Graphene loaded cobaltous oxide catalyst and preparation method thereof

A cobalt oxide and graphene technology, applied in the field of graphene-supported cobalt oxide catalyst and preparation thereof, can solve problems such as easy deactivation, and achieve the effects of low cost, mild conditions and easy control, and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] A preparation method of graphene supported cobalt oxide catalyst, comprising the following steps:

[0023] Step 1. At room temperature, take cobalt acetate and distilled water according to the mass ratio of 1:20-21; add the taken cobalt acetate into the distilled water, and magnetically stir to make it completely dissolve, so as to prepare an aqueous solution of cobalt acetate, which is set aside;

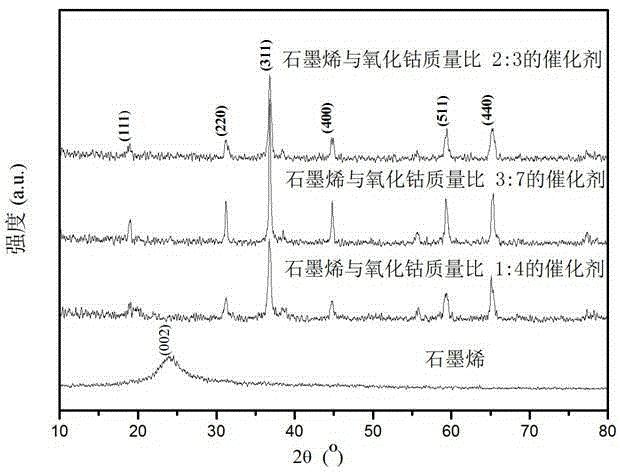

[0024] Step 2, according to the mass fraction of 1.12% graphene oxide aqueous solution, the mass ratio of graphene and the cobalt oxide prepared in the above step 1 is a ratio of 1:4-2:3, and the mass fraction is 1.12% graphite oxide Aqueous solution of graphene oxide; the obtained graphene oxide aqueous solution is added to the distilled water of 3.7-4.6 volumes of distilled water obtained in the above step 1, and placed in an ultrasonic reactor with a power of 168W for 60-120 minutes to obtain diluted graphene oxide aqueous solution, spare;

[0025] Step 3. Mix the prepar...

Embodiment 1

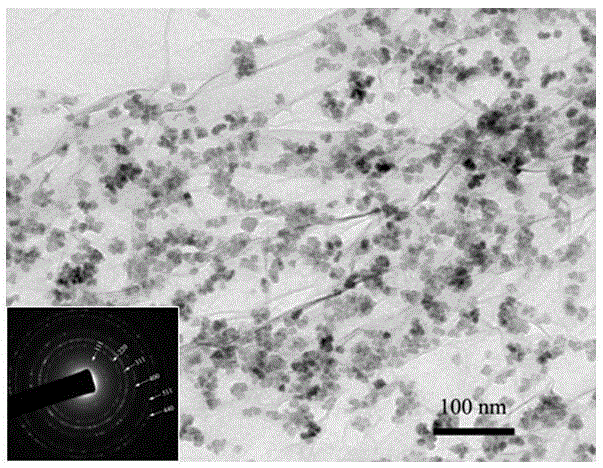

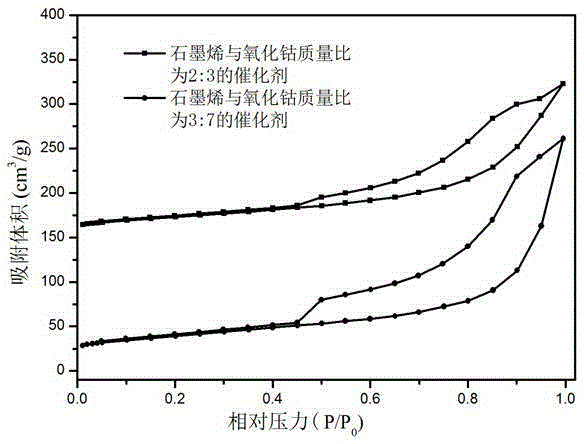

[0030] At room temperature, 2.49 g of cobalt acetate was dissolved in 50 ml of distilled water, and magnetically stirred to completely dissolve it to obtain cobalt acetate aqueous solution I, which was set aside. Take graphene oxide aqueous solution according to the mass ratio of graphene and cobalt oxide in the catalyst being 1:4, add 230 milliliters of distilled water, ultrasonic 20 minutes, obtain graphene oxide aqueous solution II, set aside; Wherein, described graphene oxide Graphite oxide was prepared by an improved Hummers method, and then ultrasonically treated for 60 minutes to obtain an aqueous solution of graphene oxide with a mass percentage of 1.12%. Mix solution I and solution II, stir magnetically for 20 minutes, add 26 ml of ammonia water with a mass percentage of 28% dropwise, and stir magnetically for 120 minutes. Put the mixed solution into a polytetrafluoroethylene-lined autoclave, conduct a hydrothermal reaction at 180°C for 12 hours, and cool to room temp...

Embodiment 2

[0033]At room temperature, 2.49 g of cobalt acetate was dissolved in 50 ml of distilled water, and magnetically stirred to completely dissolve it to obtain cobalt acetate aqueous solution I, which was set aside. Take graphene oxide aqueous solution according to the mass ratio of graphene and cobalt oxide in the catalyst being 3:7, add 215 milliliters of distilled water, ultrasonic 20 minutes, obtain graphene oxide aqueous solution II, standby; Wherein, described graphene oxide Graphite oxide was prepared by an improved Hummers method, and then ultrasonically treated for 60 minutes to obtain an aqueous solution of graphene oxide with a mass percentage of 1.12%. Mix solution I and solution II, stir magnetically for 20 minutes, add 26 ml of ammonia water with a mass percentage of 28% dropwise, and stir magnetically for 120 minutes. Put the mixed solution into a polytetrafluoroethylene-lined autoclave, conduct a hydrothermal reaction at 180°C for 12 hours, and cool to room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com