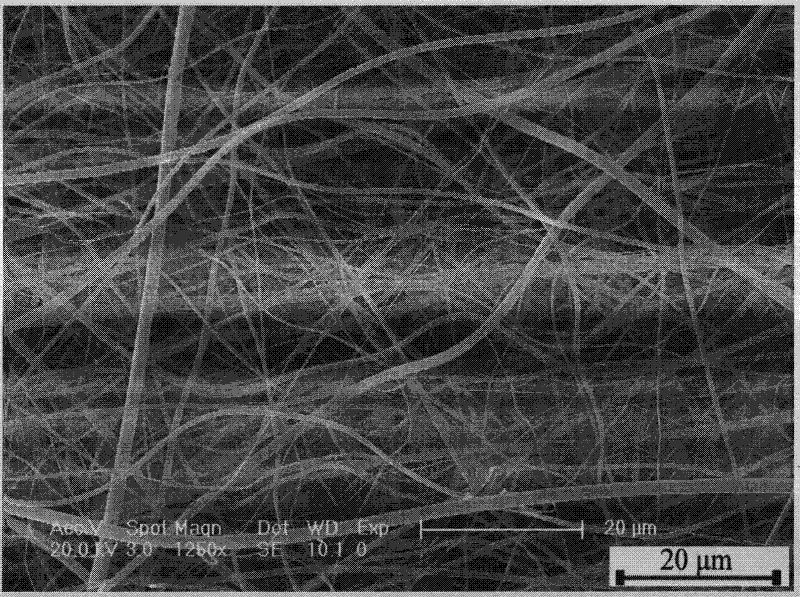

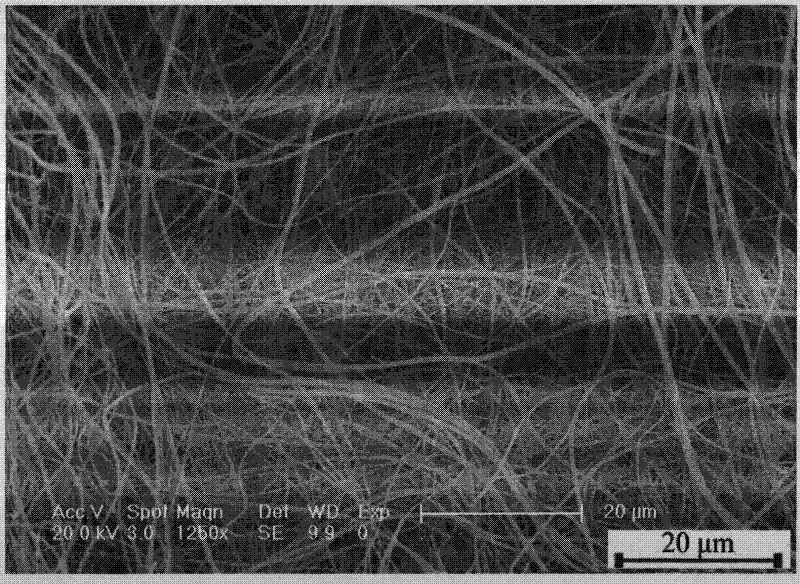

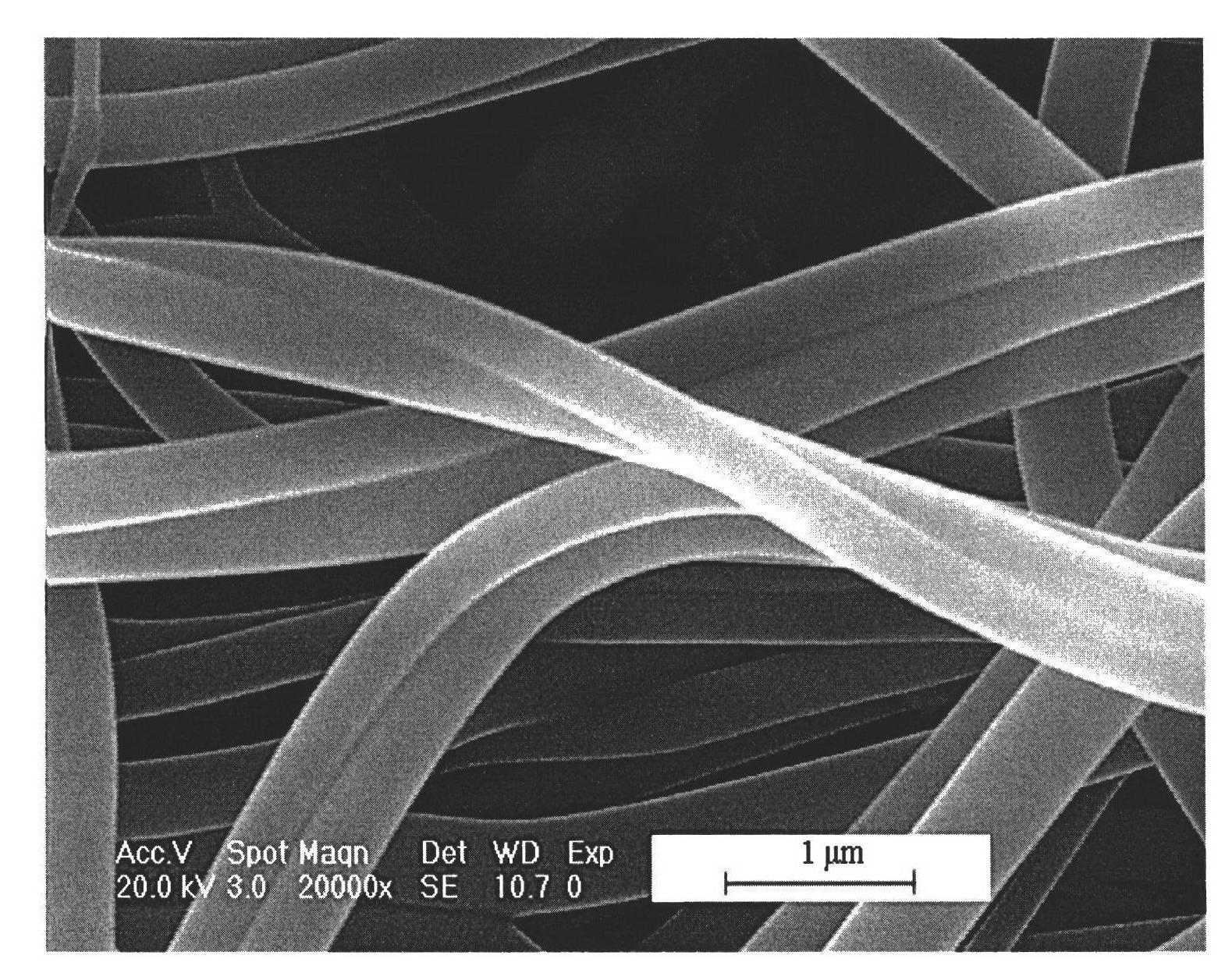

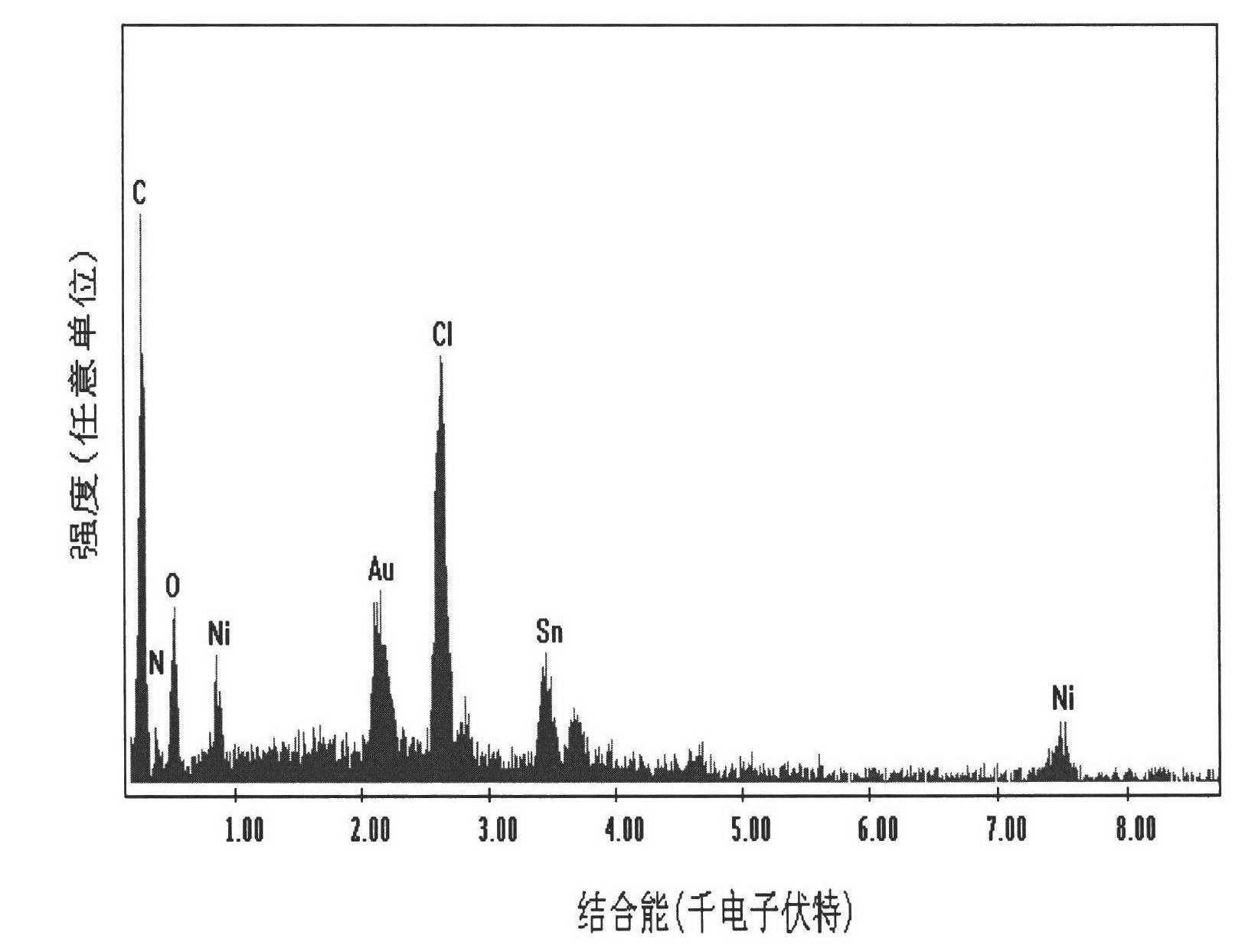

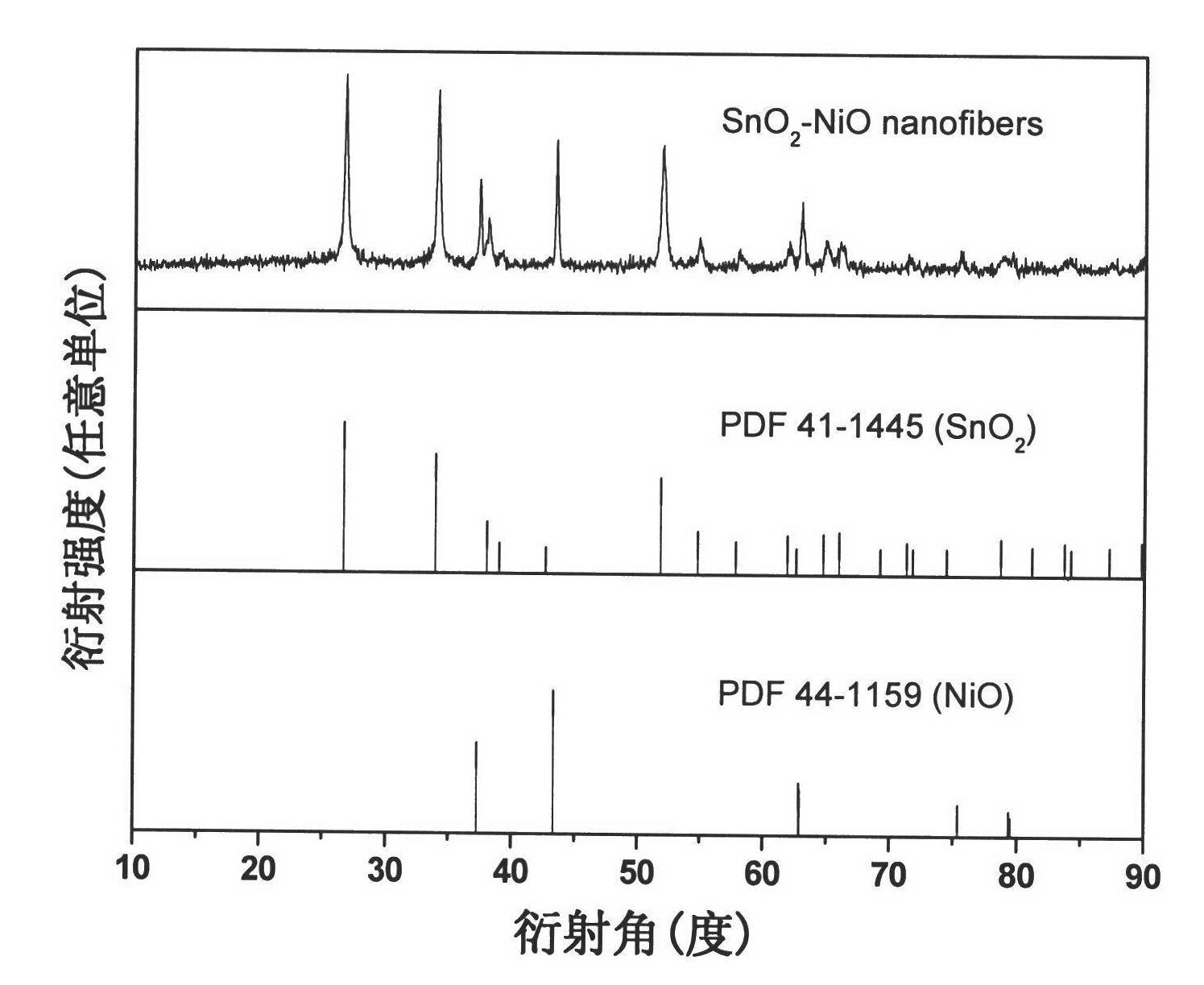

Method for preparing parallel polycrystalline nano fiber bundle of stannic oxide and nickel oxide

InactiveCN102400248ANew-spun product collectionFilament/thread formingTin dioxideN dimethylformamide

The invention relates to a method for preparing a parallel polycrystalline nano fiber bundle of a stannic oxide and a nickel oxide, which belongs to the technical field of the preparation of nano materials. In the prior art, single nano fibers of SnO2 and NiO and SnO2 / NiO nano composite powder are prepared. The method for preparing the parallel polycrystalline nano fiber bundle of the stannic oxide and the nickel oxide comprises three steps: (1), the preparation of a spinning solution, namely, adding stannic chloride pentahydrate and polyvinylpyrrolidone (PVP) to N, N-dimethylformamide (DMF) to form the spinning solution, and adding nickel acetate tetrahydrate and the PVP to DMF to form another spinning solution; (2), the preparation of a [SnCl4+PVP] / [Ni(CH3COO)2+PVP] precursor parallel composite fiber bundle, namely, obtaining the [SnCl4+PVP] / [Ni(CH3COO)2+PVP] precursor parallel composite fiber bundle by adopting an electrostatic spinning technique and using a parallel double spinning head; and (3), the preparation of SnO2 / NiO parallel polycrystalline nano fiber bundle, namely, thermally treating the [SnCl4+PVP] / [Ni(CH3COO)2+PVP] precursor parallel composite fiber bundle to obtain the SnO2 / NiO parallel polycrystalline nano fiber bundle, wherein the nano fibers of the SnO2 and the NiO respectively have a diameter of 180 nm and a length of being more than 100 [mu]m, and have favorable crystallinity. The preparation method provided by the invention is simple and feasible, can be used for batch production, and has a wide application foreground.

Owner:CHANGCHUN UNIV OF SCI & TECH

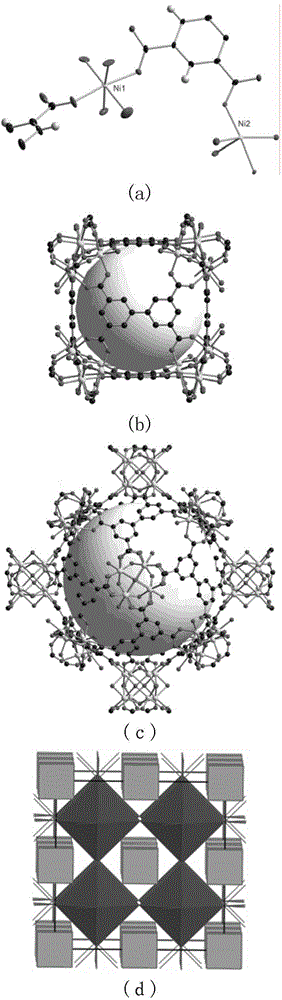

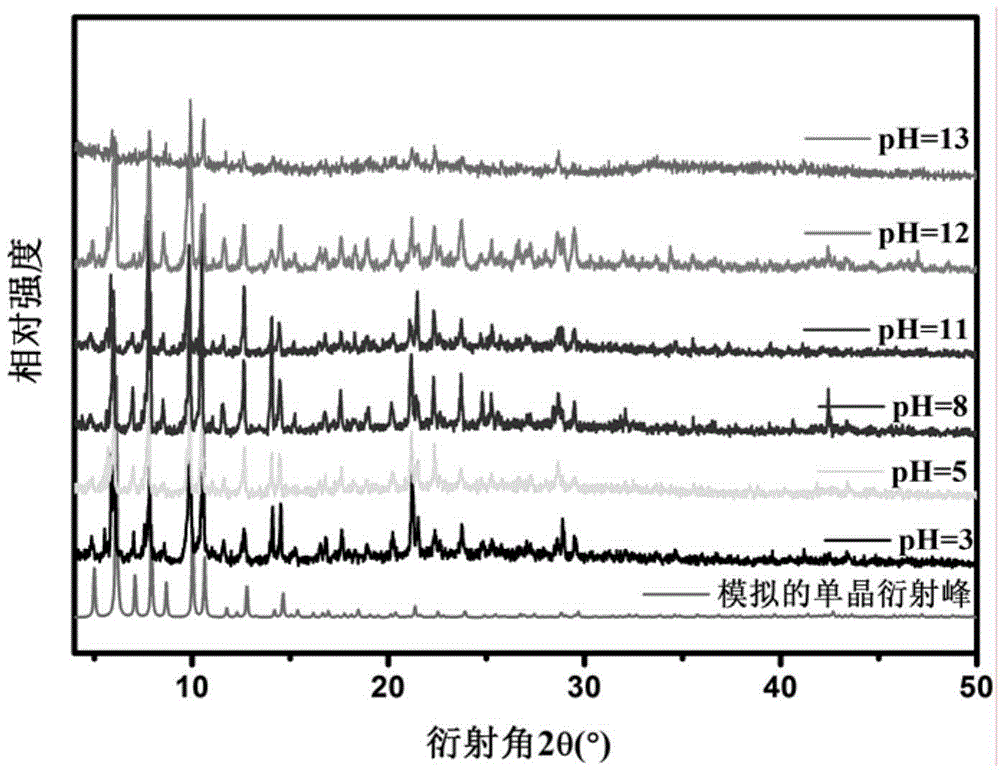

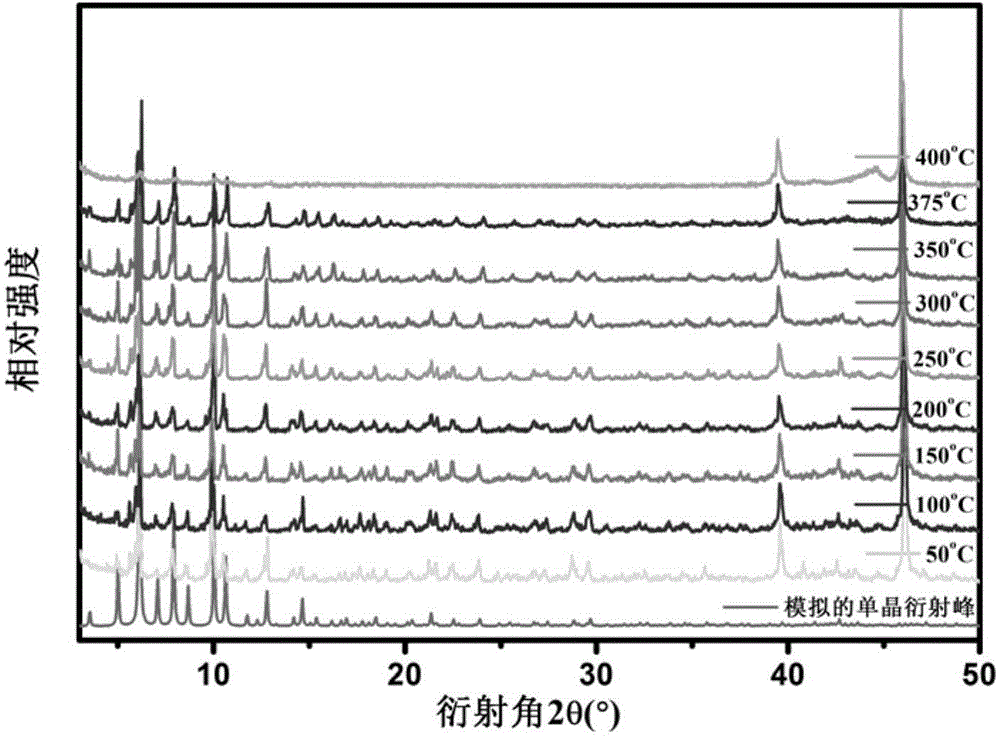

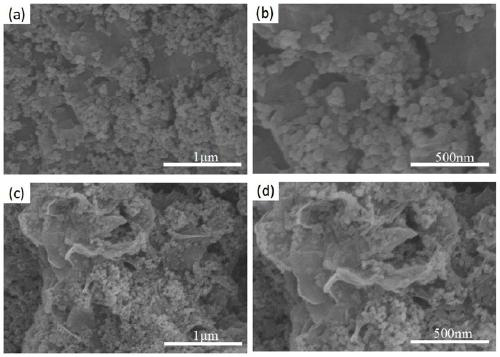

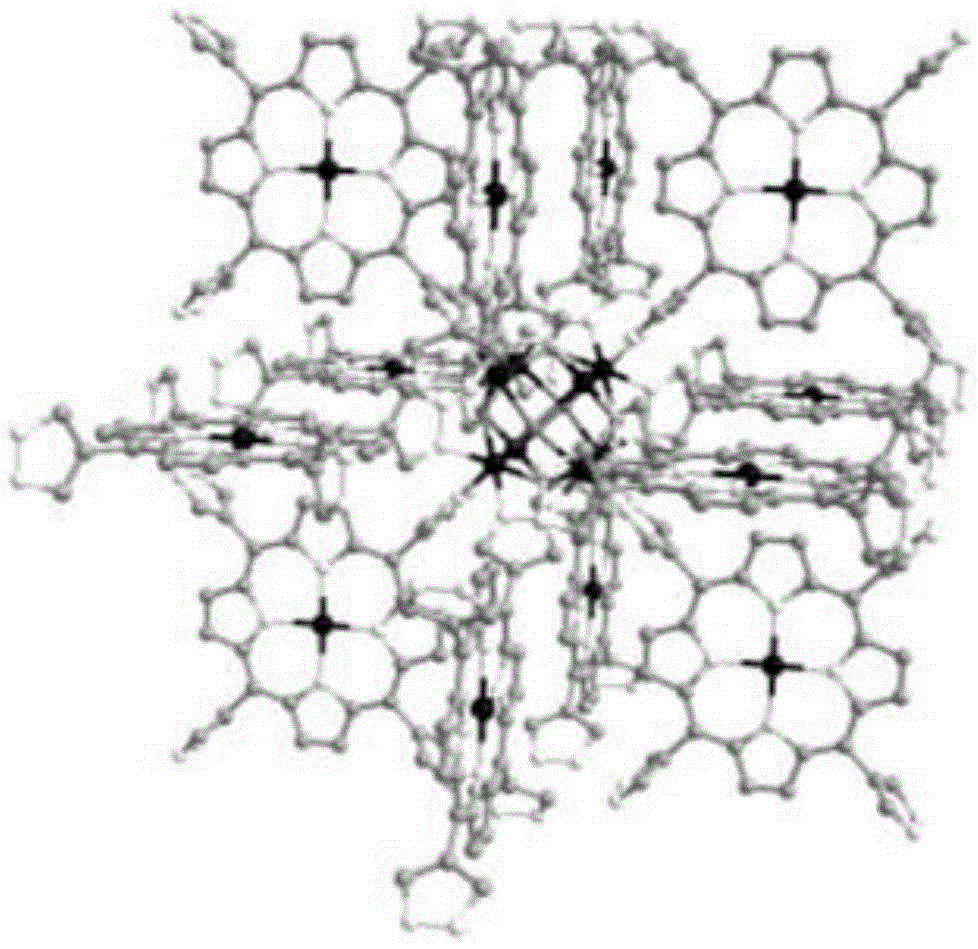

Metal-organic framework material for adsorbing N2O and preparation method thereof

InactiveCN104525133AGood acid and alkali stabilityImprove thermal stabilityNitrous oxide captureProductsMetal-organic frameworkNickel acetate tetrahydrate

Provided is a metal-organic framework material for adsorbing N2O. The chemical formula of the metal-organic framework material is shown in the specification, wherein n is a natural number greater than and equal to 1, bptc is 3, 3', 5, 5'-biphenyl tetramethyl carboxylic acid ions, DMA is N, N-dimethyl acetamide, and (CH3)2NH2 is dimethylamine positive ions; a preparation method comprises the steps of adding 3, 3', 5, 5'-biphenyl tetramethyl carboxylic acid, nickel acetate, lithium hydroxide monohydrate and concentrated nitric acid to N, N-dimethyl acetamide and distilled water, and heating the mixture. The metal-organic framework material for adsorbing N2O and the preparation method thereof have the advantages that the preparation process of a product is simple, the operation is easy, better acid-base property and heat stability of the prepared metal-organic framework material are achieved, higher adsorption capacity for N2O can be achieved, and the metal-organic framework material can be used for storing N2O.

Owner:NANKAI UNIV

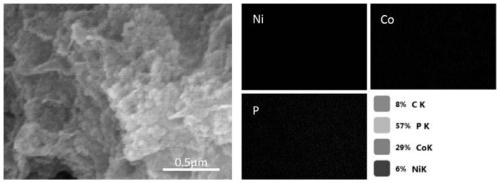

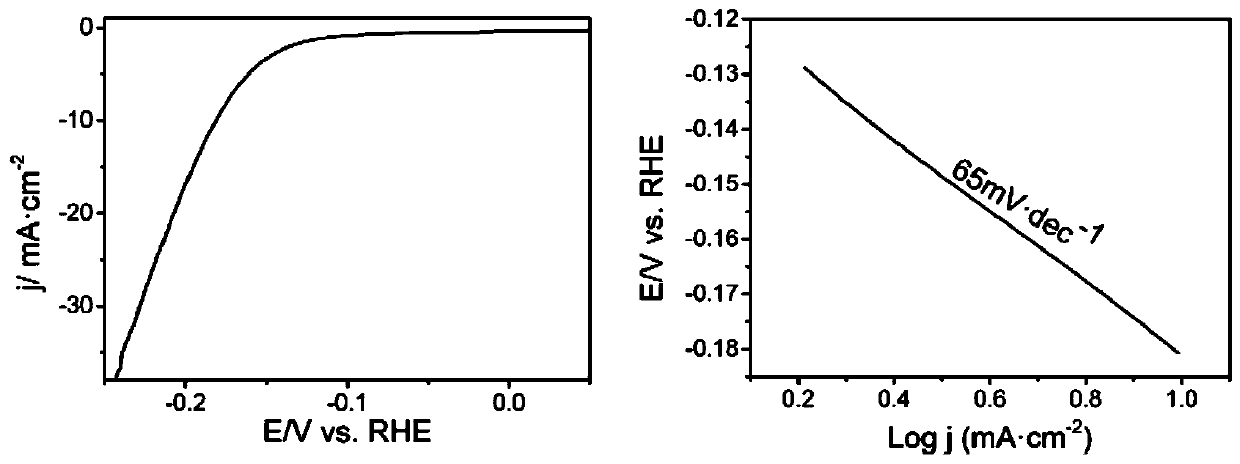

Preparation method of bimetallic phosphide composite reduction graphene nano electrocatalytic material

InactiveCN110124702ALow costSimple methodCatalyst activation/preparationElectrodesFreeze-dryingNickel acetate tetrahydrate

The invention discloses a preparation method of a bimetallic phosphide composite reduction graphene nano electro-catalytic material, which comprises the following steps of: 1) dissolving graphene oxide in water, and ultrasonically homogenizing; 2) respectively adding nickel acetate tetrahydrate and cobalt acetate tetrahydrate into graphene oxide solution, and uniformly stirring to obtain solutionA; 3) dissolving 2,5-dihydroxyterephthalic acid and sodium hydroxide in deionized water, and uniformly stirring to obtain solution B; (4) uniformly mix and reacting solution A and solution B, centrifugally collect to obtain precipitate, washing that precipitate, and freeze drying to obtain bimetallic MOF composite graphene oxide nano material containing Ni and Co; 5) respectively placing the material obtained in the step 4) and sodium hypophosphite in a tube furnace, raising the temperature under inert atmosphere and keeping the temperature for a period of time, and cooling to room temperatureto obtain Ni and Co-containing bimetallic phosphide composite reduction graphene nano electrocatalytic material NiCO / P-rGO. The method has simple operation and low cost, and the obtained material hasbetter electrocatalytic performance.

Owner:ZHEJIANG UNIV

Porphyrin-based metal organic framework material with ultrahigh stability and synthetic method

InactiveCN105294705AGood chemical stabilitySimple processOrganic chemistryN dimethylformamideHydrogen

The invention discloses a porphyrin-based metal organic framework material with ultrahigh stability and a synthetic method, and belongs to the technical field of crystalline state materials. The chemical formula of the porphyrin-based metal organic framework material is [Ni9.77C56.64N21.24O10.92H35.47]. Under the closed condition, an organic ligand 5,10,15,20-tetra(1 hydrogen-pyrazol-4-radical) porphyrin(H4TPP) and nickel acetate generate a solvothermal reaction in N,N-dimethylformamide to obtain the porphyrin-based metal organic framework material. The metal organic framework material has ultrahigh stability, and materials of this kind can be possibly applied widely.

Owner:BEIJING UNIV OF TECH

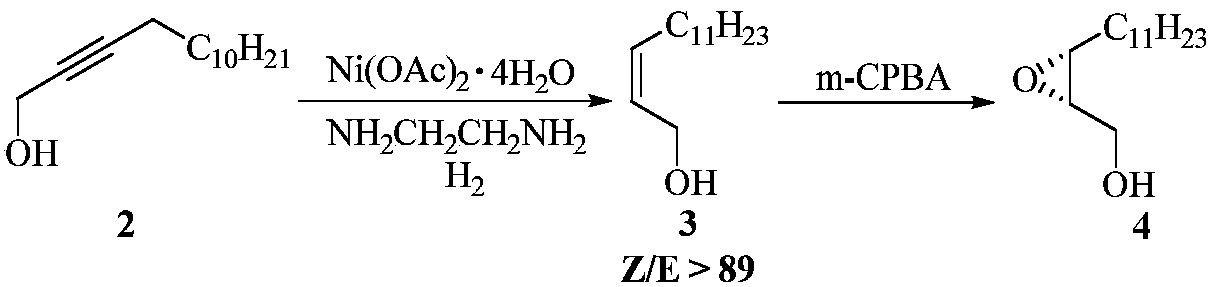

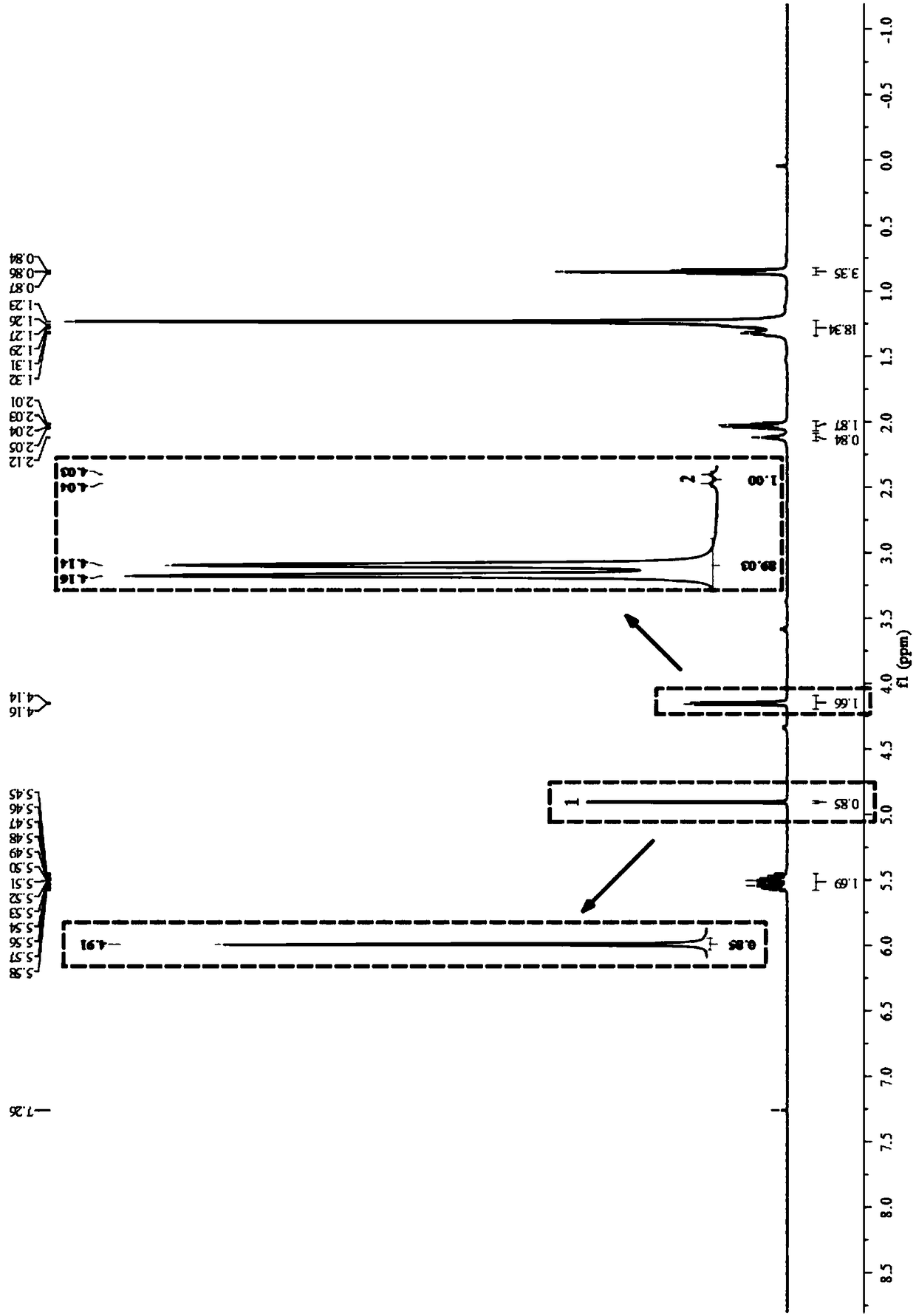

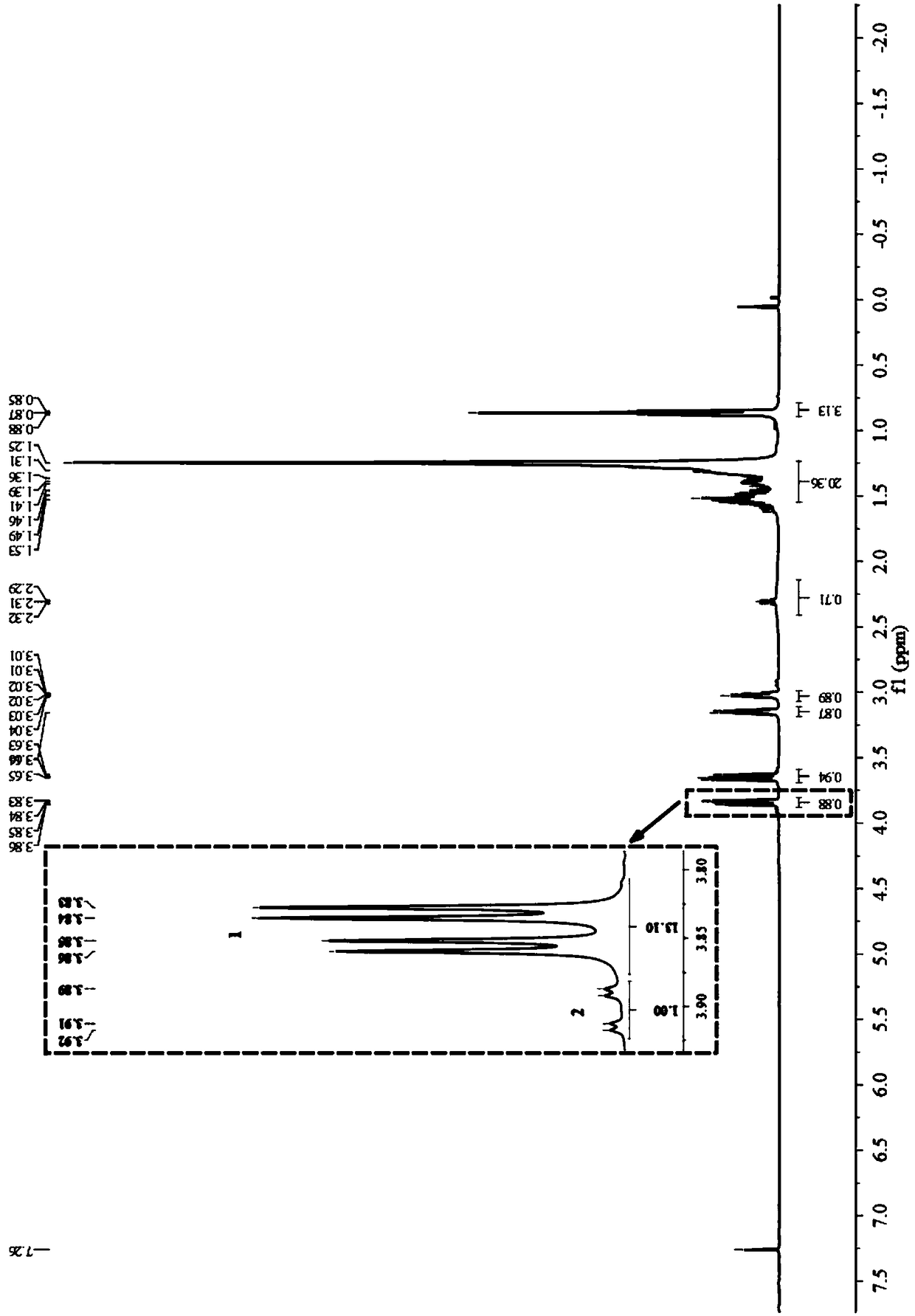

Synthetic method of sex pheromone intermediate of Hyphantria cunea

ActiveCN108299342AHigh Z/E valueHigh optical purityOrganic chemistry methodsEthylenediamineHalohydrocarbon

The invention discloses a synthetic method of sex pheromone intermediate (2S,3R)-2,3-epoxy-1-tetradecanol (4) of Hyphantria cunea. According to the method, firstly, nickel acetate tetrahydrate, sodiumborohydride, ethylenediamine as well as an alcohol as a solvent are added to a hydrogenation reactor for a reaction, then, an alcoholic solution with 2-tetradecynol dissolved is added continuously, areaction is performed after hydrogen replacement, and (Z)-2-tetradecene-1-ol is obtained; (Z)-2-tetradecene-1-ol is dissolved in a halogenated hydrocarbon solvent, a carbonate solution and a halogenated hydrocarbon solution of 3-chloroperoxybenzoic acid are added for a reaction, and (2S,3R)-2,3-epoxy-1-tetradecanol is obtained. The method is environmentally friendly and suitable for industrial production, cost is low, and reaction conditions are mild.

Owner:ZHEJIANG UNIV

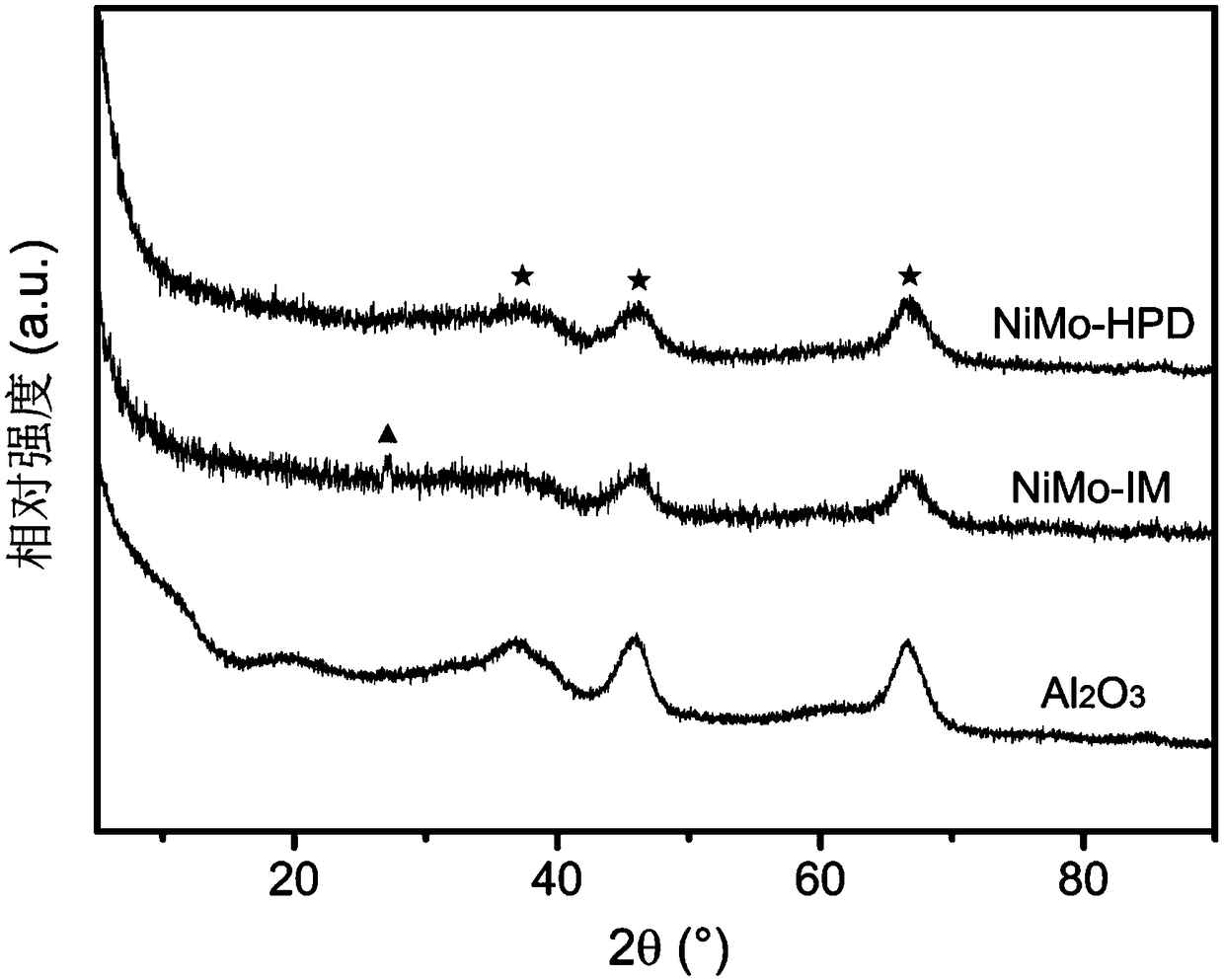

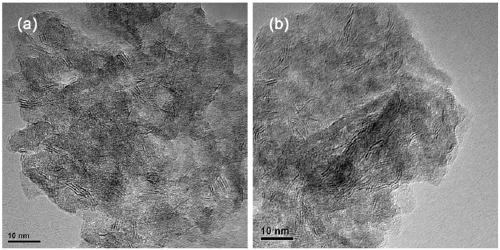

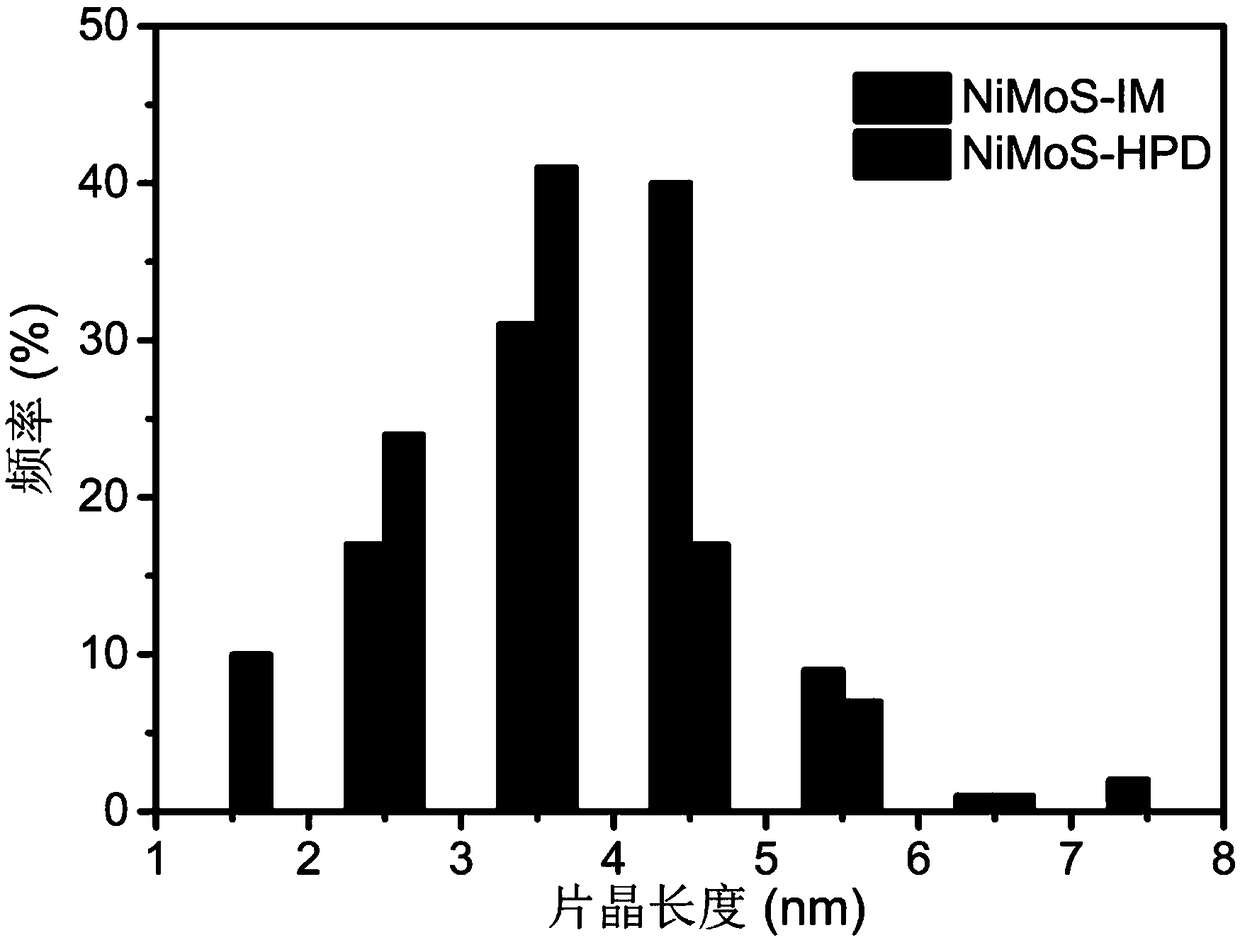

Ultra-deep desulfurization catalyst, preparation method thereof and application of catalyst

ActiveCN109364957ATightly boundIncrease the level of retouchingCatalyst activation/preparationHydrocarbon oils treatmentWater bathsAcetic acid

The invention provides an ultra-deep desulfurization catalyst, a preparation method thereof and an application of the catalyst. The preparation method of the desulfurization catalyst includes the steps: weighing ammonium paramolybdate and nickel acetate tetrahydrate, dissolving the ammonium paramolybdate and the nickel acetate tetrahydrate in glacial acetic acid and water mixed solution in a stirring manner; adding hydrazine sulfate and dissolving the hydrazine sulfate in a stirring manner; performing stirring reaction in a thermostatic water bath to obtain polyoxometallate after reaction; dispersing the polyoxometallate in water and performing ultrasonic treatment; adding aluminum oxide, uniformly stirring the materials and performing hydro-thermal decentralization loading in an autoclaveto obtain the desulfurization catalyst after reaction. The prepared desulfurization catalyst is good in dispersing performance and high in activity, ultra-deep desulfurization can be achieved, and desulfurization rate reaches up to 93.8%.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

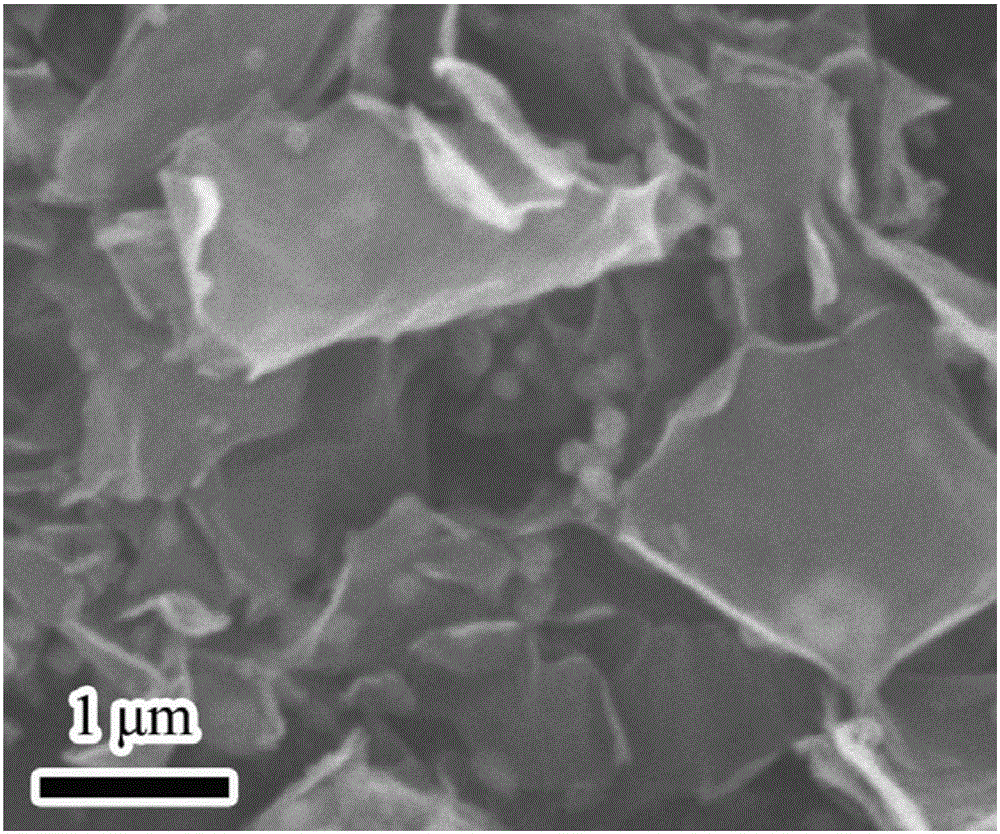

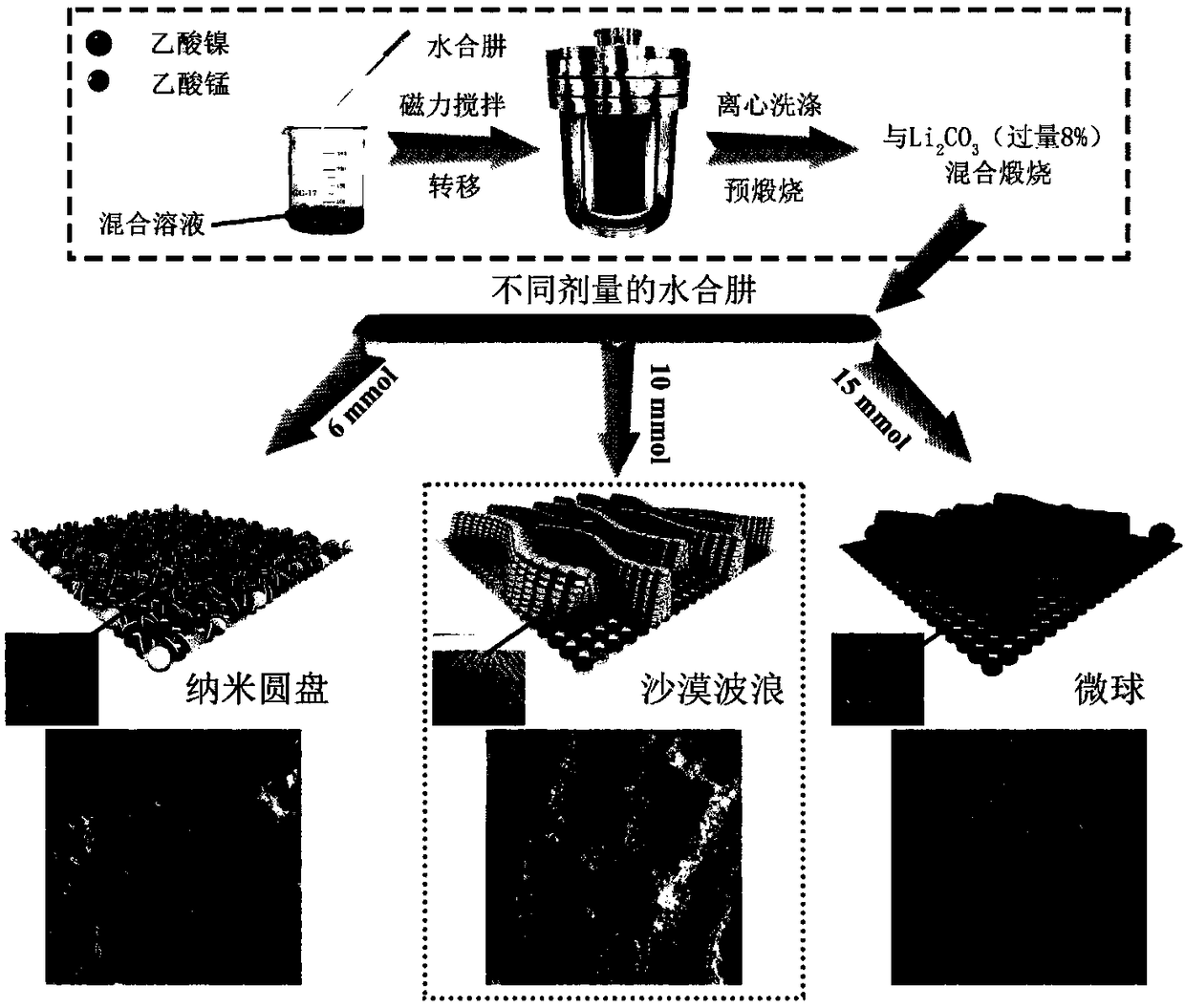

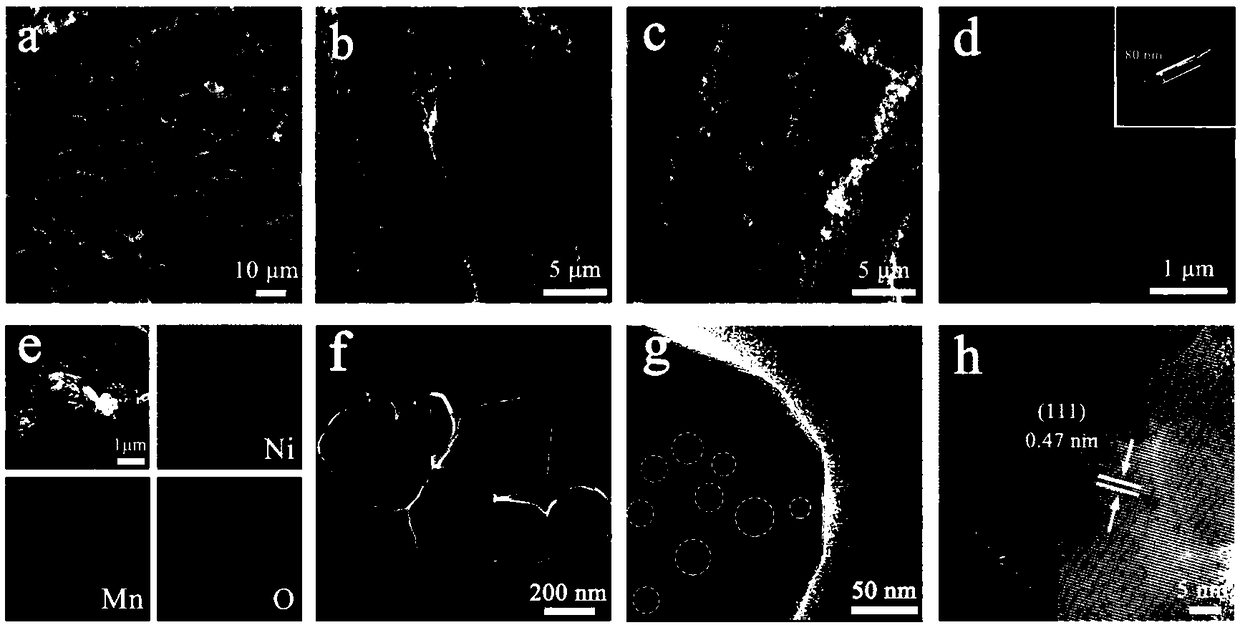

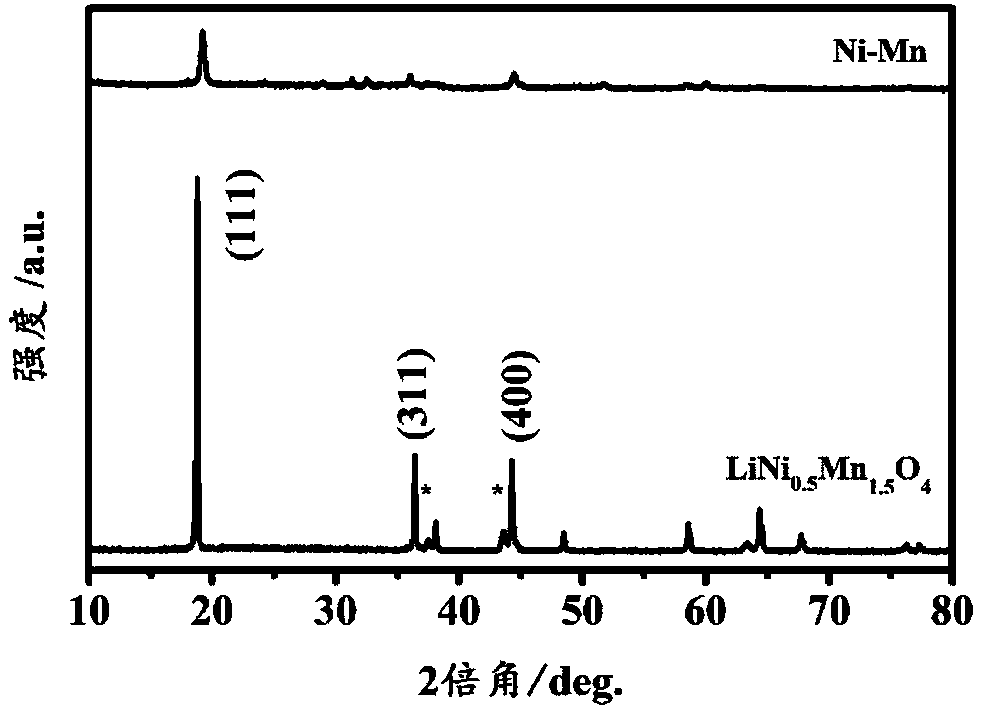

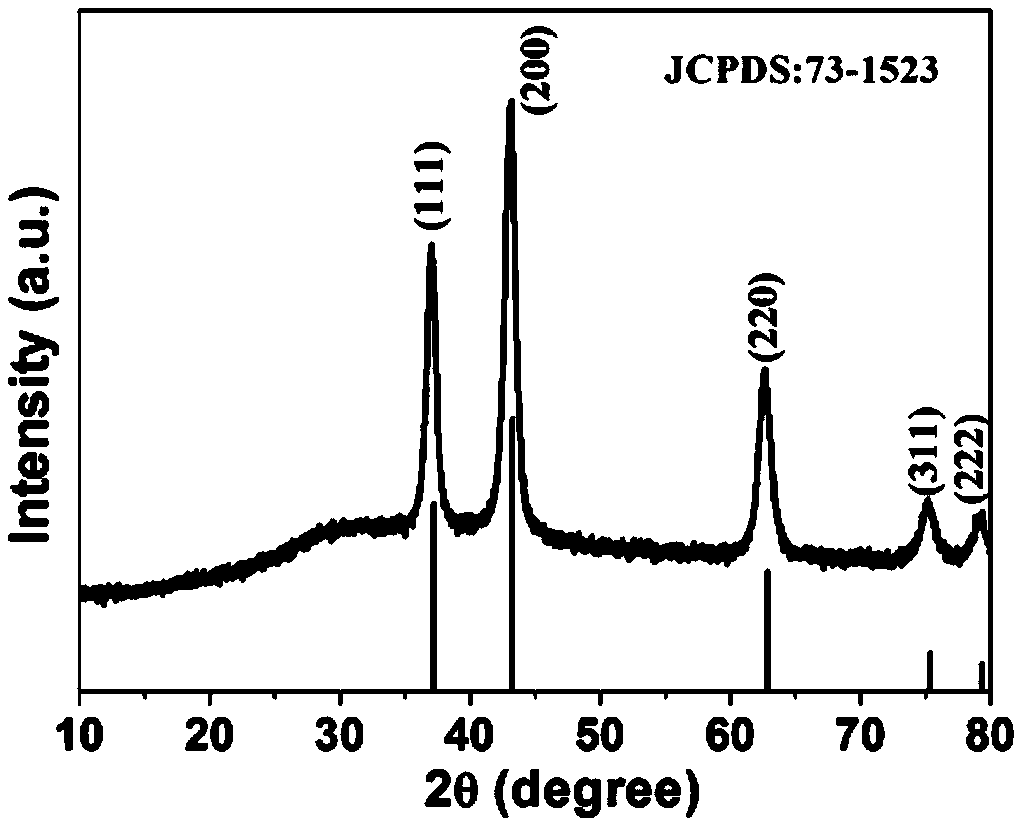

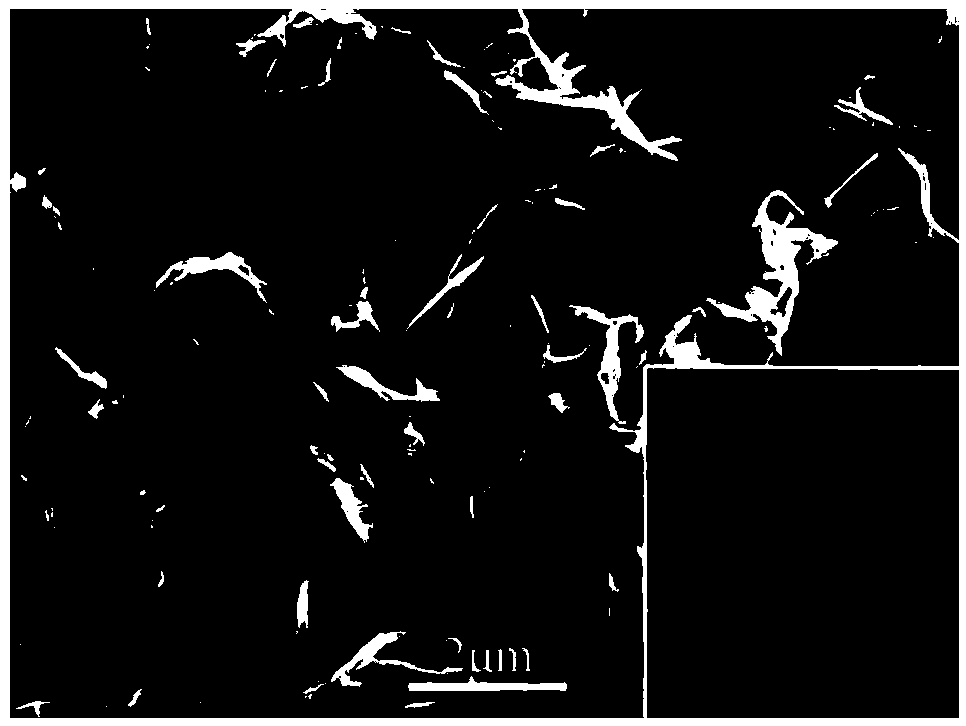

Lithium nickel manganese oxide anode material of three-dimensional desert wave structure and preparing method and application of lithium nickel manganese oxide anode material

ActiveCN108565454AQuick migrationUnhindered transmissionCell electrodesMANGANESE ACETATEElectrical battery

The invention provides a preparing method of a lithium nickel manganese oxide anode material of a three-dimensional desert wave structure, and belongs to the field of anode materials for lithium ion batteries. According to the preparing method, tetrahydrate nickel acetate and tetrahydrate manganese acetate serve as raw materials, ethylene glycol serves as an end-capping agent and a chelating agent, and hydrazine hydrate serves as a morphology guiding agent; based on the synergistic effect of hydrazine hydrate and ethylene glycol in a hydrothermal reaction, a precursor is synthesized; then through pre-roasting and control over roasting in the process of mixing lithium carbonate, preparation of the three-dimensional lithium nickel manganese oxide anode material can be achieved, and rich anddiversified morphology and performance are provided for the end product. The prepared lithium nickel manganese oxide anode materials of the three-dimensional desert wave structure are connected mutually, from the whole aspect, the wide and uninterrupted three-dimensional desert wave structure is conducive to quick transfer of electrons, and barrier-free electron transfer can be achieved; from thepartial aspect, uniform and quasi-circular nanometer discs can shorten the diffusion distance of lithium ions, an uninterrupted electricity-conductive network is formed, and excellent electricity conductivity and a high transfer rate are provided.

Owner:HUBEI UNIV

Two-dimensional oversized mint-leaf-shaped nickel oxide nano material and preparation method thereof

ActiveCN105502519ARaw materials are easy to getLow costCobalt oxides/hydroxidesMicrometerRoom temperature

The invention discloses a two-dimensional oversized mint-leaf-shaped nickel oxide nano material and a preparation method thereof. The preparation method comprises the steps that an appropriate amount of nickel acetate and urea are weighed and added into 60 milliliters of deionized water, dissolution under stirring is performed, and a light green solution is obtained; the solution is transferred into a 100-mL stainless steel reaction kettle with a polytetrafluoroethylene lining, the reaction kettle is sealed and then placed into a drying oven, the temperature is set at 110 DEG C-130 DEG C, and reacting is performed for 10-14 hours; after reacting is finished, a reaction product is naturally cooled to room temperature, filtered and washed, and a green precipitate is obtained; the dried green precipitate is put into a resistance furnace, the temperature is set at 300 DEG C-400 DEG C, heat treatment is performed for 2-4 hours, and then the two-dimensional oversized mint-leaf-shaped nickel oxide nano material is obtained. The diameter of mint leaves is 1.8-2.5 micrometers, the thickness of the mint leaves is 10-20 nm. The nano mint leaves are soft and thin and prone to be bent, and the surfaces of the mint leaves are rich in a large quantity of pore structures. According to the two-dimensional oversized mint-leaf-shaped nickel oxide nano material and the preparation method thereof, the technology is simple, operation is easy and convenient, and the repeatability is good.

Owner:ANHUI UNIVERSITY OF ARCHITECTURE

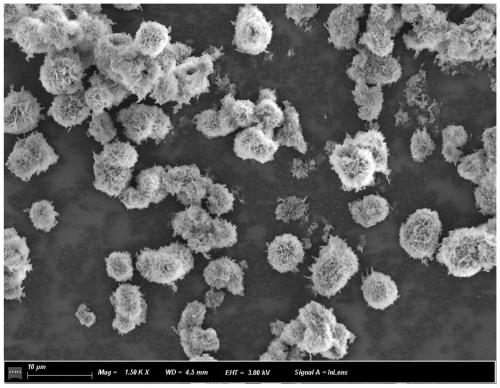

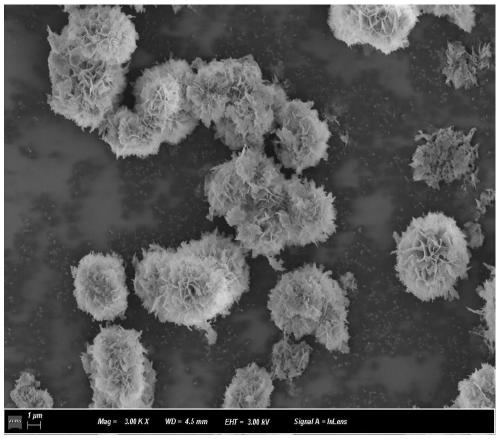

Preparation method of flower-like nickel oxide composed of porous sheets

InactiveCN111115717AImprove performanceRich pore structureNickel oxides/hydroxidesPolyethylene glycolNickel acetate tetrahydrate

The invention discloses a preparation method of flower-like nickel oxide composed of porous sheets. The preparation method is characterized by comprising the steps: dissolving nickel acetate tetrahydrate in distilled water to form a nickel acetate solution; and dissolving PVA and urea in distilled water to form a mixed solution; slowly dropwise adding the mixed solution into a nickel acetate solution, mixing, then adding polyethylene glycol 2000, dropwise adding ammonia water with the mass concentration of 25%-28% while stirring, transferring into a reaction kettle for heating after dropwise adding is completed, and then performing centrifugal washing, drying and annealing treatment to obtain black nickel oxide. The flower-like nickel oxide prepared by the method has rich pore diameter structures and large specific surface area, and is beneficial to full contact with gas to be detected; the product is uniform in morphology, uniform and controllable in size, good in dispersity and freeof agglomeration; the yield of the product is high, when the product is used for manufacturing a gas sensitive sensor, the working temperature is low, the selectivity to formaldehyde is high, the sensitivity is high, the sensitivity to formaldehyde gas of 100 ppm or below at the normal temperature can reach 19, the response time is short, the recovery time is short, and the stability performance is good.

Owner:CHONGQING UNIV OF ARTS & SCI

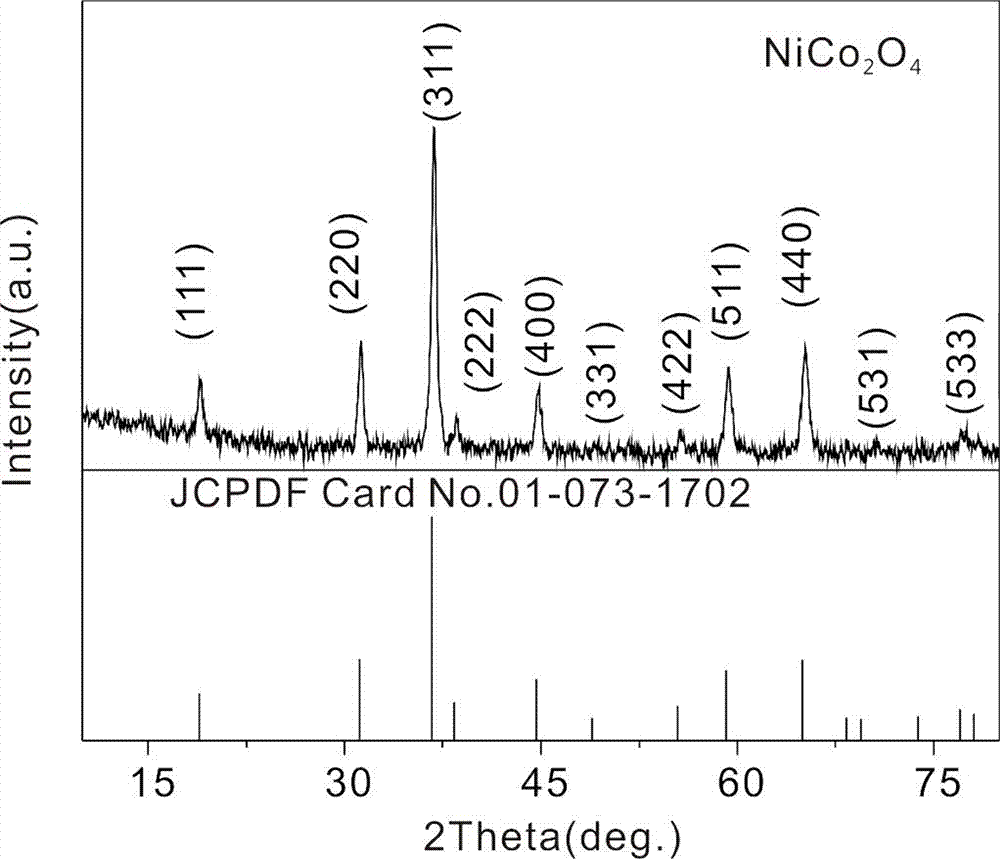

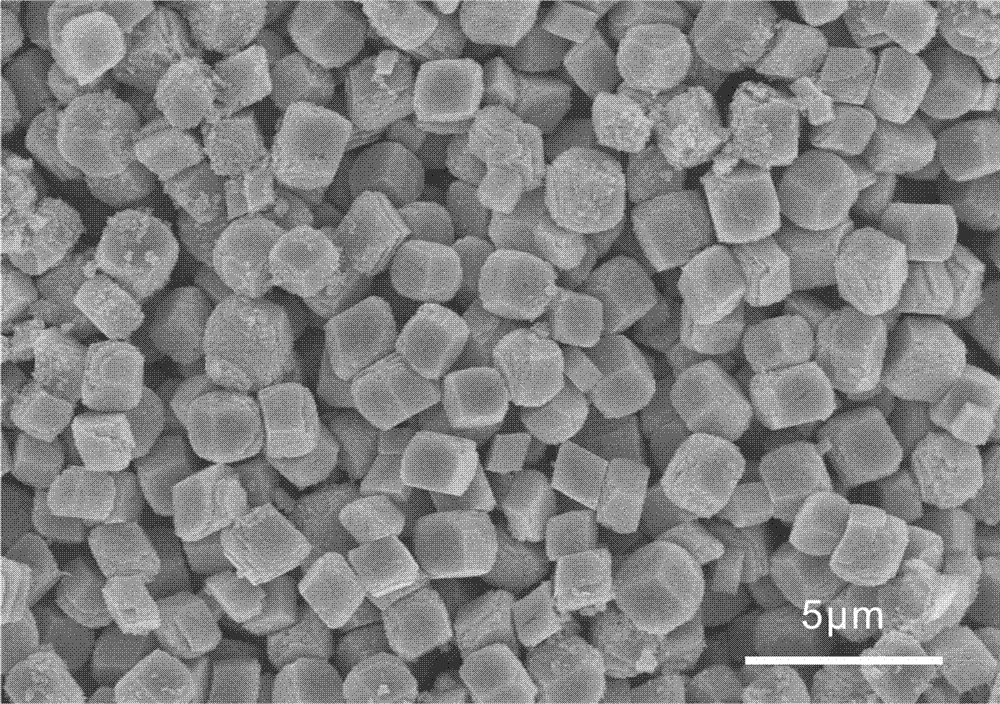

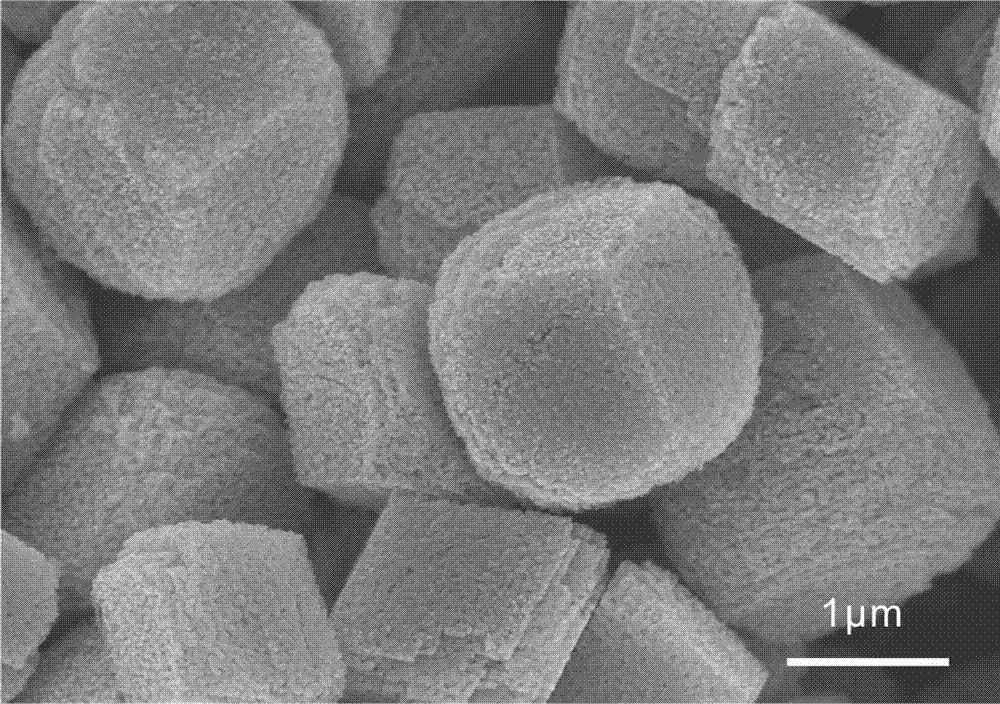

Preparation method of anode material for lithium-ion batteries

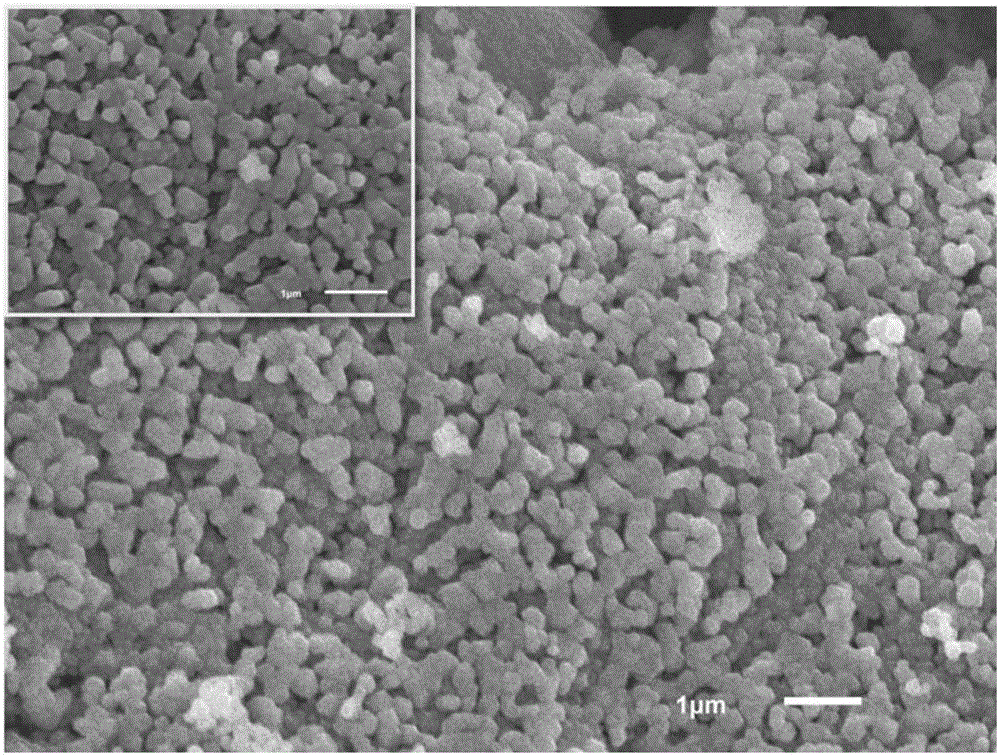

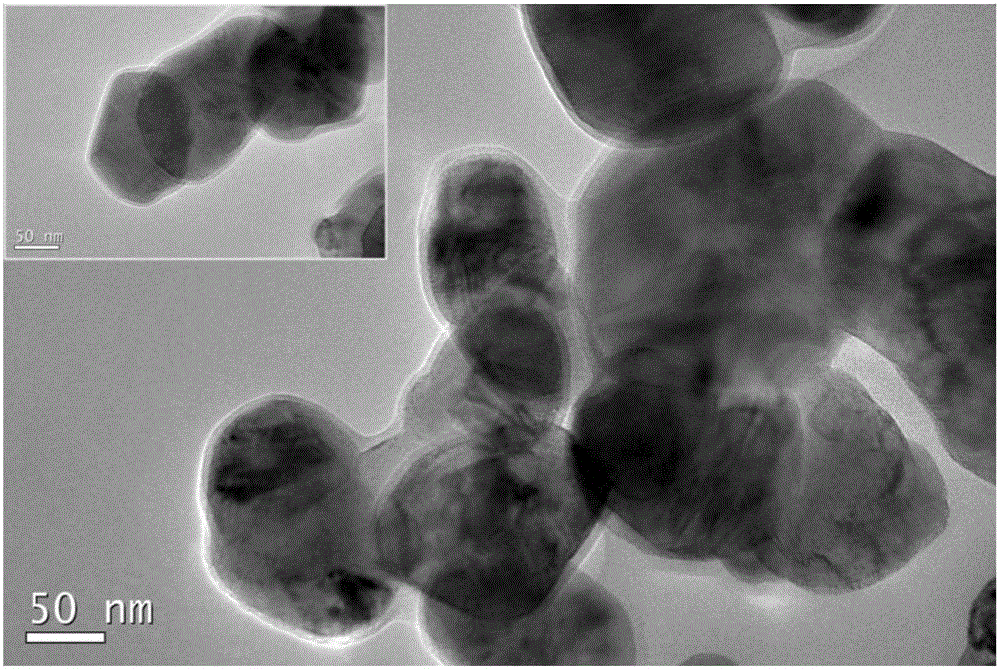

ActiveCN107403929AGood dispersionImprove cycle stabilityCell electrodesSecondary cellsHigh current densityHazardous substance

The invention discloses a preparation method of an anode material for lithium-ion batteries. According to the preparation method, urea is taken as a precipitating agent, nickel acetate tetrahydrate is taken as a nickel source, cobalt acetate tetrahydrate is taken as a cobalt source, ethylene glycol and deionized water are taken as solvents, and the anode material, which has a monodisperse porous NiCo2O4 submicron cube structure, for the lithium-ion batteries is prepared by means of a mixed solvent thermal method and a precursor annealing method. The method takes the ethylene glycol and the deionized water as reaction solvents, so that the NiCo2O4 submicron cube which is high in dispersibility and has a porous structure can be obtained only by using the mixed solvent thermal method and the precursor annealing method; the prepared anode material has first discharge capacity reaching up to 1380mAh / g under the high current density of 1A / g, and still has discharge capacity of 607mAh / g after 300-time cycling so as to have excellent cyclic stability; in a preparation process of the anode material, the requirements for a dispersion system solution are low, the solvents are convenient and easy to obtain, harmful substances are not produced, and the preparation method is environmentally-friendly; the method is simple in preparation technology, low in requirements for equipment and short in production cycle; the prepared product is larger in amount and free from impurities, thus being suitable for large-scale production.

Owner:山西宝光新材料科技有限公司

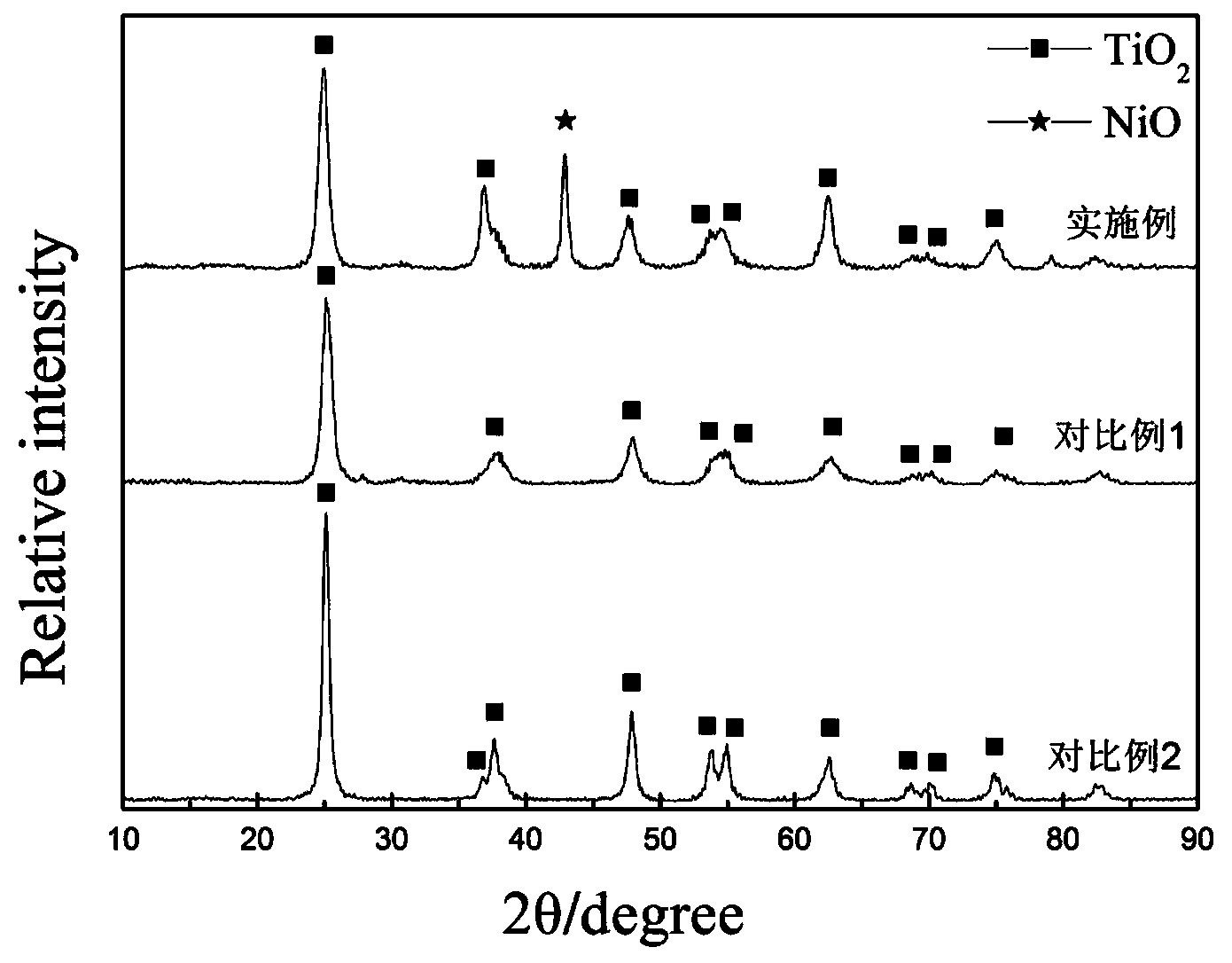

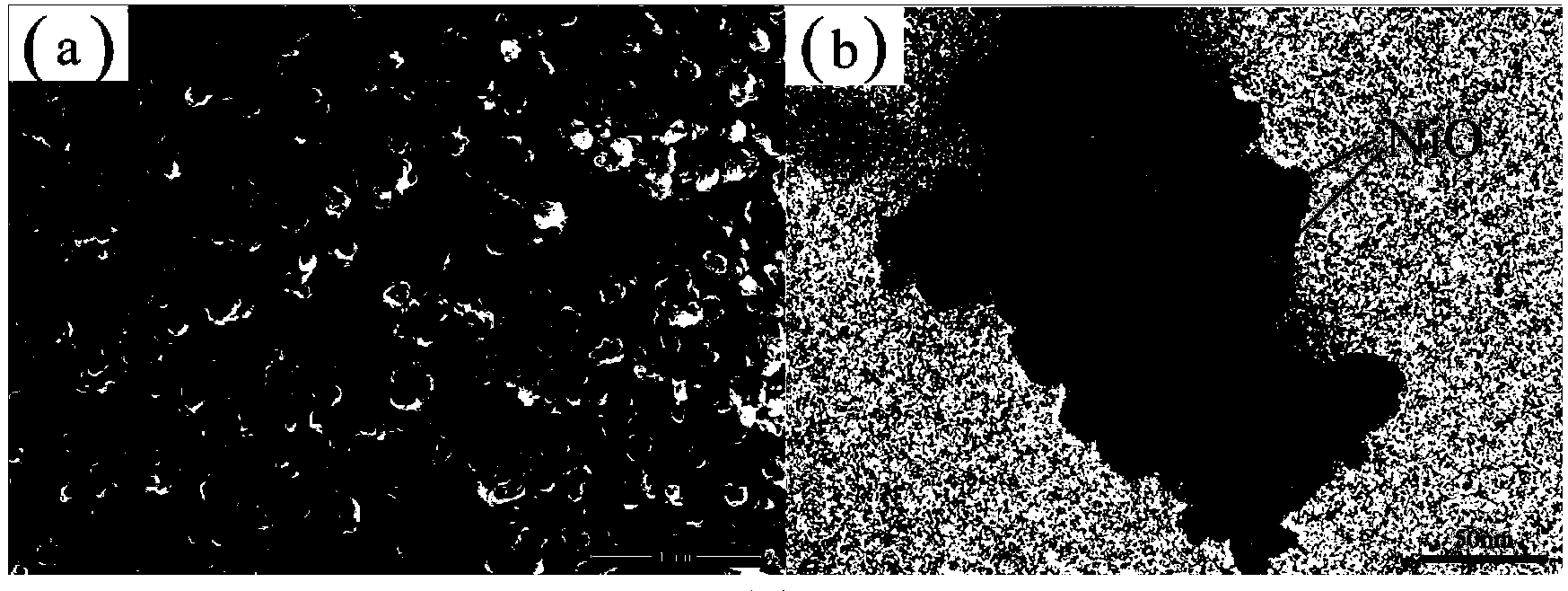

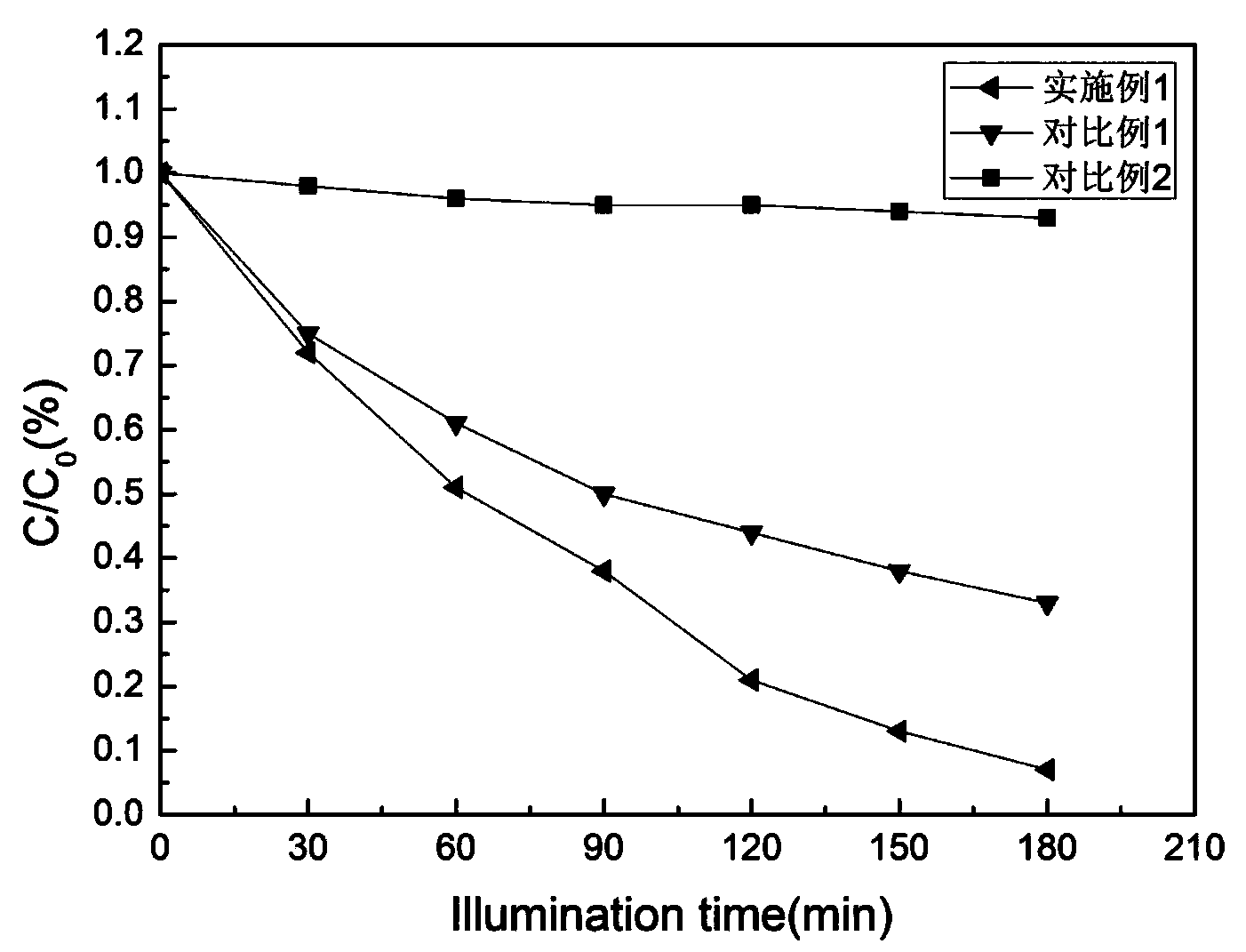

Preparation method of vanadium-boron co-doping titanium dioxide and nickel oxide composite photocatalyst

ActiveCN104226320AEasy to separateIncrease the active area of redox reactionMetal/metal-oxides/metal-hydroxide catalystsRadiationCatalytic effectNickel acetate tetrahydrate

The invention discloses a preparation method of visible-light response vanadium-boron co-doping titanium dioxide and nickel oxide composite nano photocatalyst, which belongs to the field of preparation and application of a nano material. The preparation method comprises the following steps: (1) preparing nickel oxalate dry gel by adopting nickel acetate tetrahydrate as a precursor; (2) adding the nickel oxalate dry gel in the process for preparing the boron-vanadium co-dopinng nano titanium dioxide in a sol-gel method, so as to further form composite photocatalyst gel; and (3) drying and grinding the gel, and thermally treating the gel to obtain the nano titanium dioxide nickel oxide composite photocatalyst. The photocatalyst prepared in the method is excellent in optical catalytic effect, the light frequency response range is enlarged from an ultraviolet region to a visible light region, and the optical catalytic efficiency is greatly improved. Moreover, the preparation raw material is easy to obtain, the reaction condition is moderate, and byproducts are pollution-free to the environment.

Owner:UNIV OF SCI & TECH BEIJING

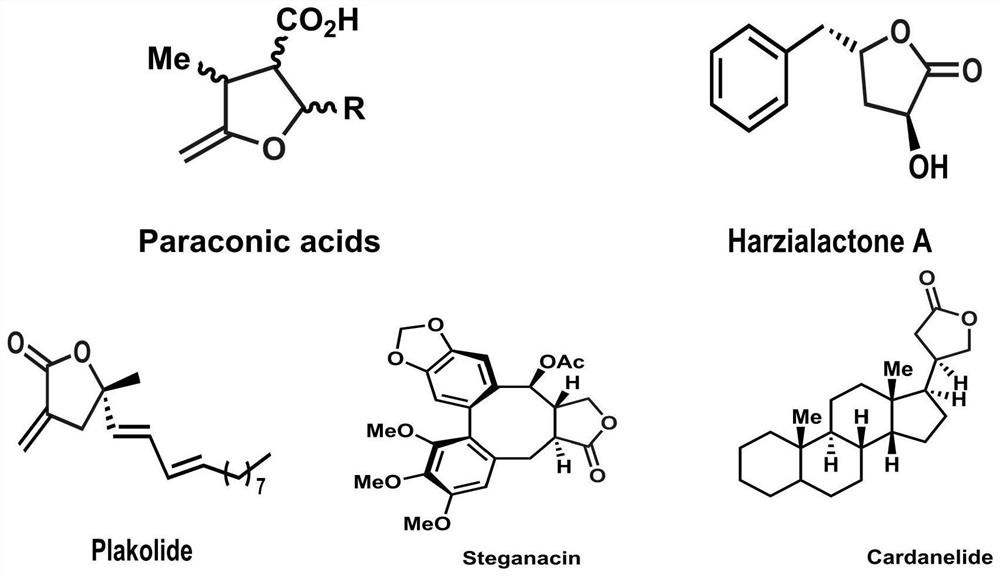

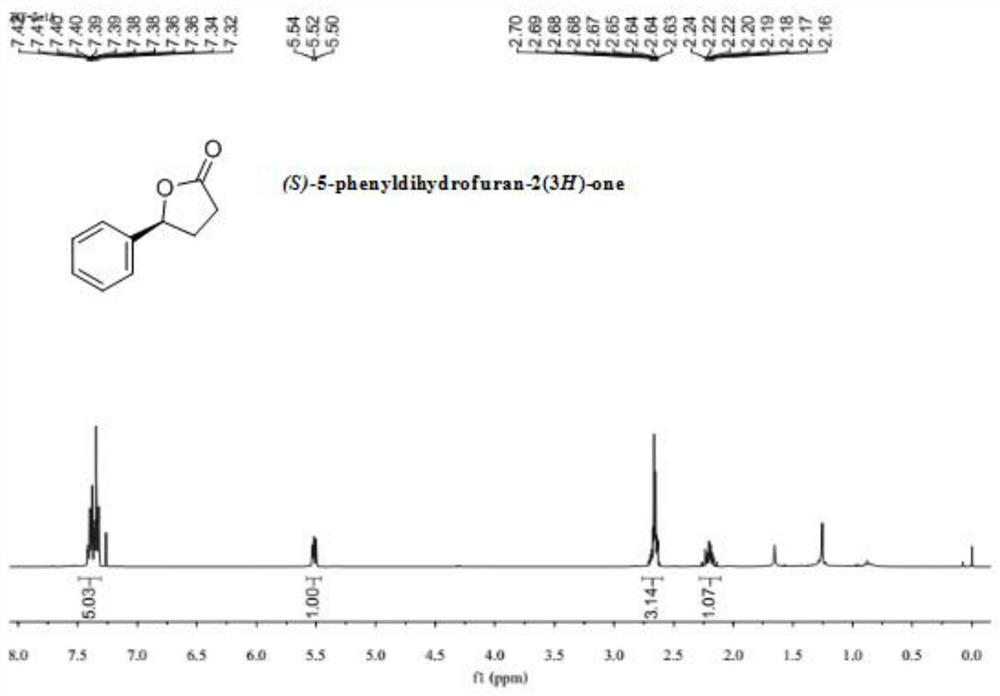

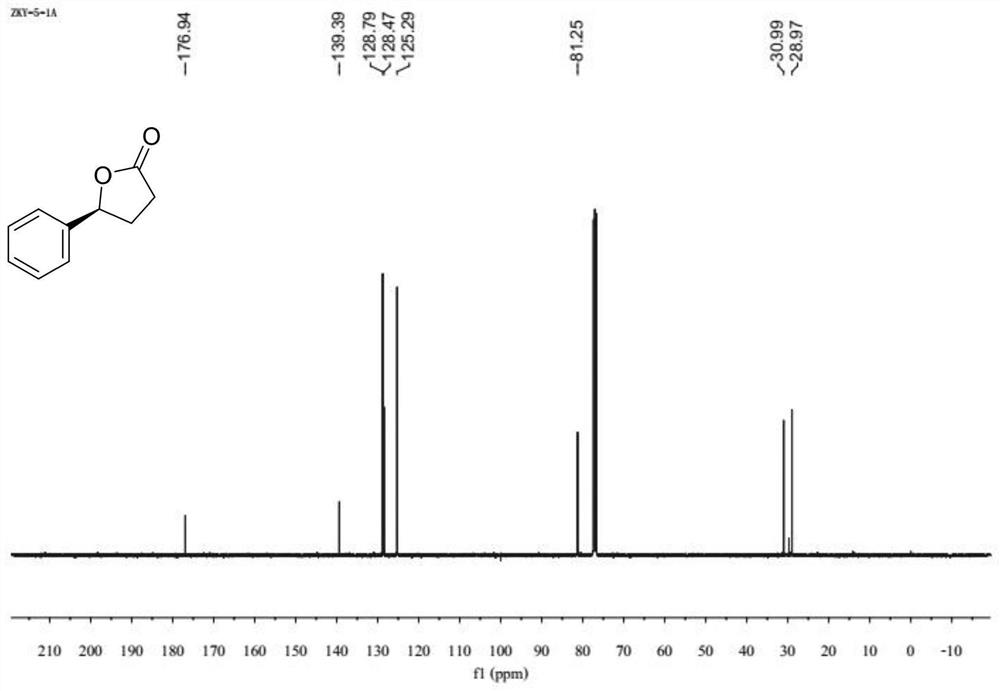

Method for asymmetrically synthesizing dihydrofuran-2-(3H)-one compound under catalysis of nickel

The invention relates to a method for asymmetrically synthesizing a dihydrofuran-2-(3H)-one compound under the catalysis of nickel, wherein the method comprises the steps: by taking gamma-ketonic acid as a raw material, adding a nickel catalyst, a ligand and Lewis acid in an organic solvent environment in which hydrogen is taken as a hydrogen source at the pressure of 0.1-6 MPa and the temperature of 50-90 DEG C, and carrying out hydrogenation reaction to synthesize the dihydrofuran-2-(3H)-one compound. By adopting a transition metal-lewis acid synergistic catalysis strategy and taking nickel acetate tetrahydrate as a transition metal catalyst, the preparation method has the advantages of easiness in obtaining and low cost; zinc trifluoromethanesulfonate is added, so that the reaction temperature is greatly reduced from 150 DEG C to 70 DEG C, and compared with a metal catalytic reaction in the prior art, the reaction is milder. The method disclosed by the invention is wide (suitable) in application range, simple in catalytic system, simple and convenient to operate and high in yield and enantioselectivity (the yield is as high as 97%, and ee is as high as 95%), the production cost is greatly reduced, and the method has remarkable social benefits and economic benefits.

Owner:YUNNAN MINZU UNIV

Preparation method of nickel oxide/poly(3,4- ethylenedioxythiophene) compound electrochromic film

The invention relates to a preparation method of nickel oxide / poly(3,4- ethylenedioxythiophene) compound electrochromic film. The preparation method comprises following steps: adding nickel acetate tetrahydrate and urea into absolute ethanol to prepare a reaction solution, putting FTO conductive glass, which has been washed by ultrasonic, into a hydrothermal reactor filled with the reaction solution, controlling the temperature in the range of 160 and 180 DEG C, maintaining the temperature for 6 to 12 hours, cooling to the room temperature, washing, burning so as to obtain FTO conductive glass with a NiO layer, dissolving 4- ethylenedioxythiophene monomers into a propylene carbonate solution of lithium perchlorate to obtain deposition liquid, then putting the FTO conductive glass with a NiO layer into the deposition liquid to play as a work electrode, taking a platinum slice as the counter electrode, then performing electro-deposition reactions so as the obtain the product. The preparation method has the advantages of simple technology and low cost, structure design in the micro-nano grade of the inorganic / organic compound electrochromic materials can be achieved, so the respective advantages of the organic and inorganic electrochromic materials can be fully utilized.

Owner:DONGHUA UNIV

Manganese-base carbon-coated nano lithium-rich oxide and preparation method as well as application thereof

ActiveCN105702936ANo generationThe reaction process is simple, quick and convenientCell electrodesSecondary cellsManganeseNickel acetate tetrahydrate

The invention belongs to the technical field of lithium batteries, and discloses a manganese-base carbon-coated nano lithium-rich oxide and a preparation method as well as an application thereof. The preparation method comprises the following steps: under a condition of stirring, dissolving PVP in DMF, then, adding lithium acetate dihydrate, manganous acetate tetrahydrate, nickel acetate tetrahydrate and cobaltous acetate tetrahydrate according to a molar ratio of 1.26:0.54:0.13:0.13, stirring and dissolving evenly to obtain a metal salt solution; then, heating up the metal salt solution to 60-120 DEG C to carry out constant temperature treatment for 10-24 hours, thereby obtaining a gel-like object; heating up the gel-like object in the air to 400-500 DEG C to carry out constant temperature treatment for 3-8 hours, cooling naturally, then taking out and performing tablet compressing, and sintering for 7-12 hours at the temperature of 800-1000 DEG C to obtain a product. According to the invention, the preparation method is simple, problems, such as hydrolysis and aggregation of transition metal ions, are avoided, and the obtained product has good electrochemical performance when being used as a lithium ion battery positive electrode material.

Owner:SOUTH CHINA NORMAL UNIVERSITY

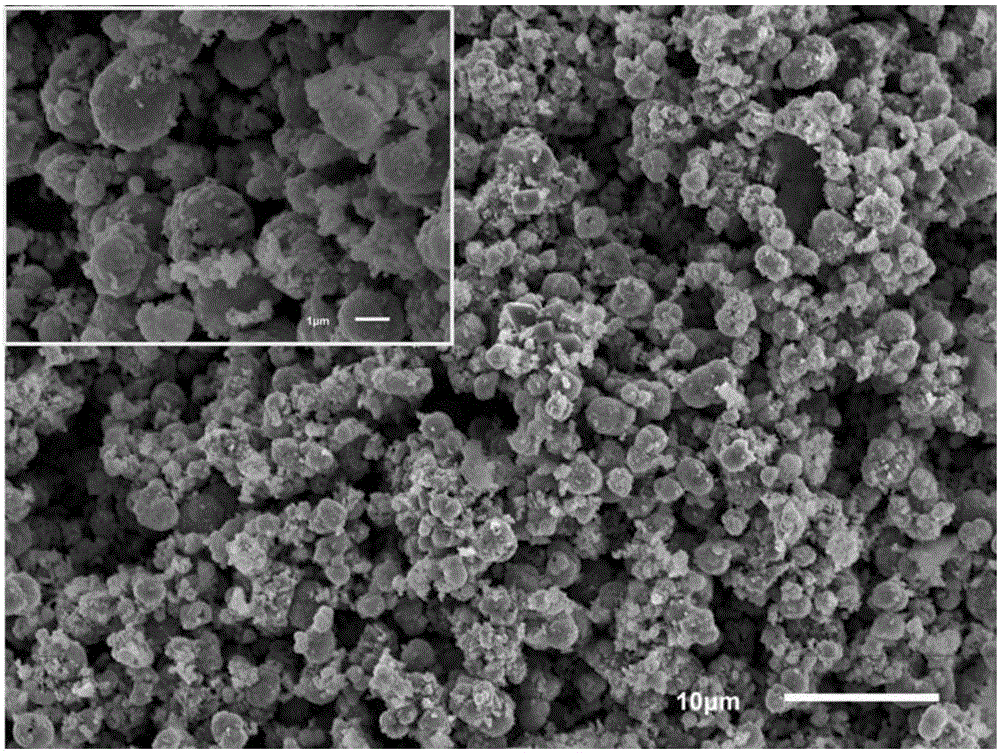

Preparation method of nickel sulfide/graphene/polyaniline composite electrode material

InactiveCN106025227AImprove conductivityImprove stabilityCell electrodesSecondary cellsIce waterFreeze-drying

The invention relates to a preparation method of a nickel sulfide / graphene / polyaniline composite electrode material. The method comprises the following steps: carrying out ultrasonic dispersion on graphene oxide uniformly, adding lauryl sodium sulfate aqueous solution and aniline respectively, performing mixing, ultrasonically forming a stable and uniform mixture, performing stirring in an ice water bath and dropwise adding ammonium persulfate acidified by hydrochloric acid, performing continuous stirring in the ice water bath for 12 hours, performing centrifugation and water washing on the obtained a dark green solution to obtain a gelatinous substance, and ultrasonically dispersing the gelatinous substance in a hydrochloric acid solution, then dropwise adding a nickel acetate tetrahydrate aqueous solution and a thioacetamide solution into the ultrasonically dispersed gelatinous substance, carrying out ultrasound continuously to reach uniformity, carrying out a hydrothermal reaction for 12 hours at the temperature of 180 DEG C, and then performing centrifugation, water washing, and freeze-drying to obtain the nickel sulfide / graphene / polyaniline composite electrode material. Compared with the prior art, the preparation method of the nickel sulfide / graphene / polyaniline composite electrode material disclosed by the invention aims at improving an anode material of a lithium ion battery, so as to obtain the anode material which is good in stability and easy to control, and improve performance of the lithium-ion battery.

Owner:SHANGHAI INST OF TECH

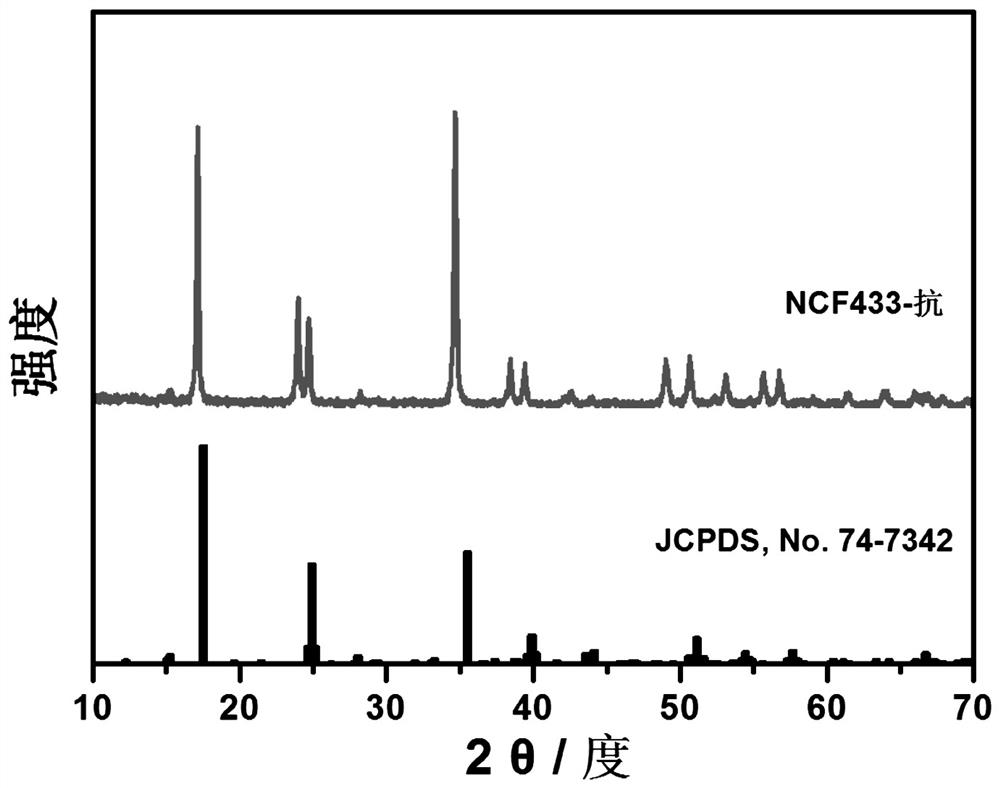

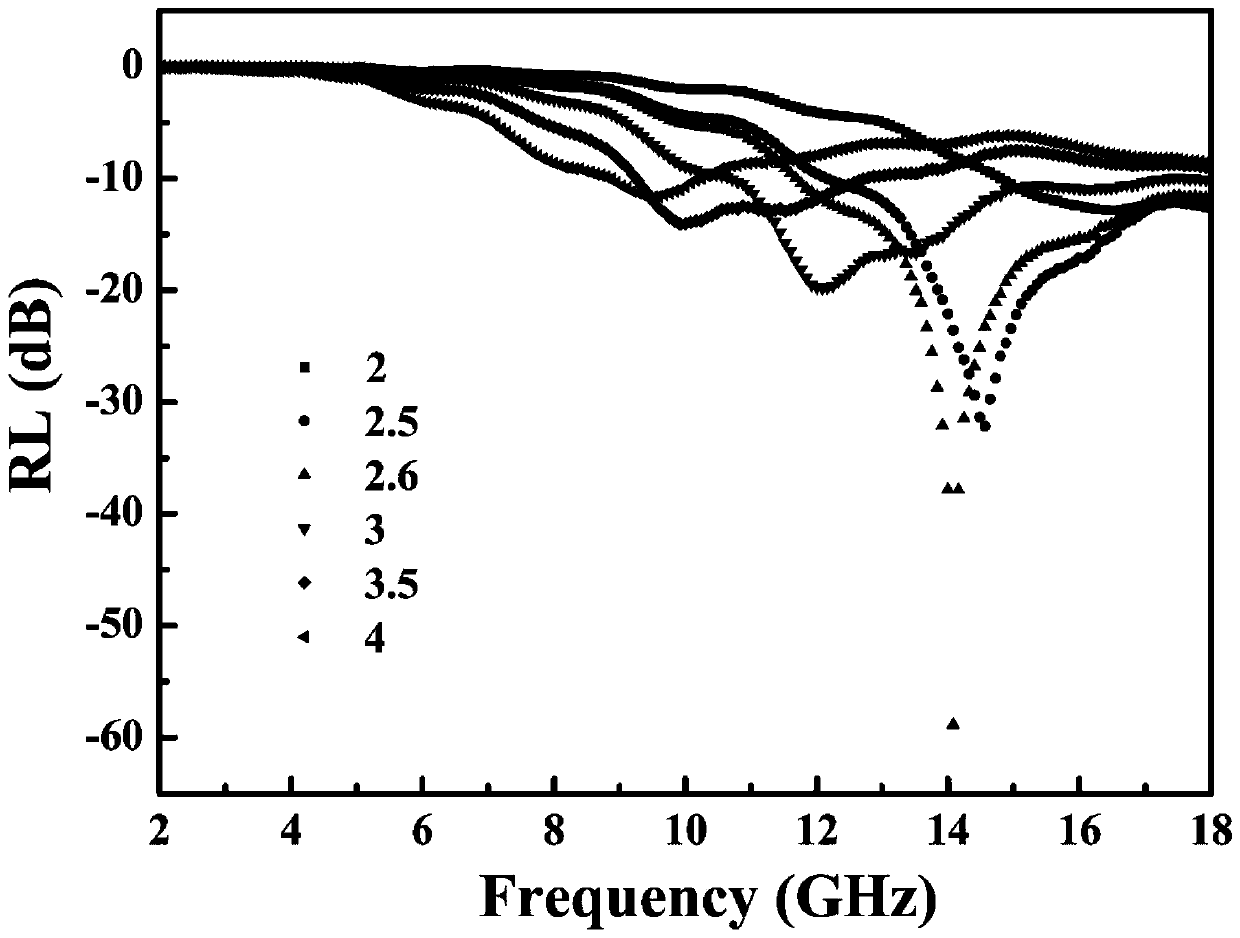

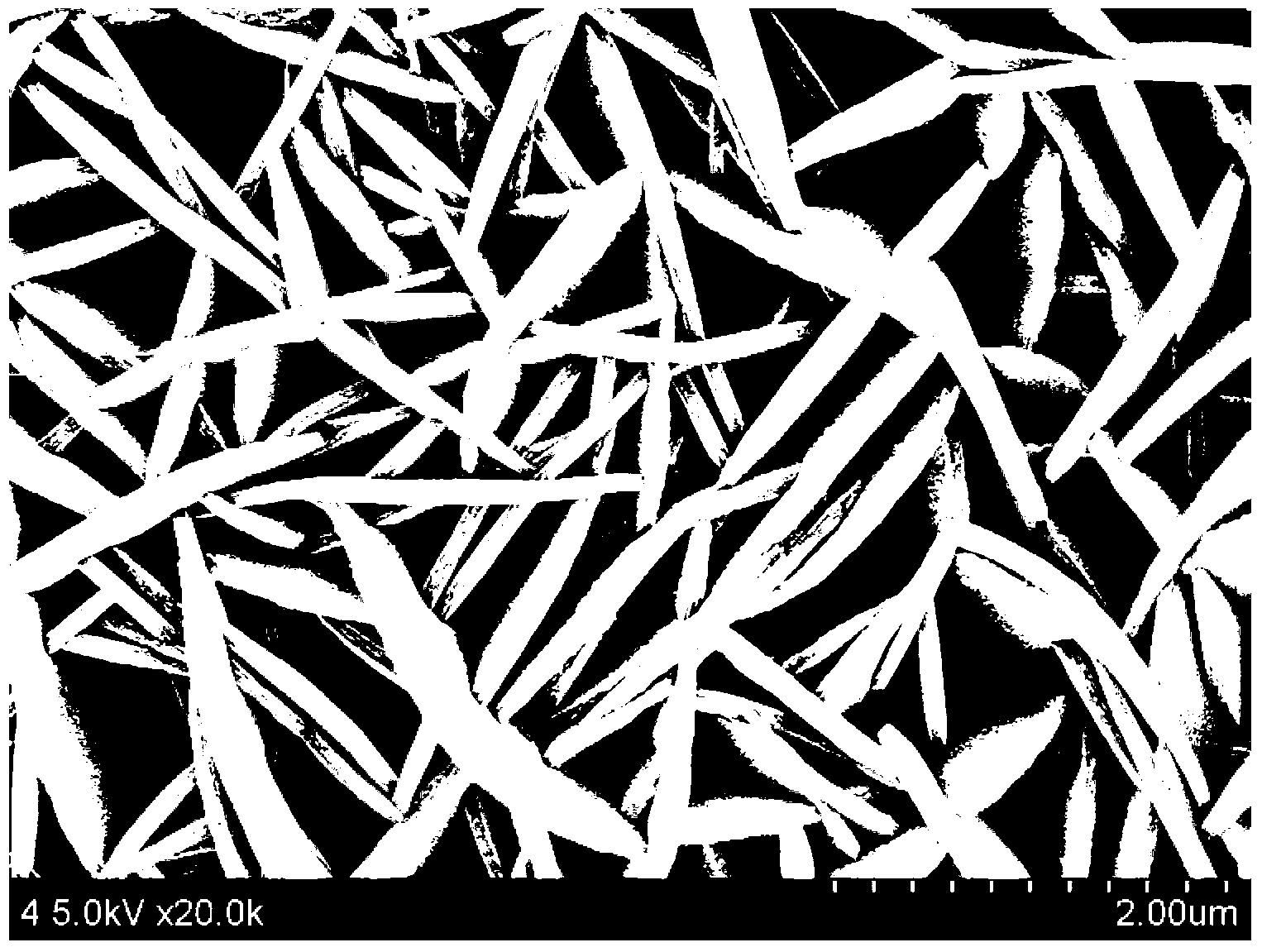

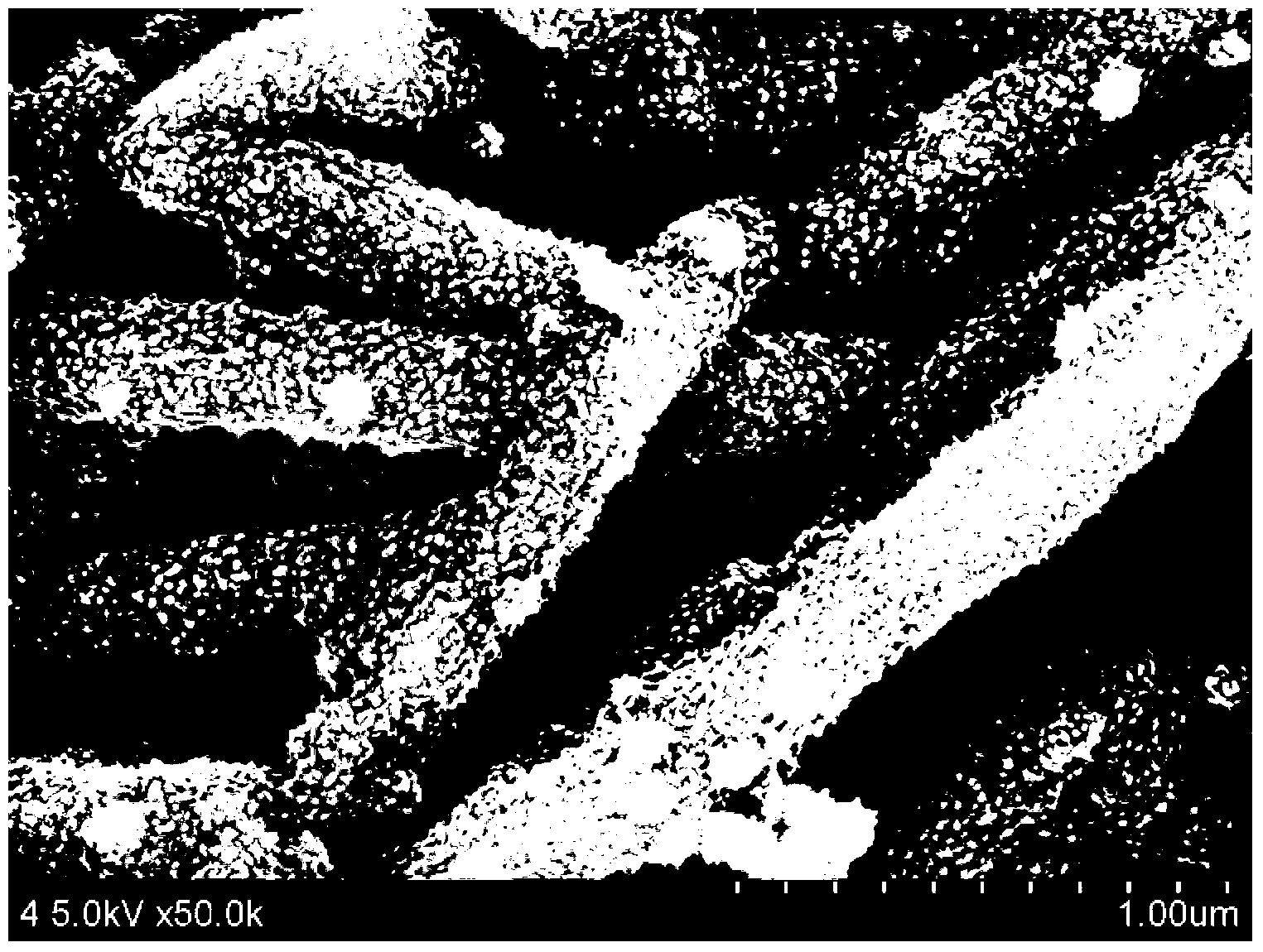

NiCo/C@CNT double-conductive network hierarchical structure material, and preparation method and application thereof

ActiveCN110669474AEasy to operateLow reaction temperatureOther chemical processesMagnetic/electric field screeningCobalt acetatePhysical chemistry

The invention provides a NiCo / C@CNT double-conductive network hierarchical structure material, and a preparation method and an application thereof. Nickel acetate tetrahydrate and cobalt acetate tetrahydrate which are used as metal sources and 2,5-dihydroxyterephthalic acid which is used as an organic ligand undergo a refluxing reaction at 80-110 DEG C for a period of time in ultrapure water usedas a reaction solvent to obtain orange-yellow precipitate, and the obtained product is centrifuged, washed and dried, and finally is calcined at 500-800 DEG C in an inert atmosphere for 1-4 h to obtain the NiCo / C@CNT double-conductive network wave-absorbing material. The hierarchical structure is formed after carbon nanotubes are generated in situ, so that the NiCo / C@CNT double-conductive networkhierarchical structure material has an excellent electromagnetic wave-absorbing performance as a wave-absorbing material.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of nickel oxide/polyaniline composite electrochromic film

InactiveCN103232174AImprove poor optical performanceImprove slow color conversionPotassium persulfateNickel acetate tetrahydrate

The invention relates to a preparation method of a nickel oxide / polyaniline composite electrochromic film, which comprises the following steps: immersing FTO (fluorine-doped tin oxide) conductive glass in a mixed solution of nickel acetate tetrahydrate, potassium persulfate, ammonia water and water, keeping the temperature at 160-180 for 6-12 hours, naturally cooling to room temperature, cleaning, and calcining to obtain FTO conductive glass having a NiO layer; dissolving an aniline monomer in a sulfuric acid solution to obtain a deposition solution, and immersing the FTO conductive glass having the NiO layer in the deposition solution; and performing electrodeposition by taking the FTO conductive glass in the deposition solution as a working electrode and a platinum sheet as a counter electrode. The invention realizes the combination of organic and inorganic electrochromic materials on the micrometer / nanometer level; and the prepared film has favorable electrochromic property and has wide application prospects in the fields such as smart windows, large-screen display and the like.

Owner:DONGHUA UNIV

Preparation method of Ni/C core-shell material

InactiveCN108654621ARich mesostructureUniform sizeCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsThermal insulationTube furnace

The invention discloses a preparation method of a Ni / C core-shell material. The preparation method of the Ni / C core-shell material comprises the following steps: adding nickel acetate tetrahydrate into deionized water, and carrying out stirring until the nickel acetate tetrahydrate is dissolved so as to obtain a solution; dissolving DHTP in THF so as to obtain a solution; fully mixing the two solutions so as to obtain a mixture, sealing the mixture in a hydrothermal kettle, and performing thermal insulation at 100-105 DEG C in an oven for 3.5-4.5 days; carrying out cooling so as to obtain a solid product, filtrating the obtained solid product, washing the filtered solid product with THF and methanol, and carrying out replacement with methanol for four days; carrying out filtrating so as toobtain a solid product, and performing vacuum drying on the solid product so as to obtain Ni-MOF-74; placing the Ni-MOF-74 in a quartz boat, putting the quartz boat into a tubular furnace, carrying out heating in the presence of argon at a heating rate of 12 DEG C / minute until the temperature reaches 220-240 DEG C, maintaining the temperature for 7-8 hours, carrying out heating at a heating rateof 5 DEG C / minute until the temperature reaches 380-390 DEG C, and maintaining the temperature for 7-8 hours; and then, carrying out cooling so as to obtain the Ni / C core-shell material. The preparation method of the Ni / C core-shell material is simple, convenient, easy to operate, and capable of successfully preparing a nano-Ni / C core-shell catalyst which is abundant in mesoporous structure, uniform in size and excellent in catalytic activity.

Owner:QIDONG XIANGRUI CONSTR CO LTD

Method for preparing nanometer trinickel nitride powder

InactiveCN110171807AImprove stabilityHigh purityNitrogen-metal/silicon/boron binary compoundsNanotechnologyNickel acetate tetrahydrateIndustrial scale

The invention discloses a method for preparing nanometer trinickel nitride powder. The method comprises the following steps: uniformly mixing nickel nitrate hexahydrate, nickel carbonate, nickel sulfate, nickel acetate tetrahydrate and urea, melamine and like nitrogen sources according to the mole ratio of the nickel element to solid nitrogen source of 1: 1 to 1: 6, and roasting for 1-6h at 300-550 DEG C in the roasting atmosphere, namely obtaining the high-purity nanometer trinickel nitride powder. The nanometer trinickel nitride powder prepared through the invention is high in purity, simplein preparation process and easy to operate, the raw material source is extensive and easy, the synthesis cost is low, the process procedure is environmentally friendly, and strong in economic practicability, and the method is a green process with industrial scale production.

Owner:SHAANXI NORMAL UNIV +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com