Preparation method for biomass-based hollow carbon microtube/Ni-Co metal sulfide composite electrode material

A technology of metal sulfide and carbon microtubes, which is applied in the manufacture of hybrid capacitor electrodes, hybrid/electric double layer capacitors, etc., to achieve high price advantages, excellent electrochemical performance, and solve the effects of large-scale application difficulties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

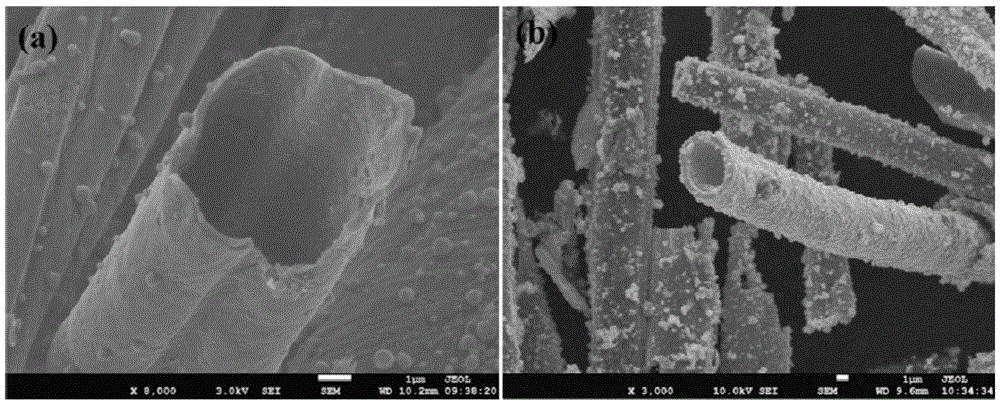

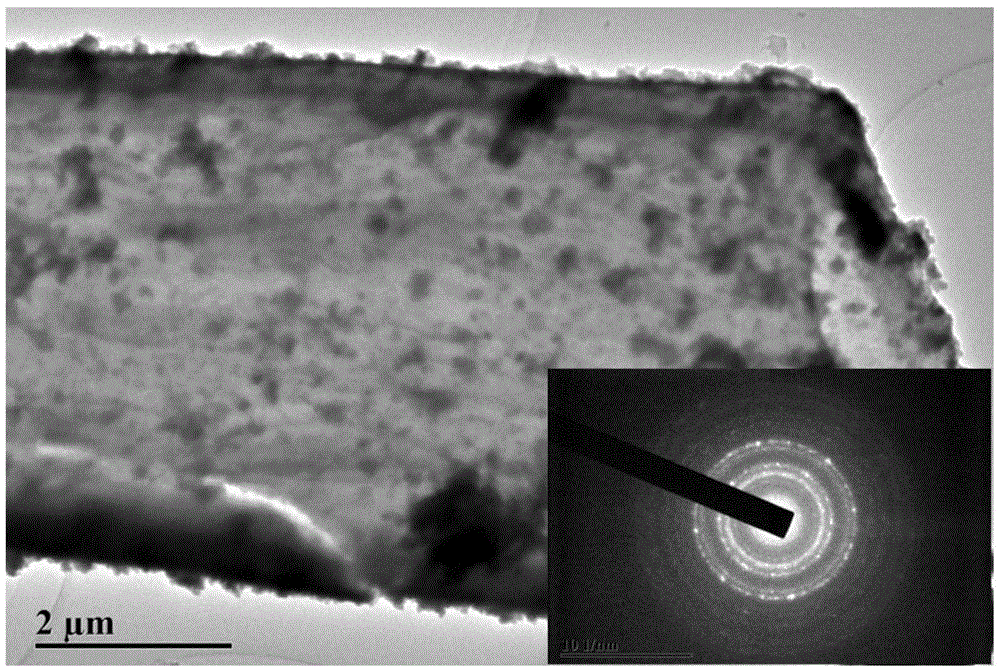

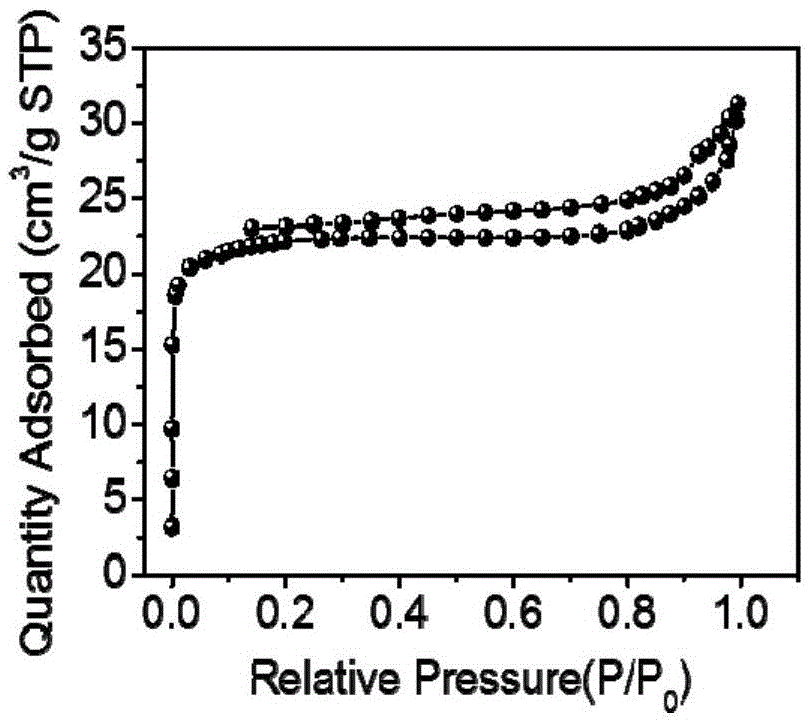

[0033] (1) Put 5g of biomass catkins in a tubular carbonization furnace, feed Ar as a protective gas, and control the gas flow rate at 5mlmin -1 g -1 , at 5°C min -1 The heating rate was increased to 1000°C, the temperature was kept constant for 2 hours, and the hollow carbon microtube was obtained by natural cooling to room temperature.

[0034] (2) Weigh the raw material nickel acetate Ni(CH 3 COO) 2 4H 2 O (1.2mmol), cobalt acetate Co (CH 3 COO) 2 4H 2 O (0.6mmol), thiourea (3.6mmol) is dissolved in 60ml dehydrated alcohol, makes mixed solution, then adds the mesoporous carbon microtube that 150mg above-mentioned step (1) makes in mixed solution, magnetically stirs 2h, well mixed.

[0035] (3) Transfer the above mixture to a polytetrafluoroethylene hydrothermal kettle with a volume of 100ml. The hydrothermal reaction kettle is placed in a blast oven, kept at a constant temperature of 180°C for 8h, then cooled to room temperature, and centrifuged at a speed of 9000rp...

Embodiment 2

[0037] (1) Put 5g of biomass catkins in a tubular carbonization furnace, feed Ar as a protective gas, and control the gas flow rate at 7mlmin -1 g -1 , at 7°C min -1 The heating rate was increased to 700°C, the temperature was kept constant for 1.5h, and then cooled to room temperature naturally to obtain hollow carbon microtubes.

[0038] (2) Weigh the raw material nickel acetate Ni(CH 3 COO) 2 4H 2 O (0.9mmol), cobalt acetate Co (CH 3 COO) 2 4H 2 O (0.9mmol), thiourea (4.5mmol) is dissolved in 80ml dehydrated alcohol, makes mixed solution, then adds the mesoporous carbon microtube that 200mg above-mentioned step (1) makes in mixed solution, magnetic stirring 3h, well mixed.

[0039] (3) Transfer the above mixture to a 100ml polytetrafluoroethylene hydrothermal kettle, place the hydrothermal reaction kettle in a blast oven, keep the temperature at 170°C for 10h, then cool to room temperature, centrifuge at 8000rpm for 20min, and then use Fully washed with water ethan...

Embodiment 3

[0041] (1) Put 8g of biomass catkins in a tubular carbonization furnace, 2 As a protective gas, the gas flow rate is controlled at 8mlmin -1 g -1 , at 10°C min -1 The heating rate was increased to 1000°C, the temperature was kept constant for 3 hours, and then cooled to room temperature naturally to obtain hollow carbon microtubes.

[0042] (2) Weigh the raw material nickel acetate Ni(CH 3 COO) 2 4H 2 O (0.6mmol), cobalt acetate Co (CH 3 COO) 2 4H 2 O (1.2mmol), thiourea (5.4mmol) is dissolved in 80ml ethylene glycol, makes mixed solution, then adds the mesoporous carbon microtube that 300mg above-mentioned step (1) makes in mixed solution, magnetic stirring 3h, well mixed.

[0043] (3) Transfer the above mixture to a 100ml polytetrafluoroethylene hydrothermal kettle, place the hydrothermal reaction kettle in a blast oven, keep the temperature at 200°C for 5h, then cool to room temperature, centrifuge at 7000rpm for 30min, and then use anhydrous Fully wash with ethan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com