Patents

Literature

145 results about "COBALTOUS ACETATE" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Graphene loaded Co-N-C oxygen reduction catalyst and preparation method thereof

InactiveCN105289695AFast deliveryImprove stabilityPhysical/chemical process catalystsCell electrodesNano structuringCarbonization

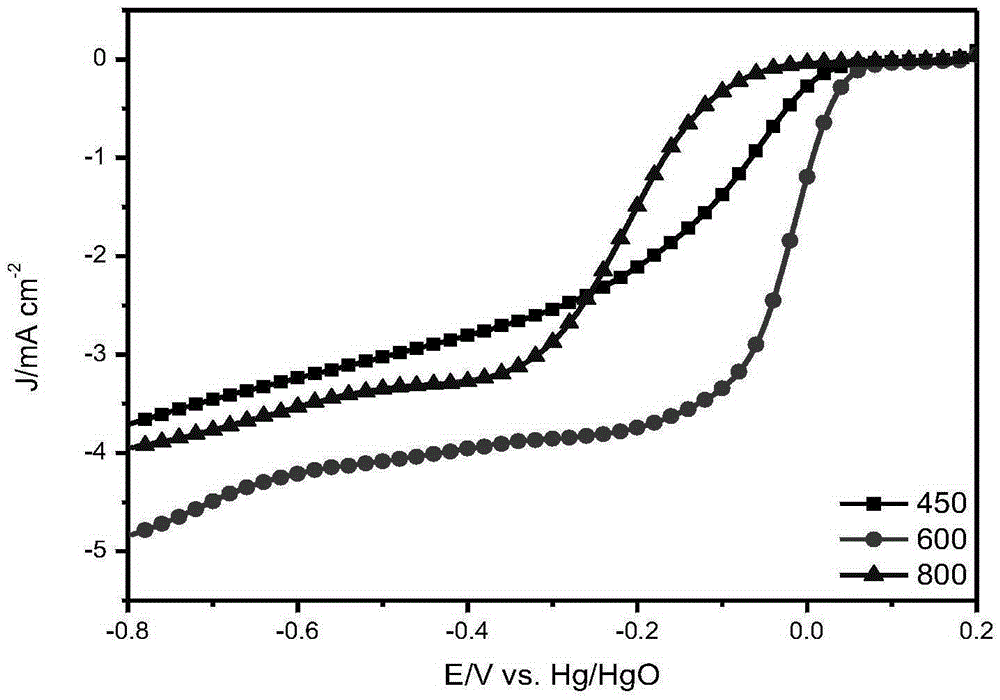

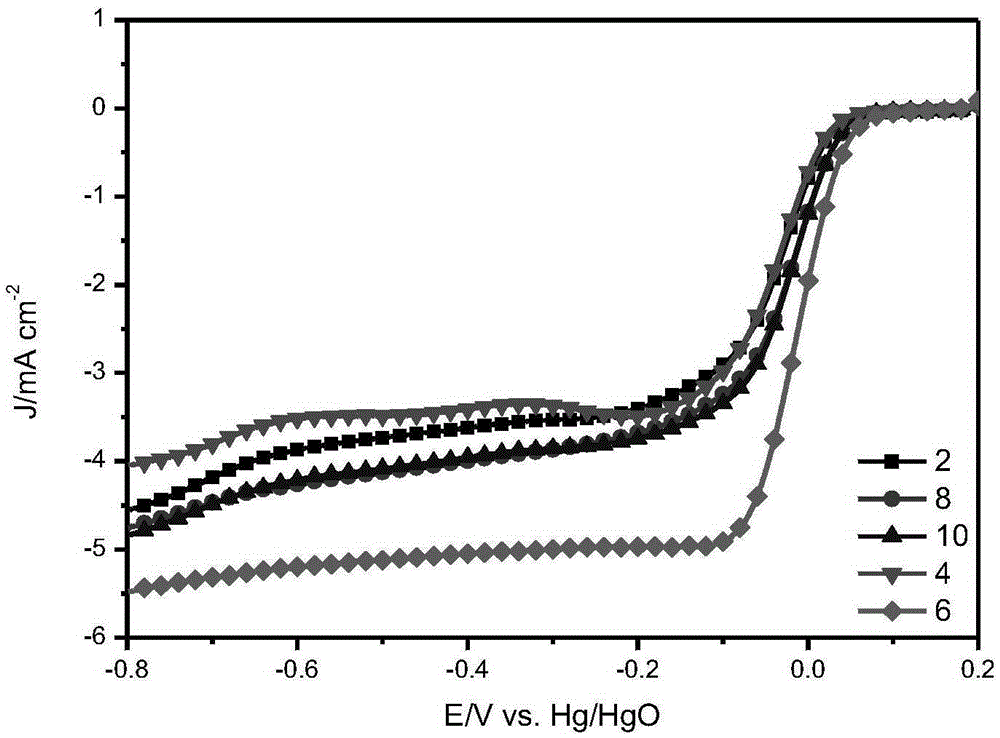

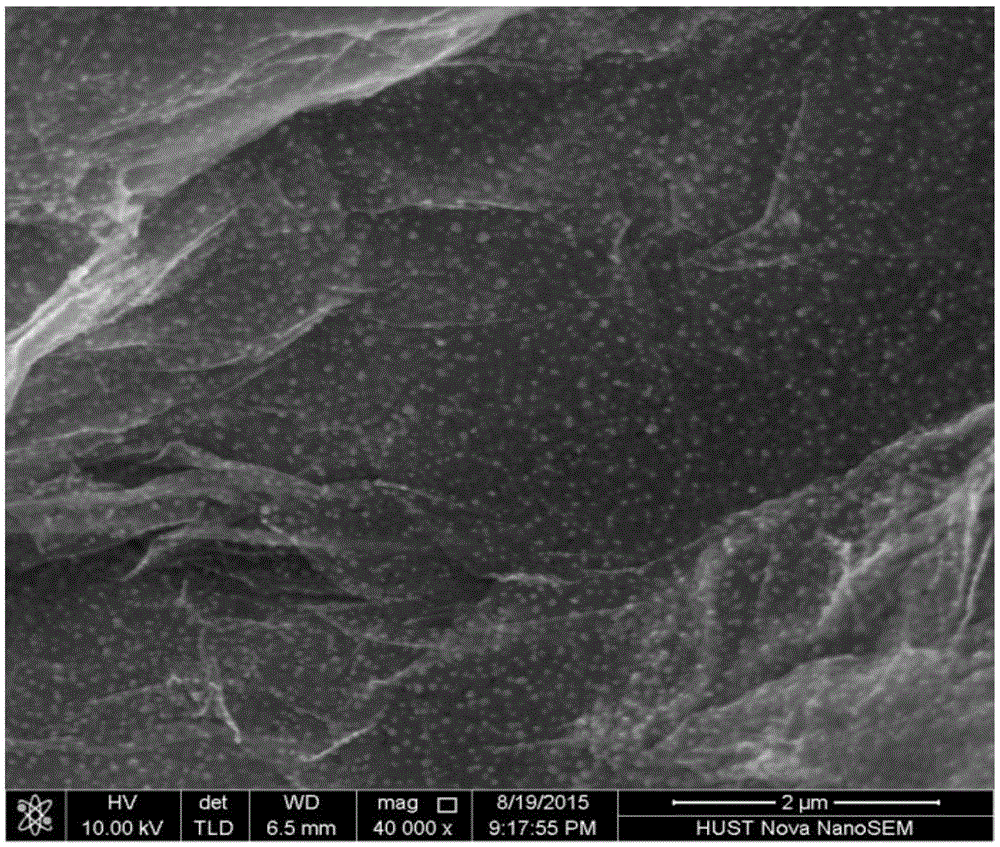

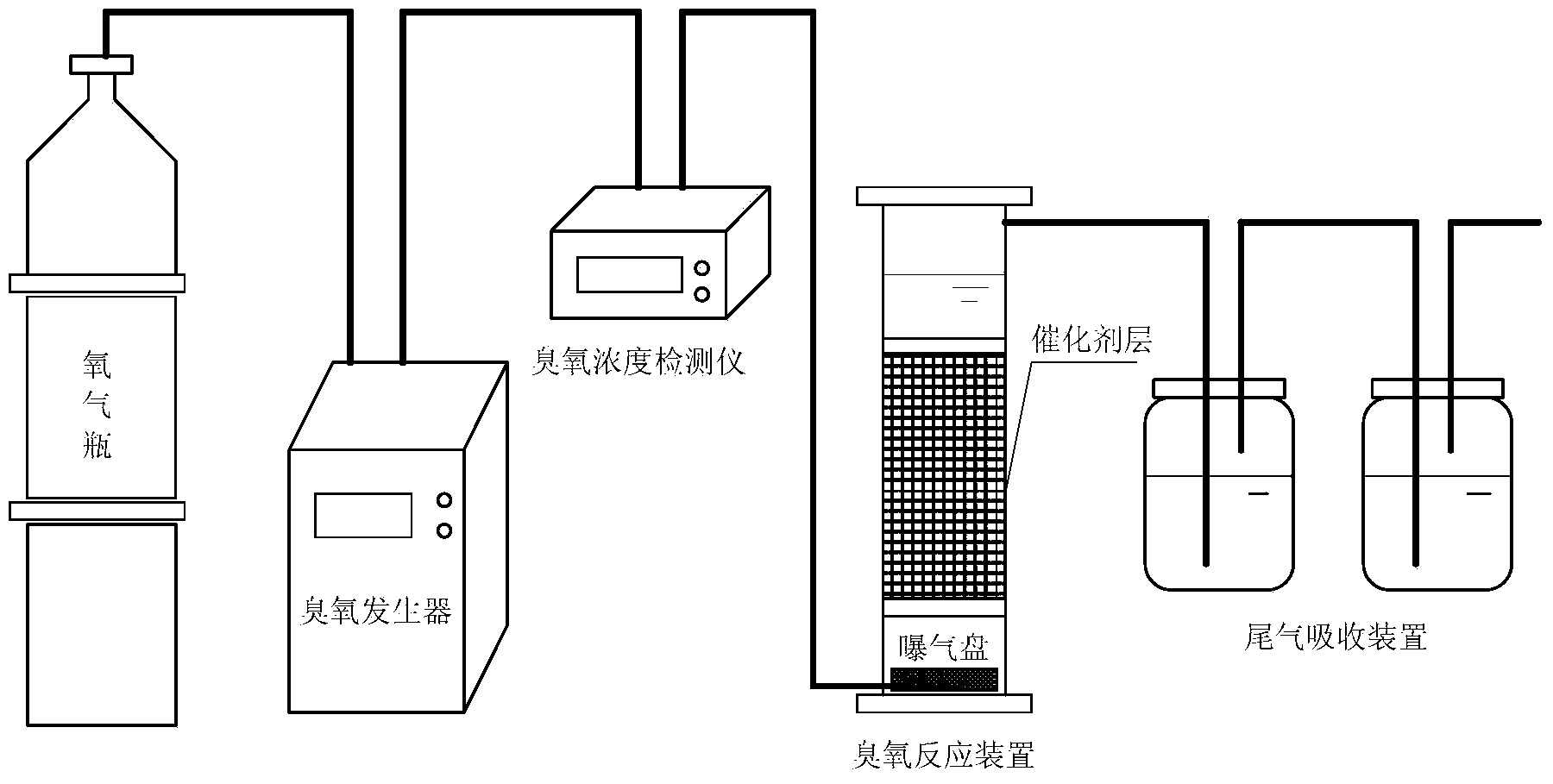

The invention discloses a graphene loaded Co-N-C oxygen reduction catalyst and a preparation method thereof. Electrostatic self-assembly is adopted to anchor ZIF-67 on the surface of graphene and then high temperature carbonization is carried out to prepare the oxygen reduction catalyst. The method comprises the following specific steps: 1. adding oxidized graphene to water, stirring at room temperature, and centrifuging to collect obtained precipitate I; 2. adding a 2-methylimidazole solution to the obtained precipitate I, stirring at room temperature, and centrifuging to collect a precipitate II; then adding a cobaltous acetate solution to the precipitate II, stirring at room temperature, and centrifuging to collect a precipitate III; 3. repeating step 2 for 2-10 times and then drying; 4. carrying out constant temperature carbonization treatment on the dried product at the atmosphere of inert gas. The nano-structure graphene prepared according to the invention has good stability and conductivity, can form a cobalt-carbon-nitrogen catalytic active center with ZIF-67, is favorable for quick transfer of electrons, can enhance the catalytic capacity of the obtained catalyst for oxygen, and is suitable for popularization and application.

Owner:WUHAN UNIV OF TECH

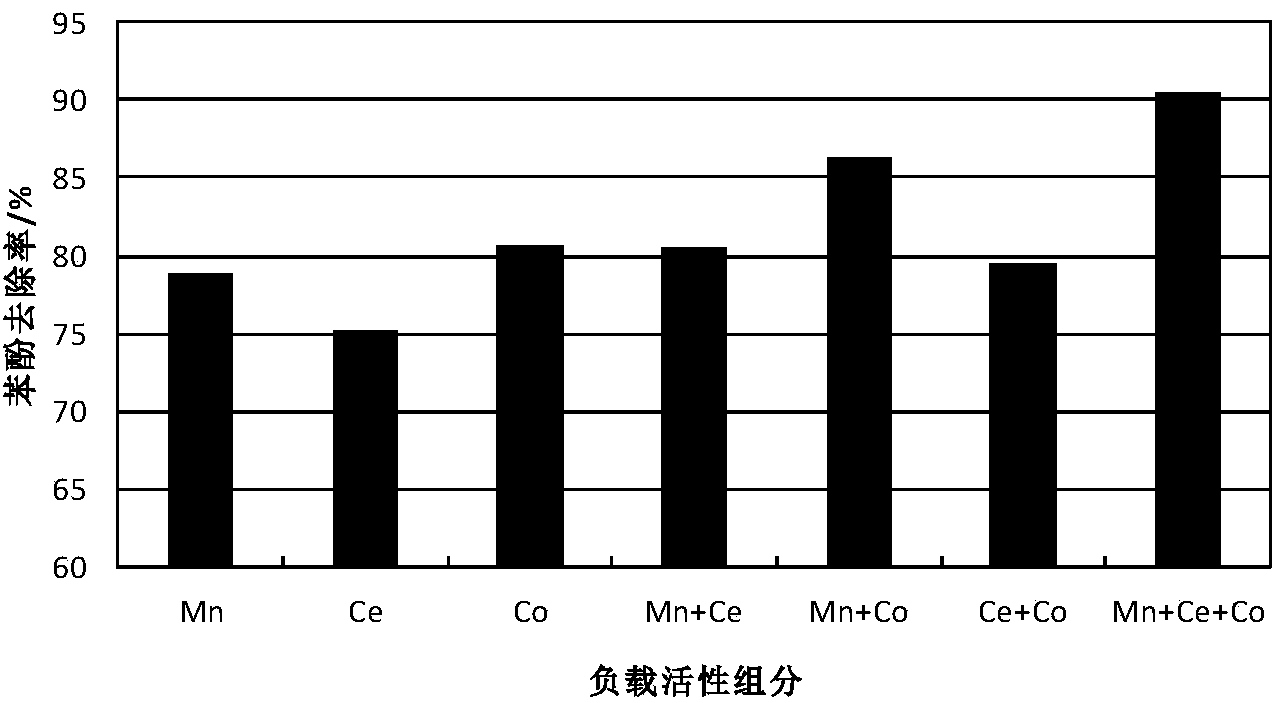

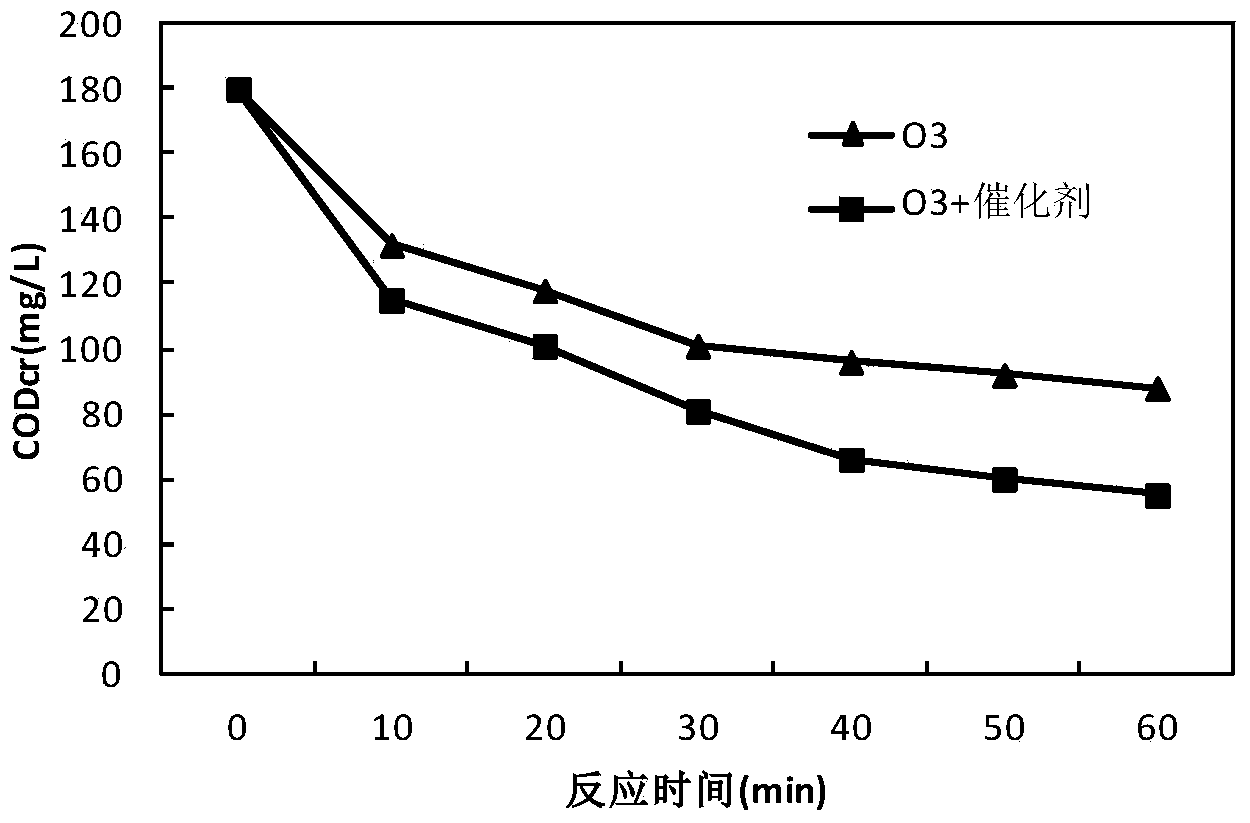

Preparation method for MnO2-CeO2-CoO/AC ternary supported catalyst for treatment of phenolic wastewater

ActiveCN104307534AEfficient catalytic degradationAccelerate the process of catalytic oxidationWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsMANGANESE ACETATECerium

The invention discloses a preparation method for an MnO2-CeO2-CoO / AC ternary supported catalyst for treatment of phenolic wastewater. The catalyst is prepared by that manganese dioxide, cerium oxide and cobalt oxide are loaded to a carrier activated carbon; the method comprises the following steps: preparing a mixed solution of manganese acetate, cerium acetate and cobaltous acetate with the concentration of 10%-30%, wherein the mass ratio of manganese to cerium to cobalt is (2-10):(1-3):1; adding a binder and the mixed solution into raw material coal dust, wherein the weight ratio of the raw material coal dust to the mixed solution to the binder is 100:(1-20):(20-30), mixing the components, and using an extruding die to extrude the mixture into carbon strips through a forming machine or pelletizing through a pelletizing machine, and sequentially performing air drying, carbonization, activation and aftertreatment on formed carbon strips or carbon balls, so that the ternary supported activated carbon catalyst with the grain size of 2-5 mm is finally obtained. In preparation, secondary pollution to the environment cannot be caused, and the prepared catalyst is good in catalytic effect, low in preparation cost and long in service life, and achieves higher application value.

Owner:TIANJIN UNITED ENVIRONMENTAL ENG DESIGN

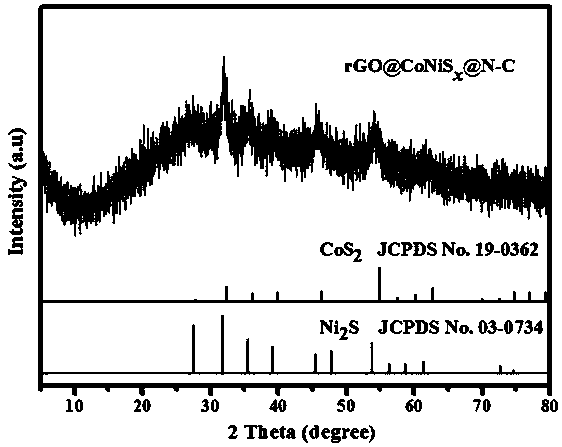

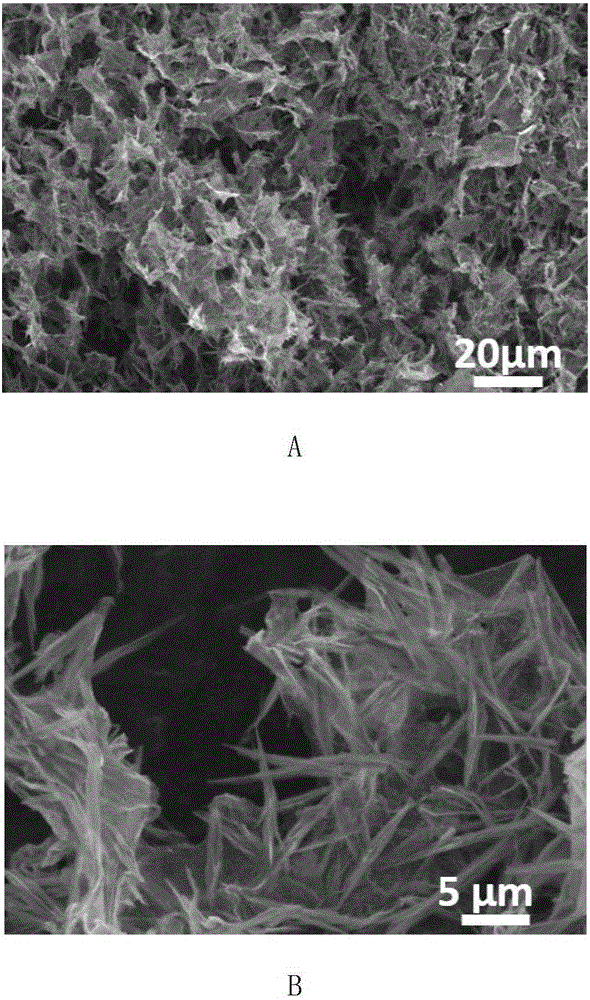

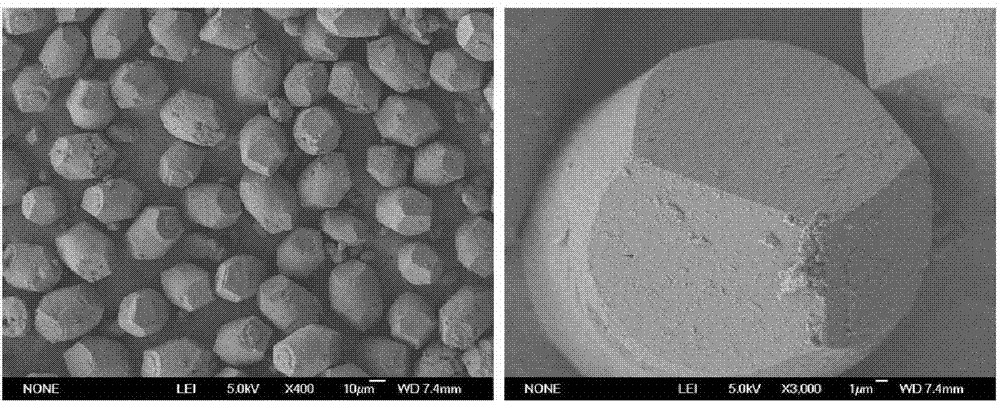

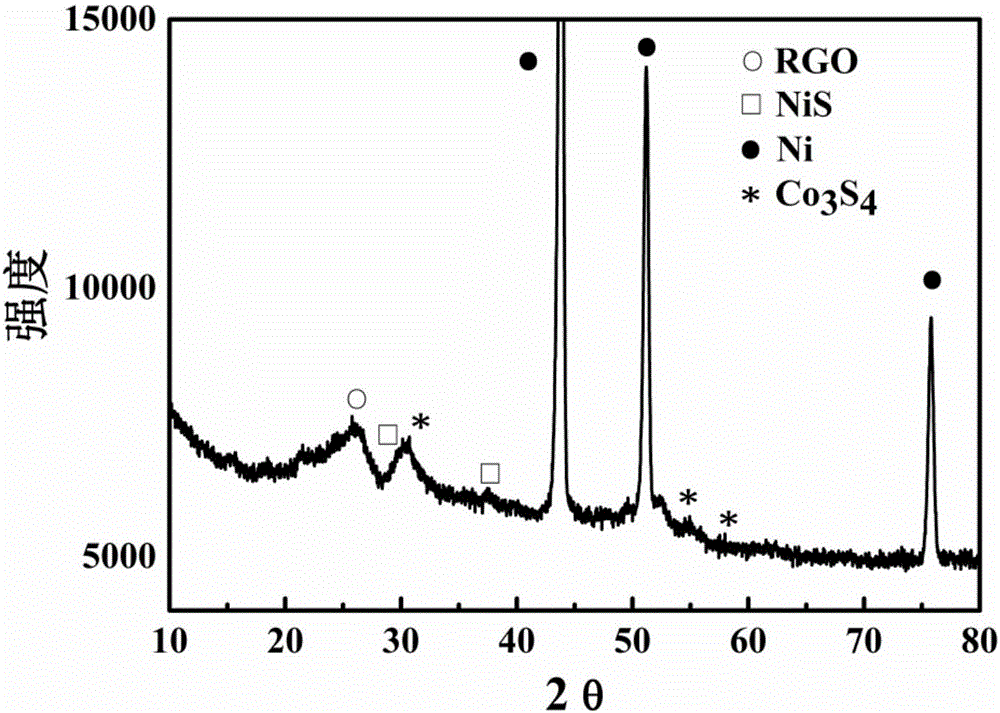

N-doped carbon-coated cobalt-nickel sulfide/graphene composite electrode material

InactiveCN108075128ASimple preparation processImprove controllabilityHybrid capacitor electrodesCell electrodesCapacitanceThiourea

The invention discloses an N-doped carbon-coated cobalt-nickel sulfide / graphene composite electrode material and a preparation method thereof, belonging to the field of preparation of an electrode material for super capacitors. The preparation method comprises the following processes: adding graphene oxide (GO) into an ethylene glycol solution, and performing ultrasonic dispersion to enable the GOto be uniformly dispersed in the ethylene glycol solution; adding polyvinylpyrrolidone (PVP), cobaltous acetate tetrahydrate and nickel acetate into a GO dispersion solution prepared above, after ultrasonic dispersion and dissolution, transferring to a round bottom flask to perform oil bath reaction and performing centrifugal washing and drying; enabling a product, which is dried via centrifugalwashing after oil bath, to calcine with thiourea to obtain the N-doped carbon-coated cobalt-nickel sulfide / graphene composite electrode material. According to the prepared electrode material, N-dopedcarbon is coated outside cobalt-nickel sulfide particles which have uniform sizes in microstructure, the electrode material is uniformly loaded on the substrate of graphene, and meanwhile, the electrode material has relatively high specific capacitance, excellent rate capability and cycling stability.

Owner:FUZHOU UNIV

Preparation method of cobaltosic oxide composite graphene three-dimensional aerogel

ActiveCN105355866AGood shape controllabilityImprove thermal stabilityMaterial nanotechnologyCell electrodesFreeze-dryingCobalt(II,III) oxide

The invention discloses a preparation method of a cobaltosic oxide composite graphene three-dimensional aerogel. With cobaltous acetate as a cobalt source and oxidized graphene as a base, by a hydrothermal-freezing-drying method, the cobaltosic oxide composite graphene three-dimensional aerogel is prepared by controlling hydrothermal reaction time. The cobaltosic oxide composite graphene three-dimensional aerogel obtained by the method disclosed by the invention is good in heat stability, high in crystallization degree and large in specific surface area; and cobaltosic oxide is high in morphology controllability, and is an ideal energy material. The preparation technology and required equipment of the cobaltosic oxide composite graphene three-dimensional aerogel are simple; the reaction temperature is obviously lowered; and mass production is easy to achieve.

Owner:SHANGHAI INST OF TECH

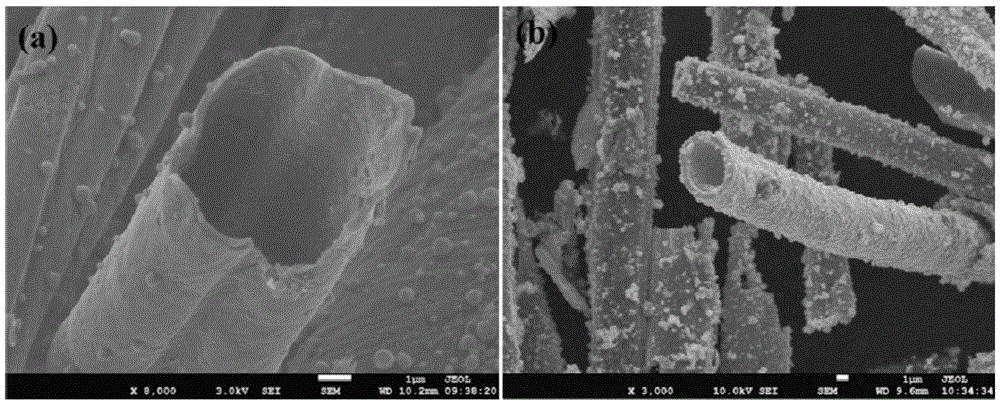

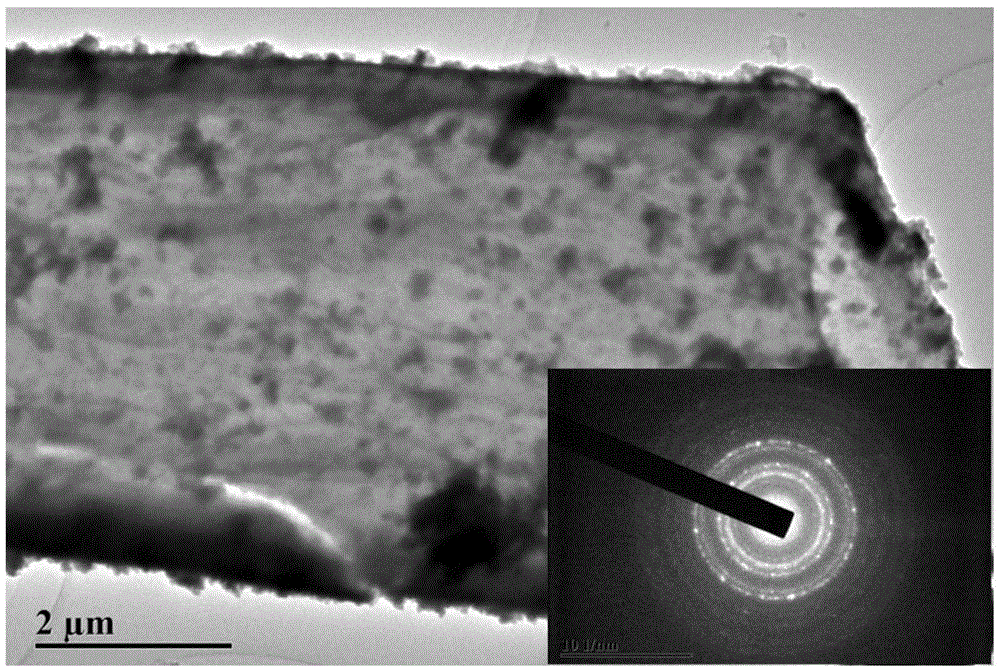

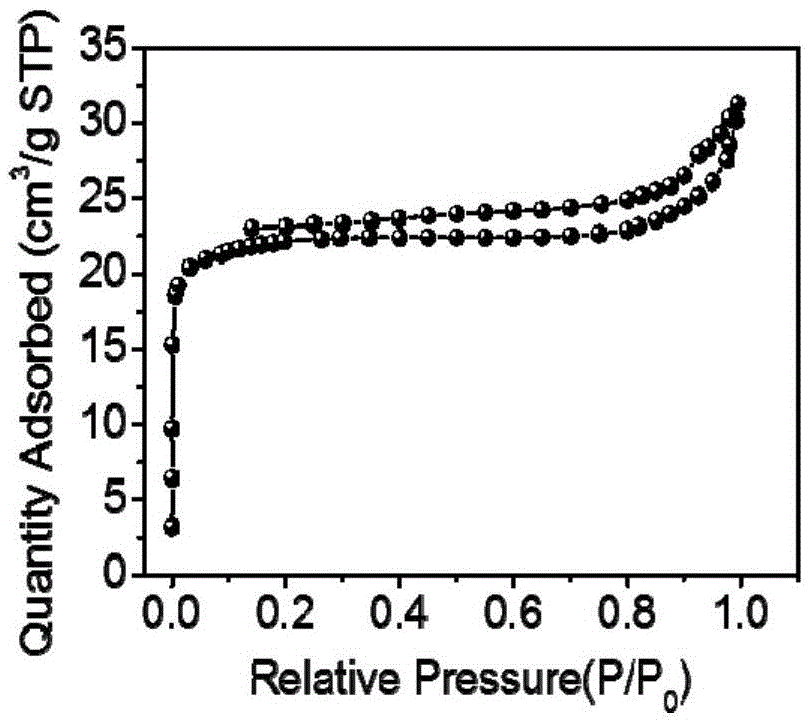

Preparation method for biomass-based hollow carbon microtube/Ni-Co metal sulfide composite electrode material

ActiveCN105609320ALow costHigh price advantageHybrid capacitor electrodesHybrid/EDL manufactureThioureaCarbonization

A preparation method for a biomass-based hollow carbon microtube / Ni-Co metal sulfide composite electrode material comprises the following steps of selecting clean and dried biomass catkins; placing the biomass catkins in a tubular carbonization stove; introducing inert gas as protective gas; carrying out high-temperature processing to prepare hollow carbon microtubes; selecting and dissolving nickel acetate, cobaltous acetate and thiourea in an organic solvent to prepare a mixed solution; adding the hollow carbon microtubes into the mixed solution, fully stirring and uniformly mixing the solution; carrying out hydrothermal reaction; naturally cooling the solution to room temperature after the reaction; and carrying out centrifuging, filtering, washing and drying to prepare the hollow carbon microtube / Ni-Co metal sulfide composite electrode material. The preparation method has the advantages of high specific capacity and excellent rate characteristic.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Catalyst used for producing promoter N-t-butyl benzothiazole sulfonamide and its preparation method

InactiveCN102309986AEasy to prepareEasy to industrializeOrganic chemistryMolecular sieve catalystsMANGANESE ACETATECerium nitrate

The invention relates to a catalyst used for producing promoter N-t-butyl benzothiazole sulfonamide and its preparation method, the catalyst is one or more metal salt of copper acetate, copper sulphate, cupric nitrate, cobaltous acetate, rose vitriol, oleic acid cobalt, cobalt nitrate, acetic acid cerium, sulfuric acid cerium, cerium nitrate, manganese acetate, manganese sulfate, manganous nitrate and the like. A carrier of the catalyst is one or more of SiO2, Al2O3, TiO2, medium-pore material molecular sieve, microporous material molecular sieve and the like. The prepared catalyst is used for synthesizing TBBS by using an oxygen oxidation process, the reaction is used for characterizing the performance of the catalyst. The catalyst amount accounts for 0.02-0.1% of weight of the reactant. The invention has the advantages that the catalyst formula is reasonable, an active ingredient and the carrier are contained, the amount is small and the catalysis effect is good, and the catalyst is capable of increasing the disperse area of the active ingredient to increase the contact area of the active ingredient and the reactant, raising the reaction speed and simultaneously reducing the catalyst amount. The catalyst enables more than 97% of yield of TBBS by optimizing the reaction condition.

Owner:KEMAI CHEM

Preparation method of cobaltosic oxide/graphene three-dimensional mixed structure flexible electrode

ActiveCN105070526ASimple methodThe method is simple and controllableHybrid capacitor electrodesHybrid/EDL manufactureComposite electrodeCobalt(II,III) oxide

The invention relates to a preparation method of a composite electrode material, in particular, a preparation method of a cobaltosic oxide / graphene three-dimensional mixed structure flexible electrode. The objective of the invention is to solve the problems of high possibility of superposition and incapability of exerting the advantage of a specific surface area of graphene as well as poor cycling stability of cobaltosic oxide in an existing chemical stripping method for preparing an electrode material. The method of the invention includes the following steps that: a pretreated graphene oxide solution is prepared; a three-dimensional structure graphene / foam nickel material is prepared; and 3, cobaltous acetate, hexamethylene tetramine and the three-dimensional structure graphene / foam nickel material are subjected to a reaction, and washing is performed, and as a result, the cobaltosic oxide / graphene three-dimensional mixed structure flexible electrode can be obtained.

Owner:HARBIN INST OF TECH

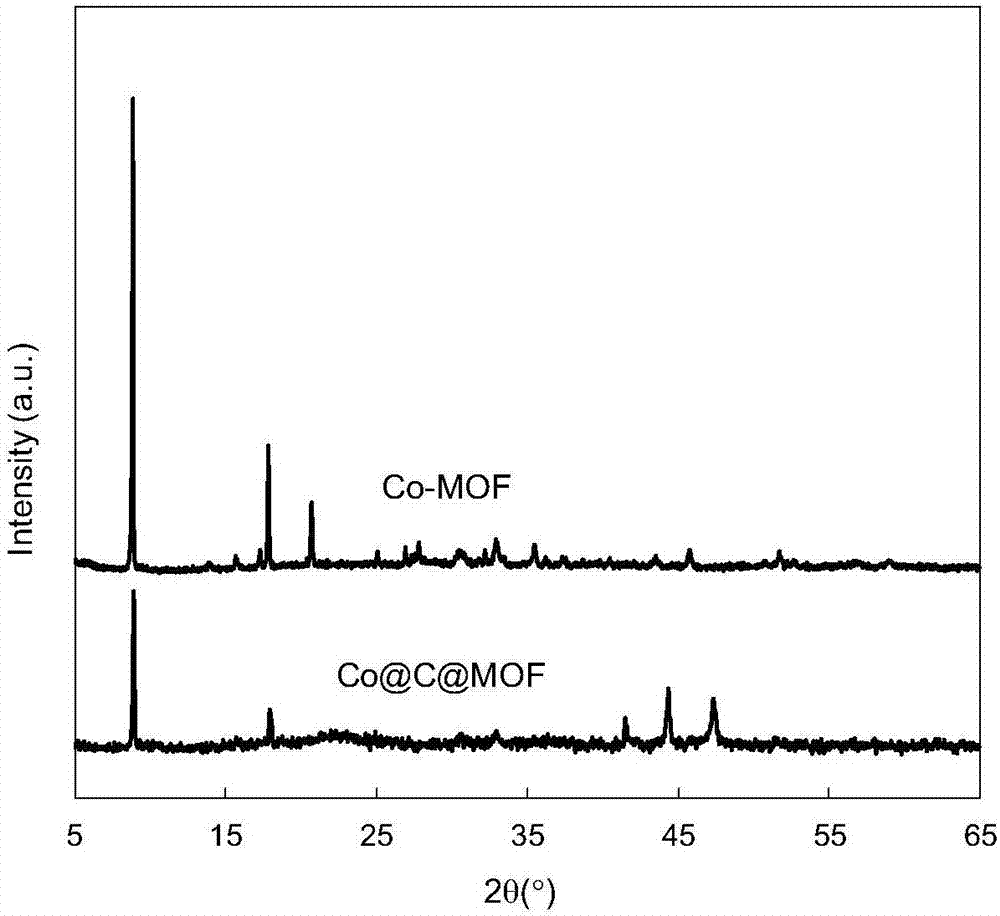

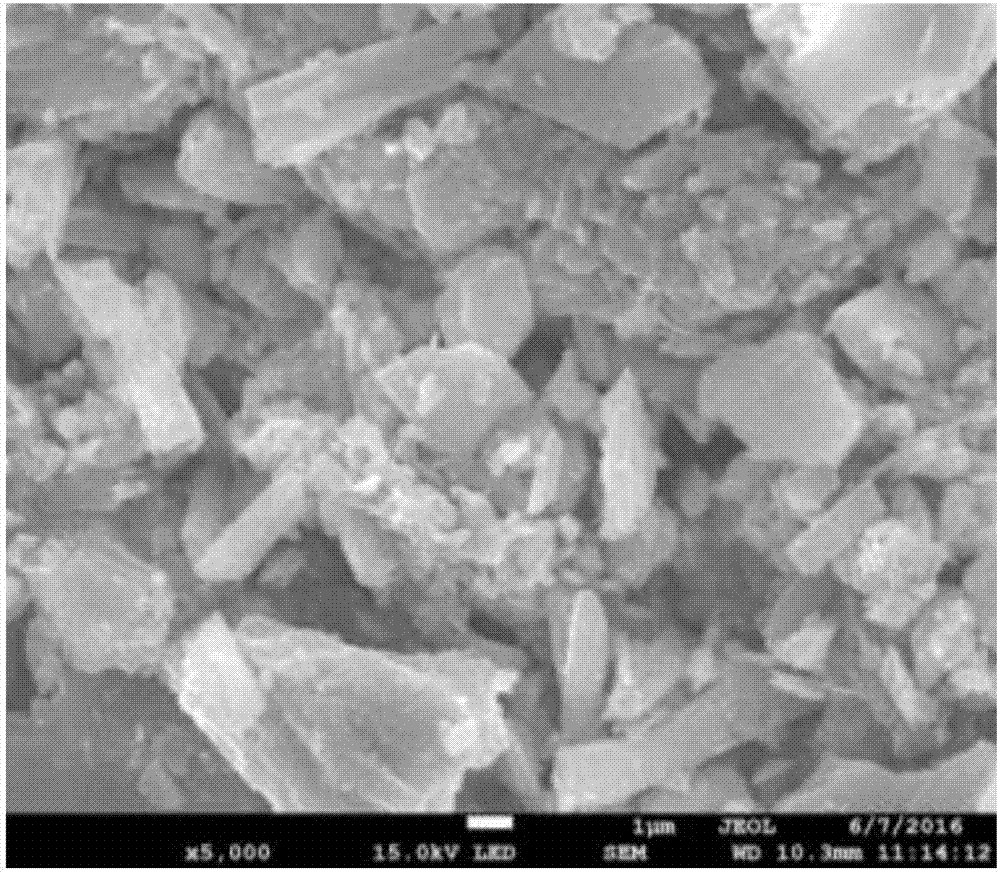

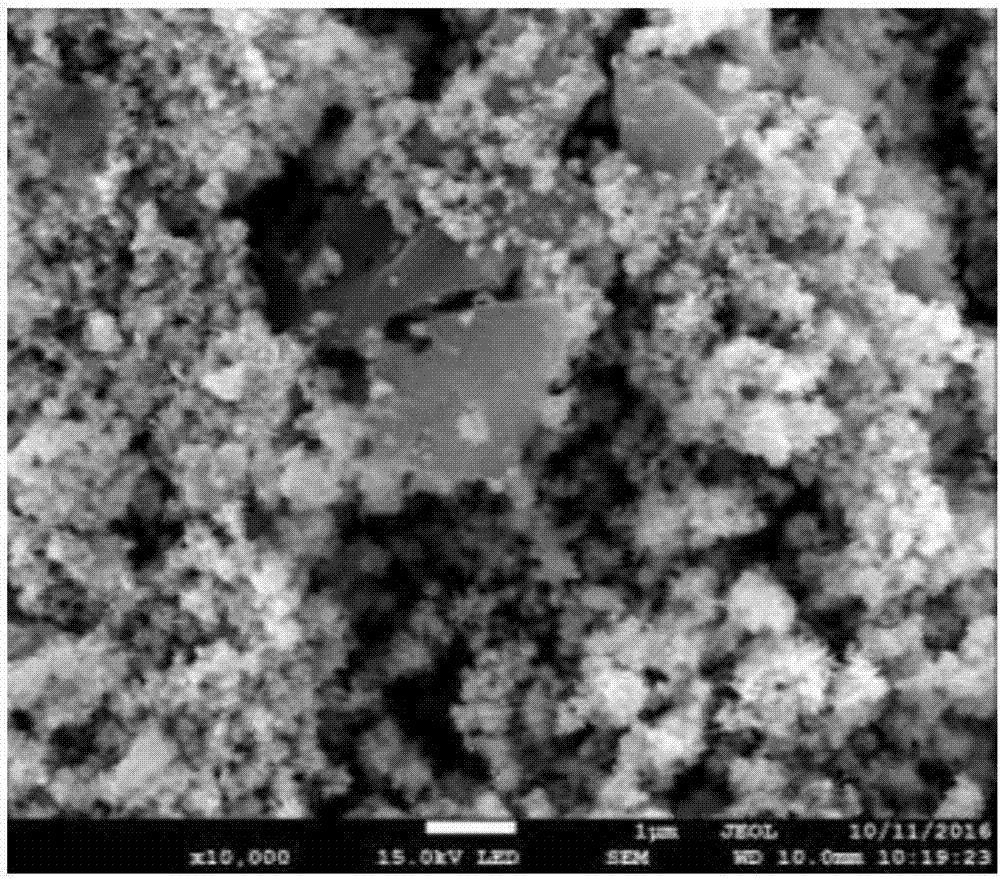

Preparation method and application of Co@C@MOF magnetic catalyst

ActiveCN106902879AStatic hydrothermal crystallization method is simpleThe equipment is easy to operateOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsDispersityMetal-organic framework

The invention discloses a preparation method and application of a Co@C@MOF magnetic catalyst. The preparation method comprises the following steps: mixing and stirring cobaltous acetate, hydrofluoric acid, terephthalic acid and water evenly, adding into a closed reaction kettle, putting the closed reaction kettle into an oven, conducting static hydrothermal crystallization, shock-chilling to the room temperature after the reaction is finished, obtaining a reaction generation liquid; conducting primary suction filtration on the reaction generation liquid, thermally washing a filter cake, conducting secondary suction filtration, sequentially washing and drying the filter cake to obtain a Co-MOF metal organic framework material; finally reducing the Co-MOF metal organic framework material in a vacuum muffle furnace to obtain the Co@C@MOF magnetic catalyst. The static hydrothermal crystallization mode is adopted, then the synthesis time is greatly shortened, the energy consumption is greatly reduced, and the production cost is saved; in addition, the obtained Co@C@MOF magnetic catalyst is even in particles, good in dispersity and high in catalytic activity.

Owner:HUBEI UNIV

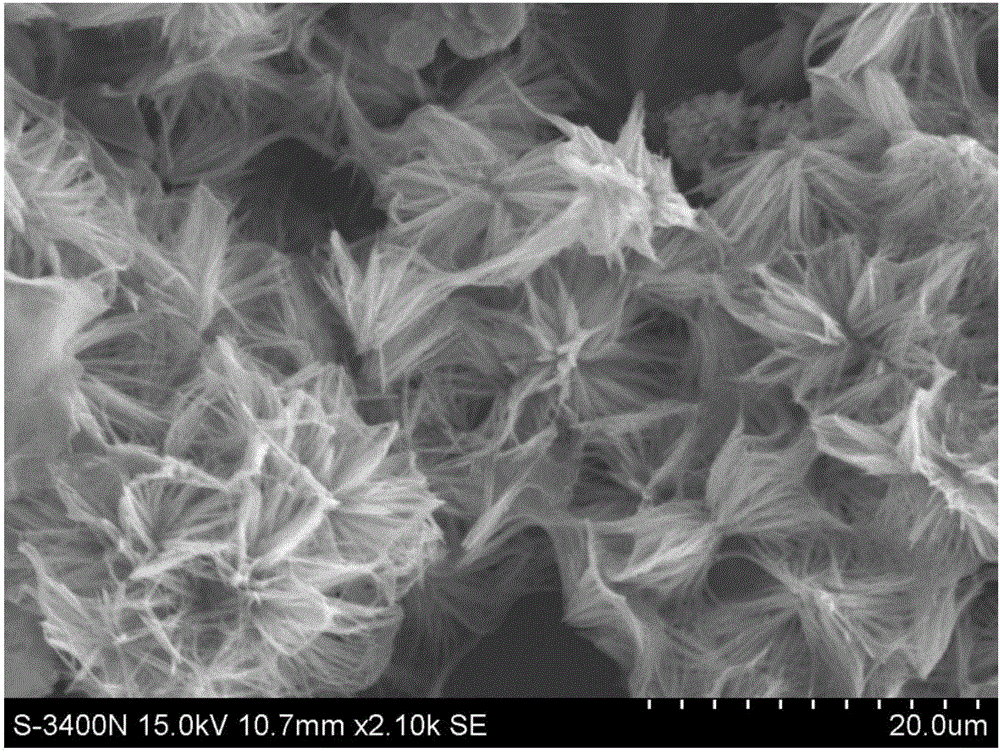

Preparation method of shape-controlled graphene/Co(OH)2 composite materials

ActiveCN105719849AShape is easy to controlStrong controllabilityHybrid capacitor electrodesHybrid/EDL manufactureNano compositesSupercapacitor

The invention belongs to the technical field of a super capacitor nano composite material, and particularly relates to a preparation method of shape-controlled graphene / Co(OH)2 composite materials. According to the preparation method disclosed by the invention, the graphene / Co(OH)2 composite materials with different order shapes are prepared under the hydrothermal condition by using graphene and cobaltous acetate tetrahydrate as raw materials, selecting different precipitators and adopting a suitable surfactant. The preparation method disclosed by the invention is simple; and the prepared composite materials with different shapes have good electrochemical performance and all have high specific capacity, and have high application value in the preparation of the super capacitor material.

Owner:SHANGHAI INST OF TECH

Cobaltosic oxide powder and preparation method thereof

InactiveCN103818972ALarge specific surface areaGood effectNitrous oxide captureProductsAcetic acidReactive site

The invention relates to a cobaltosic oxide powder and a preparation method thereof. The preparation method comprises the following steps: (1) dropwise adding ethanolamine into a cobaltous acetate water solution to form a mixed solution, wherein the molar ratio of the cobaltous acetate to ethanolamine is (1:3)-(1:6); (2) performing reaction on the obtained mixed solution under an ultrasonic condition with the ultrasonic power of 350-500 w and the ultrasonic frequency of 50-100 kHz at the temperature of 20-30 DEG C for 1-10 hours, filtering and drying to obtain cobalt hydroxide; (3) calcining the obtained cobalt hydroxide for 1-2 hours at the temperature of 150-250 DEG C to obtain the cobaltosic oxide powder. By performing ultrasonic synthesis on the cobalt hydroxide, the cobalt hydroxide and the thermal decomposition product cobaltosic oxide of the cobalt hydroxide have relatively high specific surface areas, and a plurality of gaps and active sites can be formed on the surface of the cobaltosic oxide powder, so that an excellent catalytic oxidation effect on low-concentration NO is realized.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

Four-component fuel hypergolic with 70%-98% of hydrogen peroxide

InactiveCN102863994ANot easy to age and deteriorateImprove specific impulseLiquid carbonaceous fuelsHigh concentrationKerosene

The invention relates to a four-component fuel hypergolic with 70%-98% of hydrogen peroxide. The fuel is a novel non-toxic hypergolic miscible fuel (NHMF). Aiming at the conditions that some problems exist in formulas and problem-free formulas do not open to the public in the prior art, the fuel takes alkyl-substituted alcamines compounds such as cobaltous acetate tetrahydrate, cobalt iso-octoate or cobalt acetylacetonate as main catalysts, takes dimethylethanolamine, diethylethanolamine, diisopropylethanolamine, dibutyl eth-anolamine as auxiliary catalysts, takes ethanol, propanol or butanol as a solvent, and takes aviation kerosene as an incendiary agent, and the four components are evenly mixed into an unsaturated solution. The novel fuel has the advantages of being non-toxic actually, not prone to aging and deterioration, high in specific impulse, short in ignition delay period, hypergolic and storable, capable of being applied to liquid rockets, igniters and fuel / air explosives, and the like; and is hypergolic with hydrogen peroxide with the relative high concentration.

Owner:葛明龙

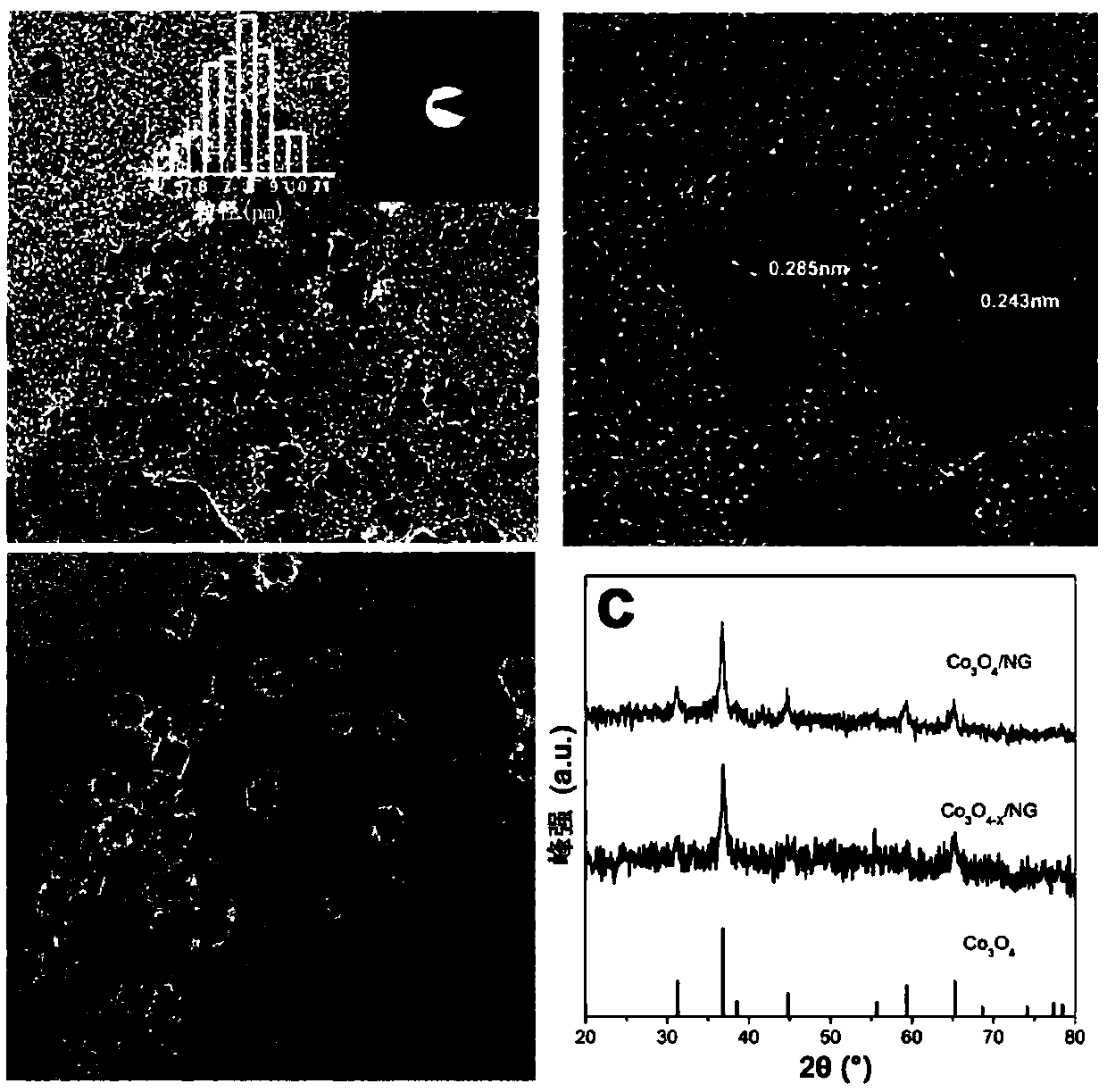

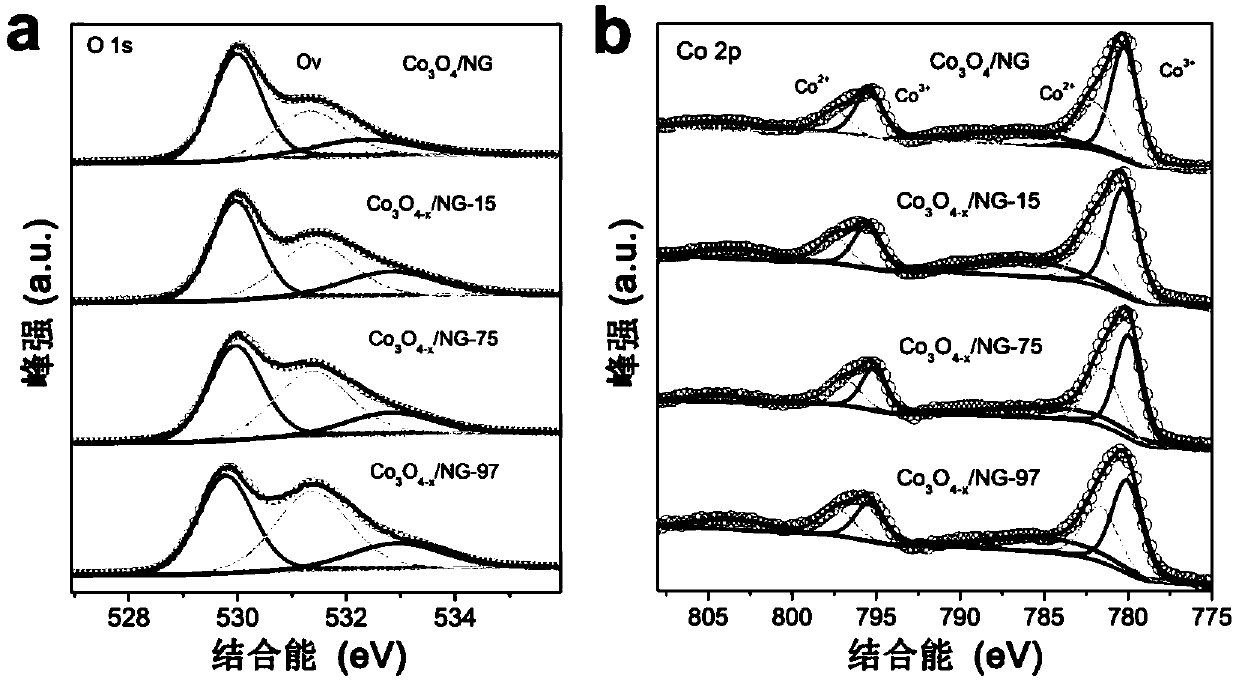

Preparation method of cobaltosic-oxide nitrogen-doped graphene synthesized by laser and with adjustable oxygen vacancies

InactiveCN109590008AImprove OER/ORR catalytic performanceSimple processPhysical/chemical process catalystsDoped grapheneOxygen vacancy

The invention discloses a preparation method of cobaltosic-oxide nitrogen-doped graphene synthesized by laser and with adjustable oxygen vacancies. The preparation method comprises the following stepsof: using oxidized graphene to ultrasonically disperse in absolute ethyl alcohol, preparing into 0.33mg / ml suspension, taking 24ml suspension, adding 1.2ml 0.2M cobaltous acetate solution, 0.5ml NH4OH solution with the concentration of 30% and 0.7ml deionized water, and carrying out oil bathing for 10 hours at a temperature of 80 DEG C; pouring the solution into a reaction kettle, and reacting for 3 hours at a temperature of 150 DEG C; then carrying out high-speed centrifugation at a speed of 12000-20000r / m, then repeatedly cleaning for 3-4 times by using the deionized water, obtaining precipitates and carrying out freezing and drying; mixing a sample and the deionized water into a test tube according to the mass ratio of 1:2-1:5, and under magnetic stirring, using 15-97mJ energy of nanosecond parallel pulse laser to irradiate the solution for 5-25 minutes; carrying out centrifuging, freezing and drying to obtain the cobaltosic-oxide nitrogen-doped graphene with the adjustable oxygenvacancy. The preparation method disclosed by the invention has the beneficial effects that by adjustment for the irradiation energy and time of low-energy laser, the concentration of the oxygen vacancies in the composite system is adjusted and the unchanged structure of the composite system is maintained.

Owner:TIANJIN UNIV

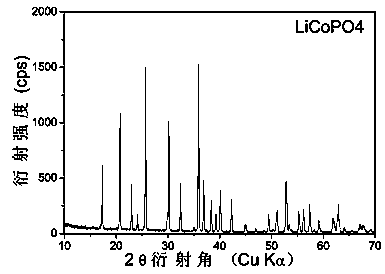

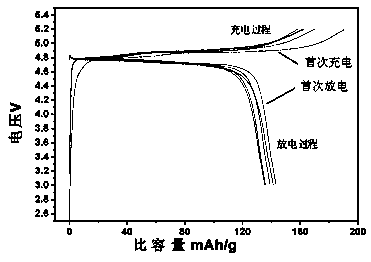

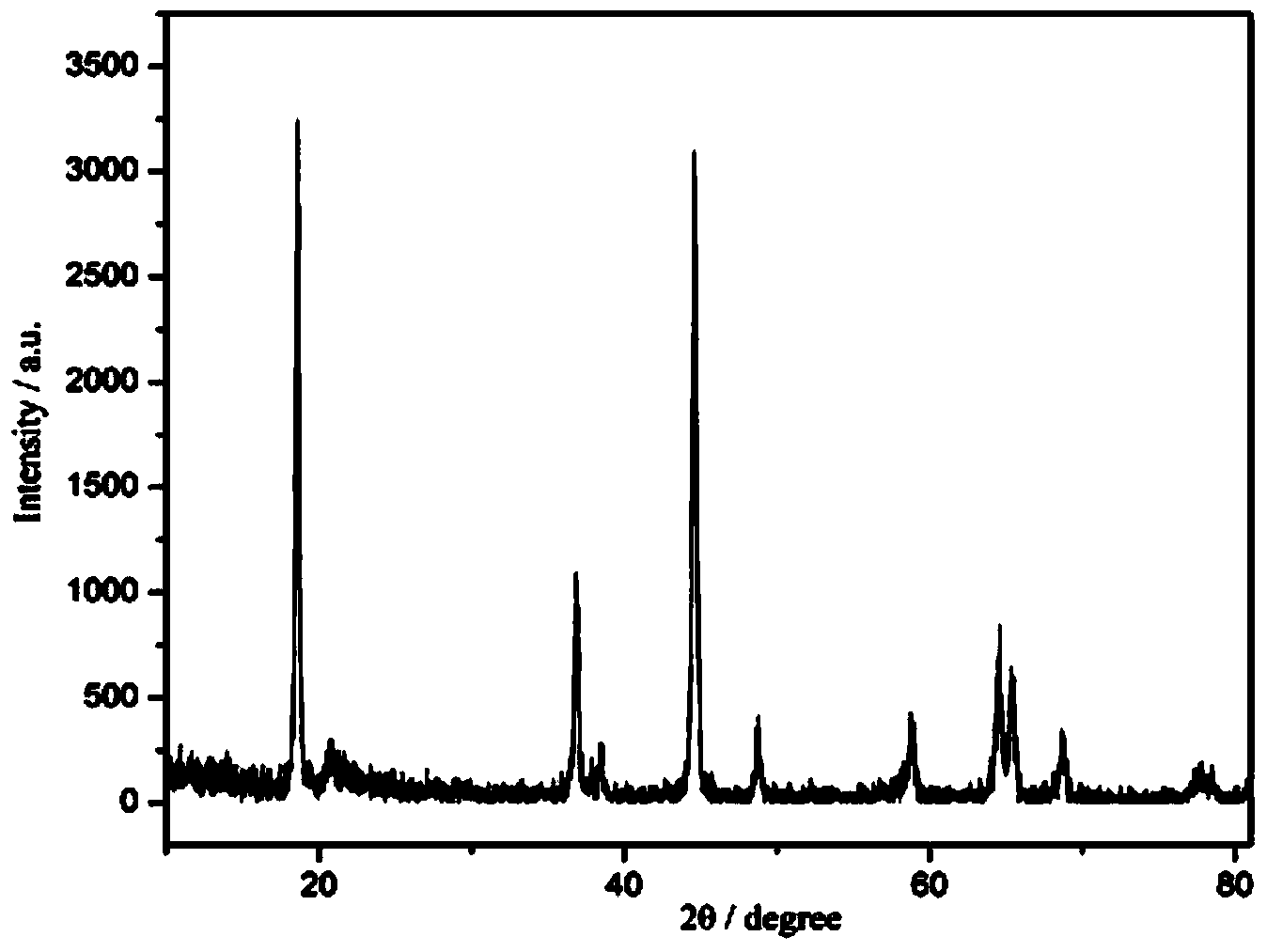

Synthetic method for cathode material lithium cobaltous phosphate used for lithium ion batteries

InactiveCN103413918AShorten migration distanceHigh rate characteristicsMaterial nanotechnologyCell electrodesO-Phosphoric AcidLithium hydroxide

The invention discloses a synthetic method for a cathode material lithium cobaltous phosphate used for lithium ion batteries. The method comprises a step of dissolving cobaltous acetate in deionized water to prepare an aqueous solution of the cobaltous acetate; a step of dissolving lithium hydroxide and sucrose in deionized water to prepare a lithium hydroxide / sucrose mixed solution; a step of adding phosphoric acid in deionized water to prepare a phosphoric acid solution; a step of adding the phosphoric acid solution into the aqueous solution of the cobaltous acetate to obtain a burgundy emulsion, stirring uniformly, adding the lithium hydroxide / sucrose mixed solution into the burgundy emulsion, mixing uniformly, and adding nitric acid to obtain a precursor solution; a step of subjecting the precursor solution under stirring to spray drying to obtain a precursor of lithium cobaltous phosphate powder; and a step of subjecting the precursor of the lithium cobaltous phosphate powder to vacuum calcination at 600-750 DEG C for 16-26 h to obtain the cathode material lithium cobaltous phosphate with a spherical porous structure and a high specific capacity.

Owner:SHANGHAI INST OF TECH

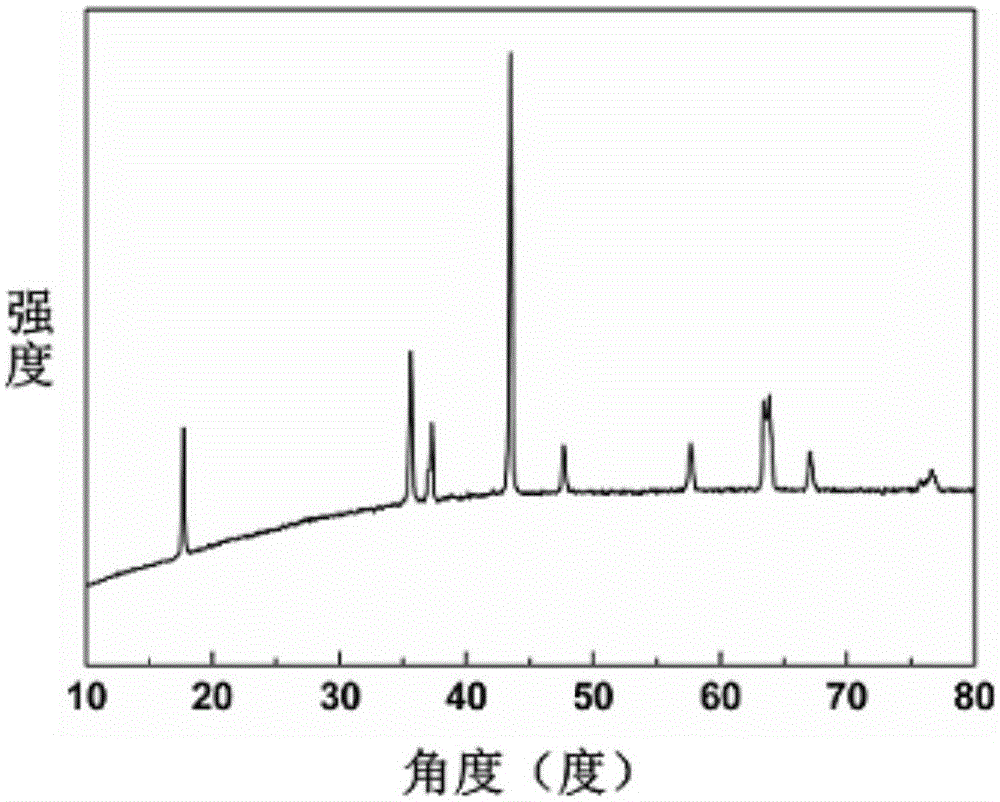

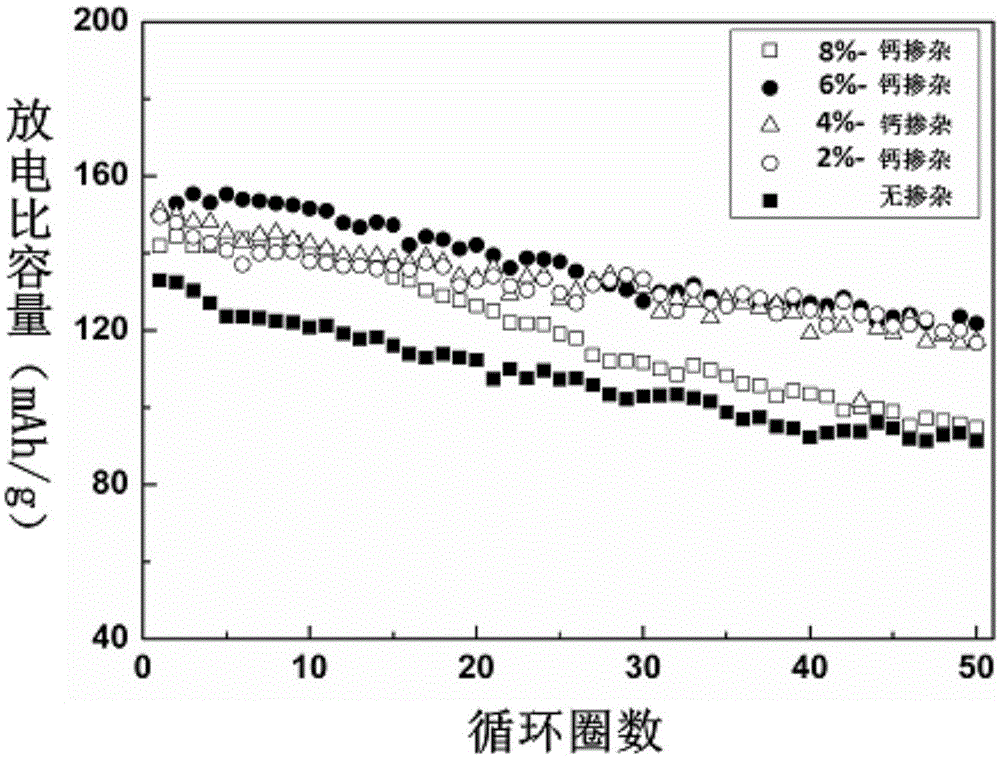

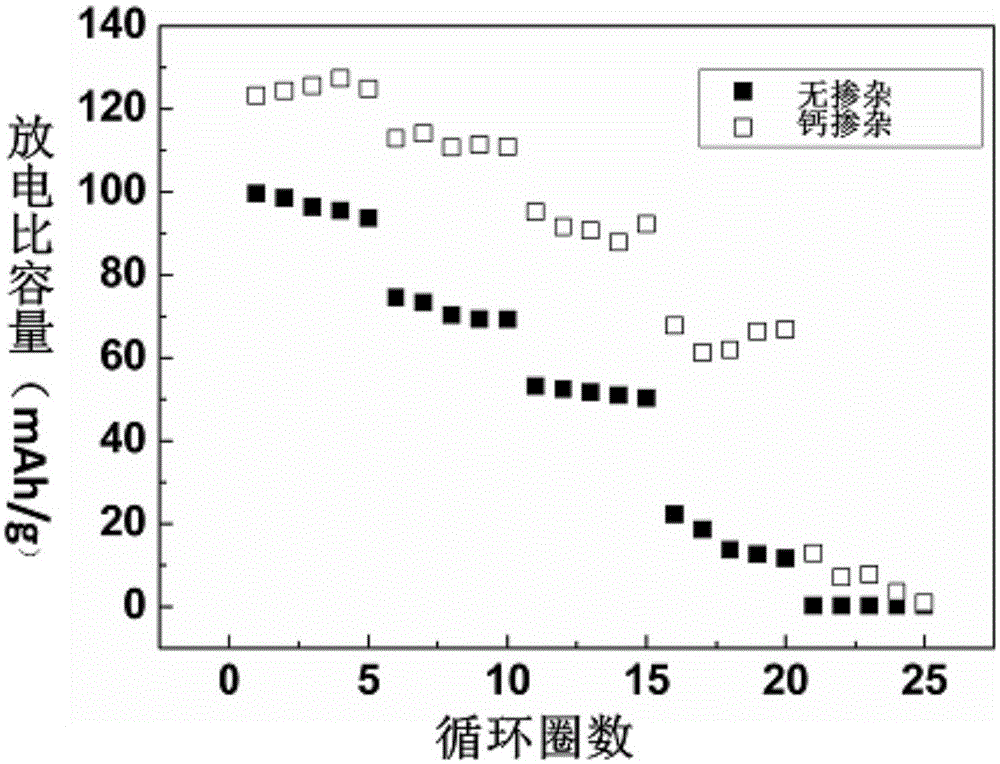

Calcium-doped ternary positive electrode material of lithium ion battery and preparation method thereof

InactiveCN105161714AIncrease productionThe results are reproducibleCell electrodesSecondary cellsMANGANESE ACETATESodium-ion battery

The invention relates to a calcium-doped ternary positive electrode material of a lithium ion battery and a preparation method thereof, belonging to the technical field of inorganic materials. The calcium-doped ternary positive electrode material of the lithium ion battery is prepared by doping calcium element into the ternary material, and adopting a simple solid phase method and high-temperature solid phase sintering reaction. The preparation method comprises the steps of grinding and mixing nickel acetate, manganese acetate, cobaltous acetate, calcium nitrate LiOH.H2O uniformly to obtain a mixture, increasing the temperature to 500DEG C according to the temperature increasing rate being 3 DEG C-5 DEG C, and maintaining the temperature for 5-8h; and increasing the temperature to 700-1000 DEG C by the same temperature increasing rate, calcining for 12-24h, and naturally cooling to the room temperature. Compared with the material without doping, the calcium-doped ternary positive electrode material has the advantages that the specific capacity, the cycle stability, the rate capability and other aspects of the battery are greatly improved.

Owner:UNIVERSITY OF CHINESE ACADEMY OF SCIENCES

Environment-friendly constant-temperature hole sealing agent for aluminum and aluminum alloy and hole sealing technique thereof

ActiveCN107805837AImprove stabilityImprove permeabilitySurface reaction electrolytic coatingEnvironmental resistanceAccelerant

The invention provides an environment-friendly constant-temperature hole sealing agent for aluminum and an aluminum alloy. The environment-friendly constant-temperature hole sealing agent comprises the following components of, by total weight, 3%-15% of magnesium acetate, 0%-10% of cobaltous acetate, 5%-15% of tripropylene glycol methyl ether, 5%-15% of surfactants, 0%-10% of dust inhibiting agents, 0%-8% of accelerants, 0.5%-10% of pH buffer agents, 0%-10% of corrosion inhibitors and the balance deionized water. The environment-friendly constant-temperature hole sealing agent is good in stability and permeation effect; a hole sealing film is dense and can completely seal gaps on the surface of a workpiece; the hole sealing condition requirement is low, after hole sealing, the surface of the workpiece is flat, bright and free of discoloring, powder forming is avoided, oil fouling resistance and fingerprint resistance are achieved, and the strength, hardness and corrosion resistance ofthe workpiece are improved; the environment-friendly constant-temperature hole sealing agent does not contain elements of nickel, fluorine, chromium and the like and is safe and environmentally friendly, pollution to the operation environment is avoided, and damage to health of a human body is avoided; and the cost is low, energy consumption is less, and the environment-friendly constant-temperature hole sealing agent is suitable for being produced industrially on a large scale.

Owner:JIANGSU FEITUO INTERFACE ENG TECH CO LTD

Preparation method of high-specific-capacity lithium-rich anode material

InactiveCN103956478AEvenly distributedSmall particle sizeCell electrodesSecondary cellsWater bathsMANGANESE ACETATE

The invention relates to a preparation method of a high-specific-capacity lithium-rich anode material, belongs to the field of chemical power source material preparation and lithium ion battery anode materials. The preparation method comprises the following steps of dissolving manganese acetate, nickel acetate, cobaltous acetate and lithium acetate in a solvent, stirring the manganese acetate, the nickel acetate, the cobaltous acetate and the lithium acetate so as to obtain an acetate solution which is uniformly mixed, carrying out magnetic stirring and evaporating under heating of a water bath until a mixing liquid is thick colloid, and placing the mixing liquid in a drying box to dry so as to obtain precursor powder; warming the dried precursor powder to calcine twice, and reducing to room temperature by adopting a furnace cooling manner so as to obtain a multi-element lithium-rich material Li1.2Mn0.54Ni0.13 Co0.13O2. A material prepared by the preparation method provided by the invention is high in bulk phase crystallinity, the grain diameter of a material is small, the distribution is uniform, a transition metal element proportion approaches to a theoretical value, a synthesis step is simple, the material is easy for mass production, synthesizing nondeterminacy factors in a process are less, the characteristics give the high specific capacity and the cycling stability for the material, and an electrochemical property of the material is excellent.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

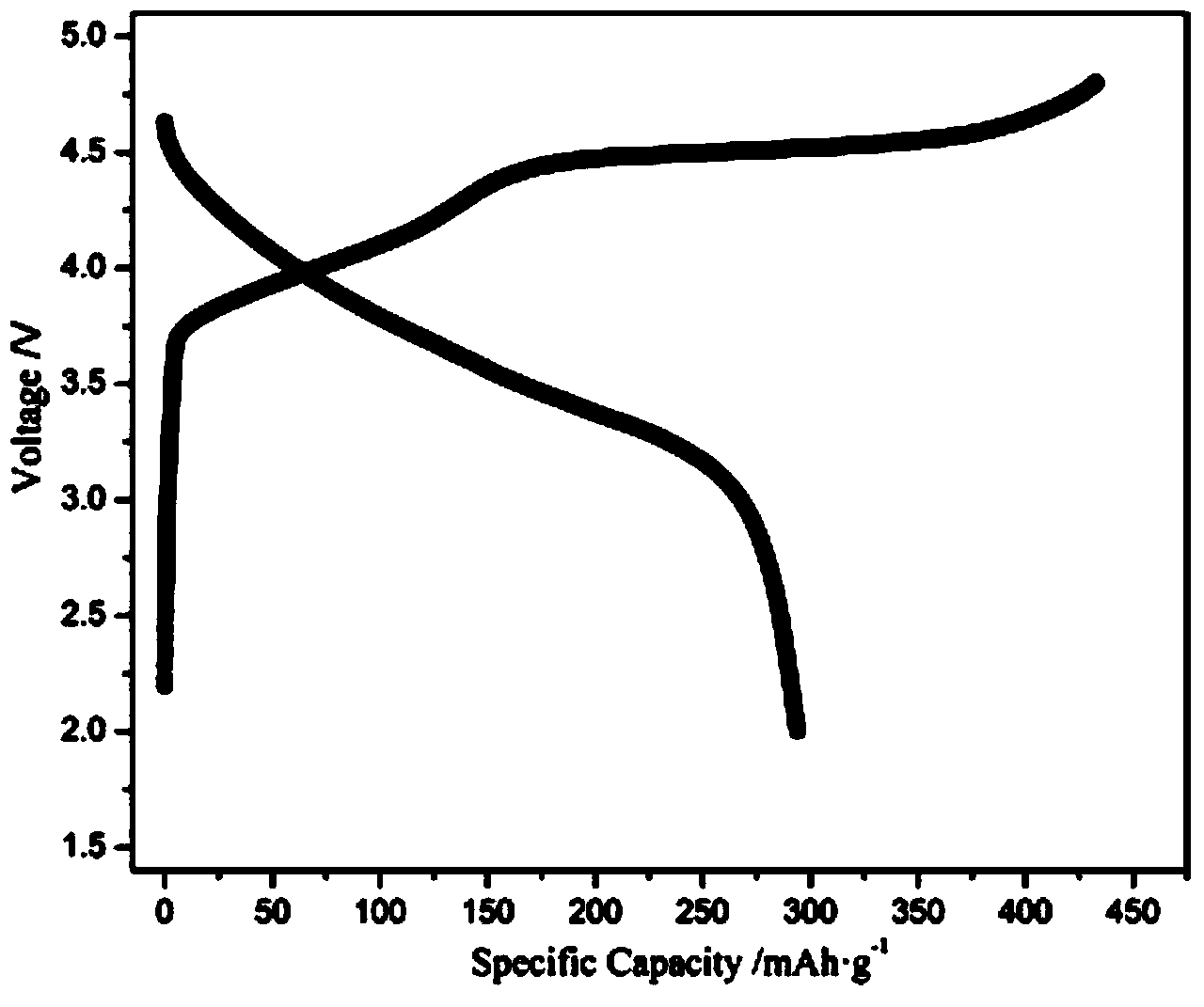

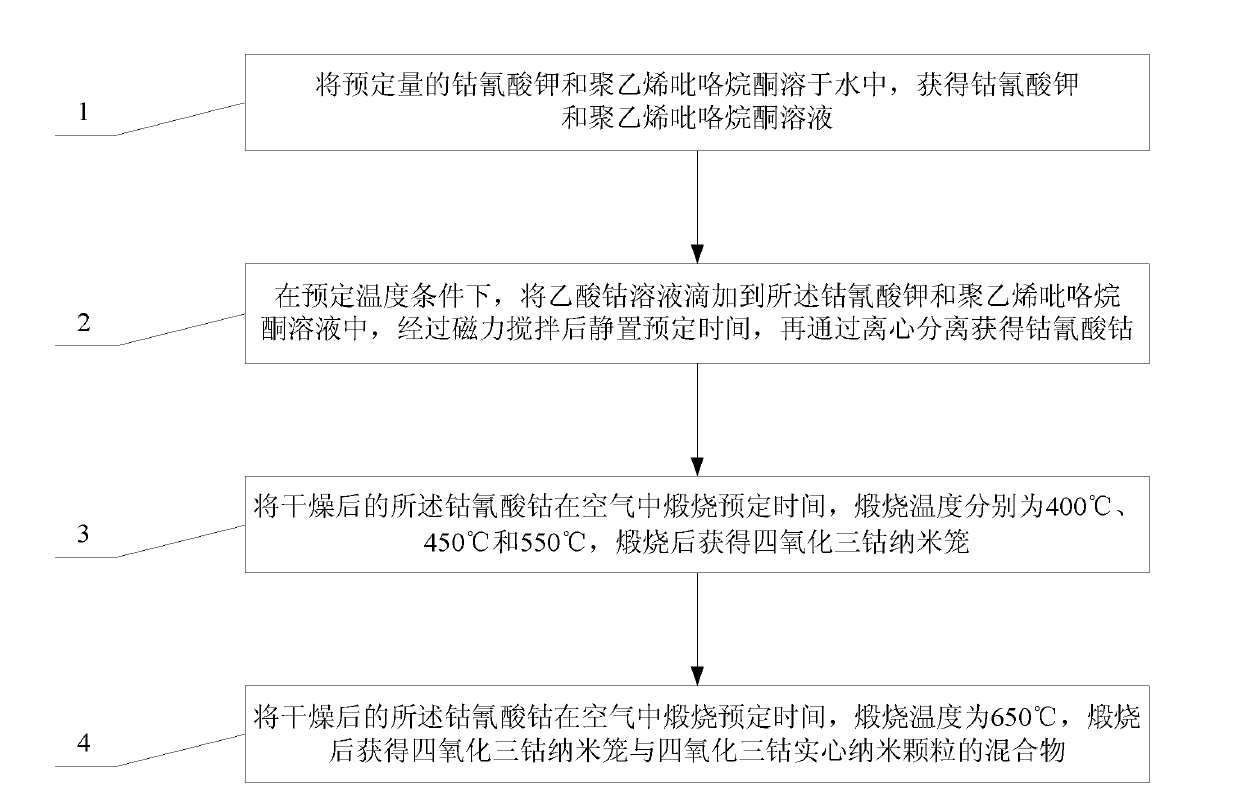

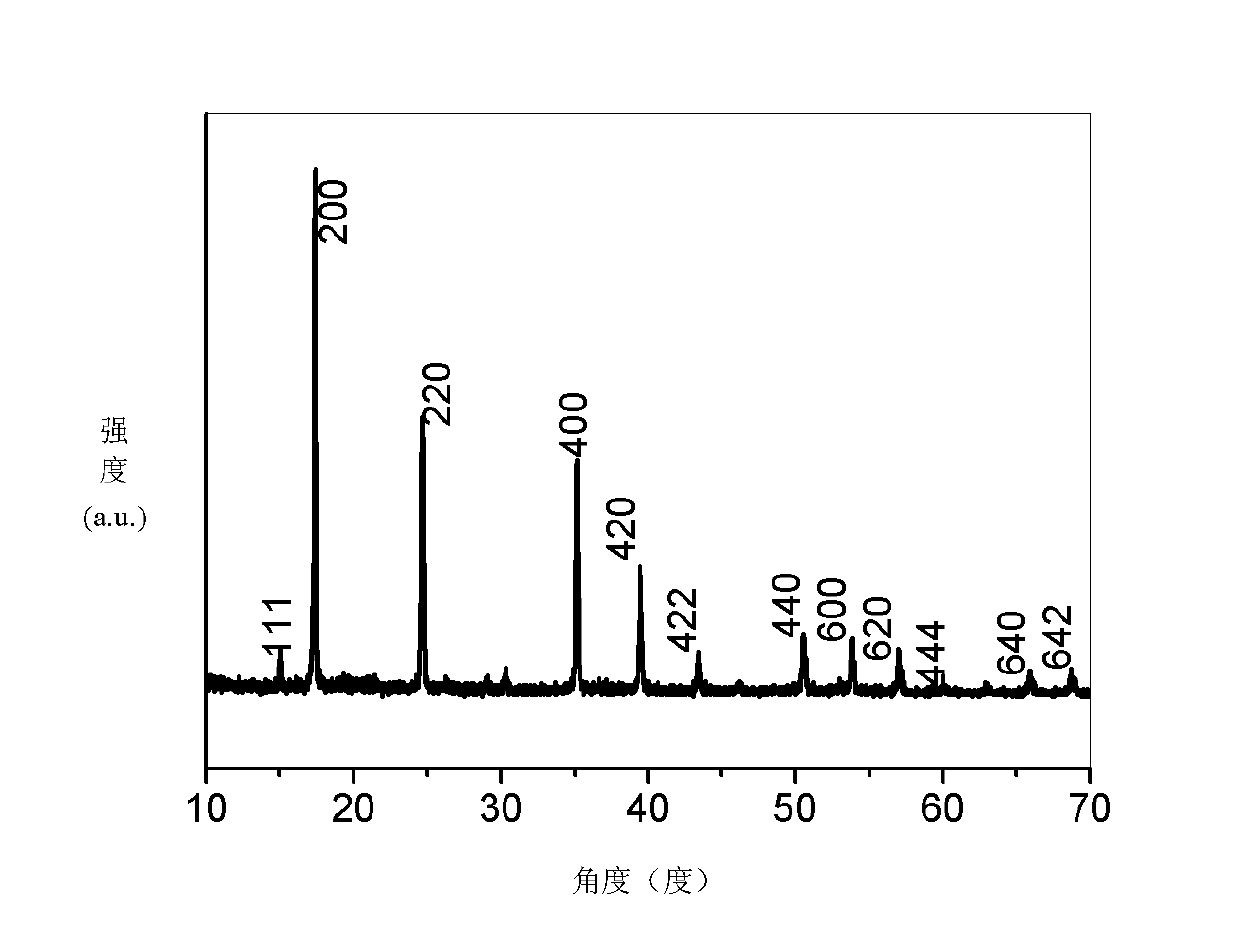

Preparation method of cobaltosic oxide nano cage and cobaltosic oxide nano cage prepared by adopting same

InactiveCN102437325ASimple preparation processAchieve mass productionMaterial nanotechnologyCell electrodesHigh pressureLithium-ion battery

The invention provides a preparation method of a cobaltosic oxide nano cage and the application of the cobaltosic oxide nano cage prepared by adopting the method in a lithium ion battery. The corresponding method comprises the steps that a predetermined amount of cobalt potassium cyanate and polyvinylpyrrolidone are dissolved in distilled water, and a cobalt potassium cyanate and polyvinylpyrrolidone solution is obtained; a cobaltous acetate solution is dropwise added to the cobalt potassium cyanate and polyvinylpyrrolidone solution, is magnetically stirred and then stands still for predetermined time, and then cobalt cyanate cobalt is obtained through centrifugal separation; the dried cobalt cyanate cobalt is calcined in air respectively at the calcination temperatures of 400 DEG C, 450 DEG C and 550 DEG C, and the cobaltosic oxide nano cage is obtained after the calcination; the dried cobalt cyanate cobalt is calcined in air for predetermined time at a calcination temperature of 650 DEG C, and a mixture of the cobaltosic oxide nano cage and cobaltosic oxide solid nanoparticles is obtained after the calcination. According to the preparation method, high temperature and high pressure are not needed, the manufacturing process is relatively simple, the requirement for equipment is not high, an operator only needs to use conventional equipment, and large-scale production can be realized.

Owner:UNIV OF SCI & TECH OF CHINA

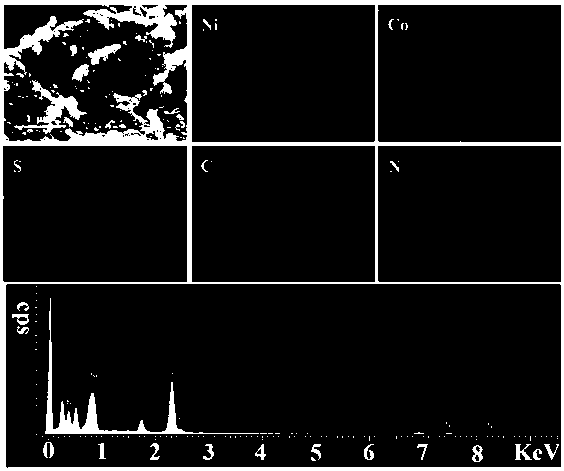

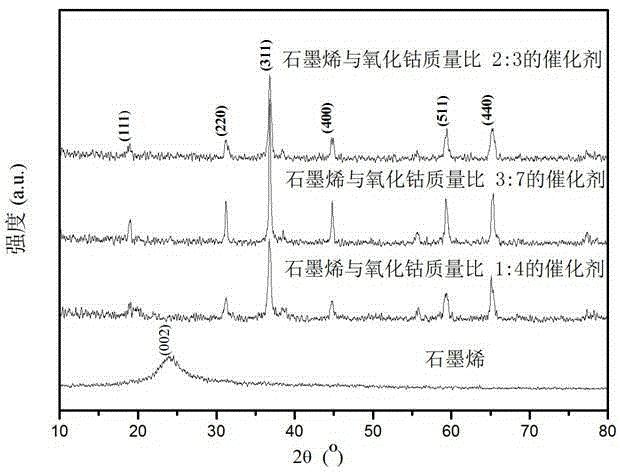

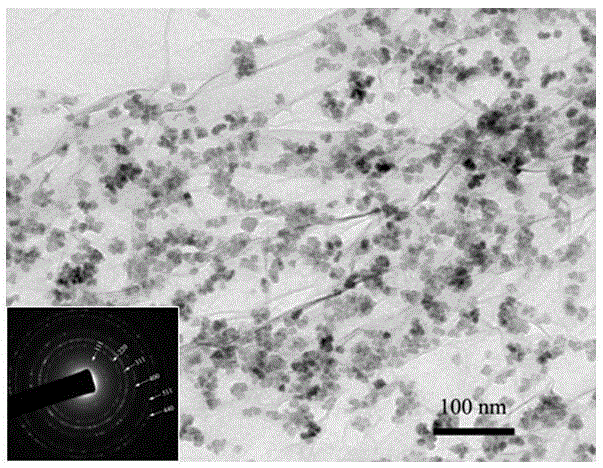

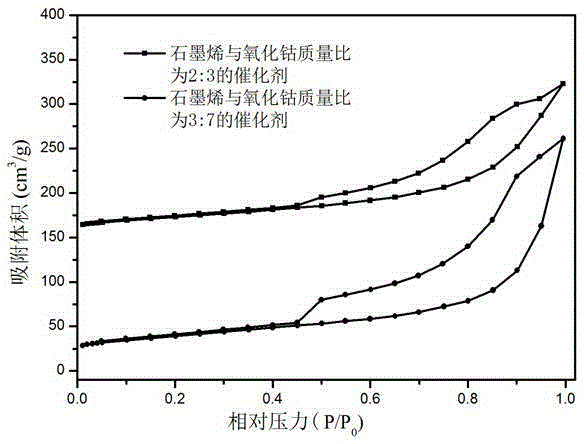

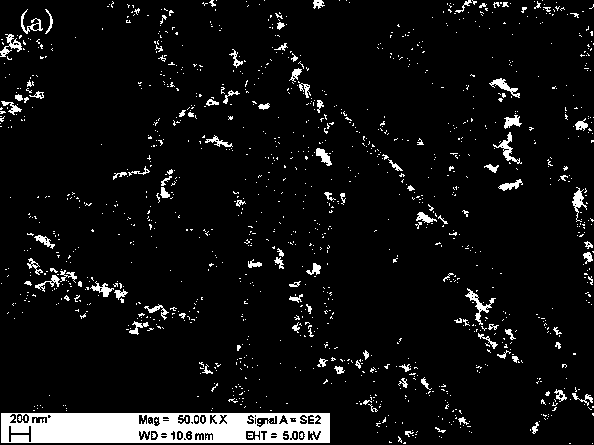

Graphene loaded cobaltous oxide catalyst and preparation method thereof

InactiveCN105268440AExcellent low temperature oxidation performanceEasy to operateMetal/metal-oxides/metal-hydroxide catalystsPtru catalystEngineering

The invention relates to a graphene loaded cobaltous oxide catalyst and a preparation method thereof. The preparation method comprises the steps that a cobaltous acetate aqueous solution and a graphene oxide aqueous solution are prepared firstly, after mixing is conducted, magnetic stirring is conducted, and a mixed solution A is obtained; ammonia water is dropwise added into the mixed solution A, magnetic stirring is conducted, and a mixed solution B is obtained; the mixed solution B is filled into a high-pressure reaction kettle with a polytetrafluoroethylene lining, a hydrothermal reaction is conducted for 10-14 h at 160-190 DEG C, and a mixture is obtained; after speed centrifugal separation is conducted on the obtained mixture, supernatant liquor is removed, residual solid matter is transferred to a drying oven after being washed, drying is conducted for 8 h at 60 DEG C, and the graphene loaded cobaltous oxide catalyst is prepared. The prepared catalyst can be applied to catalyzing of carbon monoxide low-temperature oxidation, the carbon monoxide can be completely oxidized into carbon dioxide at 100 DEG C, and the carbon monoxide can be completely converted into the carbon dioxide for at least 3000 min at 100 DEG C.

Owner:HENAN POLYTECHNIC UNIV

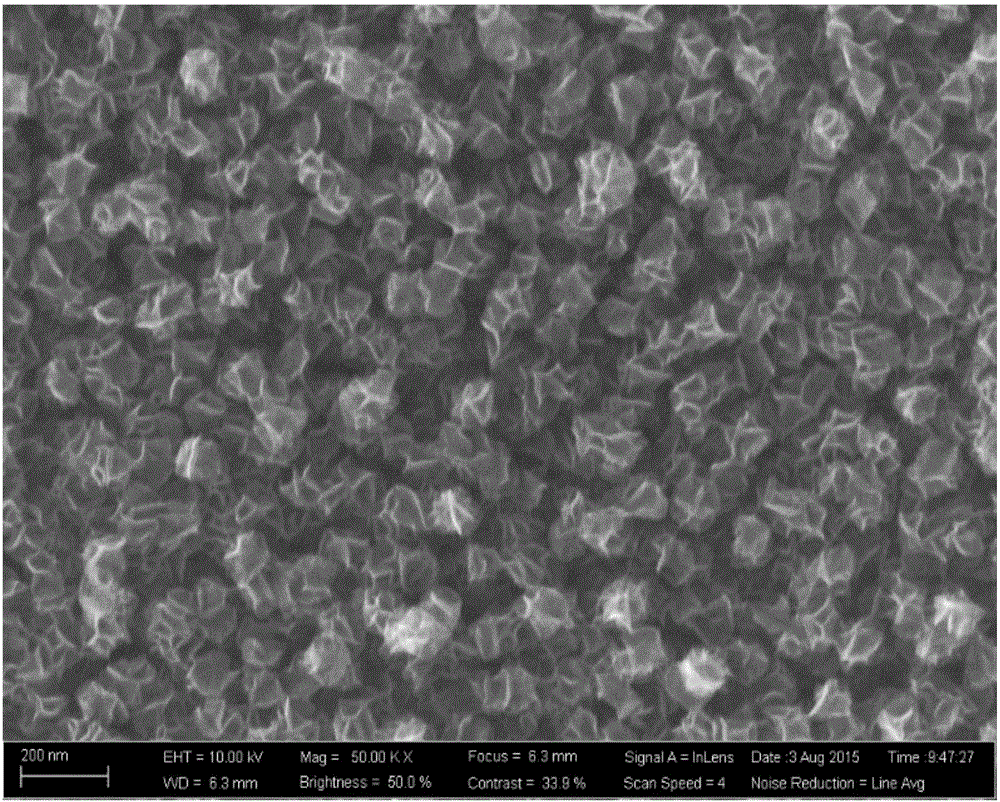

Preparation method of supercapacitor electrode material nickel and cobalt composite nanometer oxide

InactiveCN105513836AHigh specific capacitanceLow priceHybrid capacitor electrodesHybrid/EDL manufactureCOBALTOUS ACETATEEthanol

The invention discloses a preparation method of a supercapacitor electrode material nickel and cobalt composite nanometer oxide. The preparation method comprises the following concrete steps of (1) dissolving nickel acetate, cobaltous acetate tetrahydrate and urea into deionized water, stirring for 20 minutes, adding ethanol amine, and then stirring for 10 minutes to obtain a mixed solution; (2) pouring the obtained mixed solution into a hydrothermal reaction kettle, carrying out a hydrothermal reaction in the hydrothermal reaction kettle at the temperature of 110 to 130 DEG C for 6 to 48 hours, and then cooling to the room temperature to obtain a reaction product; (3) sequentially centrifuging, washing and drying the obtained reaction product, then heating to 200 to 500 DEG C at the heating rate of 5 DEG C / min, calcining for 3 hours, and finally preparing the supercapacitor electrode material nickel and cobalt composite nanometer oxide comprising three different structures of nanosheets, nano particles and nano wires. The preparation method provided by the invention is simple, green and environmental friendly, low in cost, and beneficial to large-scale application of the nickel and cobalt composite nanometer oxide electrode material in the industry of supercapacitors.

Owner:HENAN NORMAL UNIV

Preparation method of nitrogen-doped ordered porous carbon coated silicon nanometer composite material

InactiveCN107317011AIncrease capacityImprove cycle performanceMaterial nanotechnologyCell electrodesPorous carbonCalcination

The invention discloses a preparation method of a nitrogen-doped ordered porous carbon coated silicon nanometer composite material. The preparation method comprises the following steps: firstly adopting dopamine hydrochloride coated silicon nanometer particles, then using cobaltous acetate for catalysis treatment, and finally carrying out high-temperature calcinations to obtain the target product. The preparation method of the composite material disclosed by the invention is simple, the obtained product is good in cycle stability and cycle specific capacity, and the composite material can serve as an excellent negative electrode material for lithium ion batteries.

Owner:HEFEI UNIV OF TECH

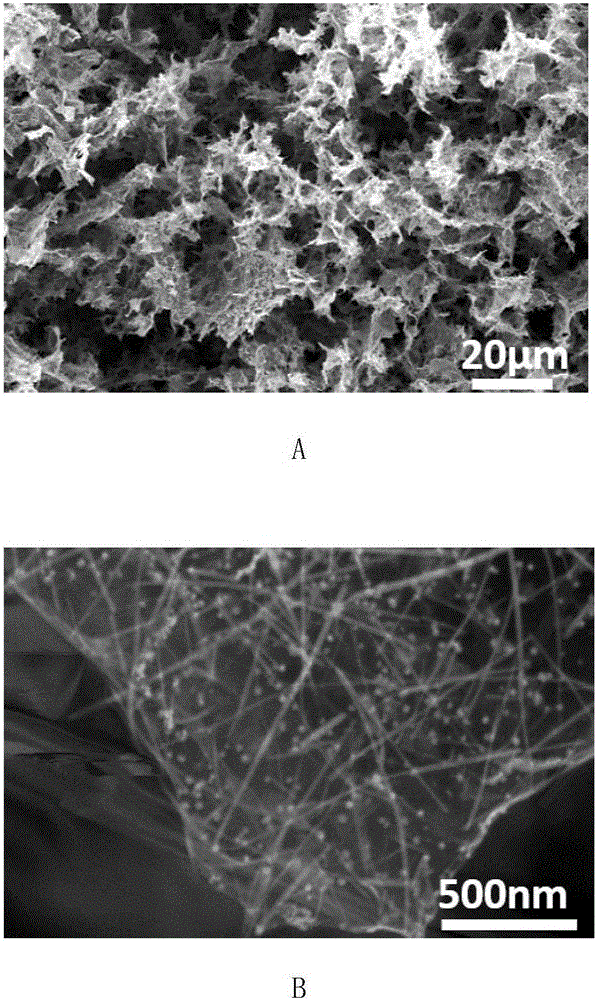

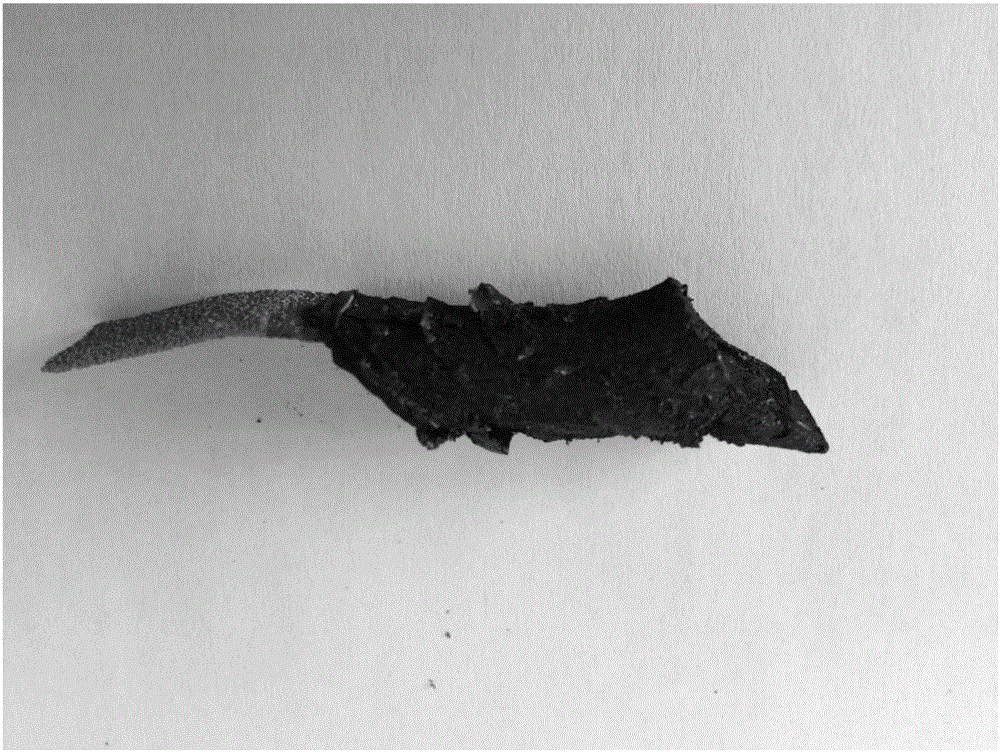

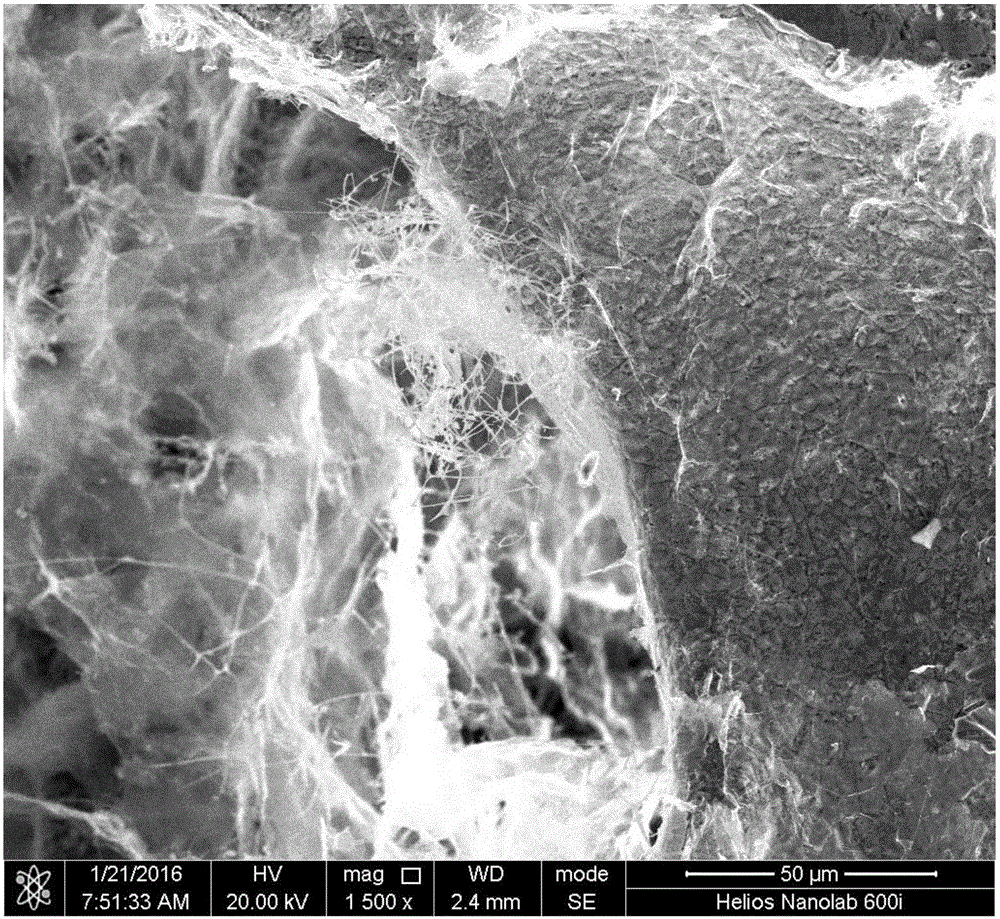

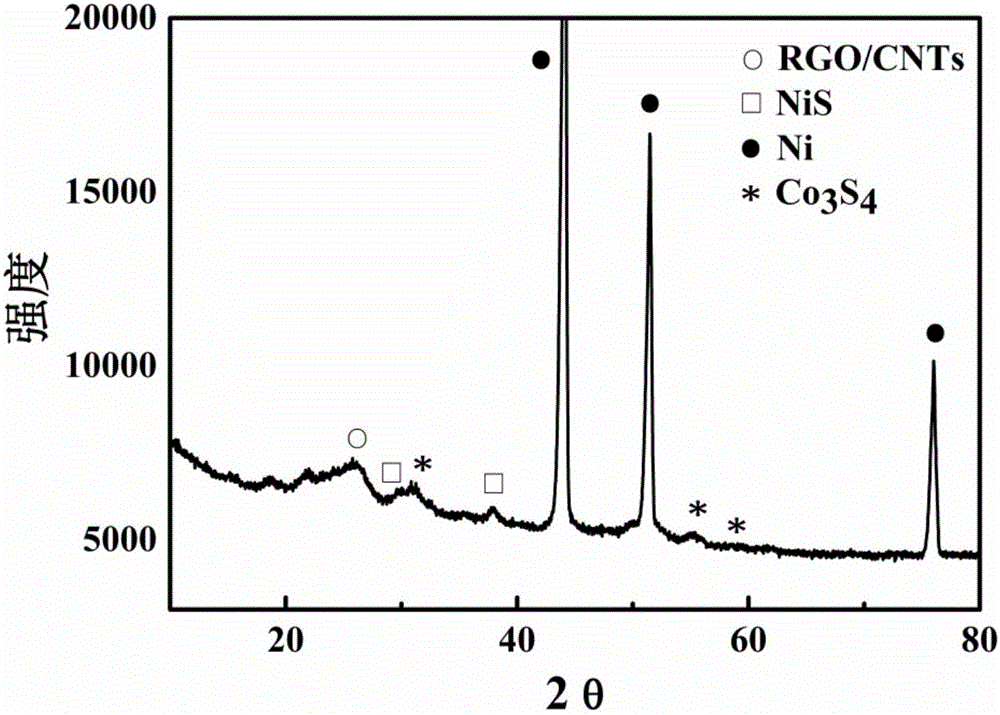

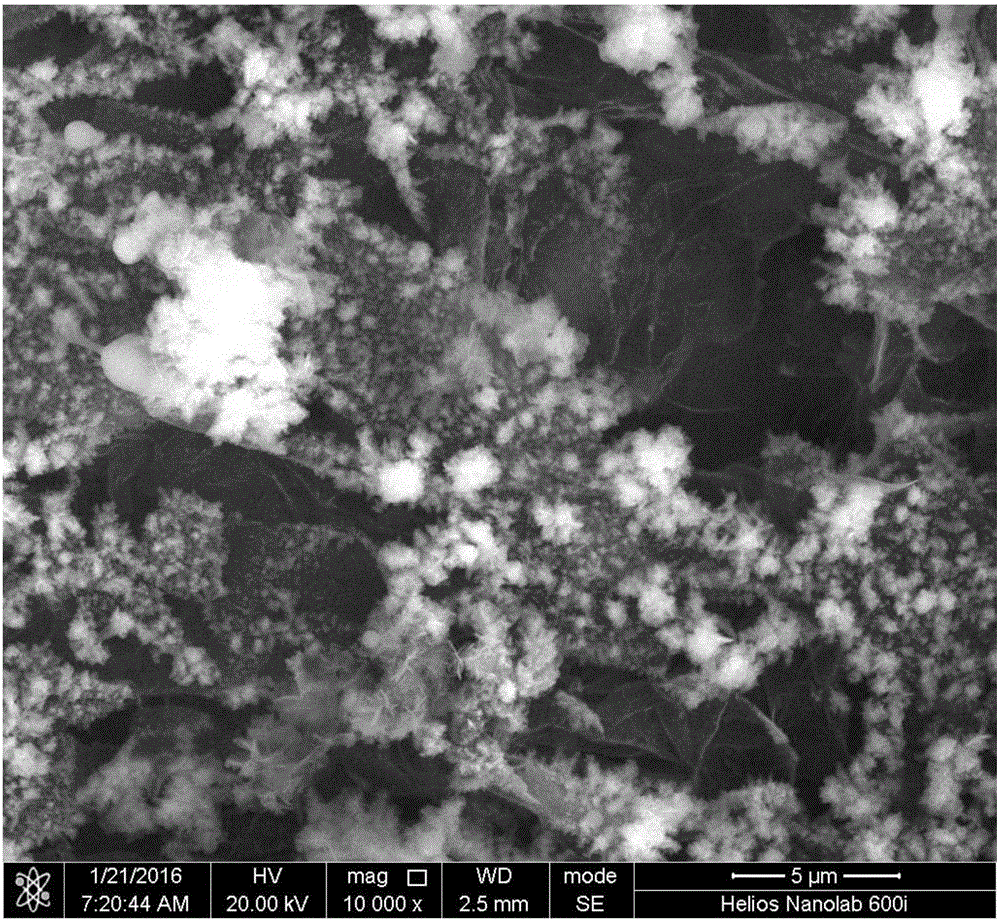

Preparation method for nickel sulfide/graphene/carbon nano tube/cobalt sulfide three-dimensional composite hydrogen storage material

ActiveCN105883939AHigh hydrogen storage activityLarge specific surface areaNickel sulfidesFreeze-dryingCarbon nanotube

The invention provides a preparation method for a nickel sulfide / graphene / carbon nano tube / cobalt sulfide three-dimensional composite hydrogen storage material and relates to a method for preparing the composite hydrogen storage material. The method aims at solving the technical problem that an existing cobalt sulfide composite material cannot be used as an electrochemical hydrogen storage electrode. The preparation method includes the steps that 1, oxidized graphene / carbon nano tube dispersion liquid is prepared; 2, cobaltous acetate and sulfur are added into the oxidized graphene / carbon nano tube dispersion liquid, the mixture is stirred to be uniform, and mixed liquid is obtained; 3, the mixed liquid is ball-milled; 4, foamed nickel is washed; 5, the mixed dispersion liquid is added into a hydrothermal kettle, glucose is added, foamed nickel is soaked in the mixed dispersion liquid, and a hydrothermal reaction is conducted for 48-60 h at the temperature of 180-220 DEG C; after the reaction is over, leaching and freeze drying are conducted, and the nickel sulfide / graphene / carbon nano tube / cobalt sulfide three-dimensional composite hydrogen storage material is obtained. The specific area of the composite hydrogen storage material ranges from 70 m<2> / g to 81 m<2> / g, and the composite hydrogen storage material can be used as the hydrogen storage electrode.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

Catalyst used for producing promoter N-cyclohexyl benzothiazole sulfonamide and its preparation method

InactiveCN102380404AEasy to prepareEasy to industrializeOrganic chemistryMolecular sieve catalystsCerium nitrateCeric sulfate

The invention relates to a catalyst used for producing promoter N-cyclohexyl benzothiazole sulfonamide and its preparation method. The catalyst is selected from one or more of metal salts of copper acetate, copper sulphate, cupric nitrate, cobaltous acetate, cobaltous sulphate, cabaltous nitrate, cerium acetate, ceric sulfate, cerium nitrate, manganese acetate, manganese sulfate, manganese nitrate and the like. A carrier of the catalyst is selected from one or more of active carbon, SiO2, Al2O3, TiO2, mesoporous material molecular sieve, microporous material molecular sieve and the like. The prepared catalyst is used in a reaction for synthesizing CBS by oxygen through an oxidation process, the reaction is used for representing the performance of the catalyst. The catalyst amount is 0.01-0.1% of weight of a reactant. The catalyst has reasonable formula, contains active ingredients and carriers, the usage amount is less, and the catalysis effect is good. The catalyst is capable of increasing the dispersion area of the active ingredients so as to increase the contact area of the active ingredients and the reactant, raising the reaction speed and simultaneously reducing the amount of the catalyst. The CBS yield can reach more than 98% by optimizing the reaction condition.

Owner:KEMAI CHEM

Cobaltosic oxide columnar structure material and preparation method thereof

The invention provides a cobaltosic oxide columnar structure material and a preparation method thereof and belongs to the field of inorganic materials. The preparation method specifically includes adding glycerol with a certain volume ratio in a cobaltous acetate aqueous solution, fully mixing, adding an appropriate amount of urea to serve as a precipitating agent, uniformly dispersing, sealing a mixed solution in a high-pressure autoclave, reacting for a certain time at the specific temperature, performing suction filtration, washing, drying, and performing calcination in the air in a muffle furnace to obtain the cobaltosic oxide with the columnar structure. According to the cobaltosic oxide columnar structure material and the preparation method thereof, the operation process of the method is simple, the productivity is high, the cost is low, any surface active agent is not added, the material is free of pollution, the prepared cobaltosic oxide is neat in appearance, uniform in dispersion, high in particle density, and the cobaltosic oxide columnar structure material and the preparation method thereof are expected to be widely used in the fields of lithium ion batteries, supercapacitor, gas sensors, biosensing and catalysis and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

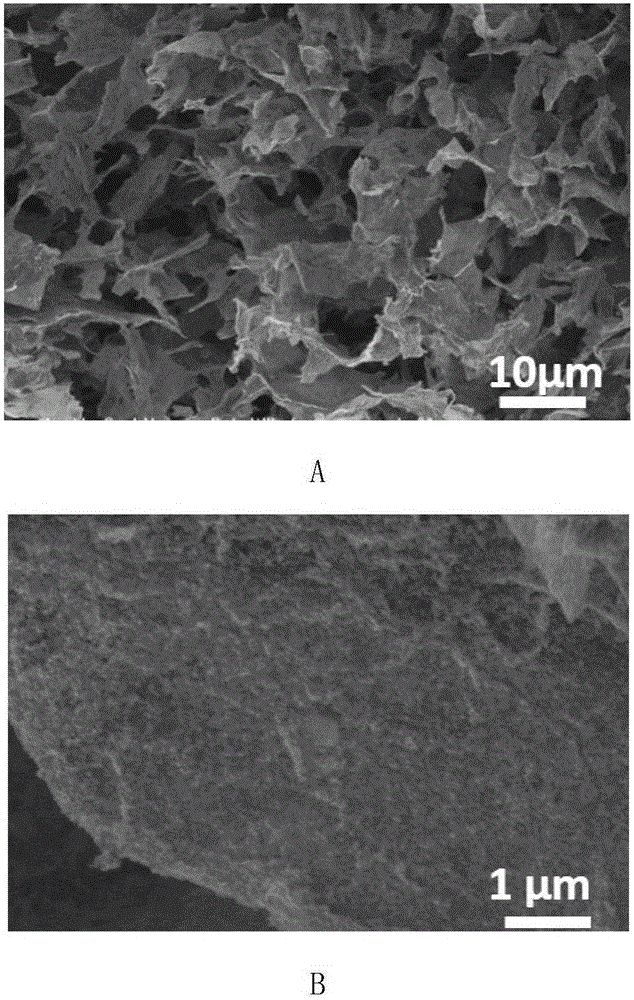

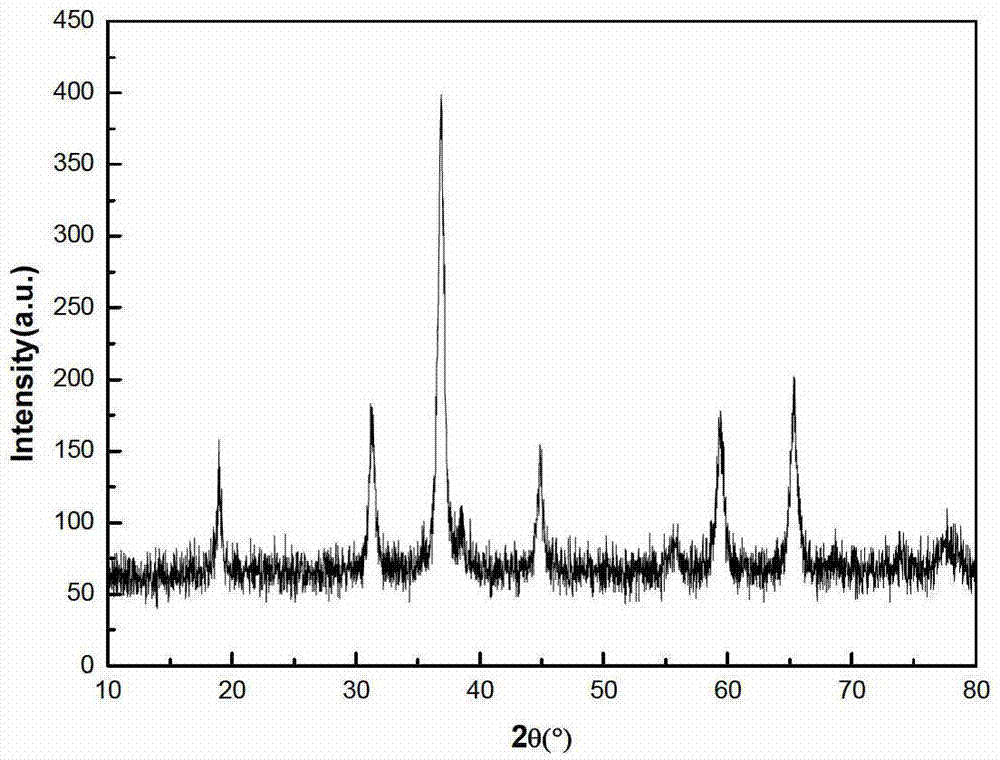

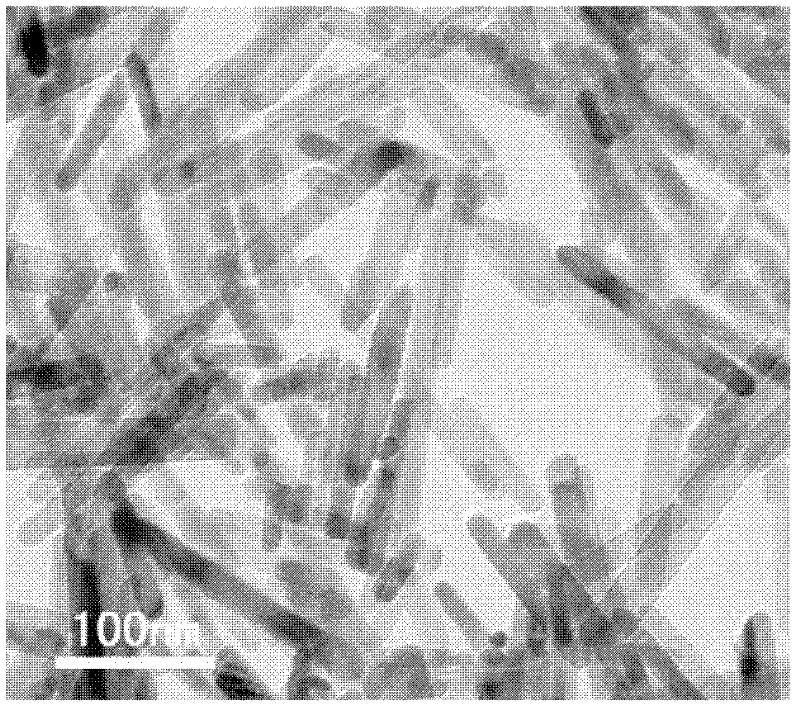

Preparation method of nickel sulfide/graphene/cobalt sulfide three-dimensional composite hydrogen storage material

ActiveCN105895869AGenerate uniformCreate a uniform structureAlkaline accumulatorsCell electrodesAcetic acidFreeze-drying

The invention provides a preparation method of a nickel sulfide / graphene / cobalt sulfide three-dimensional composite hydrogen storage material, relates to a method for preparing the three-dimensional composite hydrogen storage material and aims at solving the technical problem that an existing cobalt sulfide composite material cannot be used as an electrochemical hydrogen storage electrode. The method comprises the following steps: (1) preparing a graphene oxide disperse solution; (2) adding cobaltous acetate and sulphur to the graphene oxide disperse solution to prepare a mixed solution; (3) preparing a mixed dispersion liquid in a ball-milling manner; (4) cleaning nickel foam; and (5) adding the mixed dispersion liquid to a hydrothermal kettle, adding glucose, immersing the nickel foam into the mixed dispersion liquid, carrying out hydrothermal reaction and then carrying out cleaning and freeze drying on the product to obtain the nickel sulfide / graphene / cobalt sulfide three-dimensional composite hydrogen storage material. The specific surface area of the composite hydrogen storage material is 67-78m<2> / g; the preparation method is simple; the reaction period is short; final treatment is not needed; the hydrogen storage property is high; and the nickel sulfide / graphene / cobalt sulfide three-dimensional composite hydrogen storage material can be directly applied to the field of electrochemical hydrogen storage as the hydrogen storage electrode.

Owner:HEBEI NORMAL UNIVERSITY OF SCIENCE AND TECHNOLOGY

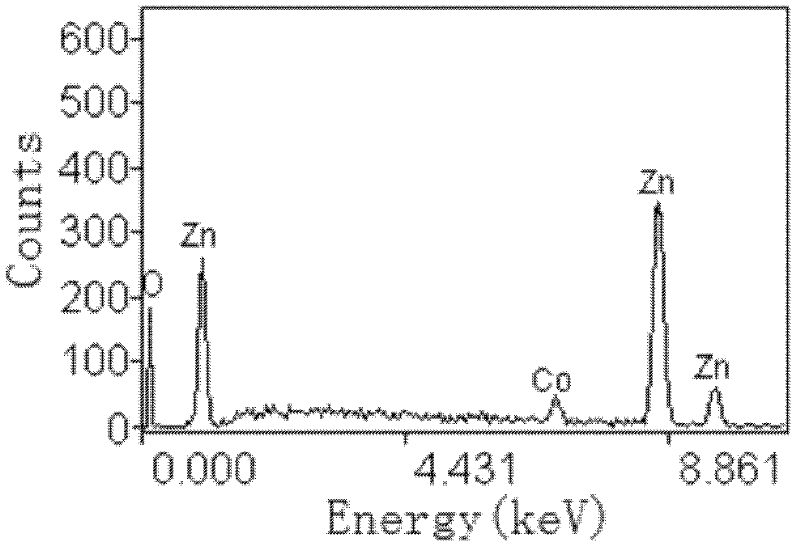

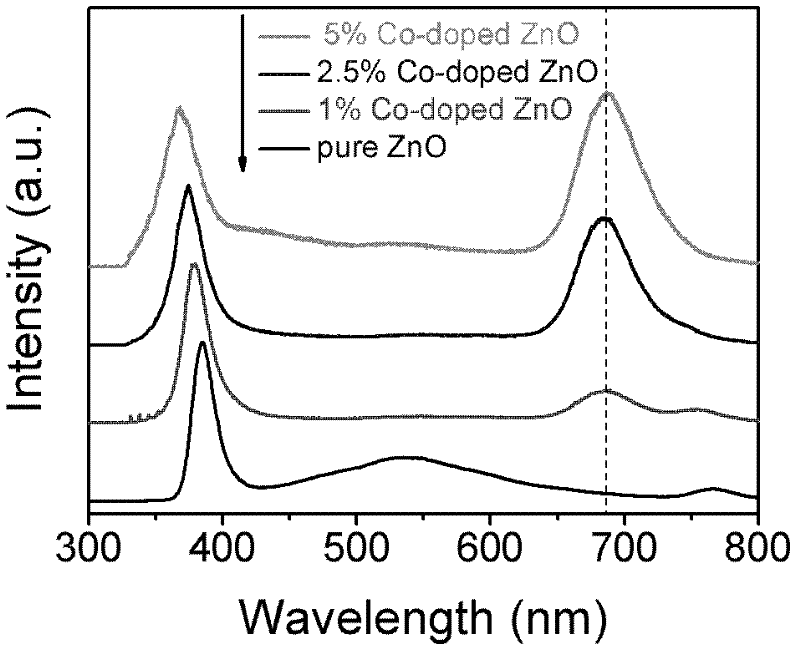

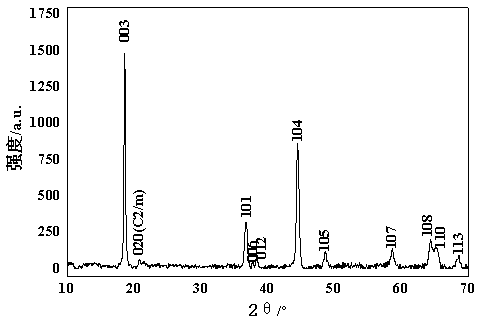

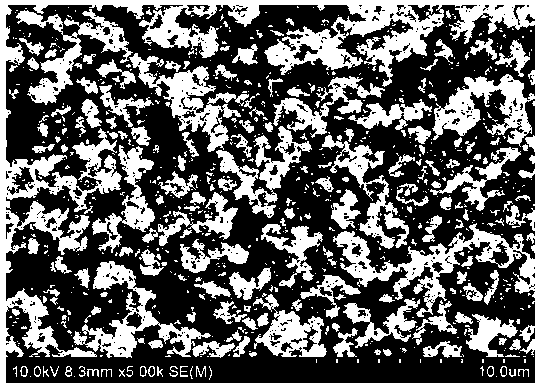

Preparation method of zinc oxide base red light nano material

InactiveCN102443390ALow costUniform shapeZinc oxides/hydroxidesLuminescent compositionsPhotoluminescenceZinc Acetate Dihydrate

The invention belongs to the field of nano material and relates to a cobalt doped zinc oxide red luminescent nano material. A specific technology is as below: (1) mixing zinc acetate and cobaltous acetate according to a molar proportion and dissolving into absolute ethyl alcohol; (2) dropwise adding sodium hydroxide ethanol solution into the mixed solution and stirring continuously till formation of a stable blue solution; (3) adding polyethylene glycol 400 into the mixed solution, pouring into a reaction kettle and insulating for 16 h at 140 DEG C; (4) removing precipitate in the reaction kettle, cleaning by deionized water 8-10 times and drying to obtain a cobalt doped zinc oxide nanometer rod. According to tests on photoluminescence spectrums of zinc oxide nano samples with different cobalt doping contents by Raman spectrometer, it shows that as increasing of the cobalt doping content, red light peak at 687 nm is enhanced substantially.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of pale rosin pentaerythritol ester

ActiveCN104140763ALight colorShort reaction timeNatural resin chemical modificationPentaerythritolRoom temperature

The invention discloses a preparation method of pale rosin pentaerythritol ester. The preparation method includes the following steps that rosin is vacuumized, depressurized and distilled, so that refined rosin is obtained; the refined rosin is added to a reaction container, and under the protection effect of nitrogen, the refined rosin is heated, molten and cooled to room temperature; a catalyst and xylene are sequentially added to a reaction still and are evenly stirred, pentaerythritol is slowly added in a dropwise mode, ultrasonic waves with the power ranging from 1500 W to 1600 W are introduced to the reaction still, and under the condition of the ultrasonic waves, when the chrominance of the solution is smaller than or equal to 5 garner color number through esterification reaction, reaction is stopped, wherein the catalyst is a mixture of zinc oxide, cobaltous acetate and sodium thiosulfate. The prepared product is light in color and can be widely applied to industries of oil paint, paint, printing ink and the like.

Owner:GUANGXI ZHONGCHANG RESIN

Lithium-rich multi-component lithium ion battery positive pole material and preparation method thereof

InactiveCN103066274ASimple preparation processReduce manufacturing costCell electrodesMANGANESE ACETATEPhysical chemistry

The invention discloses a lithium-rich multi-component lithium ion battery positive pole material and a preparation method thereof. The molecular formula of the lithium-rich multi-component lithium ion battery positive pole material is Li1.13Ni0.20Co0.20Mn0.47O2. The preparation method comprises the following steps of: completely dissolving cobaltous acetate, nickel acetate, manganese acetate and lithium acetate in alcohol by an alcoholysis solid-phase method; then drying a mixture of the dissolved cobaltous acetate, nickel acetate, manganese acetate and lithium acetate at 120 DEG C, thereby obtaining solid powder of a transition metal acetate precursor; and finally, sintering the obtained solid powder of the transition metal acetate precursor twice in a high-temperature tubular furnace system, and then carrying out ball-milling fully on the sintered solid powder to obtain the lithium-rich multi-component lithium ion battery positive pole material with particle diameter being less than 1 micron, favorable morphology and structure, small particle diameter distribution and good battery performance. The preparation method has the characteristics of simple preparation technology, low production cost, adaptability to large-scale production and the like.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Method for producing rosin glycerin ester

The invention discloses a method for producing rosin glycerin ester, and belongs to the technical field of rosin deep processing.Rosin glycerin ester is prepared from rosin, anthraquinone, hydrogen peroxide, cetyl trimethyl ammonium bromide, 4,4'-sulfobis(6-tertiary butyl-3-methylphenol), 15-12 parts of glycerin and cobaltous acetate.The method includes the steps that rosin is refined, and hydrogen peroxide, cetyl trimethyl ammonium bromide, glycerin and cobaltous acetate are added and heated to 200-250 DEG C and react for 3-4 h at the constant temperature under the ultrasonic wave of 1100-1200 W power; anthraquinone and 4,4'-sulfobis(6-tertiary butyl-3-methylphenol) are added, then distillation is conducted at the pressure below the triple point.The produced rosin glycerin ester has the advantages of being high in purity and light in color.

Owner:FINJET CHEM IND LTD

Method for producing pentalyn

InactiveCN105778765AHigh softening pointHigh purityNatural resin chemical modificationAnthraquinonesPentaerythritol

The invention discloses a method for producing pentalyn, and belongs to the technical field of rosin deep processing.The pentalyn is prepared from, by weight, 100 parts of rosin, 0.0001-0.0002 part of anthraquinone, 5-8 parts of hydroquinone, 0.001-0.002 part of 4,4'-sulfo-bis(6-tert-butyl-3-methylphenol), 15-25 parts of pentaerythritol and 0.01-0.02 part of cobaltous acetate.The method comprises the steps that firstly, rosin is refined, the hydroquinone, the pentaerythritol and the cobaltous acetate are added, temperature is increased to 300-350 DEG C under vacuum pressure, constant-temperature stirring is performed, and the reaction is performed for 2-4 h; the anthraquinone and the 4,4'-sulfo-bis(6-tert-butyl-3-methylphenol) are added, then, temperature is increased to 200-220 DEG C under the vacuum pressure for distillation.The obtained pentalyn has the advantages of being high in softening point and purity.

Owner:FINJET CHEM IND LTD

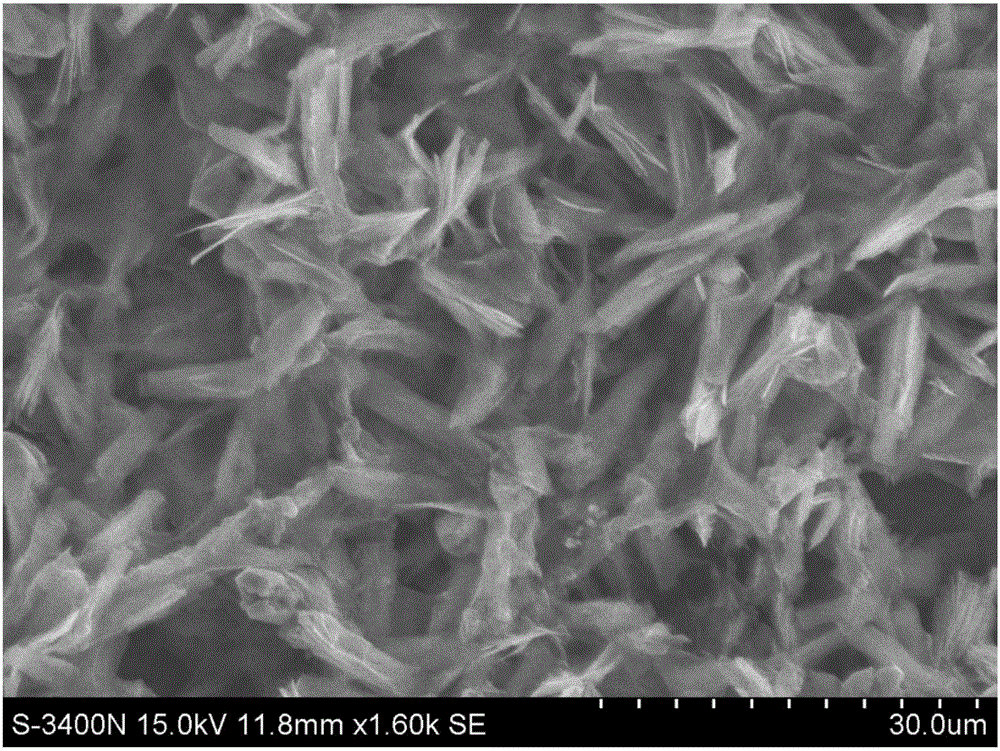

Alkaline mode cobalt vanadate micrometer sheet material and preparation method thereof

ActiveCN106784816ARich material fieldsImprove discharge capacityMaterial nanotechnologyCell electrodesNew energyActive matter

The invention discloses an alkaline mode cobalt vanadate micrometer sheet material and a preparation method thereof and belongs to the field of new energy materials. Chemical constitution of the alkaline mode cobalt vanadate micrometer sheet material is Co3(OH) 2V2O7.2H2O, the alkaline mode cobalt vanadate micrometer sheet is of a regular hexagonal structure, and the diameter is 0.5 to 2mu m. The preparation method of the alkaline mode cobalt vanadate micrometer sheet materials comprises the steps: (1) preparing cobaltous acetate and metavanadic acid into a mixed solution according to a molar ratio of Co to V as 1 to (1 to 2); (2) evenly stirring and reacting for 2 to 24h in 150 to 180 DEG C to obtain coarse product solution; (3) cooling the coarse product solution obtained in the step (2) to room temperature and washing and drying obtained precipitate to obtain the alkaline mode cobalt vanadate micrometer sheet material. The alkaline mode cobalt vanadate micrometer sheet material is synthesized through a one-step hydrothermal method and a wet method, and no any surface active agent and no any formwork is utilized in a preparation process; thus, the alkaline mode cobalt vanadate micrometer sheet material has moderate reaction condition, simple technology and suitability for batch production; when the alkaline mode cobalt vanadate micrometer sheet material is assembled into a battery to test electrochemical performance, a result that the alkaline mode cobalt vanadate micrometer sheet material has stable discharge capacity when being used as negative electrode active matter of lithium ion secondary battery is found.

Owner:SHIJIAZHUANG UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com