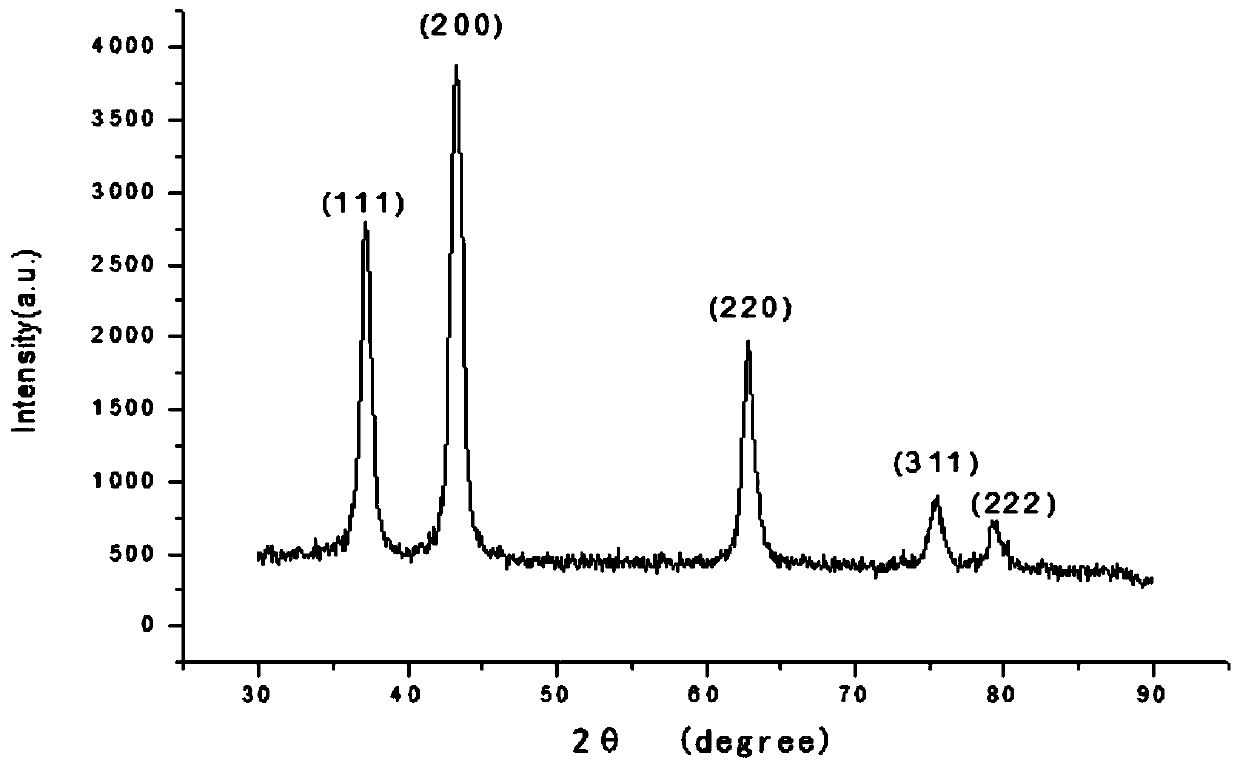

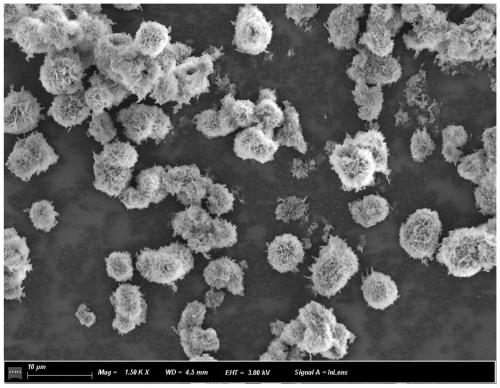

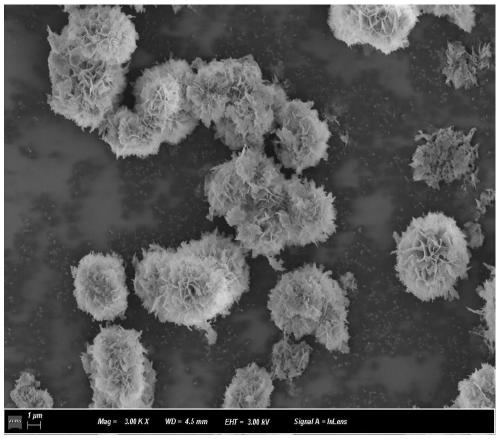

Preparation method of flower-like nickel oxide composed of porous sheets

A nickel oxide and flake technology, applied in the direction of nickel oxide/nickel hydroxide, etc., can solve the problems of formaldehyde selectivity, unsatisfactory response effect, irregular shape of nickel oxide, large size distribution span, etc., and achieve uniform size Controllable, uniform shape, and short response-recovery time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A kind of preparation method of the flower-shaped nickel oxide of porous flake composition, it is characterized in that, carry out according to the following scheme:

[0038] (1) Dissolve nickel acetate tetrahydrate in distilled water to form a nickel acetate solution, and dissolve PVA and urea in distilled water to form a mixed solution. The mass volume ratio of nickel acetate tetrahydrate and distilled water is 0.374g:5mL, and the volume of PVA, urea and distilled water The mass volume ratio is 0.25g:0.24g:5mL;

[0039] (2) Slowly add the mixed solution into the nickel acetate solution, then add polyethylene glycol 2000, add dropwise ammonia water with a mass concentration of 28% while stirring after mixing, and continue stirring at a rate of 300rpm for 10min after the dropwise addition to obtain the precursor Body solution, the volume ratio of polyethylene glycol 2000, ammonia water and mixed solution is 10:1:16;

[0040] (3) Move the precursor solution in step (2) ...

Embodiment 2

[0044] A kind of preparation method of the flower-shaped nickel oxide of porous flake composition, it is characterized in that, carry out according to the following scheme:

[0045] (1) Dissolve nickel acetate tetrahydrate in distilled water to form a nickel acetate solution, and dissolve PVA and urea in distilled water to form a mixed solution. The mass volume ratio of nickel acetate tetrahydrate and distilled water is 0.648g:5mL, and the volume of PVA, urea and distilled water The mass volume ratio is 0.25g: 0.54g: 5mL;

[0046](2) Slowly add the mixed solution into the nickel acetate solution, then add polyethylene glycol 2000, add dropwise ammonia water with a mass concentration of 25% while stirring after mixing, and continue stirring at a rate of 300rpm for 10min after the dropwise addition to obtain the precursor Body solution, the volume ratio of polyethylene glycol 2000, ammonia water and mixed solution is 10:1:18;

[0047] (3) Move the precursor solution in step (2)...

Embodiment 3

[0051] A kind of preparation method of the flower-shaped nickel oxide of porous flake composition, it is characterized in that, carry out according to the following scheme:

[0052] (1) Dissolve nickel acetate tetrahydrate in distilled water to form a nickel acetate solution, and dissolve PVA and urea in distilled water to form a mixed solution. The mass volume ratio of nickel acetate tetrahydrate and distilled water is 0.623g:5mL, and the volume of PVA, urea and distilled water The mass volume ratio is 0.25g:0.48g:5mL;

[0053] (2) Slowly add the mixed solution into the nickel acetate solution, then add polyethylene glycol 2000, add dropwise ammonia water with a mass concentration of 28% while stirring after mixing, and continue stirring at a rate of 300rpm for 10min after the dropwise addition to obtain the precursor Body solution, the volume ratio of polyethylene glycol 2000, ammonia water and mixed solution is 10:1:17;

[0054] (3) Move the precursor solution in step (2) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com