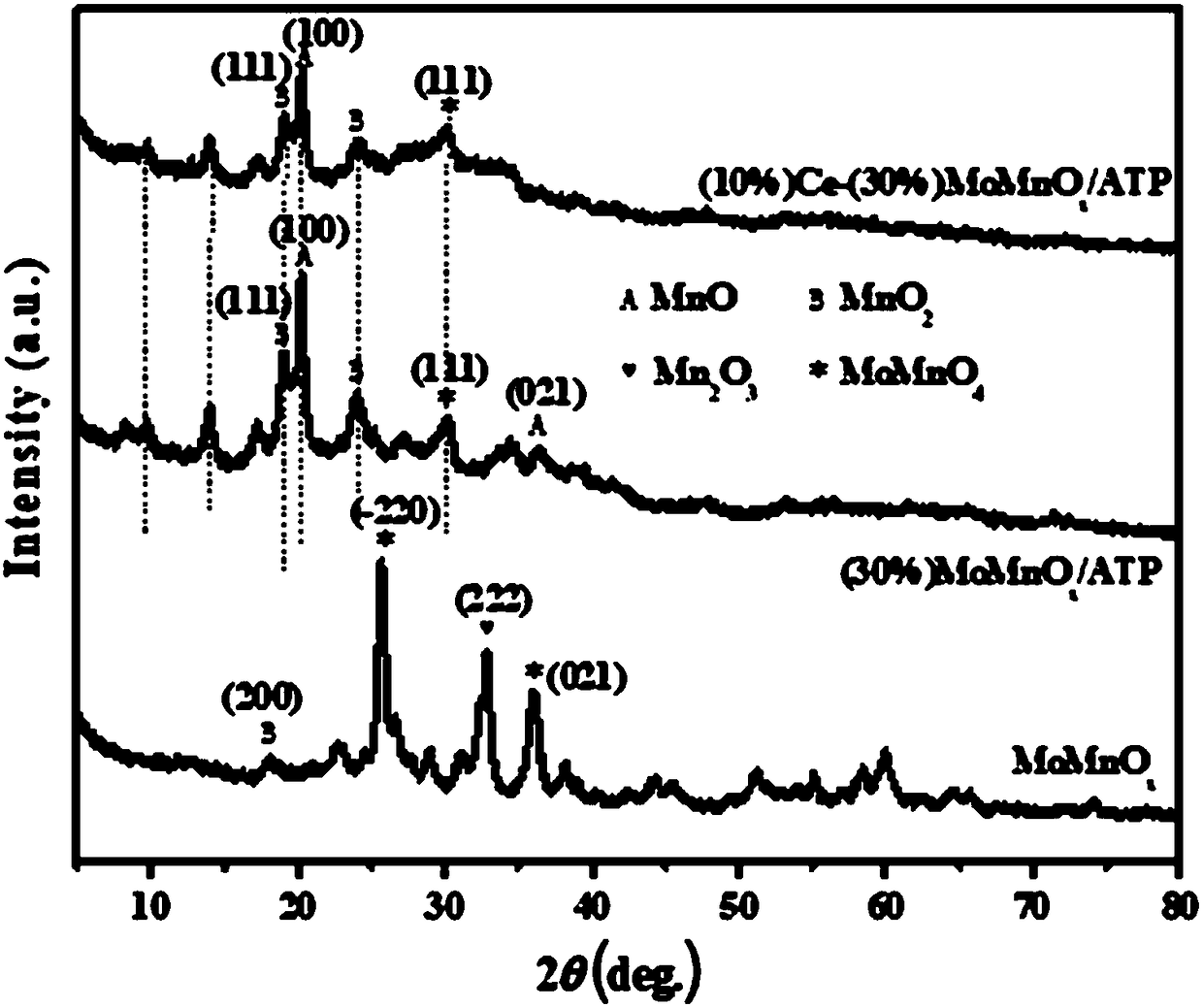

Low-temperature CeO2-modified MnMoOx/attapulgite SCR denitration catalyst

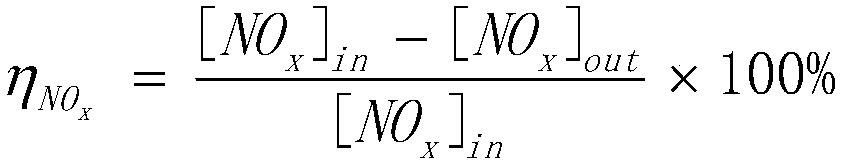

A denitration catalyst and attapulgite technology, which is applied in the field of CeO2 modified MnMoOx/attapulgite low-temperature SCR denitration catalyst, can solve the problems of enhanced redox capacity, narrow denitration activity range, and high denitration reaction temperature, and achieves excellent sulfur resistance performance, The effect of improving denitrification capacity and enhancing denitrification capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

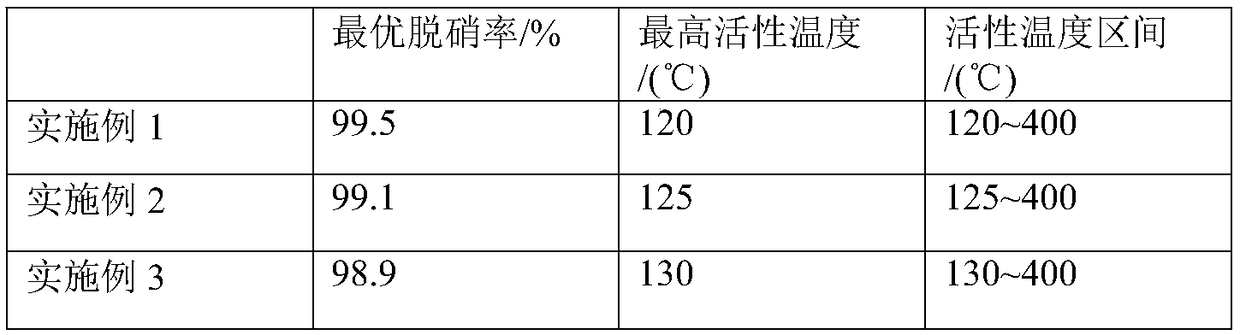

Embodiment 1

[0015] (1) Dissolve 16.3mL of concentrated sulfuric acid in 300mL of distilled water to make a 1mol / L sulfuric acid solution. Then weigh 10g of attapulgite raw material and disperse it in the prepared sulfuric acid solution, ultrasonicate for 1min, transfer the solution to a three-neck flask, stir it mechanically for 4h, wash it to neutral with suction, and dry it in an oven at 110°C for 12h. Grinding and sieving to obtain acidified ATP;

[0016] (2) Weigh 0.3513g of ammonium molybdate tetrahydrate, 1.4255g of 50% manganese nitrate solution, 1.5g of acidified attapulgite in a 500mL beaker, add 300mL of distilled water and transfer it to a 500mL three-necked flask after ultrasonication is completely uniform Add ammonia water dropwise under vigorous stirring conditions to adjust the pH of the solution to 10, then mechanically stir for 24 hours, filter under reduced pressure, wash with distilled water until neutral, dry the filter cake in an oven at 110°C for 12 hours, take it ou...

Embodiment 2

[0020] (1) Dissolve 16.3mL of concentrated sulfuric acid in 300mL of distilled water to make a 1mol / L sulfuric acid solution. Then weigh 10g of attapulgite raw material and disperse it in the prepared sulfuric acid solution, ultrasonicate for 1min, transfer the solution to a three-neck flask, stir it mechanically for 4h, wash it with suction to neutrality, and dry it in an oven at 110°C for 12h. Grinding and sieving to obtain acidified ATP;

[0021] (2) Weigh 0.3513g of ammonium molybdate tetrahydrate, 1.4255g of 50% manganese nitrate solution, 1.5g of acidified attapulgite in a 500mL beaker, add 300mL of distilled water and transfer it to a 500mL three-necked flask after ultrasonication is completely uniform Add ammonia water dropwise under vigorous stirring conditions to adjust the pH of the solution to 10, then mechanically stir for 24 hours, filter under reduced pressure, wash with distilled water until neutral, dry the filter cake in an oven at 110°C for 12 hours, take it...

Embodiment 3

[0024] (1) Dissolve 16.3mL of concentrated sulfuric acid in 300mL of distilled water to make a 1mol / L sulfuric acid solution. Then weigh 10g of attapulgite raw material and disperse it in the prepared sulfuric acid solution, ultrasonicate for 1min, transfer the solution to a three-neck flask, stir it mechanically for 4h, wash it with suction to neutrality, and dry it in an oven at 110°C for 12h. Grinding and sieving to obtain acidified ATP;

[0025] (2) Weigh 0.3513g of ammonium molybdate tetrahydrate, 1.4255g of 50% manganese nitrate solution, 1.5g of acidified attapulgite in a 500mL beaker, add 300mL of distilled water and transfer it to a 500mL three-necked flask after ultrasonication is completely uniform Add ammonia water dropwise under vigorous stirring conditions to adjust the pH of the solution to 10, then mechanically stir for 24 hours, filter under reduced pressure, wash with distilled water until neutral, dry the filter cake in an oven at 110°C for 12 hours, take it...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com