Method for starting A2N two-stage SBR denitrifying phosphorus removal

A denitrification phosphorus removal and nitrification sludge technology, applied in the field of urban sewage treatment and resource utilization, can solve the problems of difficult enrichment of denitrification phosphorus-accumulating bacteria, increase process complexity and cost, and be unfavorable for engineering applications, etc., to achieve Good water discharge effect, convenient engineering application, fast start-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

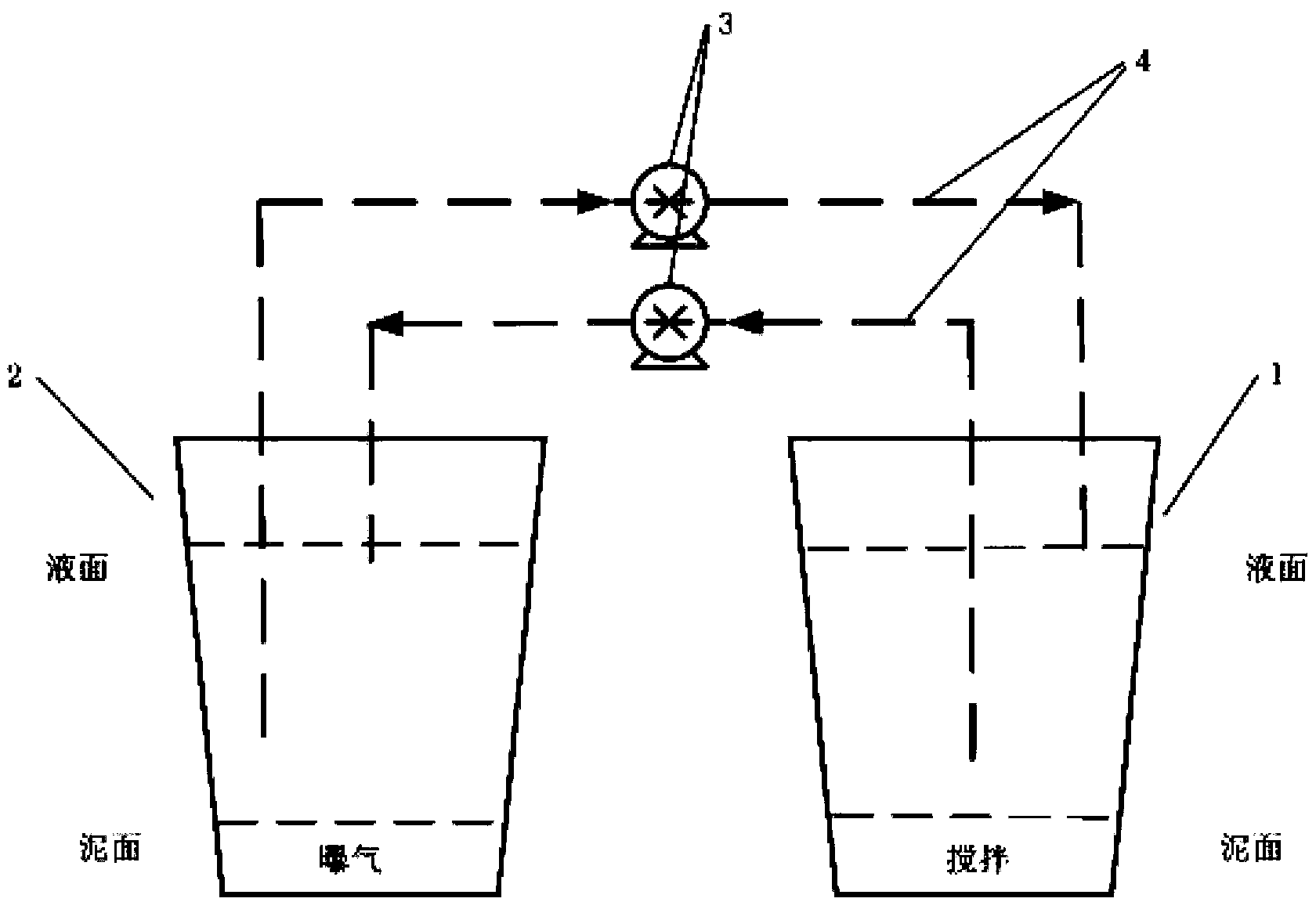

[0016] Example 1 The reactor form is two SBR reactors with an effective volume of 60L. The first SBR reactor is operated with stirring, and the second SBR reactor is operated with aeration. figure 1 . The reaction temperature is room temperature (20~25°C). First, the activated sludge retrieved from the sewage plant is inoculated in the first SBR reactor. The initial phosphorus removal rate of the sludge is only 10%. ——Aerobic intermittent mode operation: water intake—anaerobic—aerobic—sedimentation—drainage, anaerobic time is controlled at 3~5 hours, DO is less than 0.2mg / L, and aerobic time is controlled at 4~6 hours, DO is controlled at 2~3mg / L, and the precipitation time is 0.5~1 hour. After 15 days of continuous operation in this way, the phosphorus removal rate is stable at 75% to 90%. It is believed that a mature aerobic phosphorus removal sludge has been obtained. Due to the actual domestic sewage operation, more nitrite nitrogen has accumulated. The absorption of pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com