a γ-fe 2 o 3 Nanoparticle-modified nf-mno 2 /atp low temperature denitrification catalyst

A nano-particle, low-temperature denitrification technology, applied in the field of flue gas denitrification, can solve the problems of expensive catalyst carrier, narrow reaction activity range, complicated preparation method, etc., and achieve the effects of abundant reserves, wide temperature range and simple preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

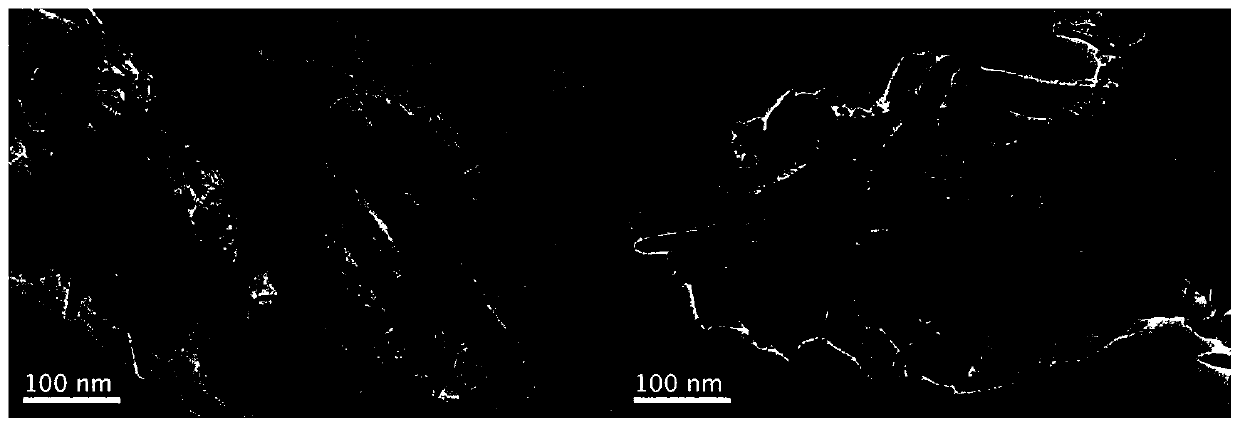

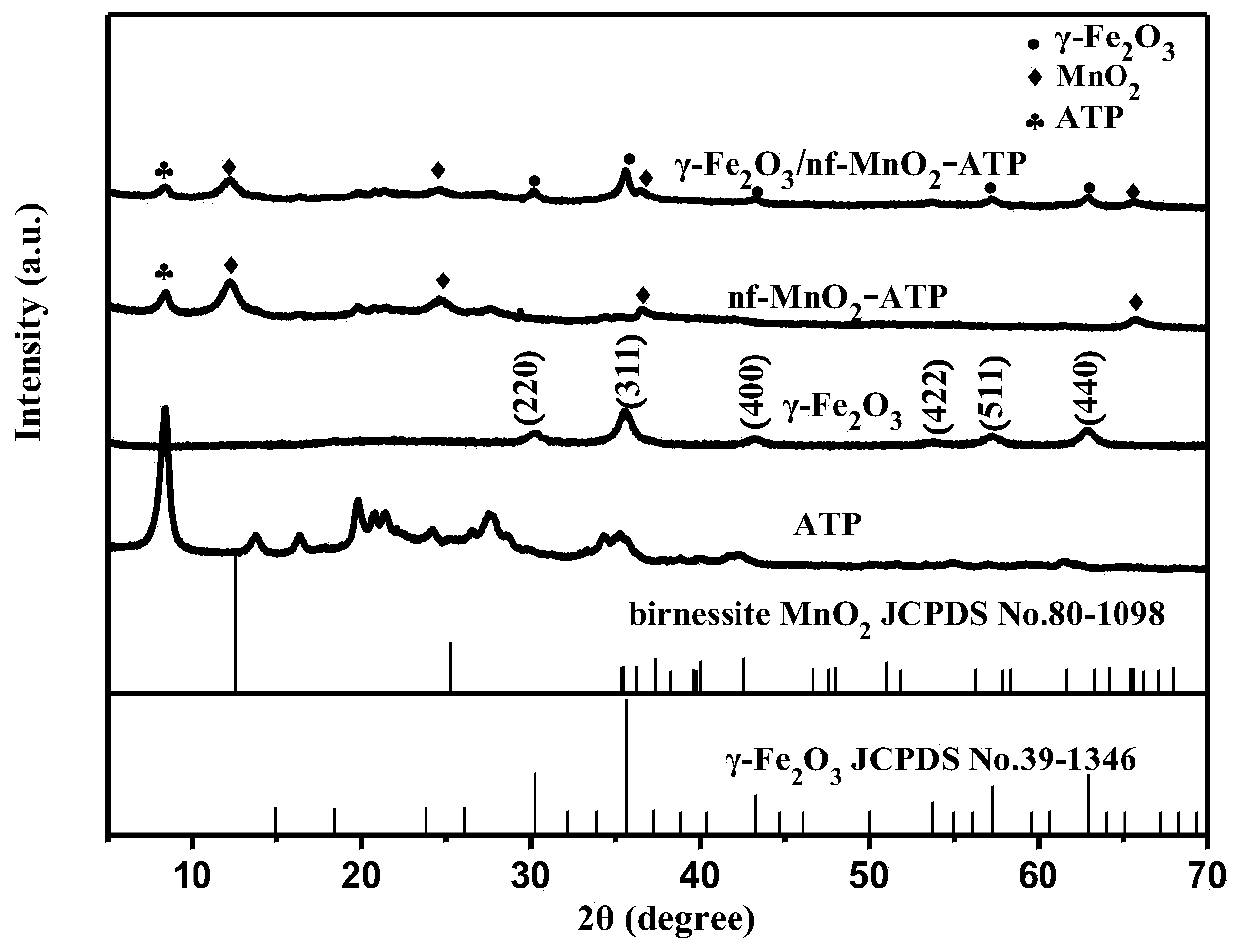

Image

Examples

Embodiment 1

[0017] (1) Attapulgite raw soil is firstly treated with 3mol / mL HNO 3 Under the condition of 80°C water bath, reflux pretreatment was carried out for 3 hours to remove impurities on the surface of the attapulgite raw soil and purify the attapulgite raw soil. After the water bath, filter with suction, wash with deionized water until neutral, and then dry at 80°C for later use. The purified attapulgite clay is abbreviated as (ATP).

[0018] (2) Grind and sieve the above-mentioned dried ATP, then weigh 1g of ATP and dissolve it in 400mL of deionized water, and ultrasonically treat for 30min to dissociate the ATP crystal beams to obtain a uniformly dispersed ATP suspension. Weigh 2gKMnO 4 Dissolve in ATP suspension, continue to sonicate for 20min, make ATP and KMnO 4 well mixed. Then transfer the above solution into a 500mL three-necked flask, add 40mL of glacial acetic acid to adjust the pH to 3, raise the temperature to 78°C, and react for 4h. After the reaction, suction filt...

Embodiment 2

[0023] (1) Attapulgite raw soil is firstly treated with 3mol / mL HNO 3 Under the condition of 80°C water bath, reflux pretreatment was carried out for 3 hours to remove impurities on the surface of the attapulgite raw soil and purify the attapulgite raw soil. After the water bath, filter with suction, wash with deionized water until neutral, and then dry at 80°C for later use. The purified attapulgite clay is abbreviated as (ATP).

[0024] (2) Grind and sieve the above-mentioned dried ATP, then weigh 1g of ATP and dissolve it in 400mL of deionized water, and ultrasonically treat for 30min to dissociate the ATP crystal beams to obtain a uniformly dispersed ATP suspension. Weigh 2gKMnO 4 Dissolve in ATP suspension, continue to sonicate for 20min, make ATP and KMnO 4 well mixed. Then transfer the above solution into a 500mL three-necked flask, add 40mL of glacial acetic acid to adjust the pH to 3, raise the temperature to 78°C, and react for 4h. After the reaction, suction filt...

Embodiment 3

[0026] (1) Attapulgite raw soil is firstly treated with 3mol / mL HNO 3 Under the condition of 80°C water bath, reflux pretreatment was carried out for 3 hours to remove impurities on the surface of the attapulgite raw soil and purify the attapulgite raw soil. After the water bath, filter with suction, wash with deionized water until neutral, and then dry at 80°C for later use. The purified attapulgite clay is abbreviated as (ATP).

[0027] (2) Grind and sieve the above-mentioned dried ATP, then weigh 1g of ATP and dissolve it in 400mL of deionized water, and ultrasonically treat for 30min to dissociate the ATP crystal beams to obtain a uniformly dispersed ATP suspension. Weigh 0.15g FeSO 4 ·7H 2 O and 0.29g FeCl 3 ·6H 2 O was dissolved in the ATP suspension, and continued to sonicate for 20 minutes to mix the ATP and the solution evenly. Then transfer the above solution into a 500mL three-necked flask, heat up to 90°C for reflux reaction in a water bath, during the reactio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com