Preparation method of high-specific-capacity lithium-rich anode material

A lithium-rich positive electrode material with high specific capacity technology, applied in battery electrodes, electrical components, electrochemical generators, etc., can solve the problems of low discharge specific capacity, unstable cycle performance, complex preparation process, etc., and achieve large specific surface area , easy mass production, and simple synthesis steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

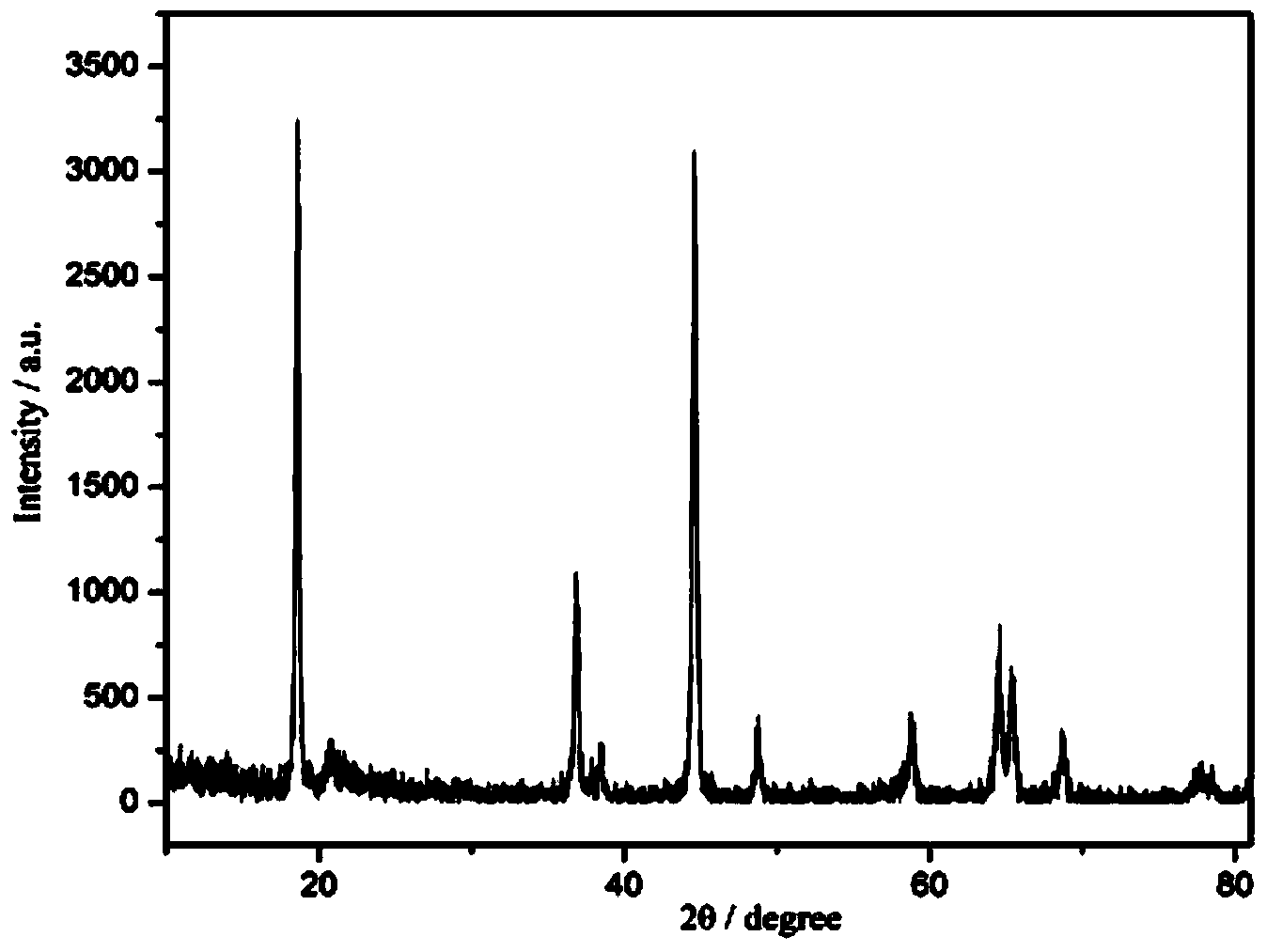

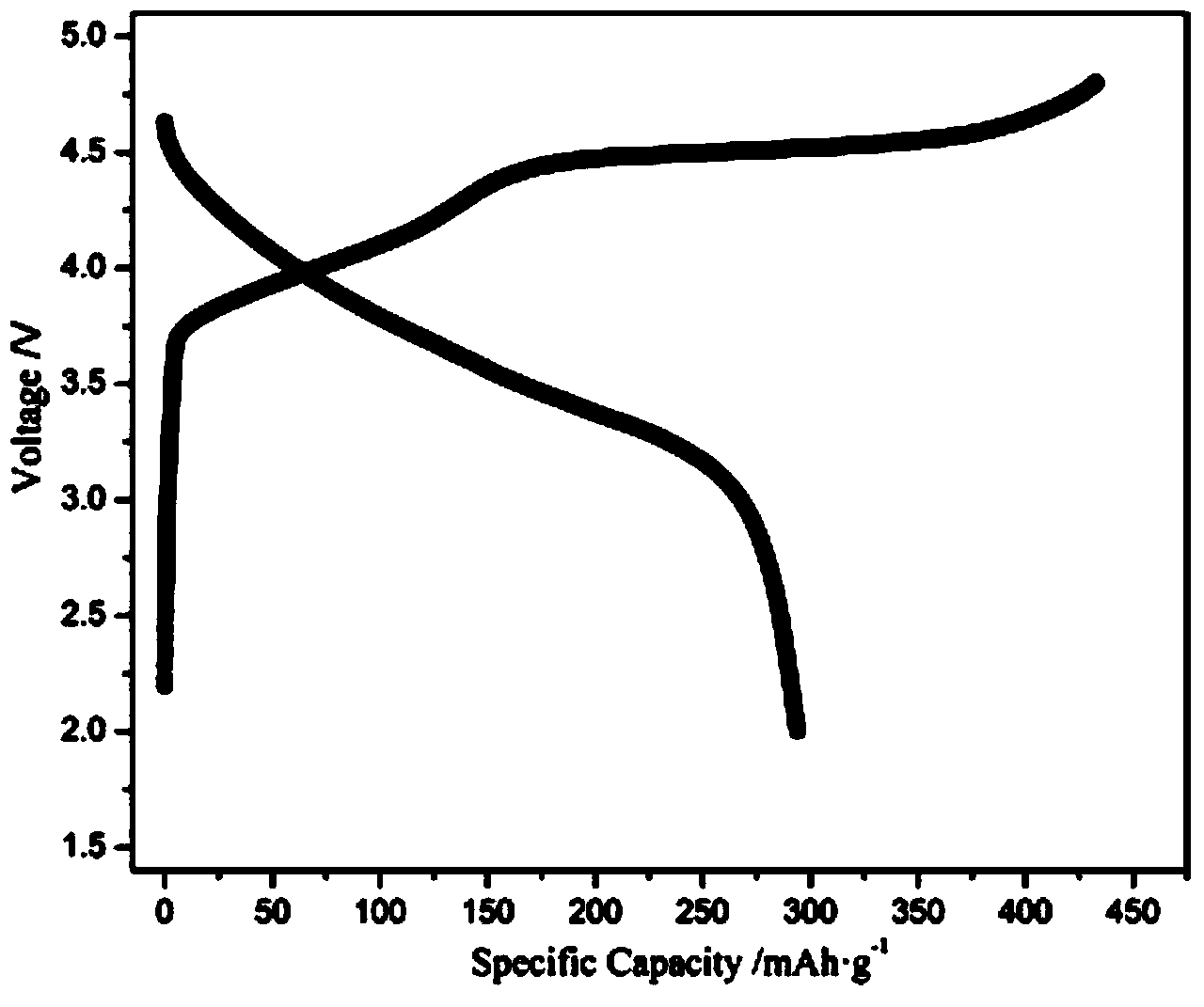

Embodiment 1

[0022] A method for preparing a high-capacity lithium-rich positive electrode material, comprising dissolving manganese acetate, nickel acetate, cobalt acetate, and lithium acetate at a stoichiometric ratio of 0.54:0.13:0.13:1.26 (because the lithium element is volatile during the calcination process, an excess of 5% is required) In ethanol, stir to obtain a homogeneously mixed acetate solution. The solution was heated in a water bath at 80°C, and evaporated with electromagnetic stirring until the mixed liquid appeared as a purple-red viscous colloid, and placed in a drying oven at 80°C for 12 hours to obtain a precursor powder. Grind the dried mixture into powder, place it in a high-temperature furnace for calcination, and raise the temperature to 500° C. at a rate of 5° C. / min. The holding time is 5 hours. After cooling, drying and grinding, the temperature was raised at a heating rate of 5°C / min, and calcined at 850°C, and the holding time was 10h. After sintering, it was ...

Embodiment 2

[0028]A method for preparing a lithium-rich cathode material with a high specific capacity, comprising dissolving manganese acetate, nickel acetate, cobalt acetate and lithium acetate in deionized water at a stoichiometric ratio of 0.54:0.13:0.13:1.26, and stirring to obtain evenly mixed acetate solution. The solution was heated in a water bath at 80°C, and evaporated with electromagnetic stirring until the mixed liquid appeared as a purple-red viscous colloid, and placed in a drying oven at 80°C for 12 hours to obtain a precursor powder. Grind the dried mixture into powder, place it in a high-temperature furnace for calcination, and raise the temperature to 500° C. at a rate of 5° C. / min. The holding time is 5 hours. After cooling, drying and grinding, the temperature was raised at a heating rate of 5°C / min, and calcined at 850°C, and the holding time was 10h. After sintering, it was cooled down to room temperature by furnace cooling, and the brown lithium-rich material Li w...

Embodiment 3

[0031] A method for preparing a lithium-rich cathode material with a high specific capacity, comprising dissolving manganese acetate, nickel acetate, cobalt acetate and lithium acetate in ethanol at a stoichiometric ratio of 0.54:0.13:0.13:1.26, and stirring to obtain a uniformly mixed acetate solution . The solution was heated in a water bath at 80°C, and evaporated with electromagnetic stirring until the mixed liquid was viscous in purple, and placed in a drying oven at 80°C for 12 hours to obtain a precursor powder. Grind the dried mixture into powder, place it in a high-temperature furnace for calcination, and raise the temperature to 500° C. at a rate of 5° C. / min. The holding time is 5 hours. After cooling, drying and grinding, the temperature is raised at a heating rate of 5°C / min, and calcined at 900°C, and the holding time is 10h. After sintering, it was cooled down to room temperature by furnace cooling, and the brown lithium-rich material Li was obtained by grindin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| retention rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com