Method for preparing nickel oxide/zinc oxide heterojunction nanometer materials

A nanomaterial, zinc oxide technology, applied in the field of preparation of nickel oxide/zinc oxide heterojunction nanomaterials, can solve problems such as low sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Step 1. Completely dissolve nickel acetate tetrahydrate: zinc nitrate hexahydrate: sodium hydroxide in distilled water at a molar ratio of 1:4:10, and magnetically stir for 10 minutes to make it a uniform and clear solution;

[0018] Step 2. Transfer the solution obtained in step 1 to a high-pressure reactor, seal it, heat it at 80°C for 18 hours, wash and centrifuge the product repeatedly with distilled water and absolute ethanol until the pH value of the solution is neutral, and place the obtained product in an oven at 50°C to dry Dry for 10 hours to obtain nickel oxide / zinc oxide heterojunction calcined powder;

[0019] Step 3. Calcining the nickel oxide / zinc oxide pre-calcined powder obtained in step 2 in a muffle furnace, the heating rate is 3°C / min, the calcination temperature is 300°C, and the calcination time is 3h to obtain nickel oxide / zinc oxide Zinc heterojunction nanomaterials.

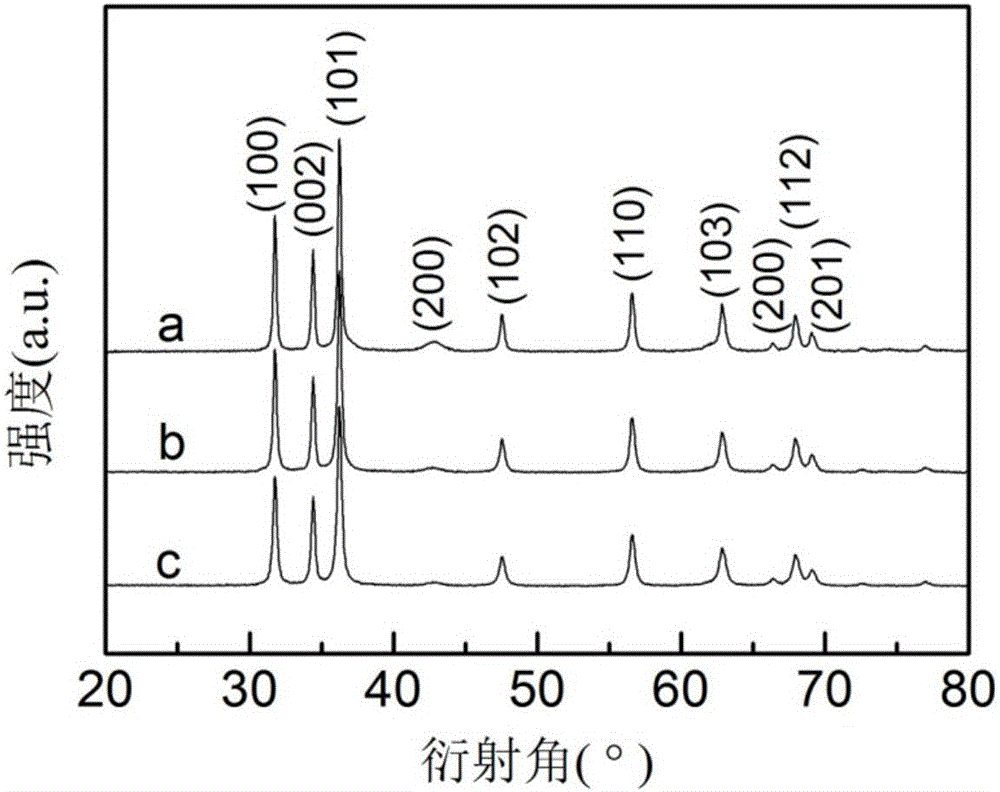

[0020] From figure 1 It can be seen from the X-ray diffraction pattern of (a...

Embodiment 2

[0022] Step 1. Completely dissolve nickel acetate tetrahydrate: zinc nitrate hexahydrate: sodium hydroxide in distilled water at a molar ratio of 1:9:20, and magnetically stir for 15 minutes to make it a uniform and clear solution;

[0023] Step 2. Transfer the solution obtained in step 1 to a high-pressure reactor, seal it and heat it at 90°C for 12 hours, wash and centrifuge the product repeatedly with distilled water and absolute ethanol until the pH of the solution is neutral, and place the obtained product in an oven at 60°C to dry Dry for 8 hours to obtain nickel oxide / zinc oxide heterojunction calcined powder;

[0024] Step 3. Calcining the nickel oxide / zinc oxide pre-calcined powder obtained in step 2 in a muffle furnace, the heating rate is 5°C / min, the calcination temperature is 350°C, and the calcination time is 2h, to obtain nickel oxide / zinc oxide Zinc heterojunction nanomaterials.

[0025] From figure 1 It can be seen from the X-ray diffraction pattern of (b) t...

Embodiment 3

[0027] Step 1. Completely dissolve nickel acetate tetrahydrate: zinc nitrate hexahydrate: sodium hydroxide in distilled water at a molar ratio of 1:19:40, and magnetically stir for 20 minutes to make it a uniform and clear solution;

[0028] Step 2. Transfer the solution obtained in step 1 to a high-pressure reactor, seal it, heat it at 100°C for 6 hours, wash and centrifuge the product repeatedly with distilled water and absolute ethanol until the pH of the solution is neutral, and place the obtained product in an oven at 70°C to dry Dry for 6 hours to obtain nickel oxide / zinc oxide heterojunction calcined powder;

[0029] Step 3. Calcining the nickel oxide / zinc oxide pre-calcined powder obtained in step 2 in a muffle furnace, the heating rate is 8°C / min, the calcination temperature is 400°C, and the calcination time is 1h to obtain nickel oxide / zinc oxide Zinc heterojunction nanomaterials.

[0030] From figure 1 It can be seen from the X-ray diffraction pattern of (c) that...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com