Synthesis of coordination polymer and application of coordination polymer to cathode material for lithium-ion battery

A technology of coordination polymers and complexes, used in battery electrodes, secondary batteries, secondary battery manufacturing, etc., can solve problems such as poor solubility and low specific capacity, and achieve improved stability, good cycle performance, and good electrical Effects of chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

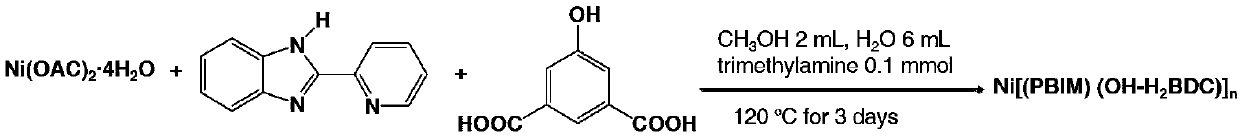

[0031] Embodiment 1, complex [Ni(PBIM)(OH-BDC)] n Synthesis.

[0032] (1) Please refer to figure 1 , which is a diagram of the synthetic reaction steps of the complex in the present invention.

[0033] Weigh nickel acetate tetrahydrate (Ni(OAc) 2 4H 2 O) (0.5mmol), 2,2'-pyridylbenzimidazole (PBIM) (0.1mmol), 5-hydroxyisophthalic acid (OH-BDC) (0.2mmol), triethylamine (0.1mmol) dissolved In 2mL of methanol and 6mL of water, heated to 120 degrees Celsius in a reaction kettle for 3 days, and cooled to room temperature after the reaction to obtain crystals of the complex.

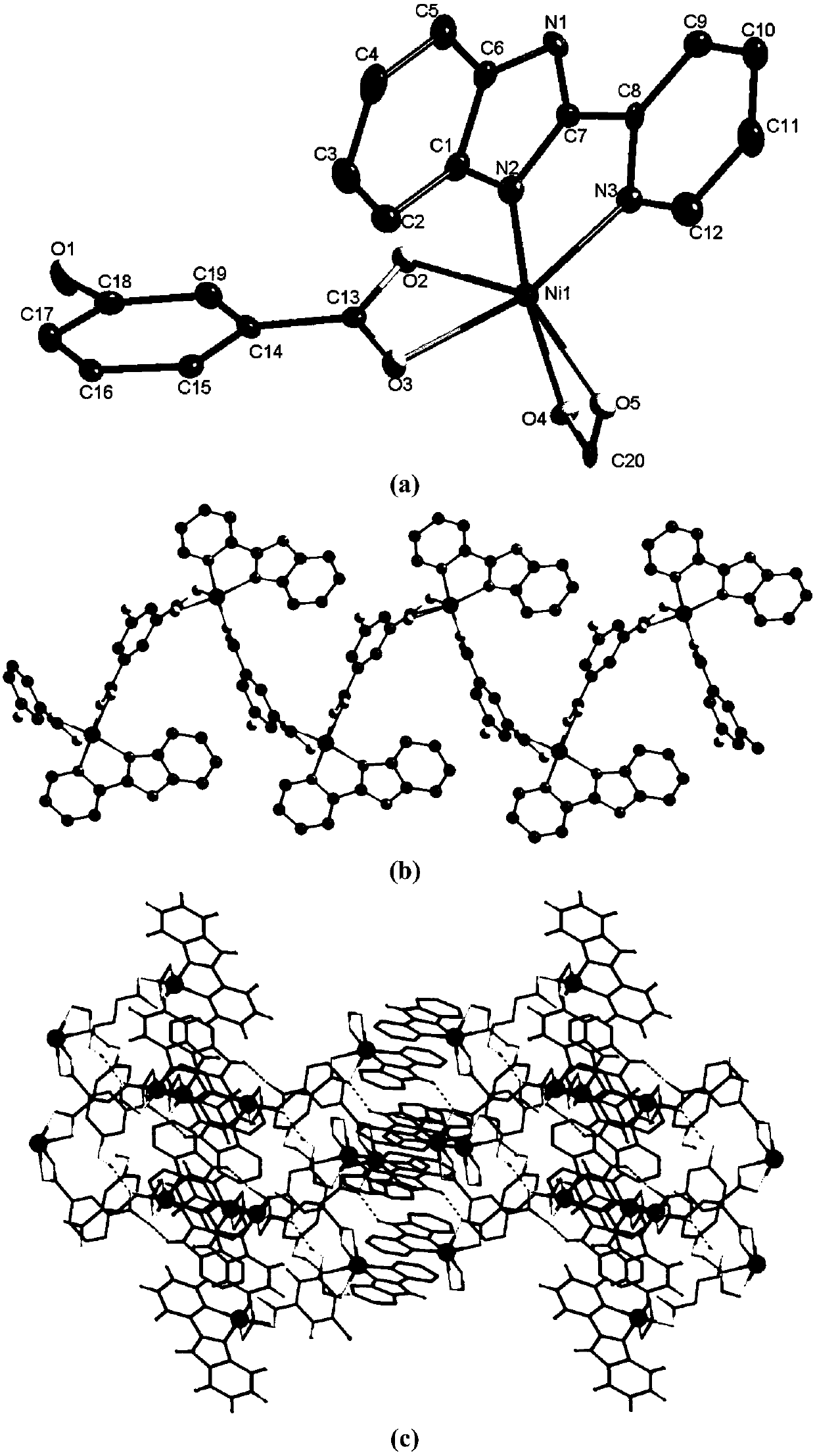

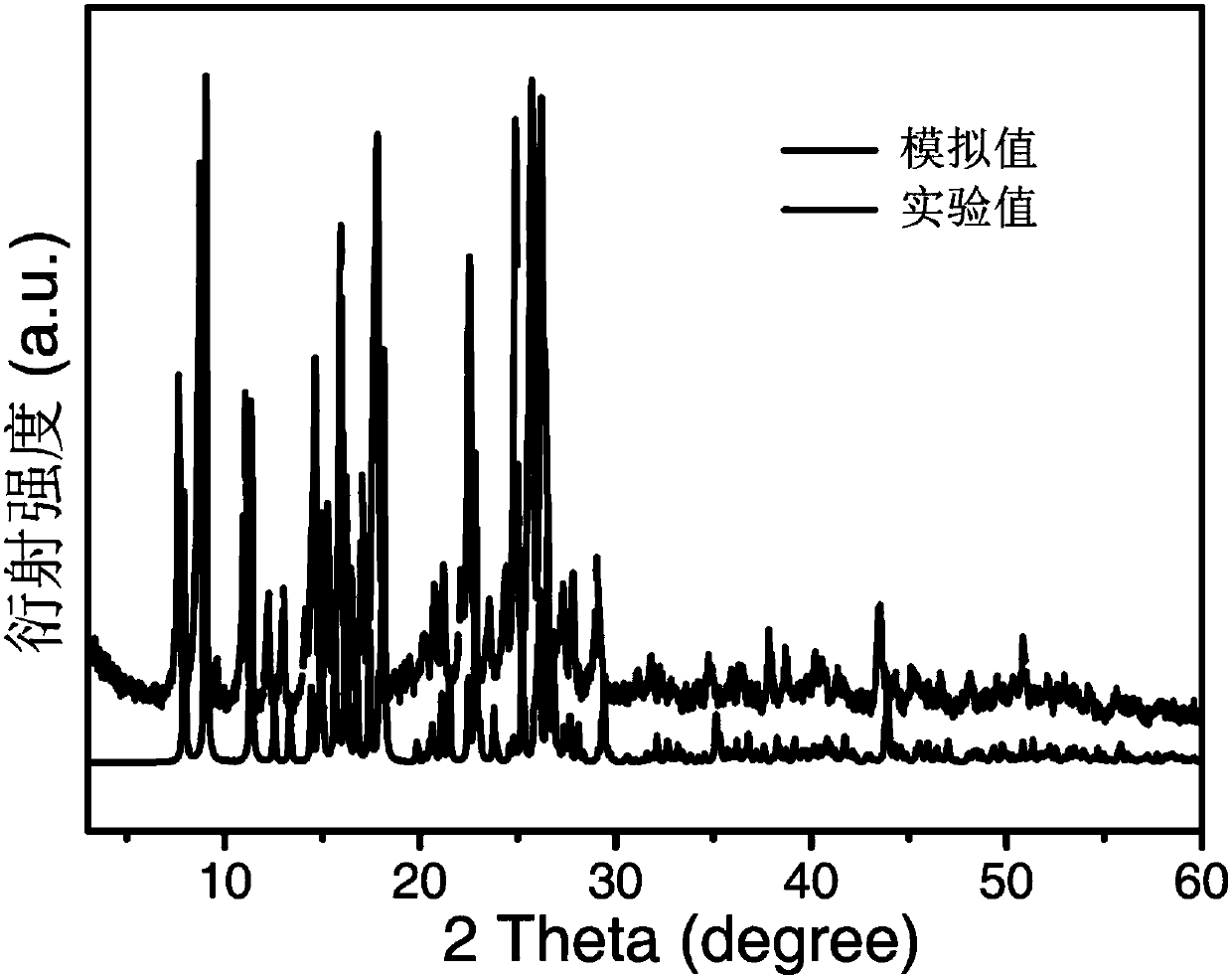

[0034] (2) Take the crystal in the reaction kettle in step 1 on a glass sheet, select a transparent and crack-free regular crystal with a size of 0.3*0.5*0.5mm under a microscope, and measure it on a Supernova X-ray single crystal diffractometer. Mo-Kα Ray Monochromated by Monochromator is the incident radiation source, with Diffraction points were collected by scanning, and their coordinates and anisotr...

Embodiment 2

[0036] Embodiment 2, complex [Ni(PBIM)(OH-BDC)] n Application as a negative electrode material in the preparation of lithium-ion batteries

[0037] (4) Take the complex crystal prepared in step (1) and dry it in a vacuum oven at 60°C for 8 hours. Then weigh the dried complex [Ni(PBIM)(OH-BDC)] with a mass ratio of 6:3:1 n , the conductive agent (ketjen black) and the binder (polyvinylidene fluoride) are ground and mixed evenly, adjusted into a slurry with a solvent (N-methylpyrrolidone), coated on a copper foil, and dried at 80 degrees Celsius for 12 hours in a vacuum to obtain an electrode piece. Select the MSK-T10 manual slicer with a mold size of 12 mm in diameter to slice the obtained electrode sheets into circular electrode sheets, and weigh them for later use.

[0038] (5) A lithium sheet is used as the counter electrode, a Celgard 2400 membrane is used as the diaphragm, and 1mol / L lithium hexafluorophosphate (LiPF 6 ) is electrolyte, and volume ratio ethylene carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com