Manganese-base carbon-coated nano lithium-rich oxide and preparation method as well as application thereof

A carbon nano and oxide technology, which is applied in the field of manganese-based carbon-coated nano-lithium-rich oxide and its preparation, can solve the problems of difficult to achieve uniform coating, large initial capacity loss, poor rate performance, etc., and achieve a simple and fast reaction process Convenience, improved electrochemical performance, and improved electronic conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

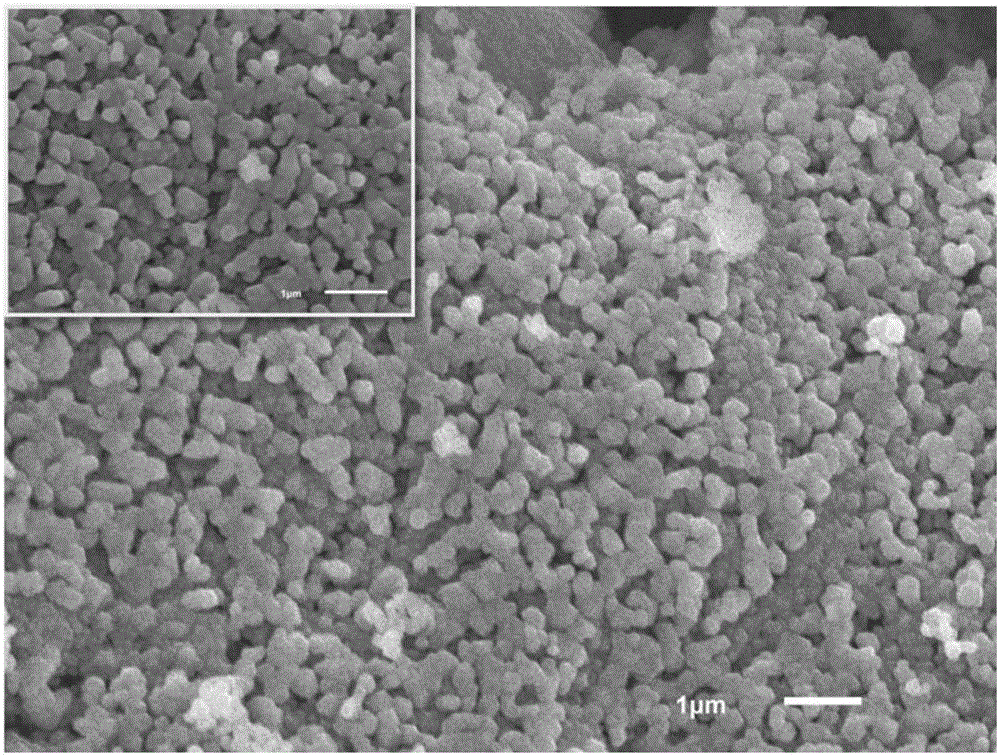

Embodiment 1

[0025] The preparation method of a manganese-based carbon-coated nano-lithium-rich oxide in this embodiment, the specific preparation steps are as follows:

[0026] (1) Under stirring conditions, add 200mL of DMF to a 500mL high-necked beaker, then add 0.2g of PVP and stir for 30min until the PVP is completely dissolved in DMF.

[0027] (2) Under continuous mechanical stirring, add lithium acetate dihydrate, manganese acetate tetrahydrate, nickel acetate tetrahydrate and cobalt acetate tetrahydrate in a molar ratio of 1.26:0.54:0.13:0.13 to step (1) to obtain a metal salt solution.

[0028] (3) Under continuous mechanical stirring, the temperature of the solution obtained in (2) was raised to 80° C., and reacted for 12 hours to obtain a gel.

[0029] (4) Send the gel obtained in step (3) into a muffle furnace to raise the temperature to 450° C., keep the temperature constant for 5 hours, and take out the tablet after cooling.

[0030] (5) The pressed sheet in (4) is heated to...

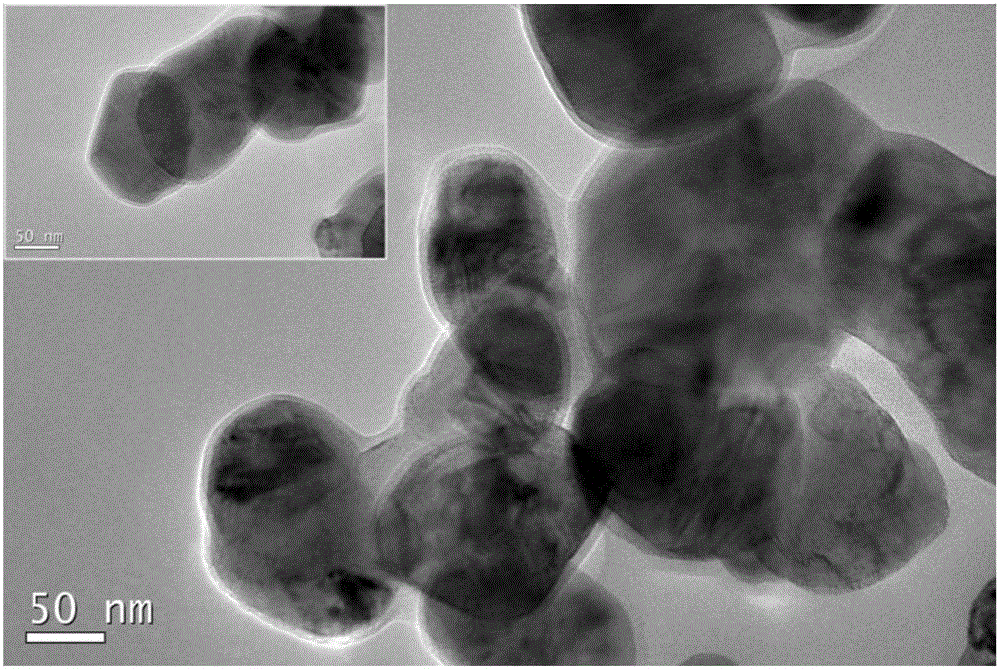

Embodiment 2

[0032] The preparation method of a manganese-based carbon-coated nano-lithium-rich oxide in this embodiment, the specific preparation steps are as follows:

[0033] (1) Under stirring conditions, add 200mL of DMF into a 500mL high-necked beaker, then add 1g of PVP and stir for 30min until the PVP is completely dissolved in DMF.

[0034] (2) Under continuous mechanical stirring, add lithium acetate dihydrate, manganese acetate tetrahydrate, nickel acetate tetrahydrate and cobalt acetate tetrahydrate in a molar ratio of 1.26:0.54:0.13:0.13 to step (1) to obtain a metal salt solution.

[0035] (3) Under continuous mechanical stirring, the temperature of the solution obtained in (2) was raised to 80° C., and reacted for 12 hours to obtain a gel.

[0036] (4) Send the gel obtained in step (3) into a muffle furnace to raise the temperature to 450° C., keep the temperature constant for 5 hours, and take out the tablet after cooling.

[0037] (5) The pressed sheet in (4) is heated to...

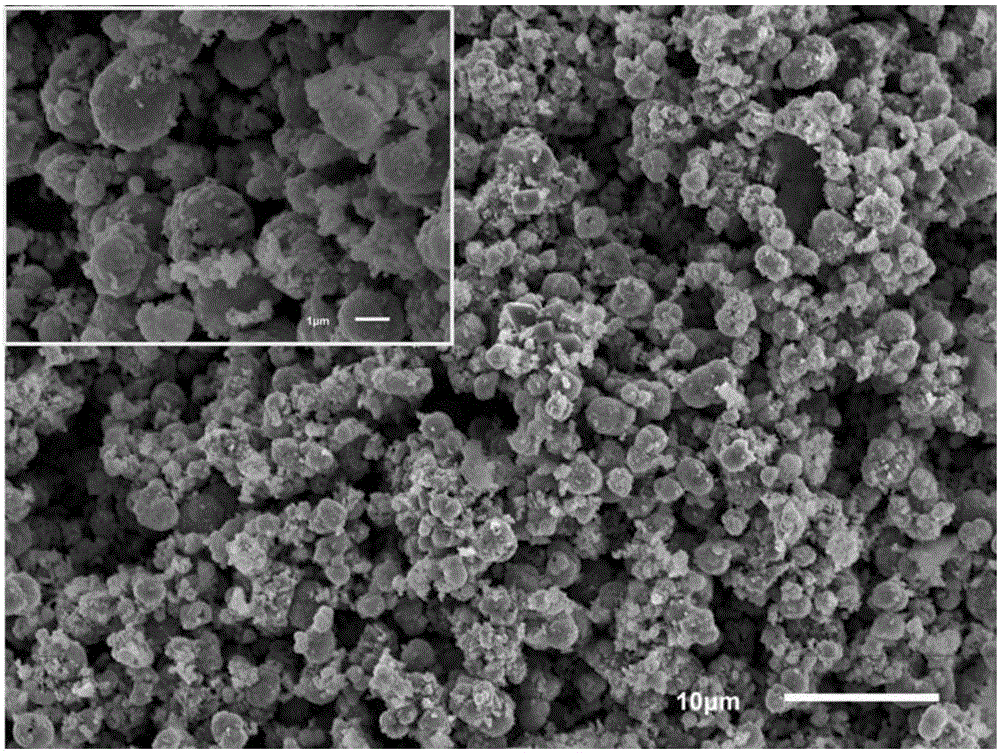

Embodiment 3

[0039] The preparation method of a manganese-based carbon-coated nano-lithium-rich oxide in this embodiment, the specific preparation steps are as follows:

[0040] (1) Under stirring conditions, add 200mL of DMF into a 500mL high-necked beaker, then add 2g of PVP and stir thoroughly for 30min until PVP is completely dissolved in DMF.

[0041] (2) Under continuous mechanical stirring, add lithium acetate dihydrate, manganese acetate tetrahydrate, nickel acetate tetrahydrate and cobalt acetate tetrahydrate in a molar ratio of 1.26:0.54:0.13:0.13 to step (1) to obtain a metal salt solution.

[0042] (3) Under continuous mechanical stirring, the temperature of the solution obtained in (2) was raised to 80° C., and reacted for 12 hours to obtain a gel.

[0043] (4) Send the gel obtained in step (3) into a muffle furnace to raise the temperature to 450° C., keep the temperature constant for 5 hours, and take out the tablet after cooling.

[0044] (5) The pressed sheet in (4) is he...

PUM

| Property | Measurement | Unit |

|---|---|---|

| discharge efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com