Patents

Literature

109 results about "Fe2o3 nanoparticles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

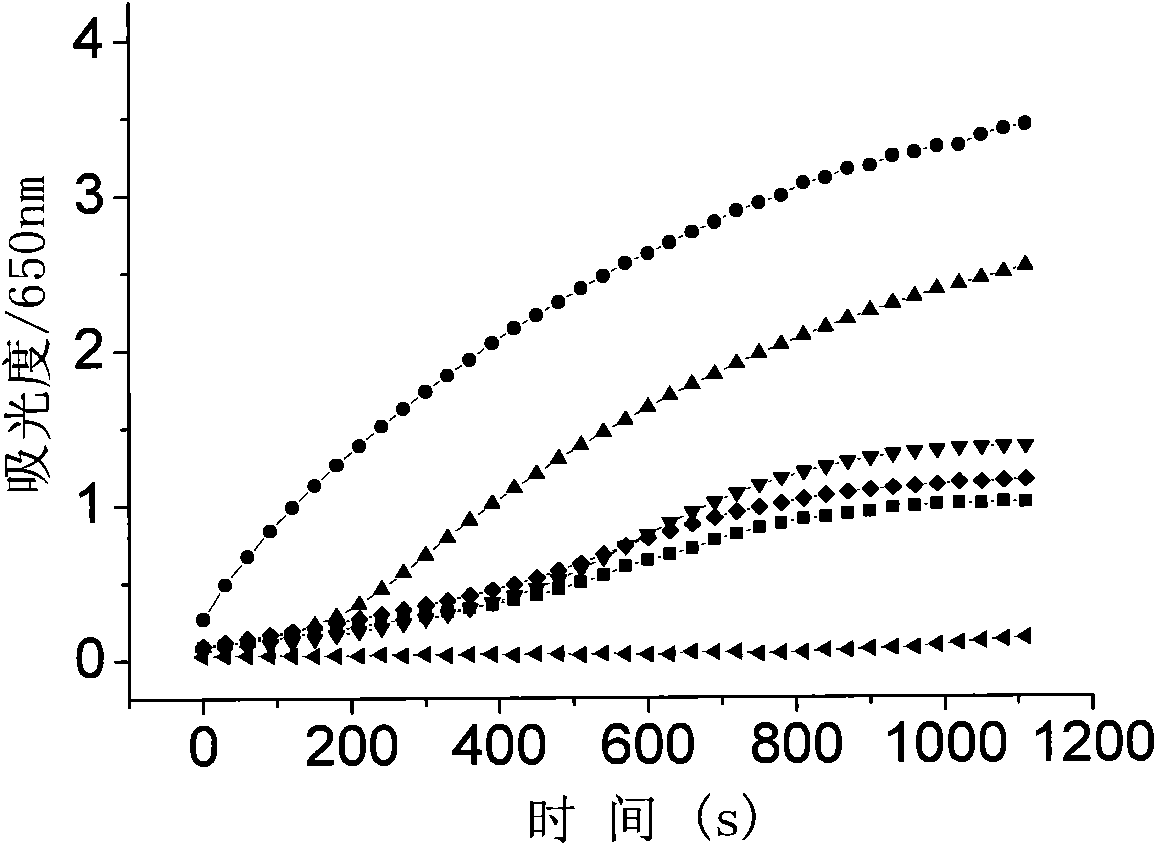

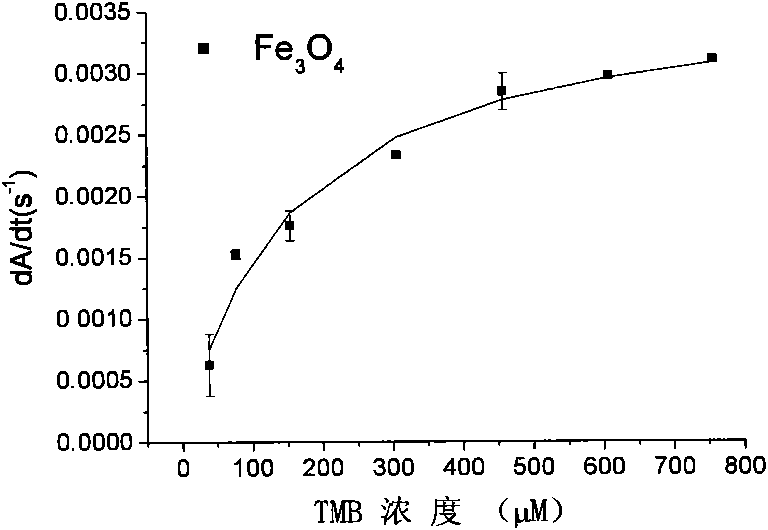

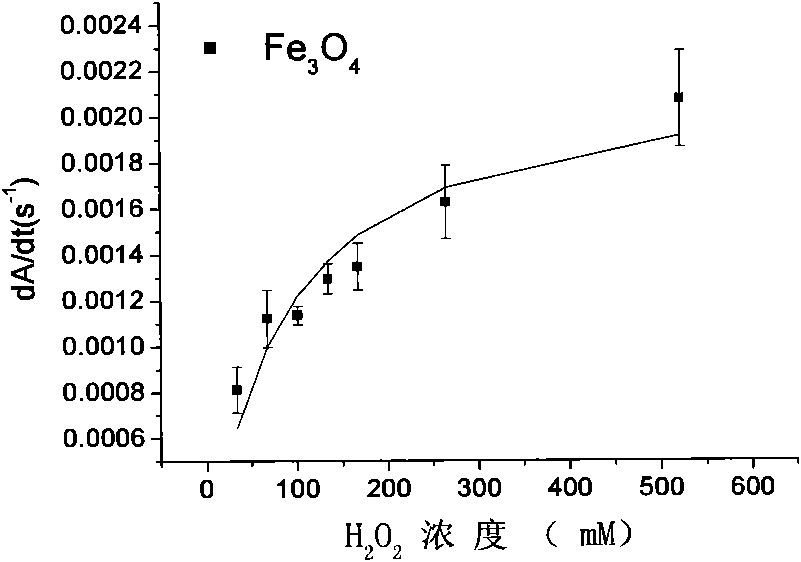

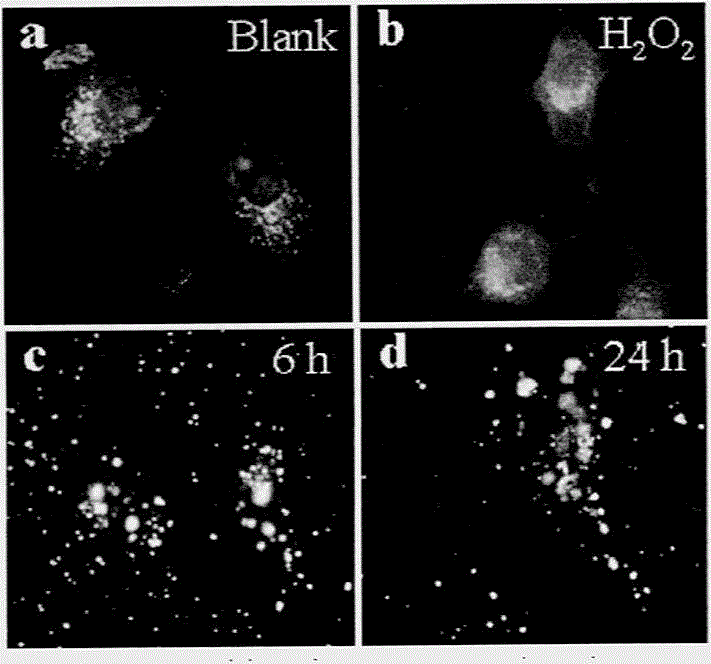

Method for applying magnetic gamma-Fe2O3 nano-particle mimetic enzyme to biological detection

InactiveCN101672771AImprove stabilityGood biocompatibilityMaterial analysis by observing effect on chemical indicatorColor/spectral properties measurementsHorse radish peroxidaseHydrogen supply

The invention relates to a magnetic gamma-Fe2O3 nano-particle mimetic enzyme and provides a method for applying a magnetic gamma-Fe2O3 nano-particle mimetic enzyme to biological detection. The magnetic gamma-Fe2O3 nano-particle mimetic enzyme replaces a horse radish peroxidase (HRP) to be used in biological detection. The method comprises the following steps: coupling carboxyl groups on the surface of magnetic gamma-Fe2O3 nano-particles and a specific molecular probe to construct a specific nano probe; combining the nano probe with the specificity of the corresponding target molecules to be detected; developing by using a developer containing peroxides and hydrogen-supply zymolytes; and measuring the absorbency or carrying out the micro-observation so as to realize the qualitative and quantitative detection on target molecules.

Owner:SOUTHEAST UNIV

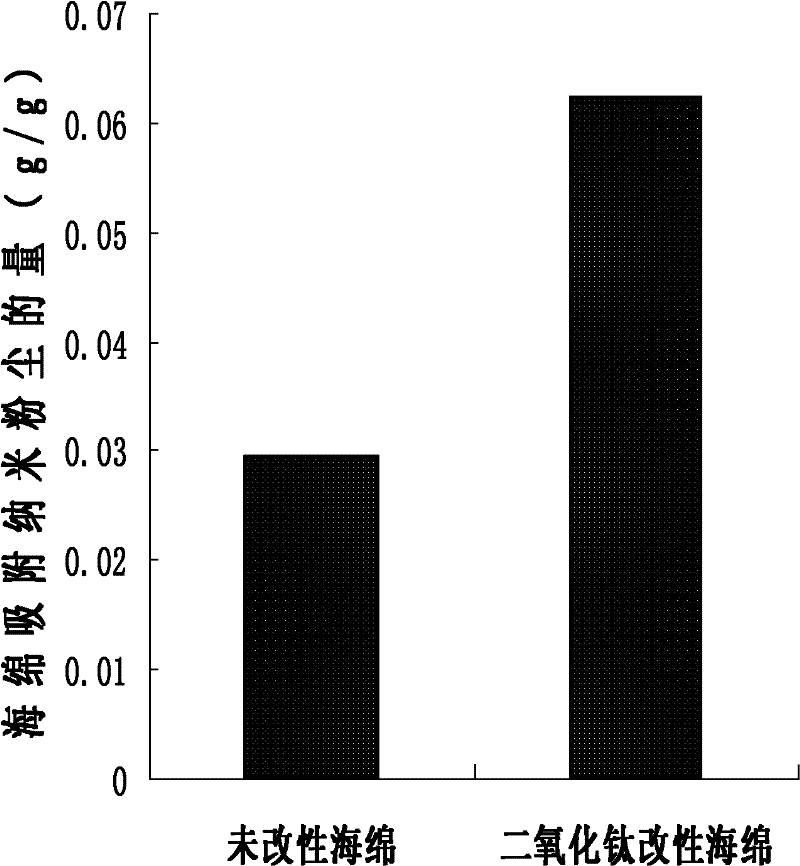

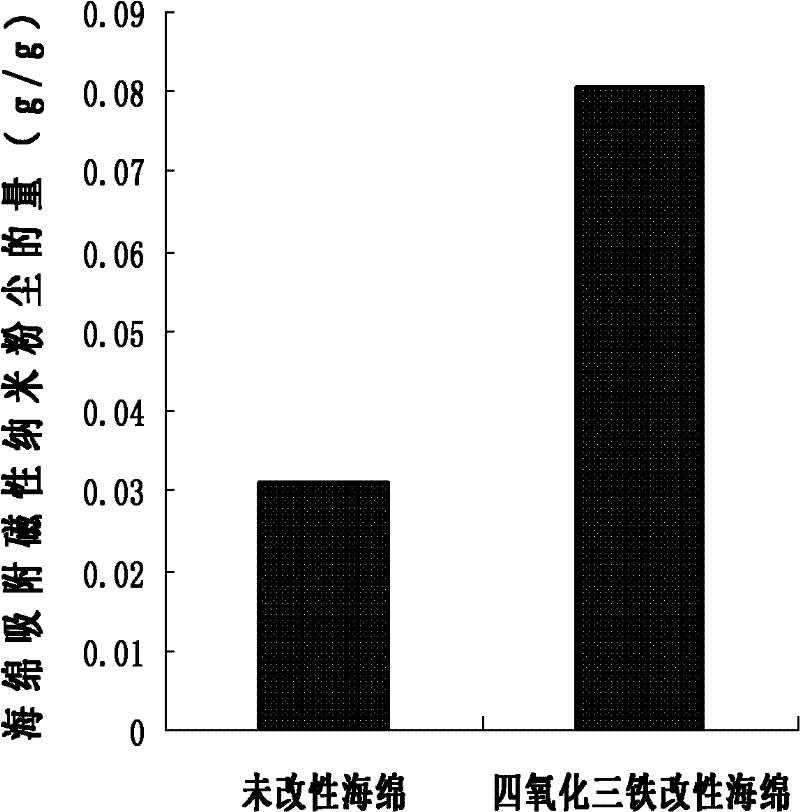

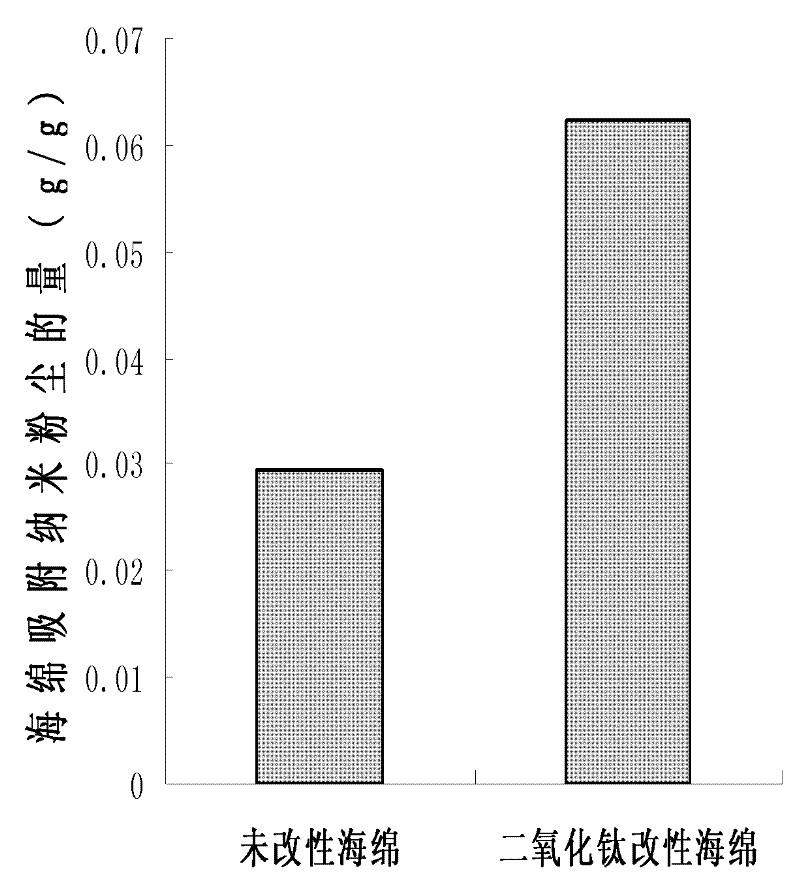

Inorganic nanoparticles-modified polyurethane sponge mask material, and preparation method and application thereof

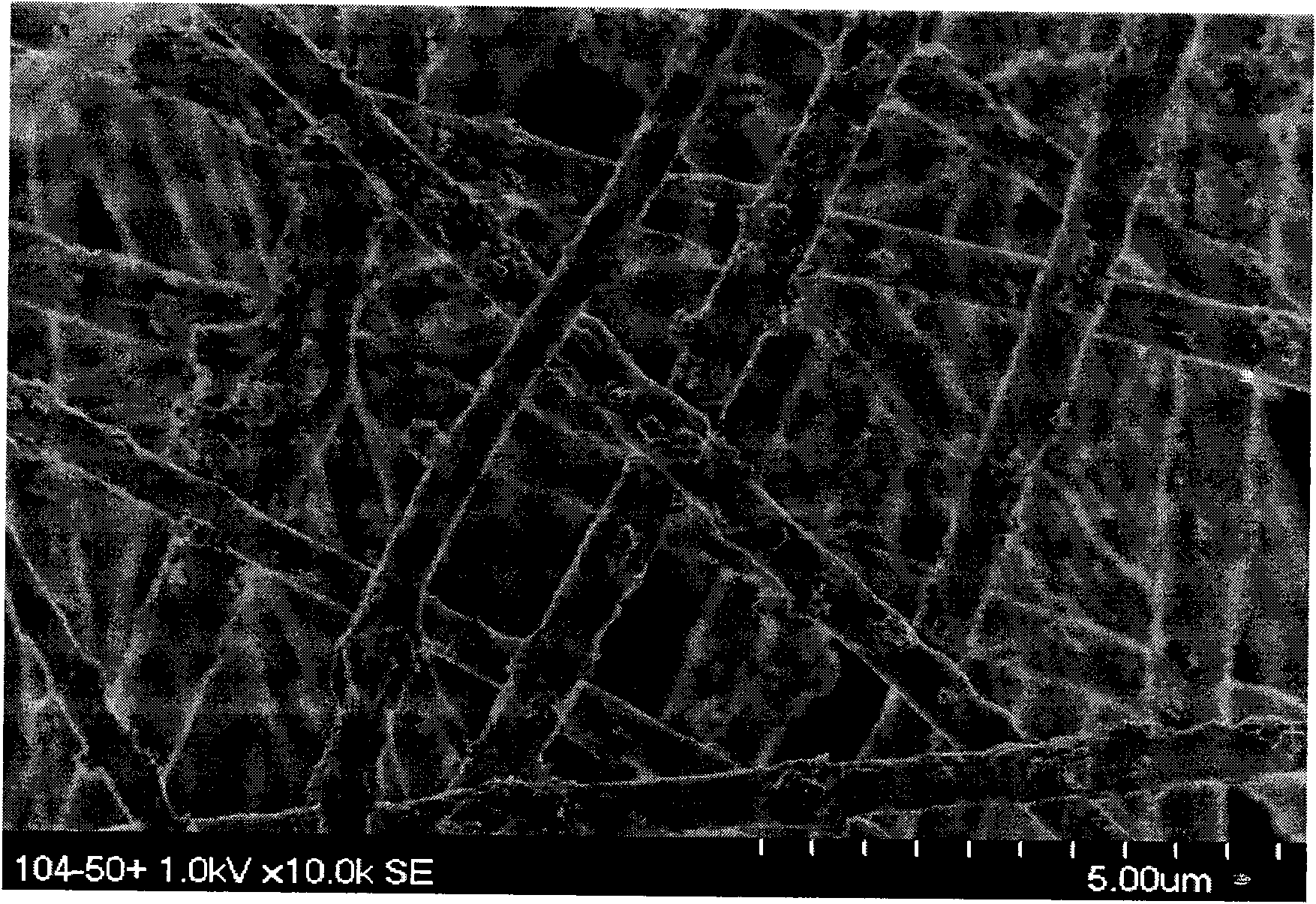

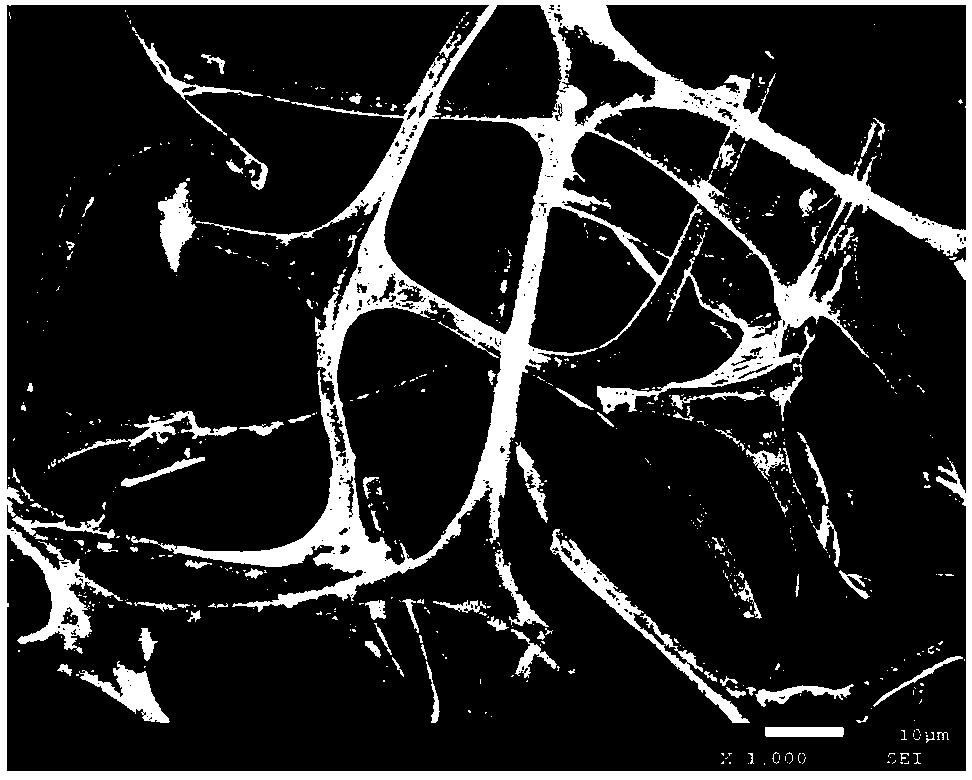

InactiveCN102190882ARegular 3D network structureRegular three-dimensional network structure, poresProtective garmentFiberCarbon fibers

The invention provides an inorganic nanoparticles-modified polyurethane sponge mask material and a preparation method thereof, and also provides application of the inorganic nanoparticles-modified polyurethane sponge mask material in manufacturing a mask. In the invention, the inorganic nanoparticles used for modifying sponge comprise magnetic Fe3O4 nanoparticles, magnetic Fe2O3 nanoparticles, TiO2 nanoparticles, ZnO nanoparticles, mesoporous SiO2, carbon nanotubes and carbon fibers. The inorganic nanoparticles have the advantages of small particle size, large specific surface area, strong adsorption performance and like and contain charges on the surfaces, and a plurality of the nanoparticles have strong ultraviolet absorption capability, photocatalytic activity, and antibacterial and antiviral actions. The inorganic nanoparticles-modified polyurethane sponge mask material provided by the invention has high efficiency and capability in filtering out sub-micron dust, viruses and bacteria, has the function of adsorbing poisonous and harmful gases, has the characteristics of small gas absorption resistance, simple preparation method, low cost and broad application future, and can be recycled through water washing.

Owner:HUAZHONG UNIV OF SCI & TECH

Fe2O3 micro-nano porous sphere, preparation method thereof and uses thereof

InactiveCN102616861ALarge specific surface areaImprove thermal stabilityWater/sewage treatment by irradiationOther chemical processesMicro nanoOrganic dye

The invention discloses a Fe2O3 micro-nano porous sphere, a preparation method thereof and uses thereof. The porous sphere is formed by Fe2O3 nanoparticles having a nanometer mesoporous alpha-Fe2O3 phase structure therebetween, wherein the diameter of the sphere is 500-5000nm, the specific surface area of the sphere is 15-25m<2> / g, particle sizes of the particles are 20-60nm, and pore diameters of mesopores are 2-50nm. The method comprises the following steps: mixing ferric chloride hexahydrate, ascorbic acid, urea and water, and uniformly stirring them to obtain a mixed liquid; reacting the mixed liquid under conditions that the temperature is 140-180DEG C and the pressure is a self-generated pressure for at least 4h to obtain an intermediate product; separating, washing and drying the intermediate product to obtain porous iron carbonate; and annealing the porous iron carbonate at 450-550DEG C for at least 4h, and naturally cooling the porous iron carbonate to room temperature to prepare the Fe2O3 micro-nano porous sphere. The Fe2O3 micro-nano porous sphere can be placed in water polluted by organic dyes to photocatalytically degrade under visible light, or in water polluted by potassium dichromate to adsorb.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

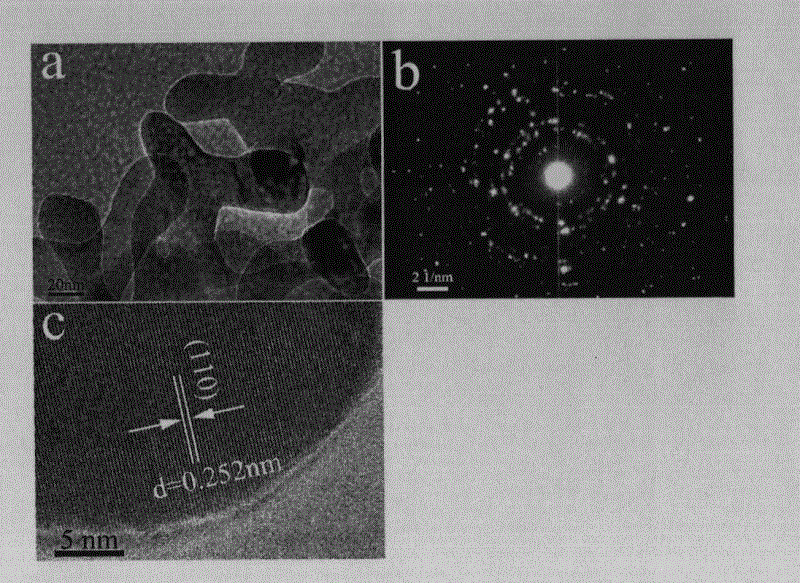

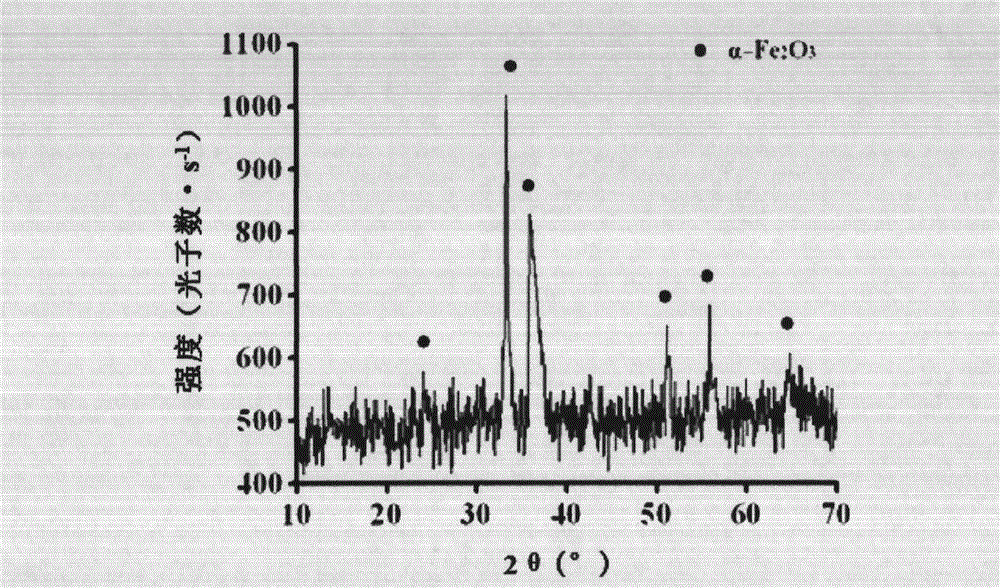

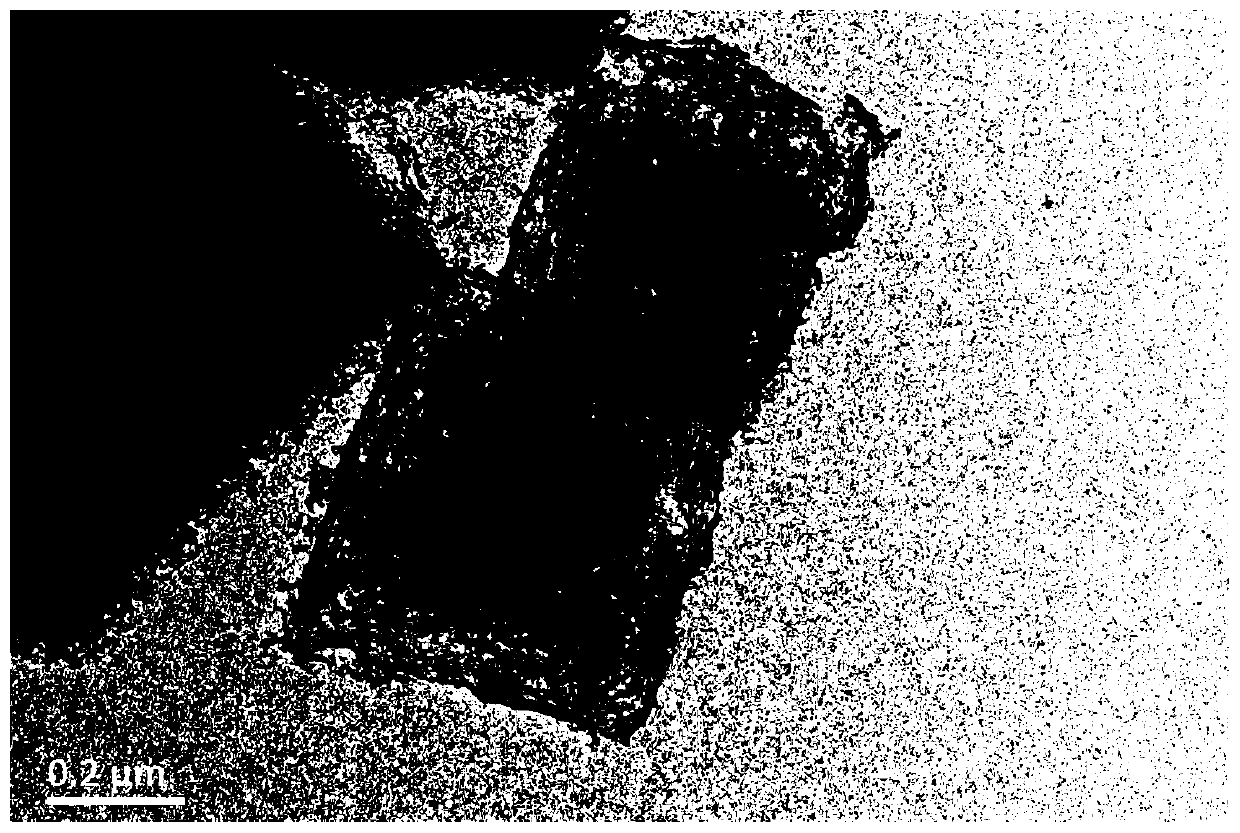

Method for preparing nano-particles of magnetic ferric oxide

InactiveCN1789146AEasy to manufactureReduce manufacturing costFerric oxidesInorganic saltsIron oxide

The invention relates to a method for preparing magnetic ferric oxide nano particle, belonging to the technological field for preparing inorganic non-metal magnetic nano material. The invention prepares ª†-Fe2O3 nano particle in stick shape and cubicalª†-Fe2O3 nano particle with the grain size being 20 nm under lower temperature by using the action of particular organic additive and inorganic salt and employing ferric iron salt as raw material without the oxidation-reduction course. The invention is characterized by simple process and easy to control the particle shape.

Owner:EAST CHINA NORMAL UNIV

Magnetic composite material and application thereof in regeneration and repair of bone tissues

ActiveCN102049066AHas superparamagnetic propertiesGood biocompatibilityTissue regenerationProsthesisHydroxybutyric acidPolyamide

The invention discloses a magnetic composite material and an application thereof in regeneration and repair of bone tissues, as well as a method for preparing the magnetic composite material and a product prepared by the magnetic composite material, wherein the magnetic composite material comprises the following components: a) 10-50g of polymer material calculated by 100ml of organic solvent, wherein the polymer material is selected from polylactic acid, polyglycolic acid, lactic acid-glycolic acid copolymer, polycaprolactone, polyamide or poly-hydroxybutyric acid; b) 10g of hydroxyapatite nano-particles calculated by 100ml of the organic solvent; and c) 2.5g of gamma-Fe2O3 nano-particles calculated by 100ml of organic solvent, wherein the organic solvent is selected from tetrahydrofuran (THF), dimethylformamide (DMF), dimethylacetamide (DMAc), chloroform or dioxane.

Owner:THE INST OF BASIC MEDICAL SCI OF CHINESE ACAD OF MEDICAL SCI

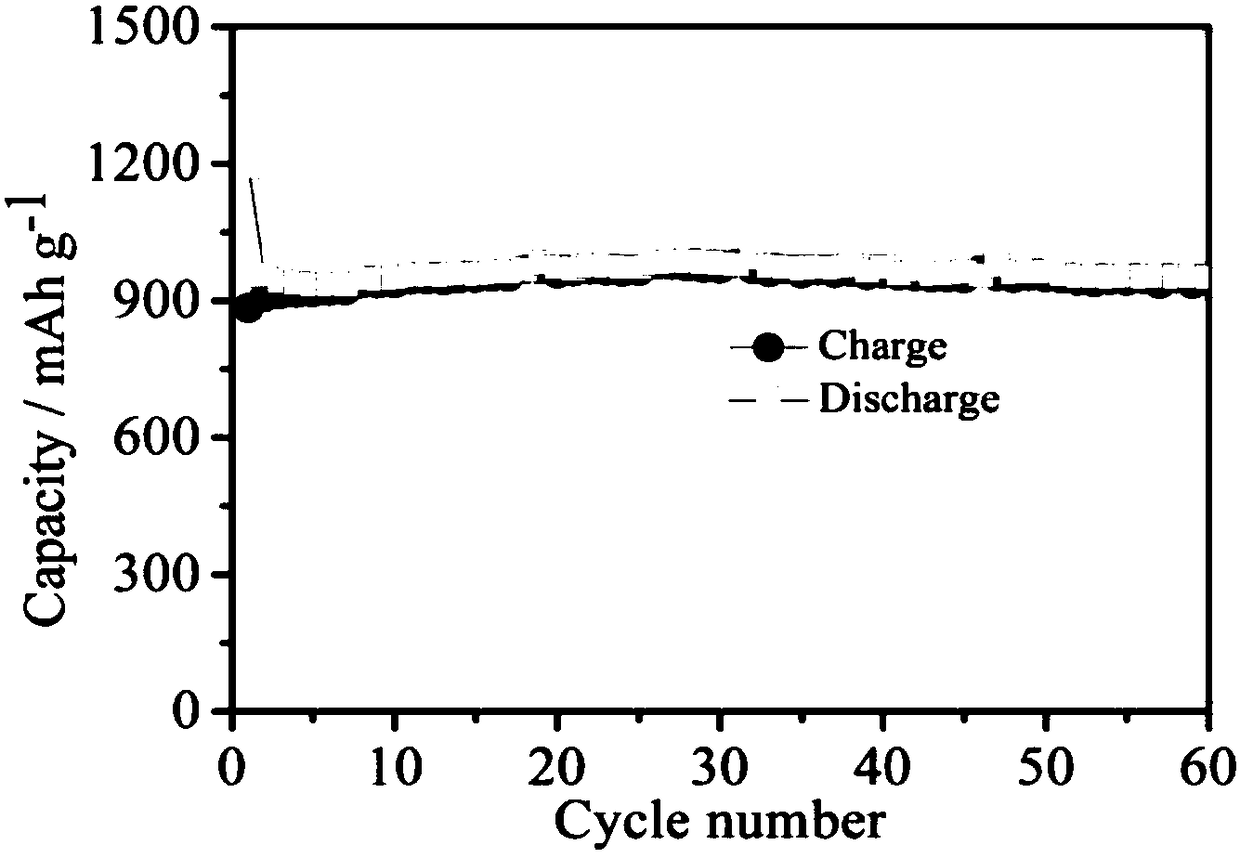

Preparation method and application of carbon-coated Fe3O4 nanoparticle lithium ion battery negative electrode material

InactiveCN104993126AHighlight substantiveSuitable for large-scale productionCell electrodesSecondary cellsCarbon coatedCalcination

The invention relates to a preparation method and an application of a carbon-coated Fe3O4 nanoparticle lithium ion battery negative electrode material, and relates to an electrode used in a lithium storage battery and formed based on an oxide active material; the preparation method is a method for preparing the carbon-coated Fe3O4 nanoparticle lithium ion battery negative electrode material by a hydrothermal method and a high temperature calcination process and comprises the steps: preparation of precursor carbon-coated Fe2O3 nanoparticles, preparation of a carbon-coated Fe3O4 nanoparticle powder, and preparation of the carbon-coated Fe3O4 nanoparticle lithium ion battery negative electrode material. The carbon-coated Fe3O4 nanoparticle lithium ion battery negative electrode material is applied as a lithium ion battery negative electrode piece for assembly of a semi-battery. The defects that carbon-coated Fe3O4 nanoparticles prepared in the prior art have larger particle size, the microtopography and the structure are difficult to control, a lithium ion battery negative electrode material prepared by the carbon-coated Fe3O4 nanoparticles has not good electrochemical performance, the preparation process is complex and the production cost is high are overcome.

Owner:HEBEI UNIV OF TECH

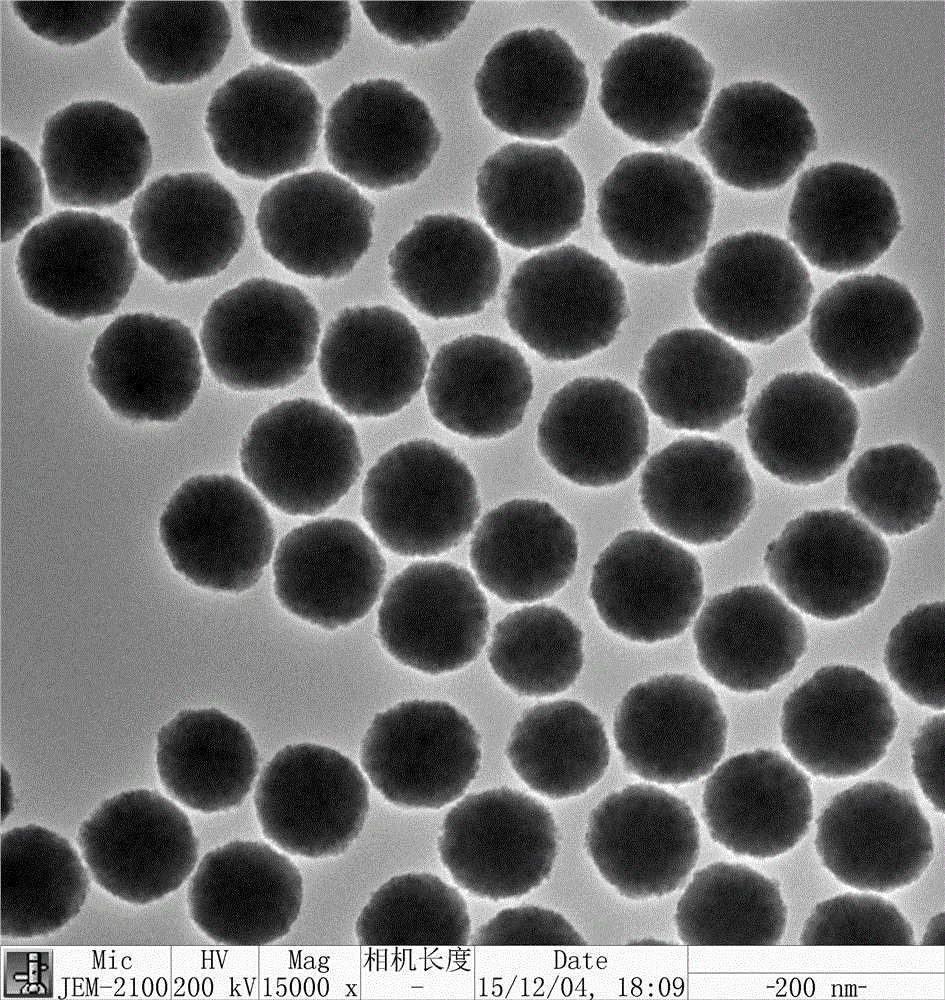

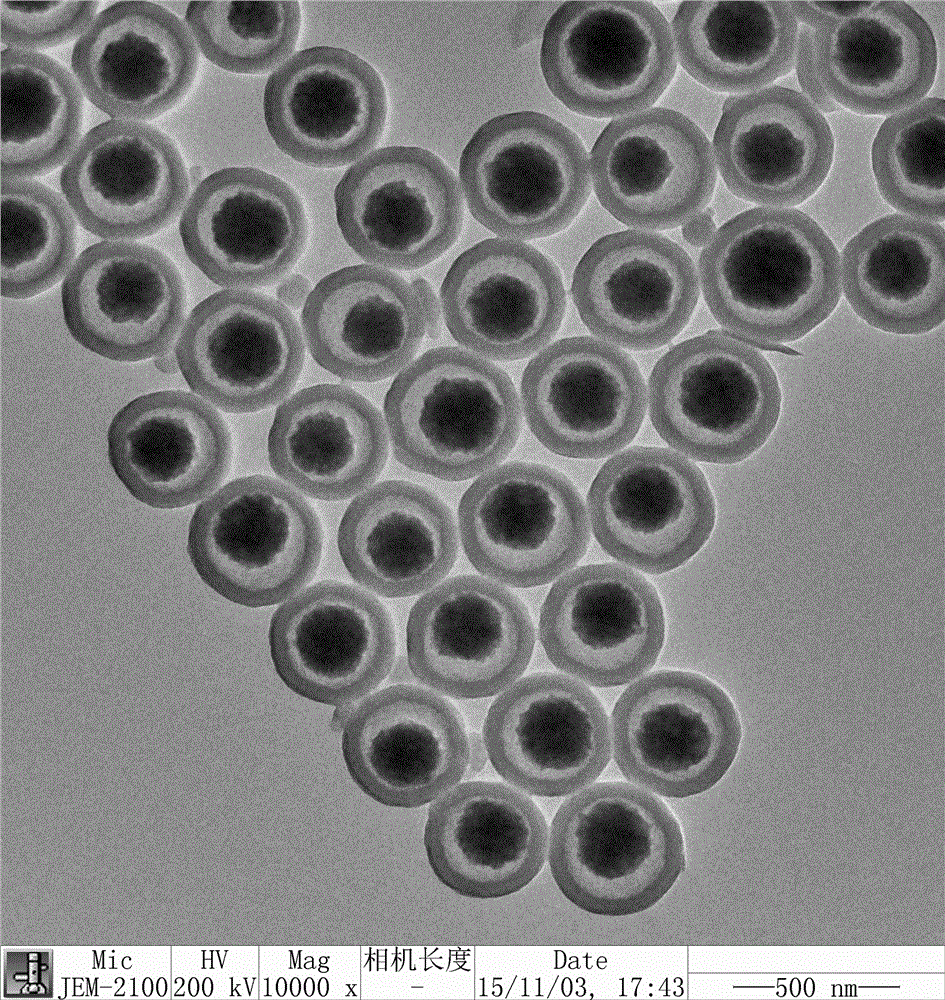

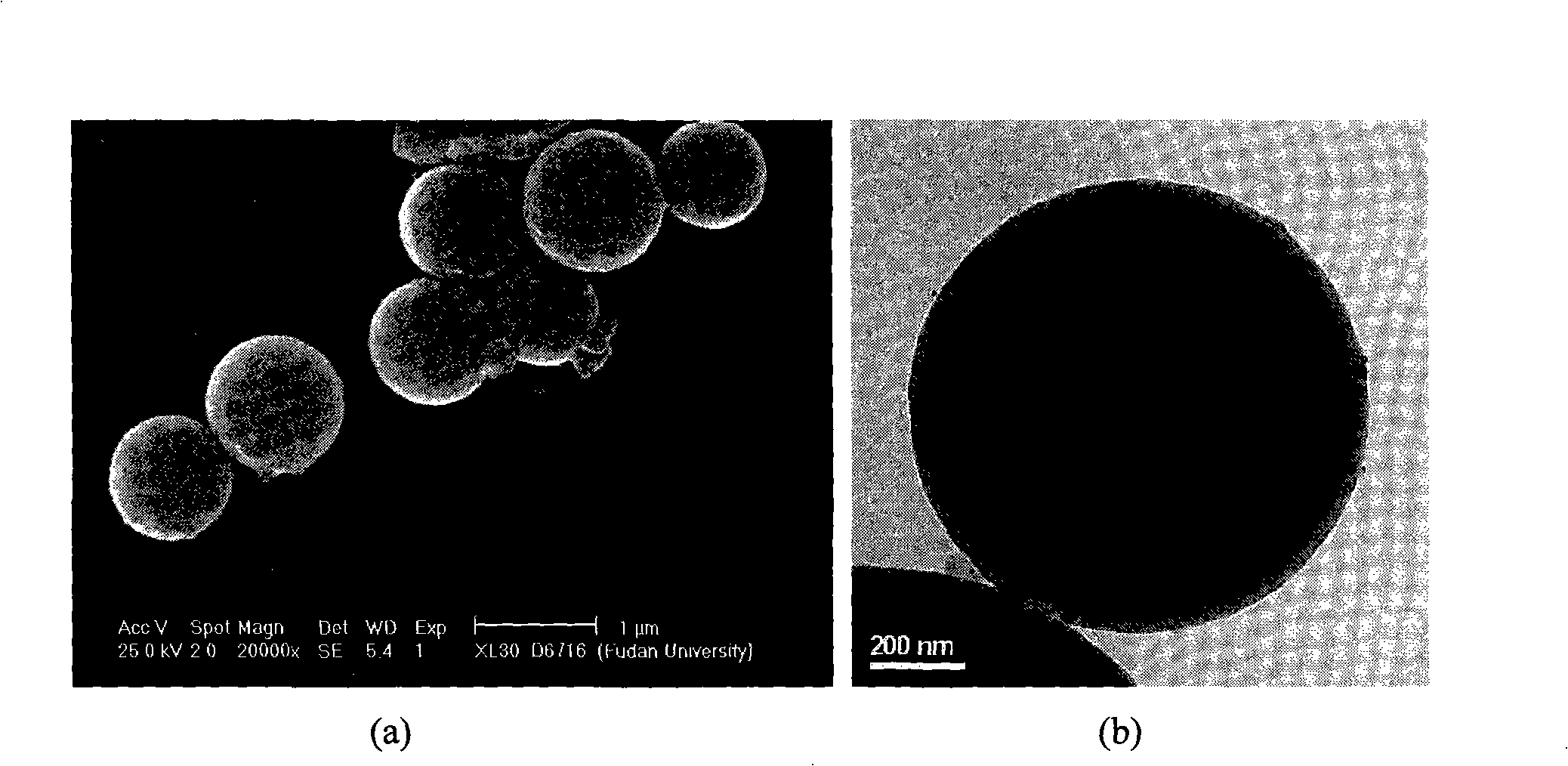

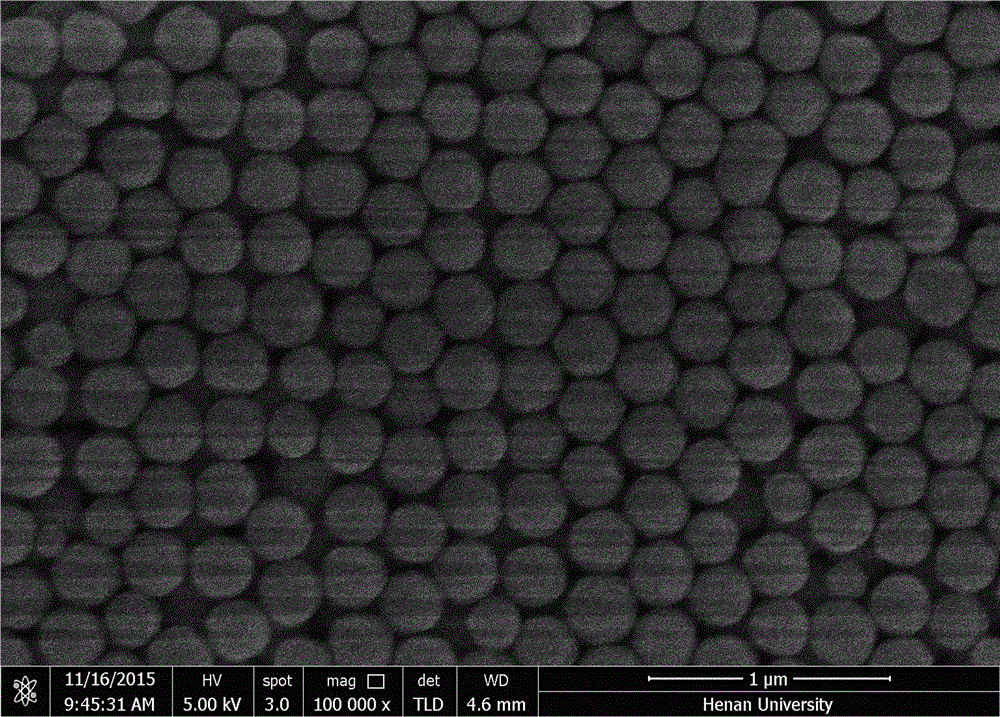

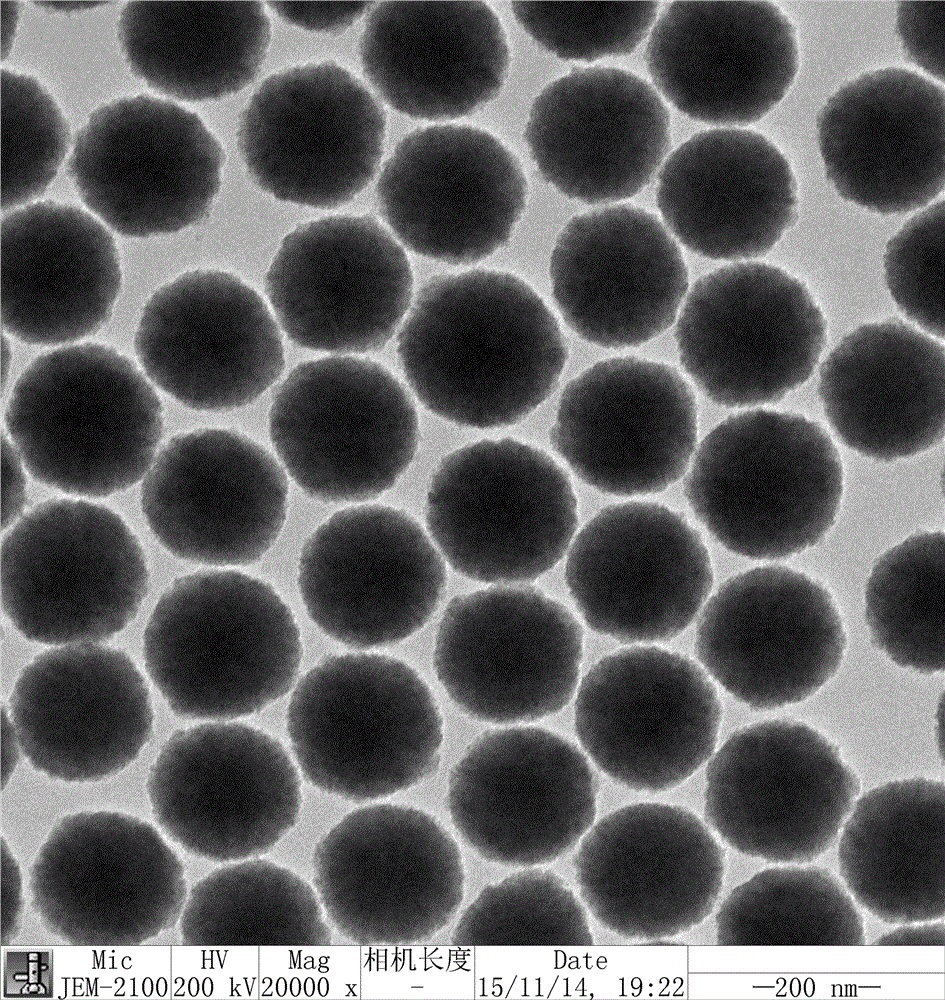

Preparation method and application of Fe3O4@SiO2 yolk-eggshell-structured hollow composite microsphere

InactiveCN105832699AGuarantee a high degree of decentralizationGood monodispersityOrganic active ingredientsMaterial nanotechnologyDrug release rateYolk

The invention provides a preparation method and application of a Fe3O4@SiO2 yolk-eggshell-structured hollow composite microsphere. The preparation method comprises the following steps: preparing Fe2O3 nanoparticles by using a solvothermal method; under the condition that no surfactant is added and TEOS is used as a silicon source, preparing a Fe3O4@SiO2 composite microsphere with controllable morphology under mild conditions by using a combination of a template method and a hydrothermal method; corroding the Fe3O4@SiO2 composite microsphere with hydrochloric acid with a certain concentration so as to obtain a Fe3O4@SiO2 yolk-eggshell-structured hollow composite microsphere; and carrying out reduction so as to prepare the Fe3O4@SiO2 yolk-eggshell-structured hollow composite microsphere with superparamagnetism. The prepared Fe3O4@SiO2 yolk-eggshell-structured hollow composite microsphere has a specific surface area of 173 m<2> / g and drug loading capacity of 139 mg / g; and with doxorubicin hydrochloride as a drug model, the Fe3O4@SiO2 yolk-eggshell-structured hollow composite microsphere has a drug release rate of as high as 68.4% within 72 h in a PBS buffer solution with a pH value of 7.4, so the composite microsphere presents good slow drug release performance.

Owner:HENAN UNIVERSITY

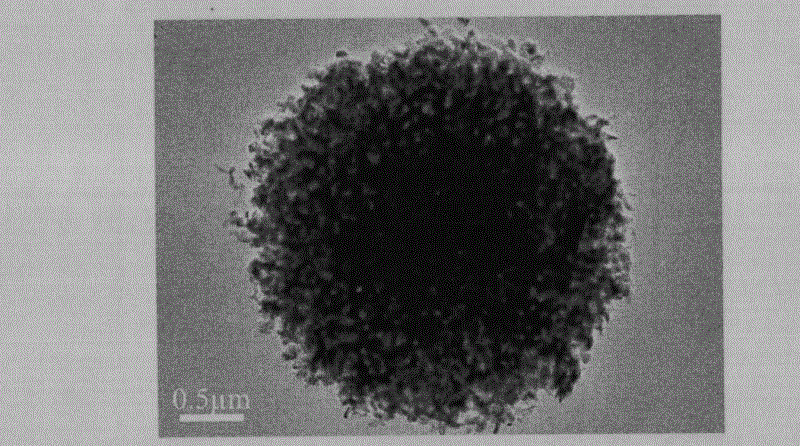

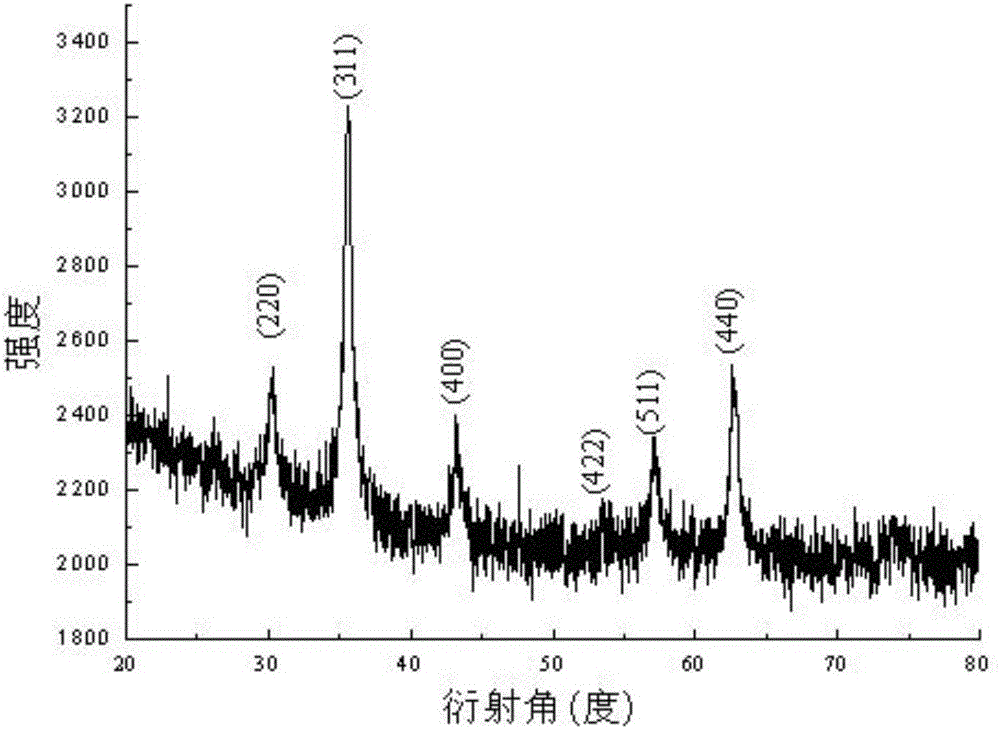

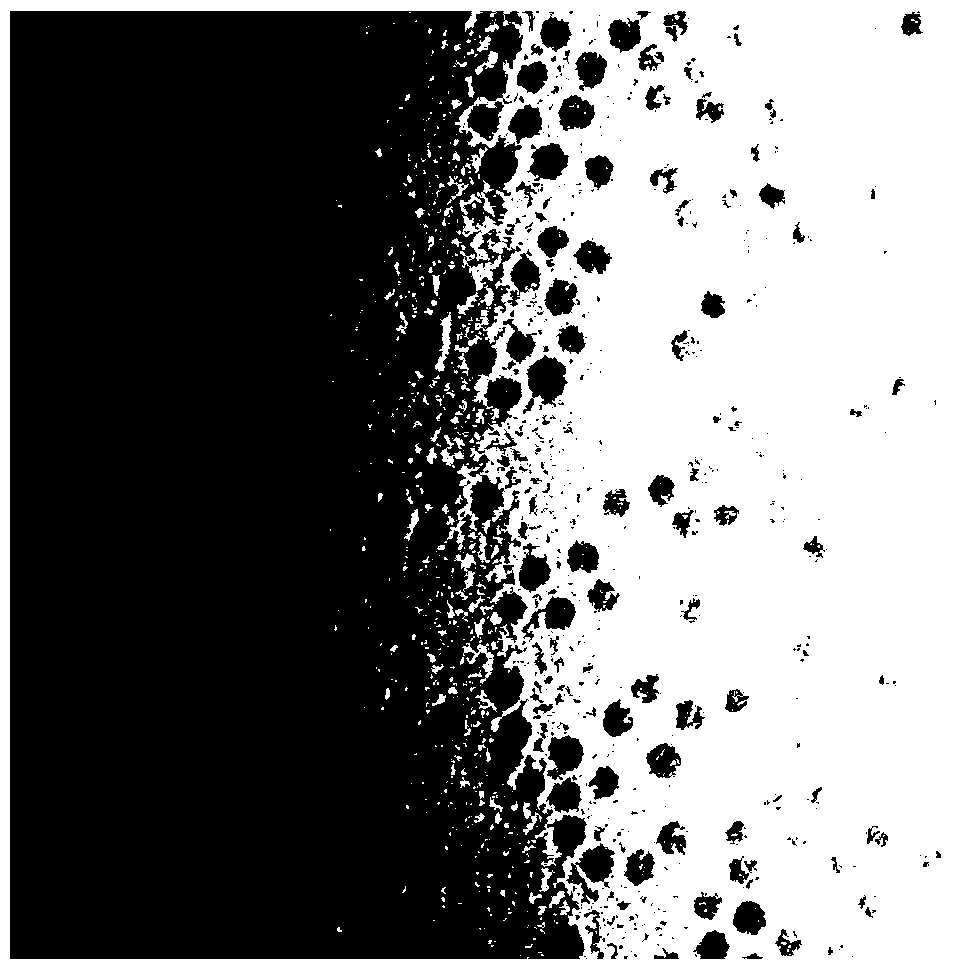

Gamma-Fe2O3/SiO2 nano-grade composite material preparation method, and nano-grade composite material particles

InactiveCN103316614AAgglomerated into largeStrong magnetic reaction effectInorganic material magnetismFerric oxidesCatalytic oxidationFe2o3 nanoparticles

The invention discloses a gamma-Fe2O3 / SiO2 nano-grade composite material preparation method, and nano-grade composite material particles. The method comprises the steps that: a mixed liquid of octadecenoic acid and octyl ether with a volume ratio of 1:6-15 is heated; a Fe(CO)5 octyl ether solution is added, wherein a molar ratio of Fe(CO)5 to octadecenoic acid is 0.03-0.3:1; the mixture is heated, and a reaction is carried out, such that Fe2O3 nano-grade particles are obtained; the particles are dispersed in cyclohexane; gamma-Fe2O3 nano-grade particles dispersed in cyclohexane are mixed with a sodium dodecyl sulfate water solution and cyclohexane; an ultrasonic treatment is carried out, such that gamma-Fe2O3 clusters are assembled; the clusters are dispersed in a water phase; the dispersed gamma-Fe2O3 clusters are dissolved in a mixed solution of deionized water, ammonia water, and anhydrous ethanol; and tetraethyl orthosilicate is added, such that the gamma-Fe2O3 / SiO2 nano-grade composite material is obtained. A molar ratio of tetraethyl orthosilicate to Fe(CO)5 is 3-10:1. The gamma-Fe2O3 / SiO2 nano-grade composite material particles provided by the invention have kiwi shapes, and have strong magnetism response and fast solid-liquid separation effect. Therefore, a magnetic separation material can be provided in fields such as water treatment, catalytic oxidation, and the like.

Owner:ZHEJIANG UNIV

Ferromagnetic multiporous silica gel microsphere and its preparation method

InactiveCN1480251ALarge specific surface areaHigh porosityGranulation by liquid drop formationInorganic material magnetismMicrosphereSuperparamagnetism

A ferromagnetic porous silica gel microsphere with 100-450 sq.m / g is composed of microspheric SiO2 particles as basic material and superparamagnetic Fe2O3 nanoparticles dispersed in said basic material. Its preparing process includes preparing Fe2O3 sol, preparing Fe2O3 / SiO2 sol, preparing composite microspheres, and preparing magnetic porous silica gel.

Owner:TIANJIN UNIV

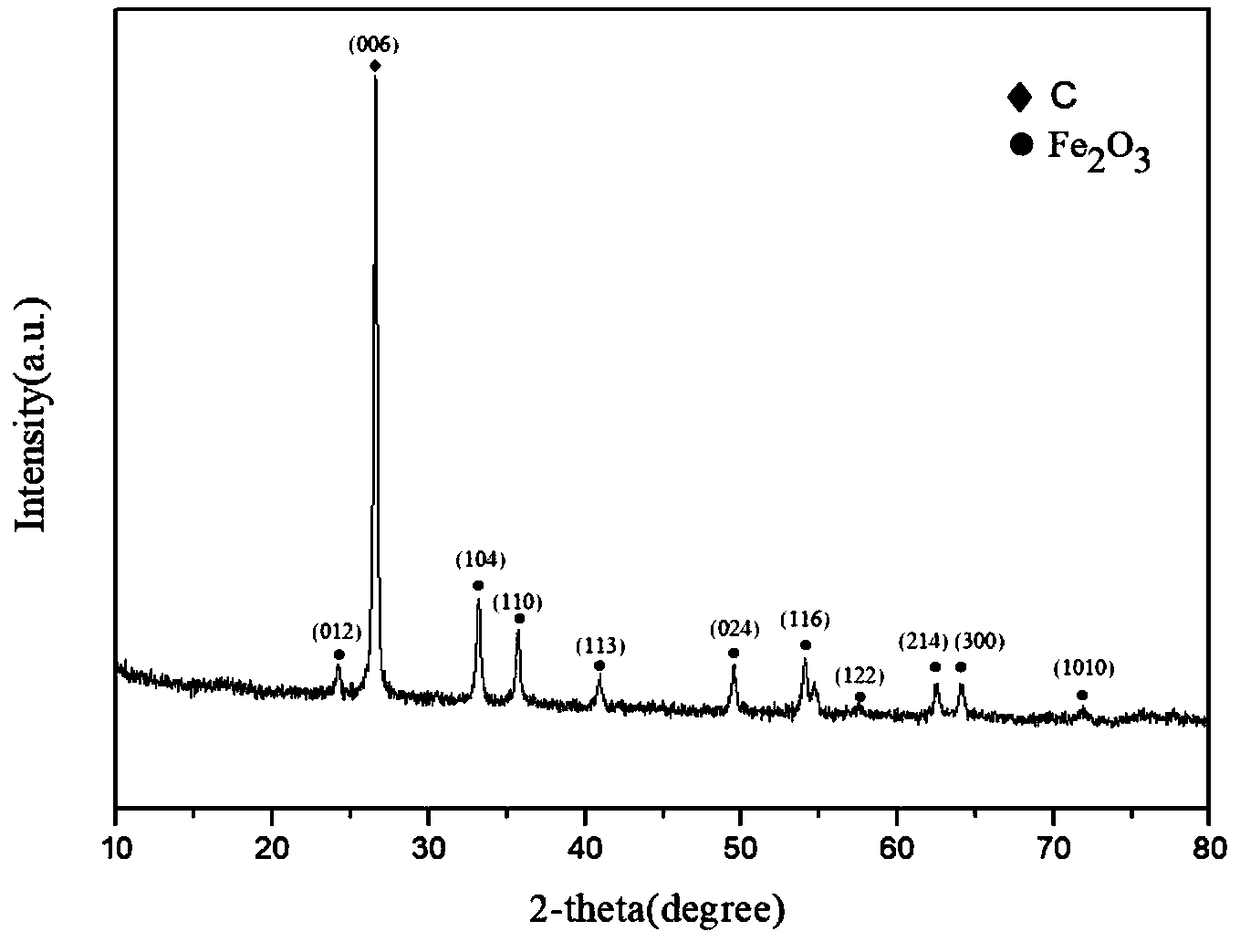

Preparation method of alpha-type fe_2O_3 nanoparticles/multilayer graphene composite material

ActiveCN109243832AWide variety of sourcesReduce manufacturing costHybrid capacitor electrodesHybrid/EDL manufactureWater bathsSolvent

The invention discloses a method for directly preparing uniform alpha-type Fe2O3 nanoparticles / multilayer graphene composite material by using iron powder. Comprises the following steps: DMF and deionized water with volume ratio of 8: 2 are mixed as mixed solvent; Expanded graphite was added and treated with ultrasonic wave for 3 hours to obtain multilayer graphene mixed solution. Fe powder, dilute nitric acid and anhydrous sodium acetate are added into that mix solution; The solution is stirred in a water bath at 70-90 DEG C for 4-10 hours, cooled and centrifugally cleaned to collect black products; 3 time of centrifugal cleaning of that reactant with alcohol and water respectively, and drying in an oven at 60 DEG C for 12 hour to obtain the dried alpha-type Fe2O3 nanoparticle / multilayergraphene composite material of the invention. The invention has the advantages of simple process, wide material source, low cost, nano-sized alpha-type Fe2O3 particles, uniform particles and good dispersibility.

Owner:HANGZHOU DIANZI UNIV

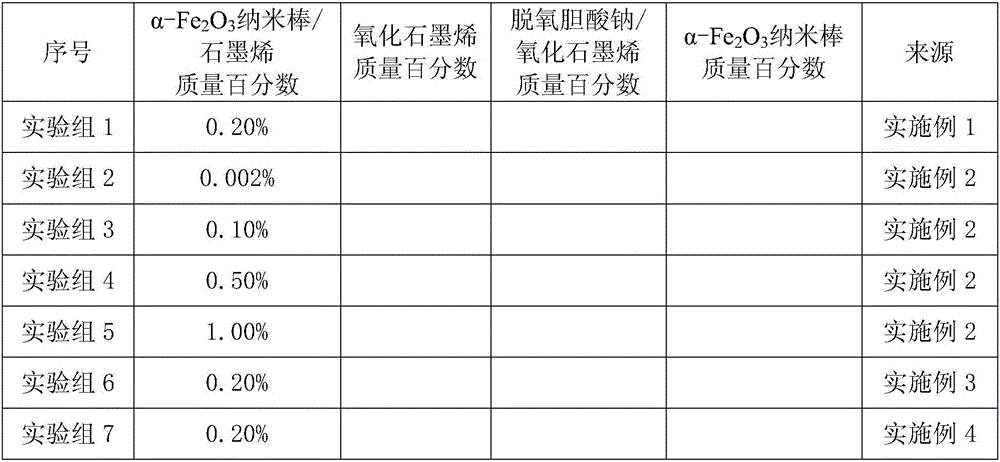

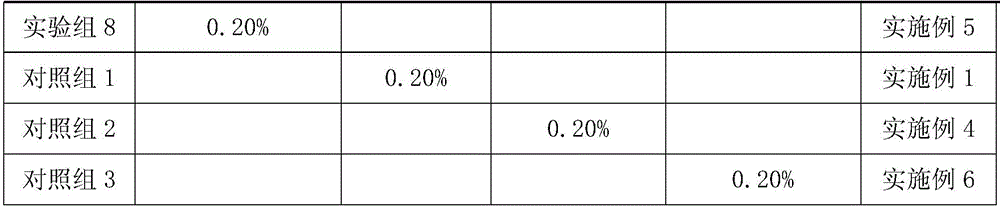

Graphene/Fe2O3 nanometer particle composite lubricating oil, lubricating oil additive and preparing method of the additive

InactiveCN106520256AReduce coefficient of frictionStable coefficient of frictionAdditivesOil additiveHydrolysis

A graphene / Fe2O3 nanometer particle composite lubricating oil additive is disclosed. The additive includes graphene the surface of which is loaded with Fe2O3 nanometer particles. The mass percentage of the graphene the surface of which is loaded with the Fe2O3 nanometer particles in lubricating oil is 0.002-1%. A method of preparing the additive is also disclosed. The additive is prepared by subjecting graphene oxide and a FeCl3 hydrate to a hydrolysis reaction, then centrifuging to obtain a solid product, washing the solid product with distilled water and ethanol for a plurality of times, and annealing. The additive has advantages of extremely good dispersibility and stability, good friction resistance and abrasion resistance and a high extreme pressure property, can be directly added into lubricating oil, and is capable of reducing the friction coefficient of a mechanical friction surface, restoring a worn surface, prolonging the service lifetime of machinery and reducing energy consumption. The method is simple, feasible, high in repetition rate and suitable for large-scale industrial production.

Owner:北京圣盟科技有限公司

Porous nitrogen-doped carbon/Fe2O3/graphene foamed flexible composite material and preparation method and application thereof

ActiveCN108199014AIncrease energy densityImprove power densityCell electrodesSecondary cellsCarbonizationNitrogen gas

The invention provides a porous nitrogen-doped carbon / Fe2O3 / graphene foamed flexible composite material and preparation method and application thereof. In the flexible composite material, Fe2O3 nanoparticle is coated with graphene, and nitrogen-doped carbon has a porous foam structure. The method comprises the steps of preparing pure melamine foam, performing calcination in nitrogen to obtain a nitrogen-doped carbon foam matrix, preparing to obtain a spinning solution after that nanometer Fe2O3, a graphene oxide solution and polyvinylpyrrolidone are mixed, taking the nitrogen-doped carbon foammatrix as a receiving device, directly spinning the spinning solution on carbon foam by a high-pressure electrostatic spinning technology to obtain a porous nitrogen-doped carbon / Fe2O3 / graphene oxide / PVP composite material, and obtaining the flexible composite material after high-temperature carbonization and cooling. The material is used for a negative electrode material of a lithium ion batteryand has the characteristics of favorable flexibility, high conductivity, high specific capacity and the like.

Owner:YINLONG ENERGY CO LTD

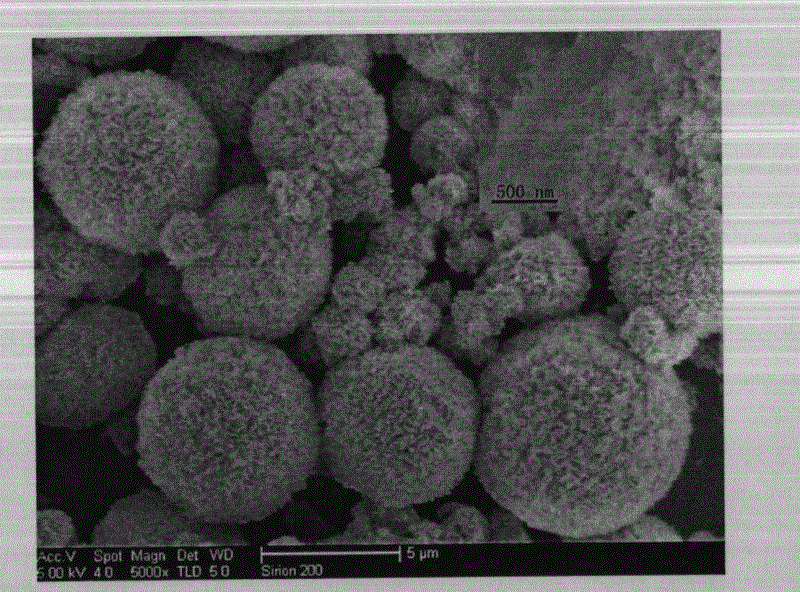

One-step synthesis method of surface loaded magnetic Fe2O3 nano-particle colloidal carbon ball

InactiveCN101302005AOne-step synthesisSimple experimentFerric oxidesTemperature controlMaterials preparation

The invention belongs to the nanometer / micrometer scale carbon sphere material preparation technical field, and in particular relates to a method of one-step synthesis for a colloidal carbon sphere with magnetic Fe2O3 nano-particles loaded on the surface. The method comprises the following steps of: dispersing 4-ferrocenyl butyric acid into de-ionized water, the dosage of the 4-ferrocenyl butyric acid in the water being between 1.25 and 8.75 mg / mL; adding the acquired mixture into a reaction kettle; placing the reaction kettle filled with the mixture into a temperature control furnace, heating the reaction kettle to a temperature of between 140 and 180 DEG C, and reacting for 12 to 24 hours, taking out the reaction kettle, naturally cooling the reaction kettle to room temperature to acquire a black product, washing and centrifugalizing, thereby acquiring the required product. The method has the advantages of adjustable technological parameter, simple operation of the whole preparation process, easily-controlled conditions and convenient after-treatment of the product, so the method can be easy for mass production. The method does not generate byproducts which pollute environment during preparation, and accords with the requirement of sustainable development, thereby being an environment-friendly synthesis process.

Owner:TONGJI UNIV

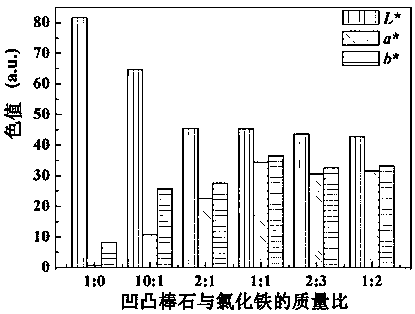

Method for preparing high thermal-stability clay mineral-iron oxide red hybrid pigment by co-precipitation technology

ActiveCN108102433ABright colorImprove thermal stabilityInorganic pigment treatmentFerric hydroxideIron salts

The invention discloses a method for preparing high thermal-stability clay mineral-iron oxide red hybrid pigment by a co-precipitation technology. The method comprises the following steps: dispersingnatural clay mineral in an iron salt aqueous solution; fully stirring and performing ultrasonic treatment; adding a precipitant; regulating the pH to 6-10; reacting for 0.5-4h at room temperature to obtain a clay mineral-ferric hydroxide hybrid precursor; centrifuging the precursor, washing, drying and calcining to obtain a series of clay mineral-iron oxide red hybrid pigment. According to the method disclosed by the invention, by adding the clay mineral, the preparation cost of the iron oxide red pigment is effectively reduced, and the agglomeration and size increase of alpha-Fe2O3 nano particles in the follow-up calcination and crystallization process are avoided; the prepared clay mineral-iron oxide red hybrid pigment has bright color and show excellent high-temperature resistance and is far more superior to the general commercial iron oxide red pigment and can meet the needs of high-end fields. Moreover, with a co-precipitation process, the method disclosed by the invention is simple in technology and facilitates large-scale production.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

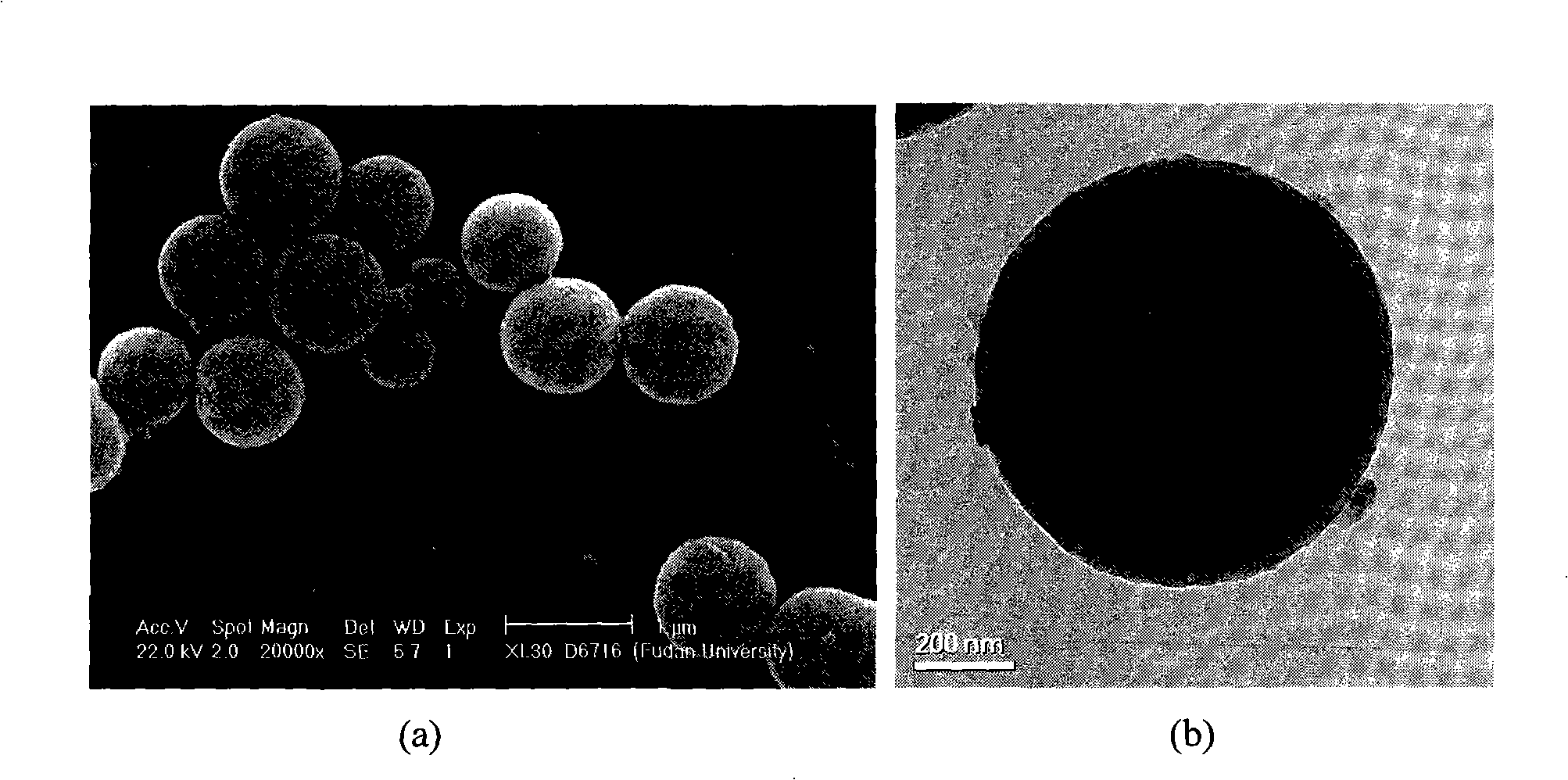

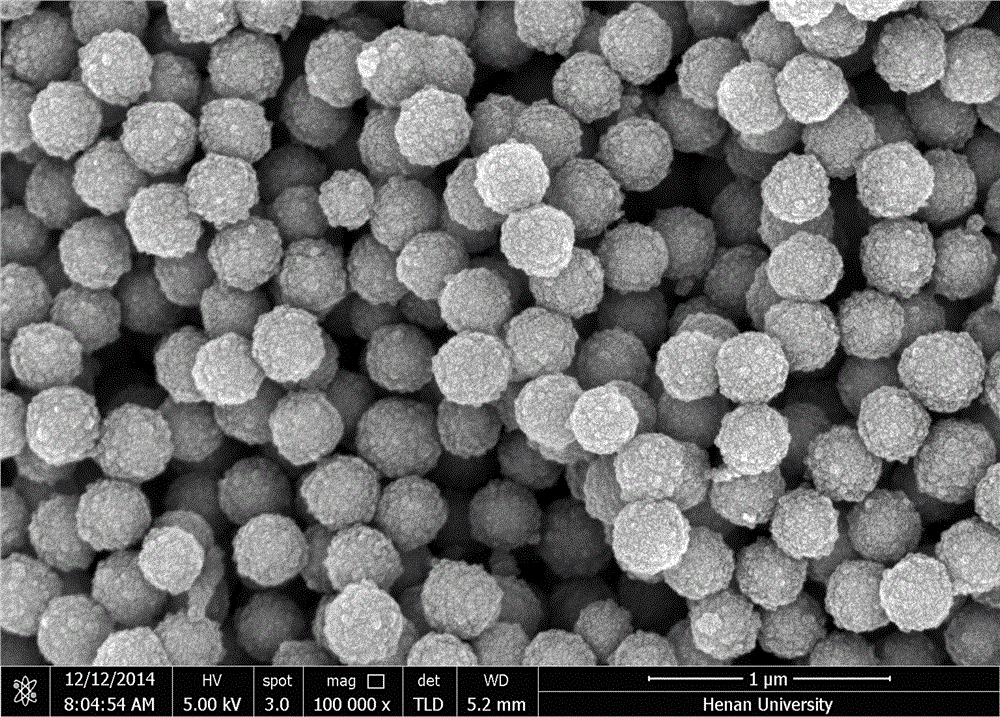

Method for preparing composite micro-spheres with Fe3O4@C core-shell structures and application of composite micro-spheres

InactiveCN105769812AGood slow releaseGood monodispersityOrganic active ingredientsEnergy modified materialsControlled releaseNitrogen

The invention belongs to a method for preparing composite micro-spheres with Fe3O4@C core-shell structures and application of the composite micro-spheres. The method includes preparing Fe2O3 nano-particles by the aid of modified solvothermal processes; preparing morphologically controllable composite micro-spheres with Fe2O3@ppy core-shell structures by the aid of combinations of template processes, hydrothermal processes and ultrasonic assisting processes without optional surfactants under mild conditions; reducing the morphologically controllable composite micro-spheres with the Fe2O3@ppy core-shell structures under the protection of nitrogen atmosphere to obtain the composite micro-spheres with the Fe3O4@C core-shell structures and superparamagnetism. The method and the application have the advantages that doxorubicin hydrochloride is used as a medicine model to carry out medicine loading and release tests, and the composite micro-spheres are excellent in medicine sustained-release and controlled-release performance as shown in the tests; the composite micro-spheres with the magnetic composite F3O4@C core-shell structures has a sustained-release function and the superparamagnetism which are integrated with each other, and accordingly the composite micro-spheres can have broad application prospects in the biomedical field of targeted therapy and the like.

Owner:HENAN UNIVERSITY

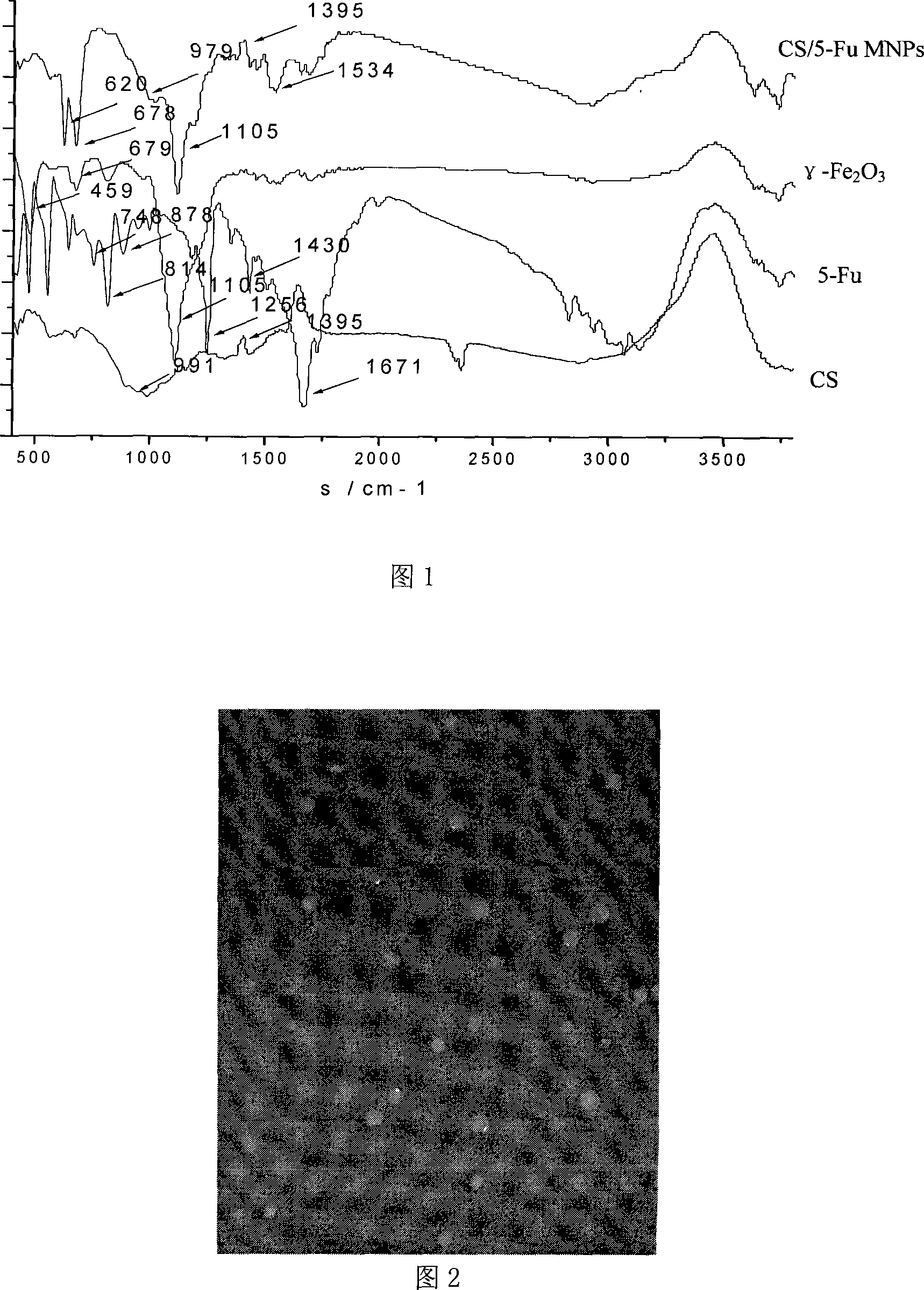

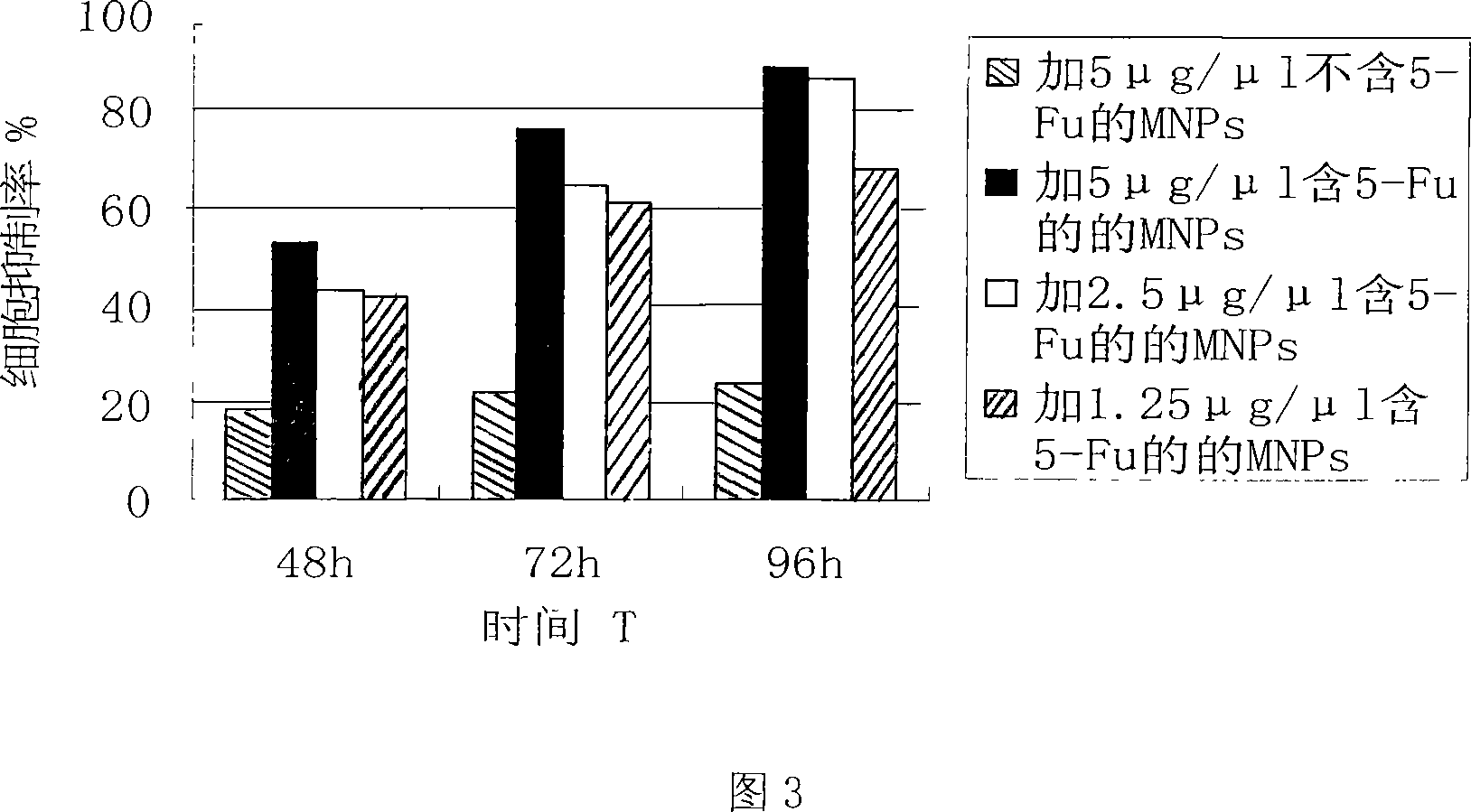

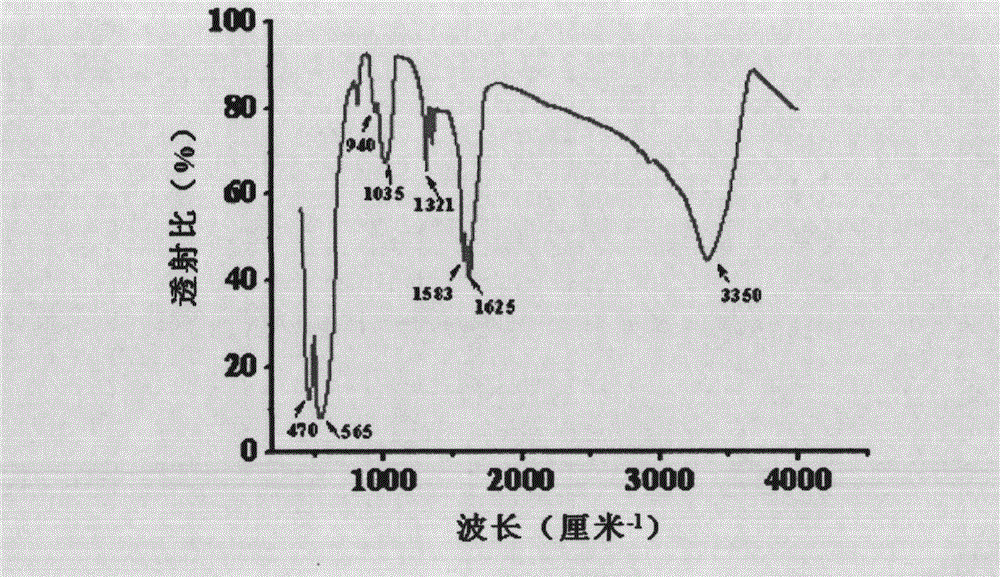

Magnetic chitosan medicine-carried nano particles and preparation method thereof

InactiveCN101085359ASignificantly pro-apoptotic effectGood dispersionPowder deliveryOrganic active ingredientsDispersityCross-link

The invention relates to a magnetic chitosan drug-loaded nanoparticle and its preparation method. Magnetic chitosan drug-loaded nanoparticle is spheroidal particle with particle diameter of 70-130nm and 5-flurouracil as active component. The preparation method comprises adopting acetic acid aqueous solution containing chitosan, gamma -Fe2O3nanoparticle and 5-flurouracil as water phase and liquid paraffin containing surfactant Span 80 as oil phase, mixing water phase and oil phase to obtain micro emulsion, washing with sodium citrate as cross-linking agent, and drying to obtain magnetic chitosan drug-loaded nanoparticle with entrapment efficiency of 40-50%, and drug loading dosage of particle of 15-25%.The inventive magnetic drug-loaded nanoparticle has obvious effects in promoting apoptosis of tumor cell, nano-graded particle diameter, good dispersity, no coacervation, and sustained release effect.

Owner:SHANGHAI NORMAL UNIVERSITY

Graphene/porous iron oxide nano-rod compound and preparation method thereof

ActiveCN104986759ALarge specific surface areaImprove conductivityMaterial nanotechnologyCarbon compoundsCvd grapheneMaterial chemistry

The invention belongs to the technical field of material chemistry and particularly relates to a graphene / porous iron oxide nano-rod compound and a preparation method thereof. The compound comprises graphene and Fe2O3 nano-particles loaded on graphene, and the Fe2O3 nano-particles adopt cellular porous structures. The compound is simple in synthetic method, and low in raw material cost.

Owner:SUZHOU UNIV

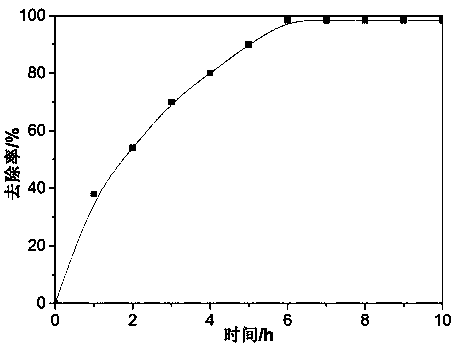

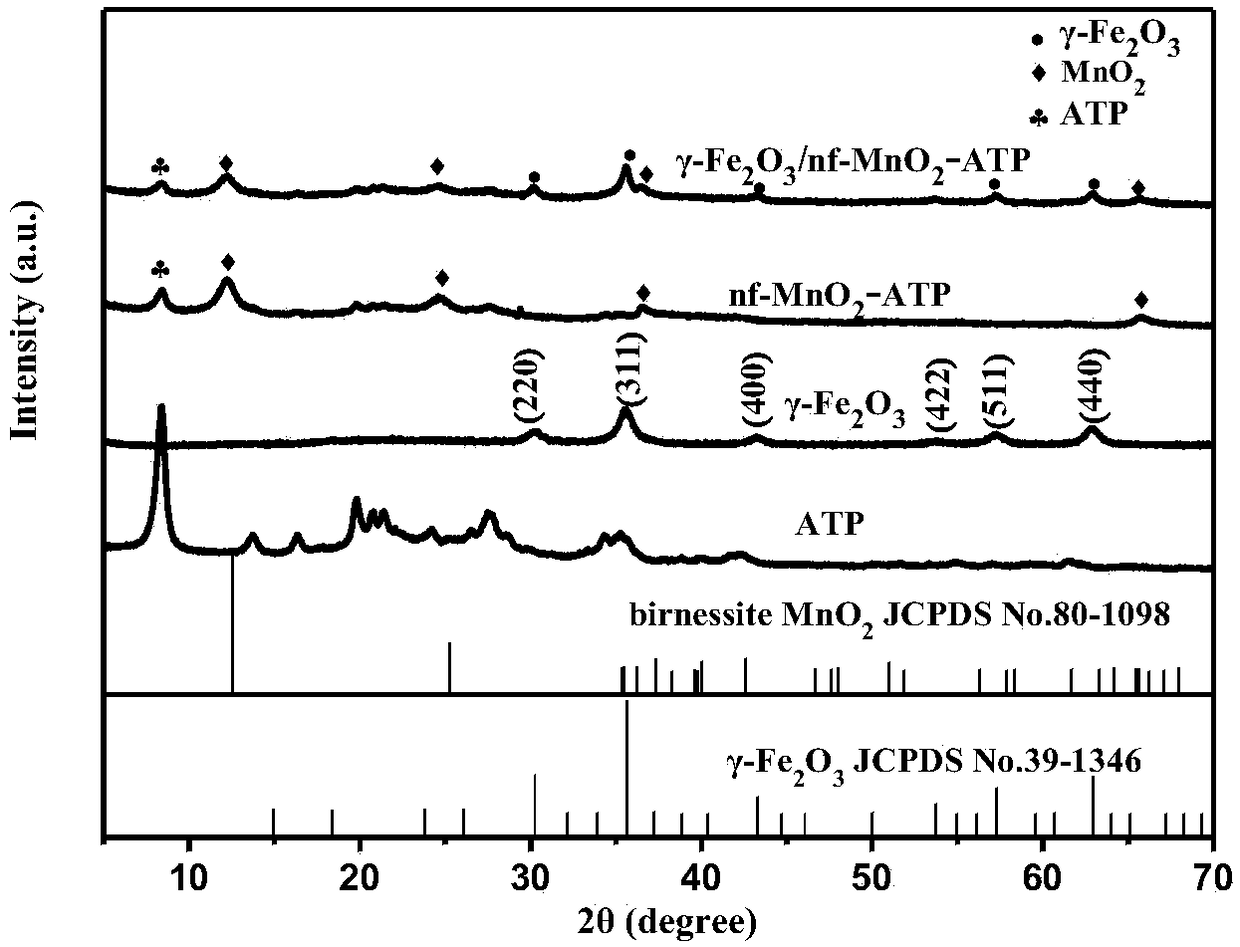

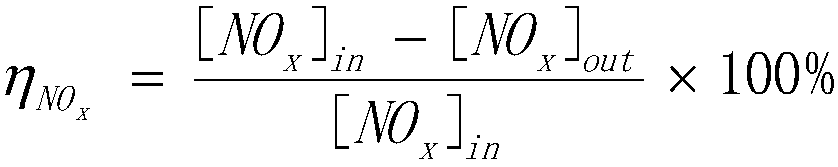

Gamma-Fe2O3 nanoparticle modified nf-MnO2/ATP low-temperature denitration catalyst

ActiveCN108465470AWide active temperatureImprove performanceGas treatmentDispersed particle separationFlue gasCatalyst support

The invention belongs to the field of flue gas denitration, and specifically provides a gamma-Fe2O3 nanoparticle modified nf-MnO2 / ATP low-temperature denitration catalyst. Directed at the disadvantages of low carrier strength, poor SO2 resistance and complicated preparation method for a conventional flue gas denitration catalyst, the invention provides the gamma-Fe2O3 nanoparticle modified nf-MnO2 / ATP low-temperature denitration catalyst and a preparation method thereof. The preparation method comprises the following steps: with attapulgite clay with large specific surface area and high adsorption performance as a carrier and a reducing agent, allowing the attapulgite clay to react with KMnO4 under a hydrothermal condition so as to prepare a nanoflower-like MnO2-coated attapulgite clay (nf-MnO2-ATP) catalyst, preparing high-performance gamma-Fe2O3 nanoparticles under a low-temperature hydrothermal condition at the same time, and subjecting nf-MnO2 / ATP to surface modification with the high-performance gamma-Fe2O3 nanoparticles so as to prepare the gamma-Fe2O3 / nf-MnO2-ATP denitration catalyst. Thus, N2 selectivity and SO2 resistance of nf-MnO2-ATP are improved. Meanwhile, the preparation method provided by the invention has mild preparation conditions and simple preparation process, and is a safe and highly-efficient preparation method for a low-temperature denitration catalyst.

Owner:CHANGZHOU UNIV

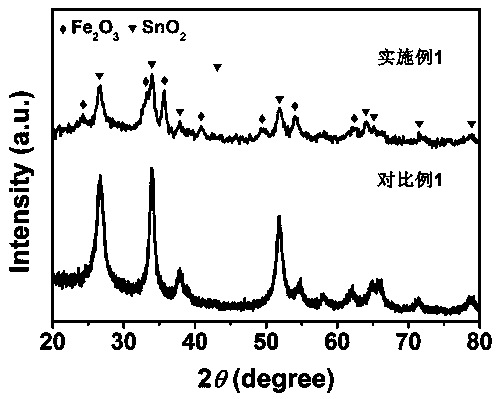

Nano SnO2/Fe2O3 blending doped silver base electric contact alloy and preparing process thereof

The invention belongs to a nanometer confounded additive composite silver based electric contact alloy and preparation technique thereof, especially to a component of nanometer SnO2 / Fe3O3 blended silver doped based electric contact alloy electrical contacts material and preparation technique thereof, wherein, co-precipitating and roasting the SnO2 and Fe2O3 chemically for preparing confounded nanometer powder with different granularity, high-energy ball milling the mixed powder of Ag, SnO2 and Fe2O3 in air or nitrogen gas environment, and shaping them. The invention can improve the moldability and electrical property of silver-based electrical contacts material and reduce the contact point burning loss rate and improve its service life.

Owner:XI'AN POLYTECHNIC UNIVERSITY

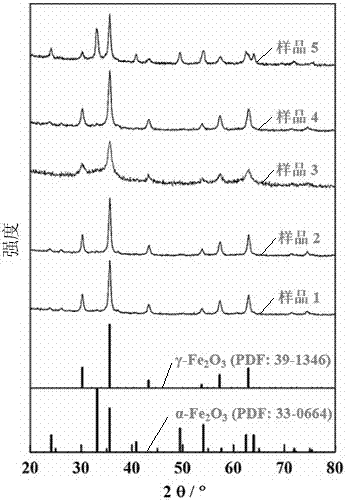

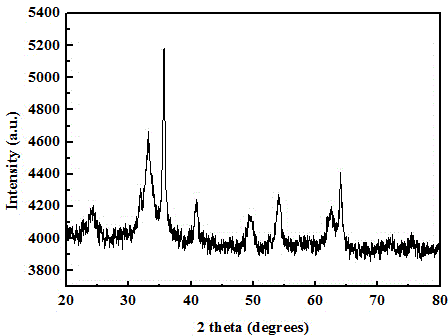

Preparation method of gamma-Fe2O3 nano material

InactiveCN107572597AEasy to prepareReduce the number of operationsMaterial nanotechnologyFerric oxidesMuffle furnaceFe2o3 nanoparticles

The invention discloses a preparation method of a gamma-Fe2O3 nano material. The preparation method comprises the following steps: preparing red brown thick liquid from Fe(NO3)3-9H2O and L-tartaric acid through an aqueous phase reaction; drying the red brown thick liquid in an air blasting oven to obtain greyish-green solid powder; re-roasting the greyish-green solid powder in a muffle furnace toobtain gamma-Fe2O3 nanoparticles. According to the preparation method disclosed by the invention, gamma-Fe2O3 is prepared from Fe(NO3)3-9H2O and L-tartaric acid through an aqueous phase reaction; thepreparation method is simple, a few operation links are adopted, and the obtained product has high purity.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of dual-shell Fe2O3/NiS nanocomposite

The invention discloses a preparation method of a dual-shell Fe2O3 / NiS nanocomposite. The method specifically comprises the following steps: preparing Fe2O3 nanoparticles through the solvothermal method by using ferric chloride as ferric salt; preparing a Fe2O3@Ni(OH)2 core-shell material through the hydrothermal method by using Fe2O3 as a carrier and nickel salt as a metal salt; and preparing thedual-shell Fe2O3 / NiS nanocomposite through the hydrothermal method by using sodium sulfide as a sulfur source. The preparation method has the advantages of high simplicity and high easiness in operation; and the prepared dual-shell Fe2O3 / NiS nanocomposite achieves good hydrogen evolution performance.

Owner:TIANJIN POLYTECHNIC UNIV

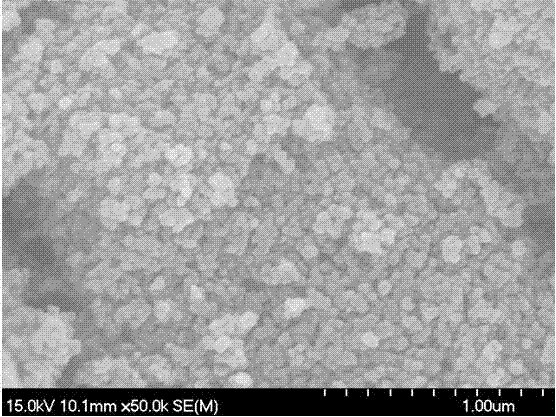

Method for preparing monodispersed alpha-Fe2O3 nanoparticles

InactiveCN103332752AStrong penetrating powerGood biocompatibilityMaterial nanotechnologyFerric oxidesBiocompatibility TestingFe2o3 nanoparticles

The invention discloses a method for preparing monodispersed alpha-Fe2O3 nanoparticles. The method comprises the following steps of firstly preparing a ferric nitrate solution and a glycine solution; then adding the above solutions into a hydrothermal reactor; then adding ultrapure water and absolute ethyl alcohol into the hydrothermal reactor; mixing the above materials uniformly; putting the reactor in a temperature-programmed controller; carrying out programmed temperature to make the temperature stabilized at 175-185 DEG C; reacting for 10-14 h at the temperature; cooling the reactor to a room temperature after the reaction is finished; washing the obtained reaction product with absolute ethyl alcohol and ultrapure water; and finally drying the reaction product with an oven. The method disclosed by the invention is simple and economic and has good repeatability; the prepared alpha-Fe2O3 nanoparticles have a hexagonal system structure, an average particle size of 50 nm and very large cell absorption efficiency and high biocompatibility and have particularly large application prospects in aspects such as conveying drugs or targeted therapy, etc.

Owner:HUNAN PROVINCIAL TUMOR HOSPITAL

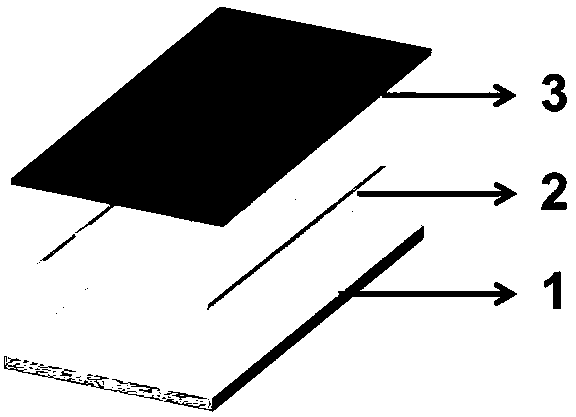

Preparation method of core-shell structure hollow microcube SnO2-Fe2O3 sensitive material and application of core-shell structure hollow microcube SnO2-Fe2O3 sensitive material

InactiveCN110687184AStable structureGood dispersionMaterial nanotechnologyMaterial analysis by electric/magnetic meansAluminium oxidesFe2o3 nanoparticles

The invention discloses a preparation method of a core-shell structure hollow microcube SnO2-Fe2O3 sensitive material and application of a core-shell structure hollow microcube SnO2-Fe2O3 sensitive material in an acetone gas sensor. The preparation method comprises the following steps of: preparing SnO2 porous hollow microcube powder by combining a solution chemical etching method with high-temperature calcination; taking SnO2 porous hollow microcube powder as a core skeleton structure, growing Fe2O3 nanoparticles on an outer shell layer of the SnO2 porous hollow microcube powder through adoption of a hydrothermal method in combination with high-temperature calcination to prepare a core-shell structure hollow microcube SnO2-Fe2O3 sensitive materiald, wherein the acetone gas sensor is manufactured on an aluminum oxide substrate sheet printed with a gold interdigital electrode in a dropwise coating manner and is used for selectively detecting an acetone gas. The preparation method is simple and controllable, and the material is stable in structure and good in dispersity; and moreover, the sensitivity and the selectivity of the acetone gas sensor can be obviously improved.

Owner:HENAN NORMAL UNIV

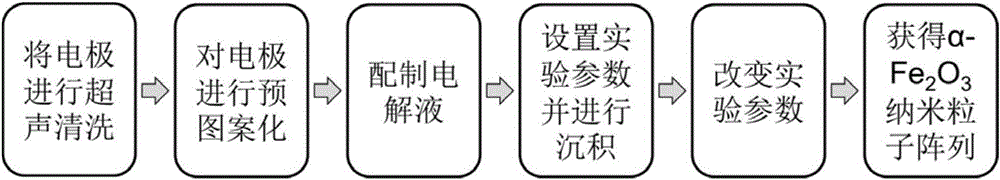

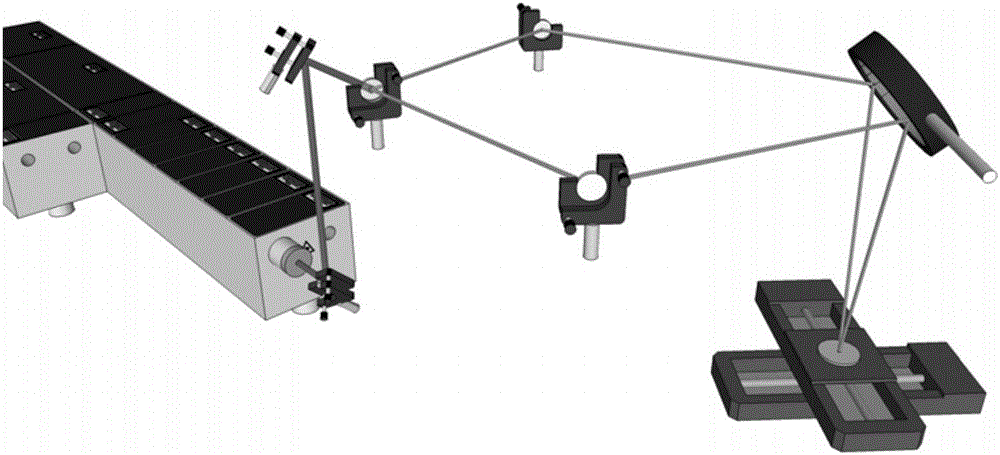

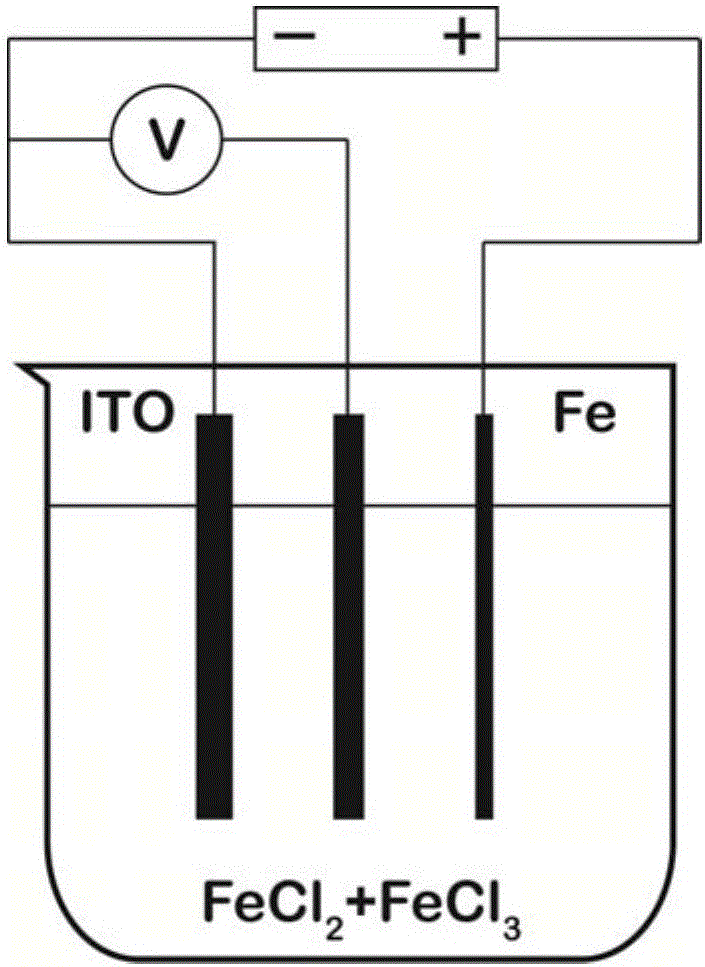

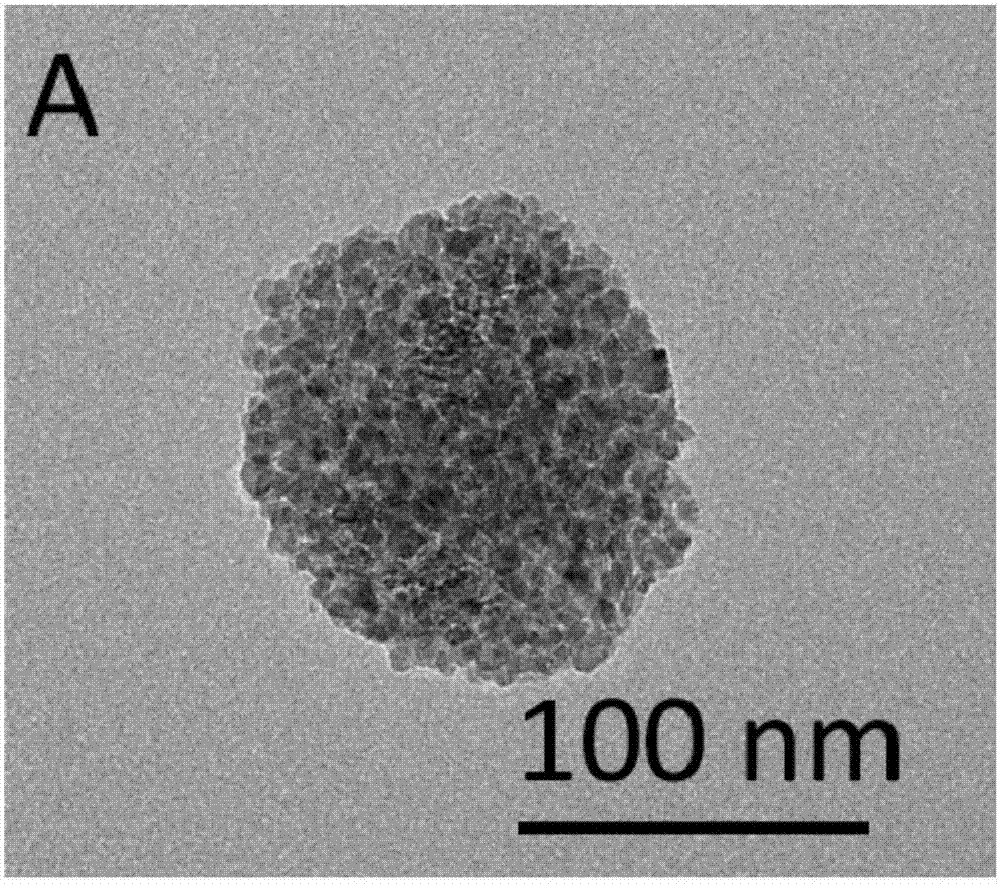

Method of adopting electrochemical deposition to prepare patterned orderly alpha-Fe2O3 nanoparticle array

ActiveCN106350846AReduce manufacturing costRaw materials are easy to getElectrolytic inorganic material coatingNanotechnologyDispersityWorkstation

A method of adopting electrochemical deposition to prepare a patterned orderly alpha-Fe2O3 nanoparticle array includes: adopting an electrochemical workstation, using ITO conductive substrate after laser interference photoetching as a working electrode, a saturated calomel electrode as a reference electrode, a high-purity iron sheet as a pair electrode and a mixed solution of FeCl2 and FeCl3 as an electrolyte, adopting a triphase electrode system to soak the working electrode, the pair electrode and the reference electrode in the electrolyte at the same time, and setting needed temperature for electrochemical deposition; adopting a timing current method to electrochemically deposit on the working electrode to obtain the patterned orderly alpha-Fe2O3 nanoparticle array having high dispersity. Double-beam single-exposure is utilized to pre-pattern the electrodes, and the nanoparticle array of a large-scale patterned orderly structure is prepared. A cathode electrodeposition method is used in the process of electrochemical deposition, equipment is simple, preparation cost is low, and high-temperature heating or annealing treatment is not needed; used chemicals are nontoxic and harmless, and the prepared patterned orderly alpha-Fe2O3 nanoparticle array is high in repeatability and stability.

Owner:CHANGCHUN UNIV OF SCI & TECH

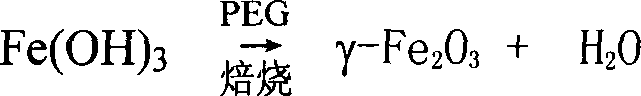

Method for preparing gamma-Fe2O3 nano particle powder

InactiveCN102923787AImprove shielding effectChemically stableMaterial nanotechnologyFerric oxidesUltravioletMaterials science

The invention provides a method for preparing gamma-Fe2O3 nano particle powder. By means of the method, gamma-Fe2O3 nano particles are prepared with iron acetate as the iron source, ethanediol as the dispersing agent and sodium carbonate as the precipitator. The method includes: grinding the iron acetate, and adding the iron acetate into the ethanediol solution to obtain turbid liquid; adding the sodium carbonate solution into the turbid liquid dropwise, continuing stirring for ageing after the dropwise adding is finished, standing for cooling the solution to the room temperature, performing suction filtration, and washing through deionized water and ethanol alternatively; and drying the obtained filter cakes to obtain the prepared gamma-Fe2O3 nano particle powder. The obtained gamma-Fe2O3 nano particle powder is stable in chemical property and high in catalytic activity, has good light resistance, weather resistance and shielding resistance on ultraviolet and can be widely used in the aspects of fine ceramics, plastic products, coating, catalysts, magnetic materials, biomedical engineering and the like. The method for preparing gamma-Fe2O3 nano particle powder is short in technological process, good in operation environment, high in product quality, superfine and even in particle, good in dispersibility and the like.

Owner:KUNMING UNIV OF SCI & TECH

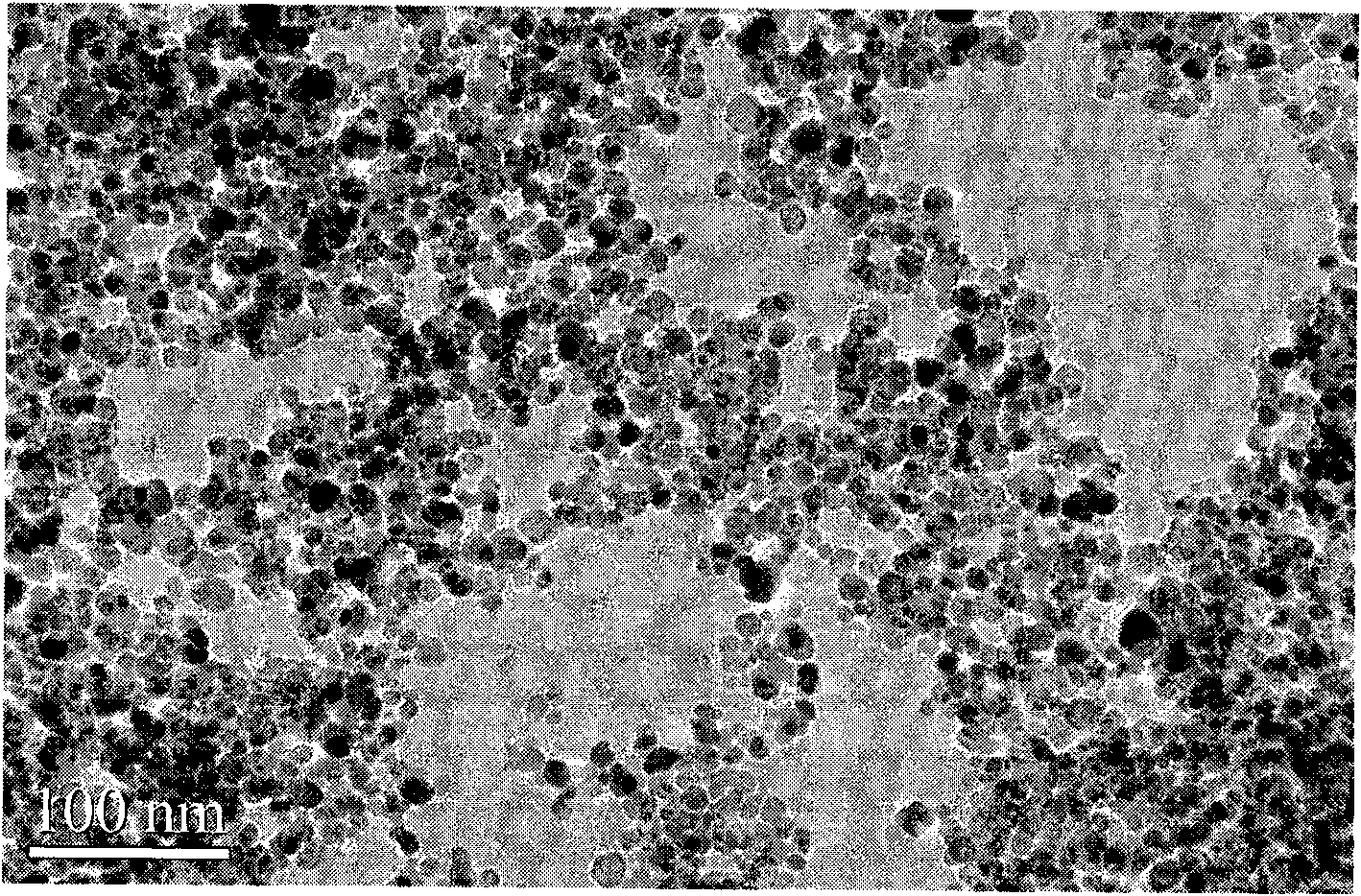

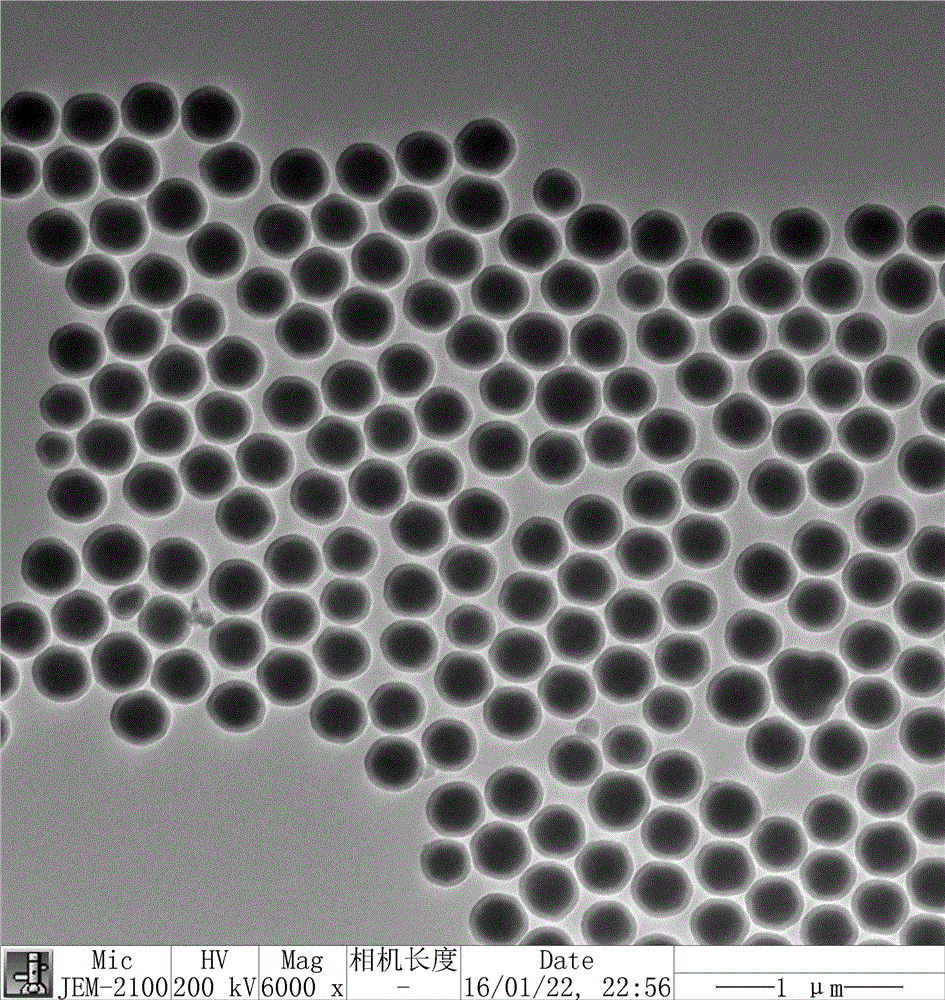

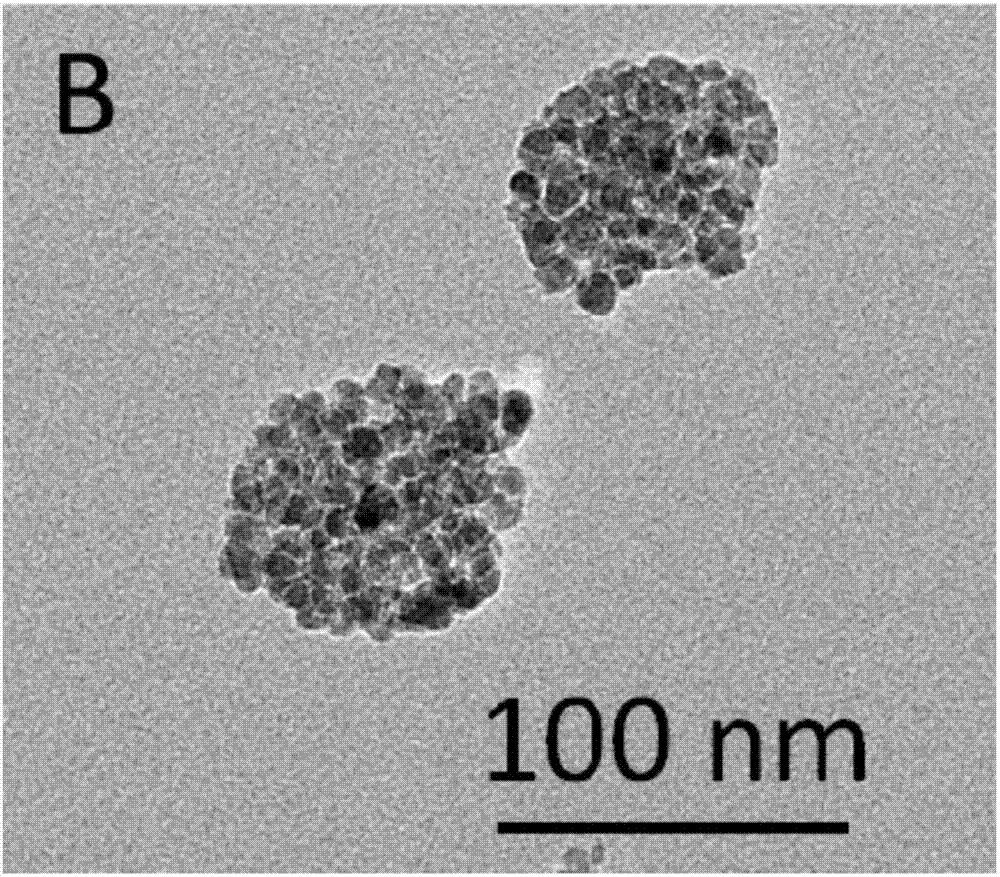

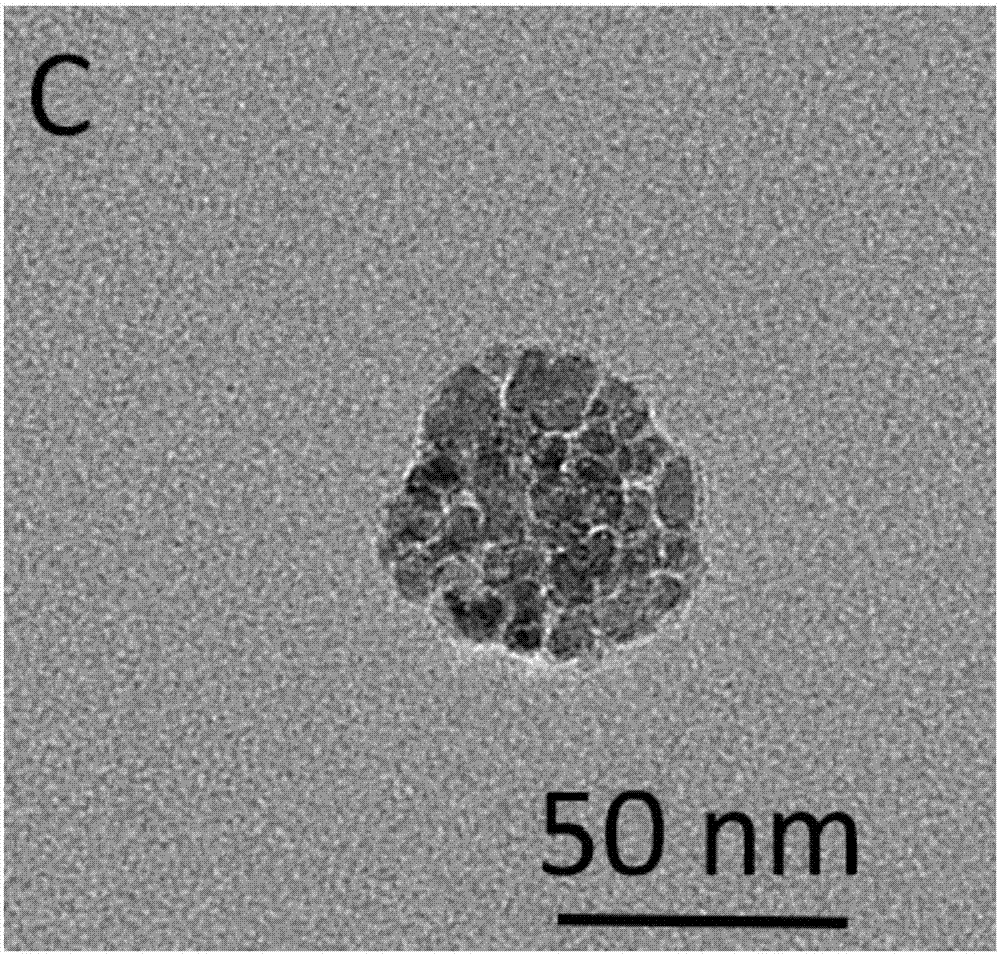

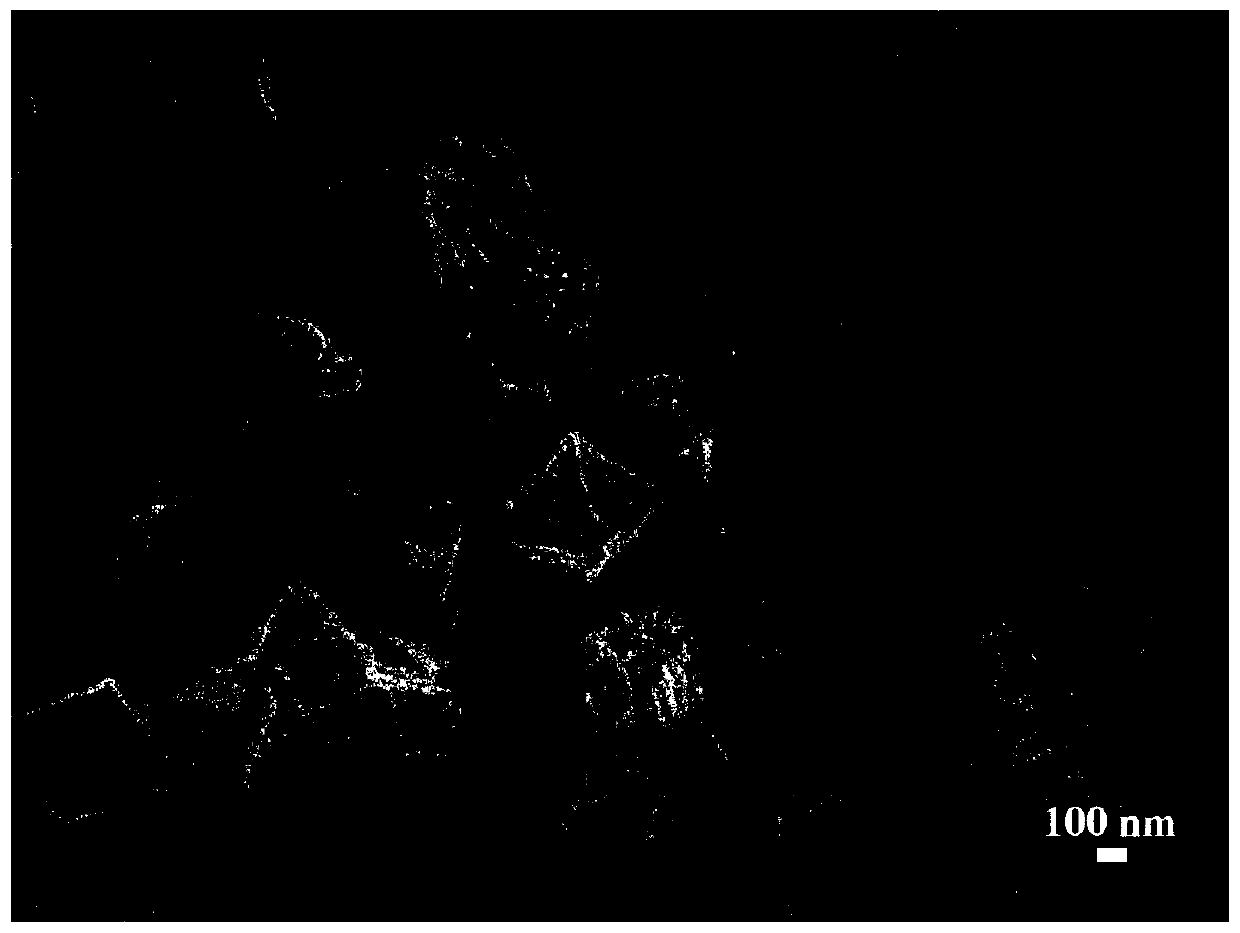

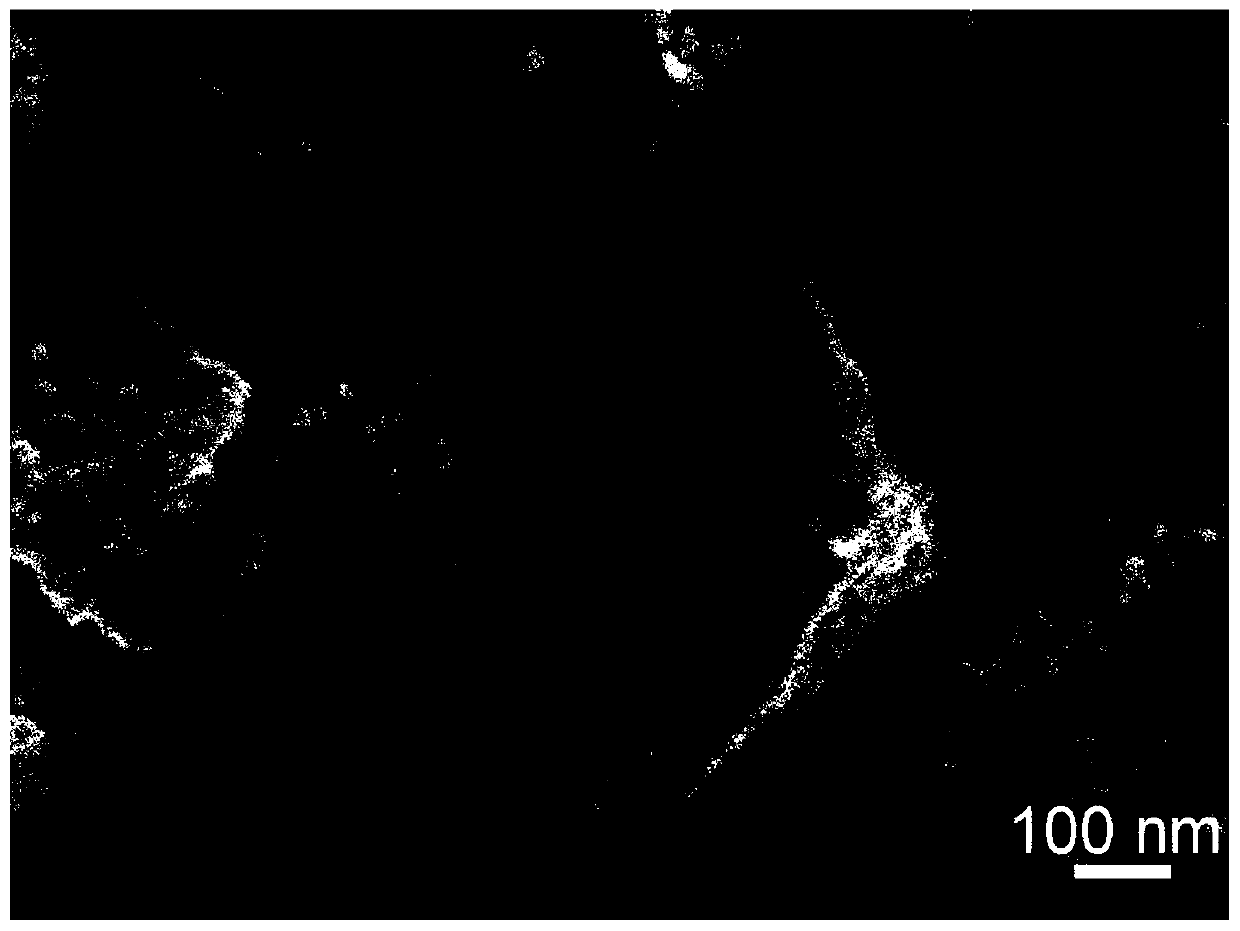

Preparation method of gamma-Fe2O3 superparamagnetic nanoclusters

InactiveCN106963724AHigh puritySimple and fast operationMaterial nanotechnologyInorganic non-active ingredientsDrug releaseSalt solution

The invention relates to a preparation method of gamma-Fe2O3 superparamagnetic nanoclusters. The method adopts gamma-Fe2O3 nanoparticles as anions, and uses a surfactant, polymer or protein as a cationic neutral block copolymer to react in a water solution so as to obtain gamma-Fe2O3 superparamagnetic nanoparticles, and controls the reactant ratio and reaction conditions to prepare gamma-Fe2O3 superparamagnetic nanoclusters of different shapes and sizes in different salt solutions. The preparation method has the advantages of simple operation, high success rate, good repeatability, and high product purity. Also the gamma-Fe2O3 superparamagnetic nanoclusters prepared by the method provided by the invention have the advantages of degradability, and controllable shape and size, etc., and can be applied to sustained drug release.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Ethyl acetate gas sensor and preparation method thereof

ActiveCN109752415AExpected to be mass-producedEasy to detectMaterial analysis by electric/magnetic meansAcetic acidHigh volume manufacturing

The invention discloses an ethyl acetate gas sensor taking PrFeO3 modified core-shell octahedral structure Fe2O3 nanoparticles as a sensitive layer, and a preparation method of the ethyl acetate gas sensor, and belongs to the technical field of gas sensors. The gas sensor comprises an Al2O3 substrate with a Pd metal interdigital electrode, and the PrFeO3 modified core-shell octahedral structure Fe2O3 nanoparticle sensitive layer prepared by adopting a coating technology on the Pd metal interdigital electrode and the Al2O3 substrate; the particle size of the nanoparticles ranges from 500 nm to700 nm; and a large amount of the PrFeO3 nanoparticles grow on the surface of core-shell octahedral structure Fe2O3. The method is simple and feasible, few in process, low in cost and low in equipmentrequirement; and the prepared ethyl acetate gas sensor is fast in gas sensitive response and suitable for mass production, and has important application values.

Owner:JILIN UNIV

Preparation method of alpha-Fe2O3 nanoparticles

InactiveCN104649329ASlow growth rateSimple processMaterial nanotechnologyFerric oxidesInorganic saltsAlcohol

The invention relates to a preparation method of alpha-Fe2O3 nanoparticles. The preparation method comprises the following steps: dispersing and dissolving a ferrum source by using an inorganic salt solution to prepare a ferrum dispersing solution; dissolving inorganic alkali by using the inorganic salt solution to prepare an inorganic alkaline dispersed solution, wherein anions of the inorganic salt are equal to those of the ferrum source in quantity; firstly heating the ferrum source dispersed solution to 50-95 DEG C, dropwise adding the inorganic alkaline dispersed solution to the ferrum source dispersed solution under a stirring condition, and after addition, further stirring till brown precipitates generated by reaction are no long increased; and carrying out centrifugal separation on the precipitates and sequentially washing with water, a mixed liquid of water and ethanol and absolute ethyl alcohol, and then drying in vacuum to obtain the alpha-Fe2O3 nanoparticles. The reactants need not to be roasted again. The process is simple and the energy consumption is low. The prepared iron sesquioxide nanoparticles are brown nanoparticles which are in alpha-Fe2O3 configuration, wherein the crystal grains are 15-20nm and the specific surface area is 78-101m<2> / g.

Owner:LUOYANG NORMAL UNIV

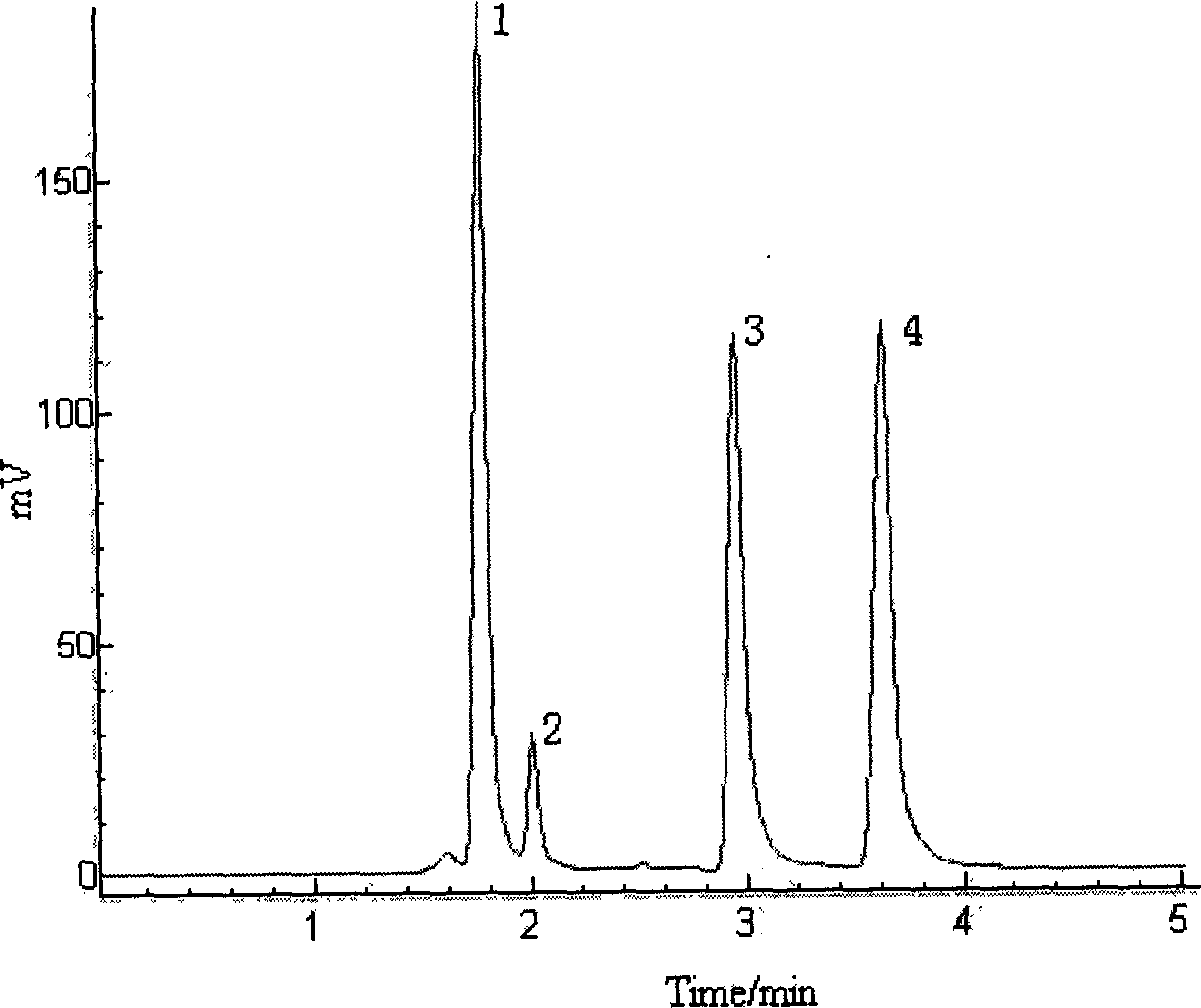

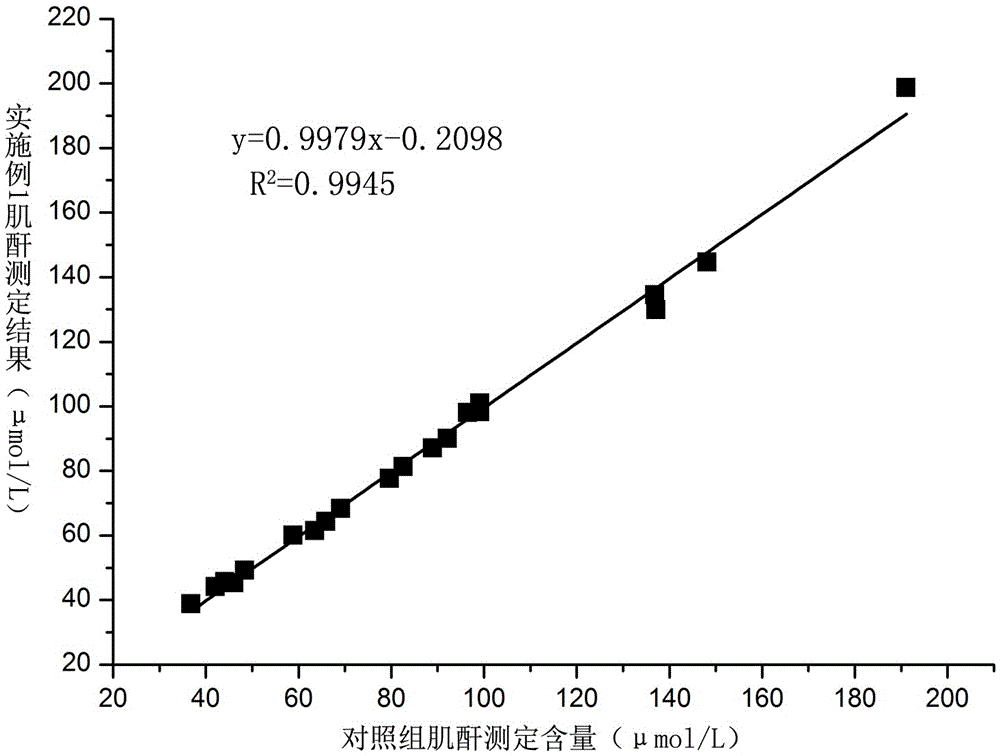

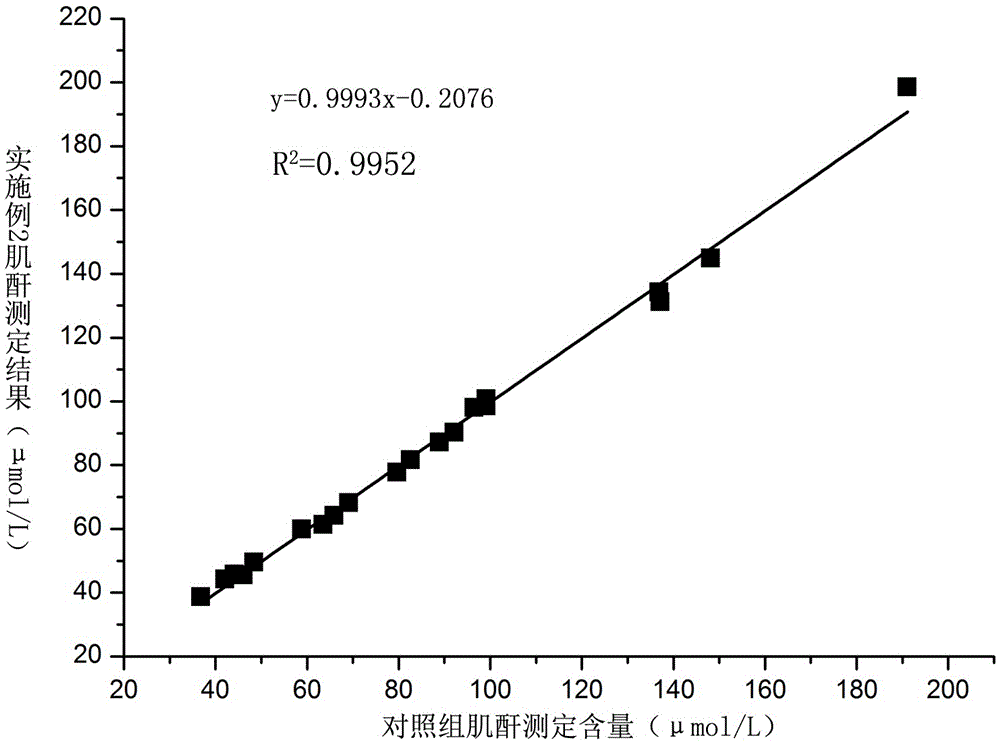

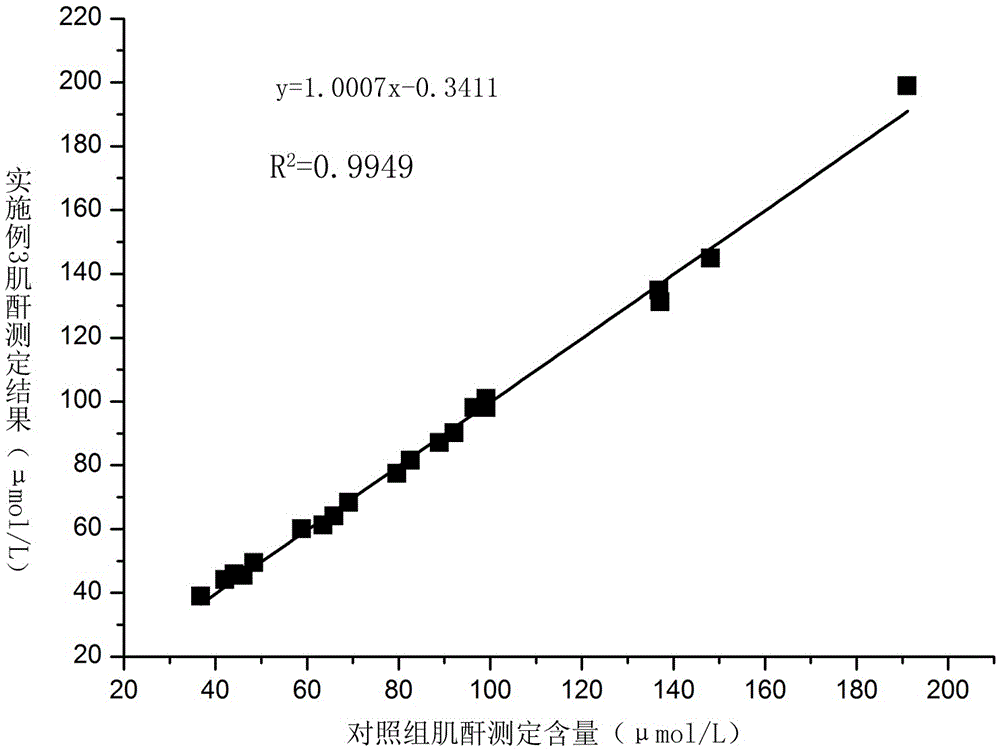

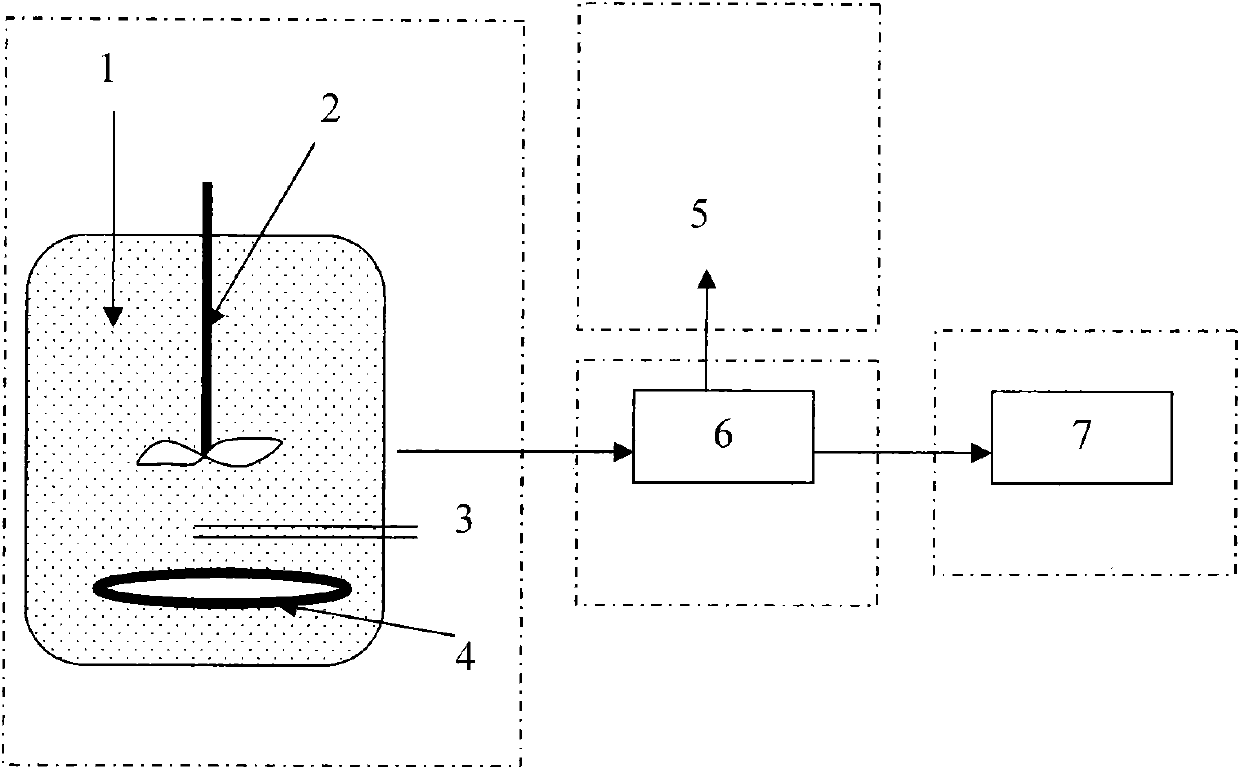

A serum creatinine detection reagent

ActiveCN104459164BEliminate distractionsHigh activityMicrobiological testing/measurementBiological testingMethylanilineCreatinine rise

The invention discloses a serum creatinine detecting reagent, and belongs to the technical field of clinical in-vitro detection. According to the serum creatinine detecting reagent, gamma-Fe2O3 nano-particles are added into a reagent R1, so that the activity of peroxidase and the specificity to a substrate are enhanced, and the interferences of reducing substances, such as ascorbic acid, uric acid, glutathione and bilirubin, are reduced; meanwhile, the gamma-Fe2O3 nano-particles also serve as a catalyst of a reaction; the interference of endogenous creatine is effectively eliminated by the combination action of the gamma-Fe2O3 nano-particles and the peroxidase. In addition, the serum creatinine detecting reagent adopts N-ethyl-N-(2-hydroxy-3-sulfonated propyl)-3-methylaniline sodium salt (TOOS) as a chromogen, so that the reagent is more stable; the analysis sensitivity is high. The substances, such as lipase and lipoprotein lipase, are also added into the reagent R1, so that the influence of lipid turbidity can be removed effectively; therefore, the reagent of the invention has higher anti-jamming capability and stability.

Owner:BIOBASE BIODUSTRY (SHANDONG) CO LTD

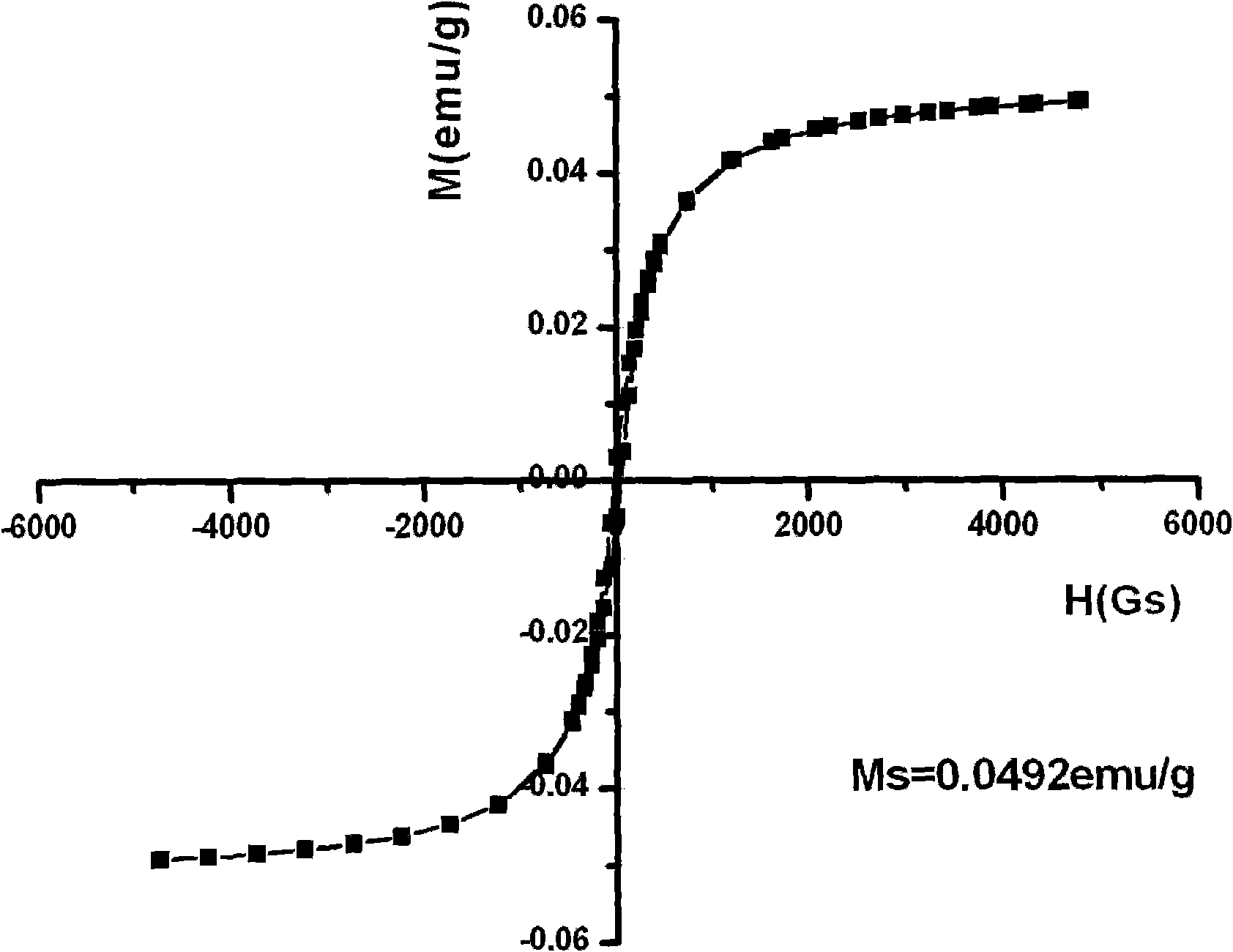

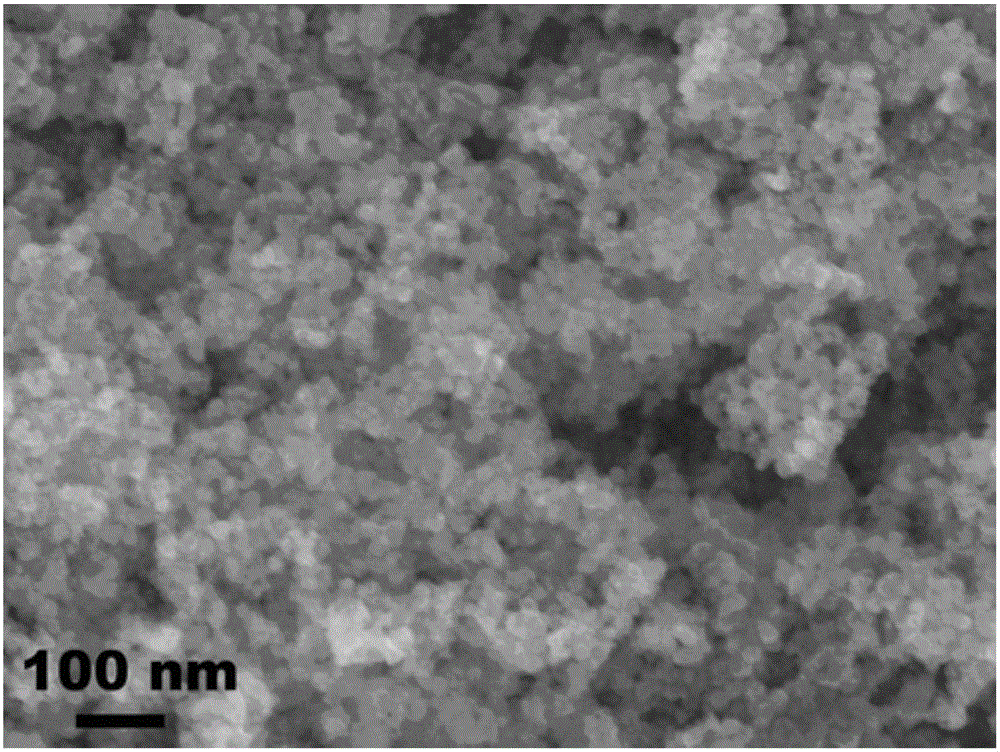

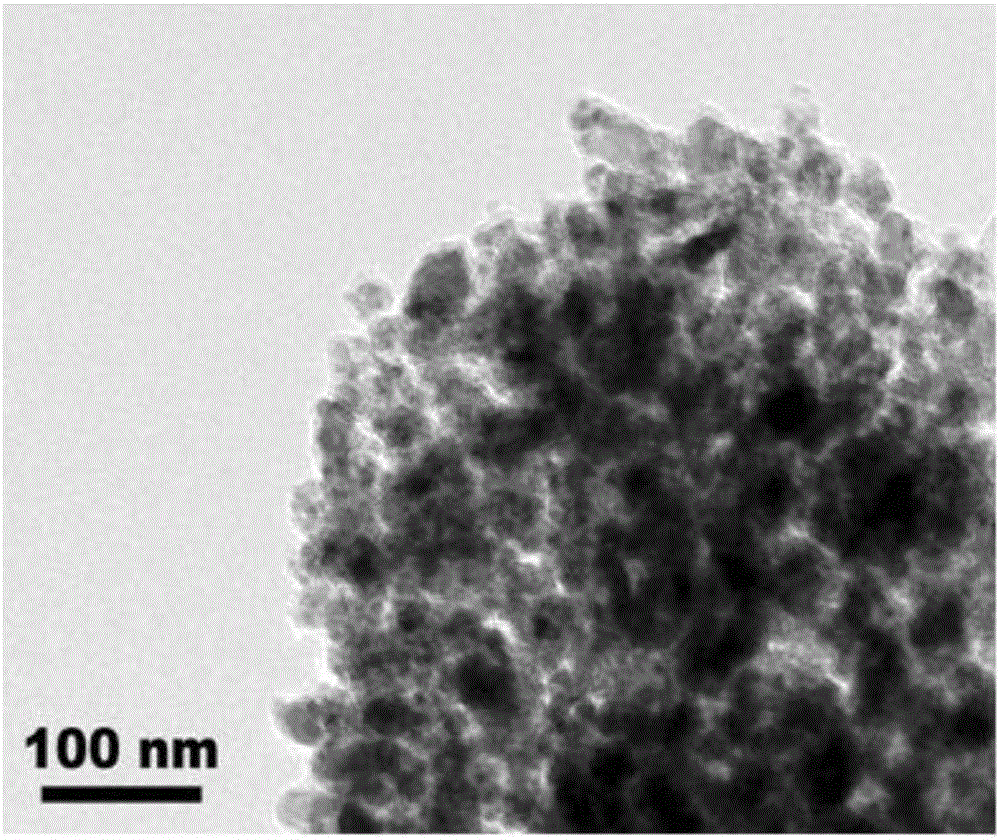

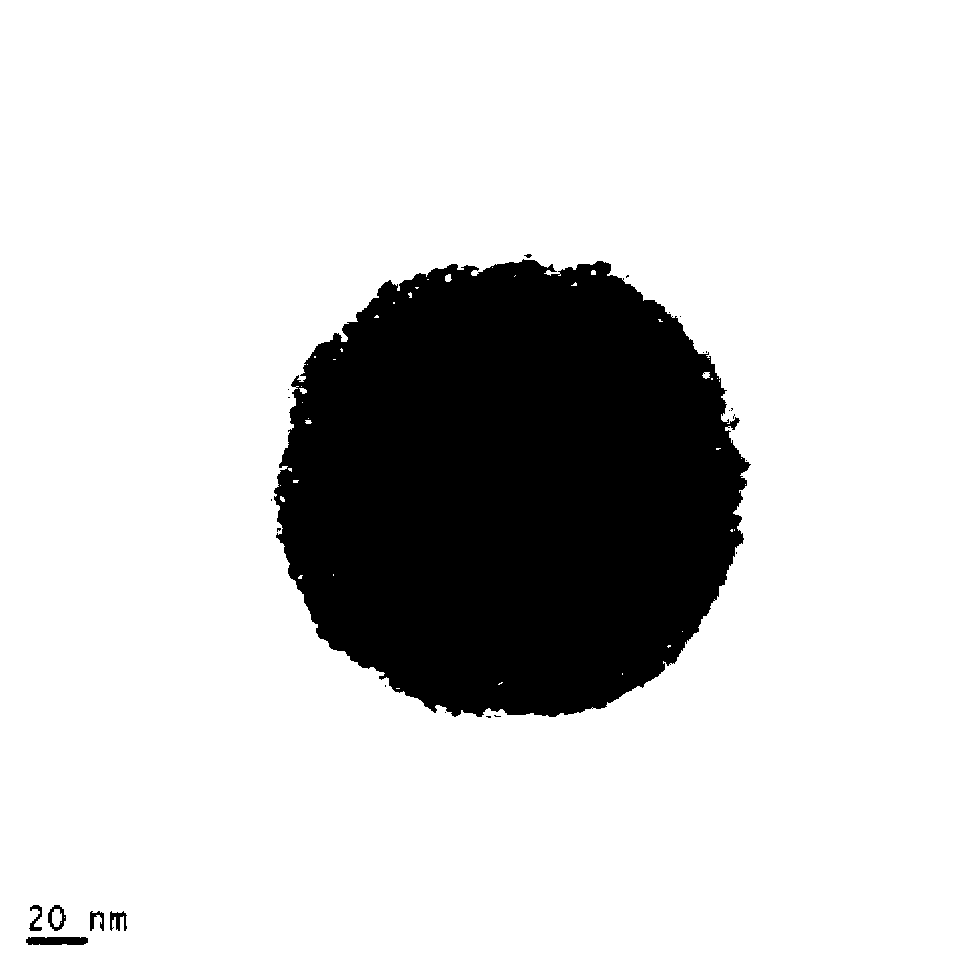

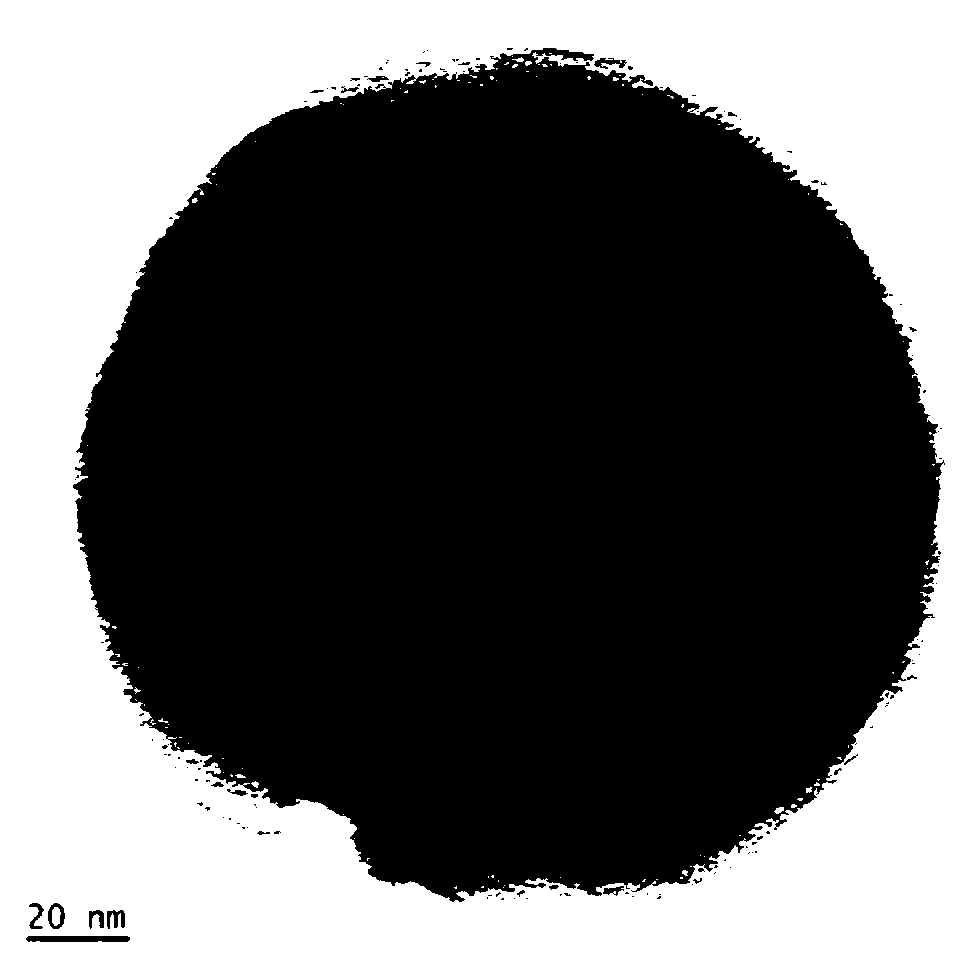

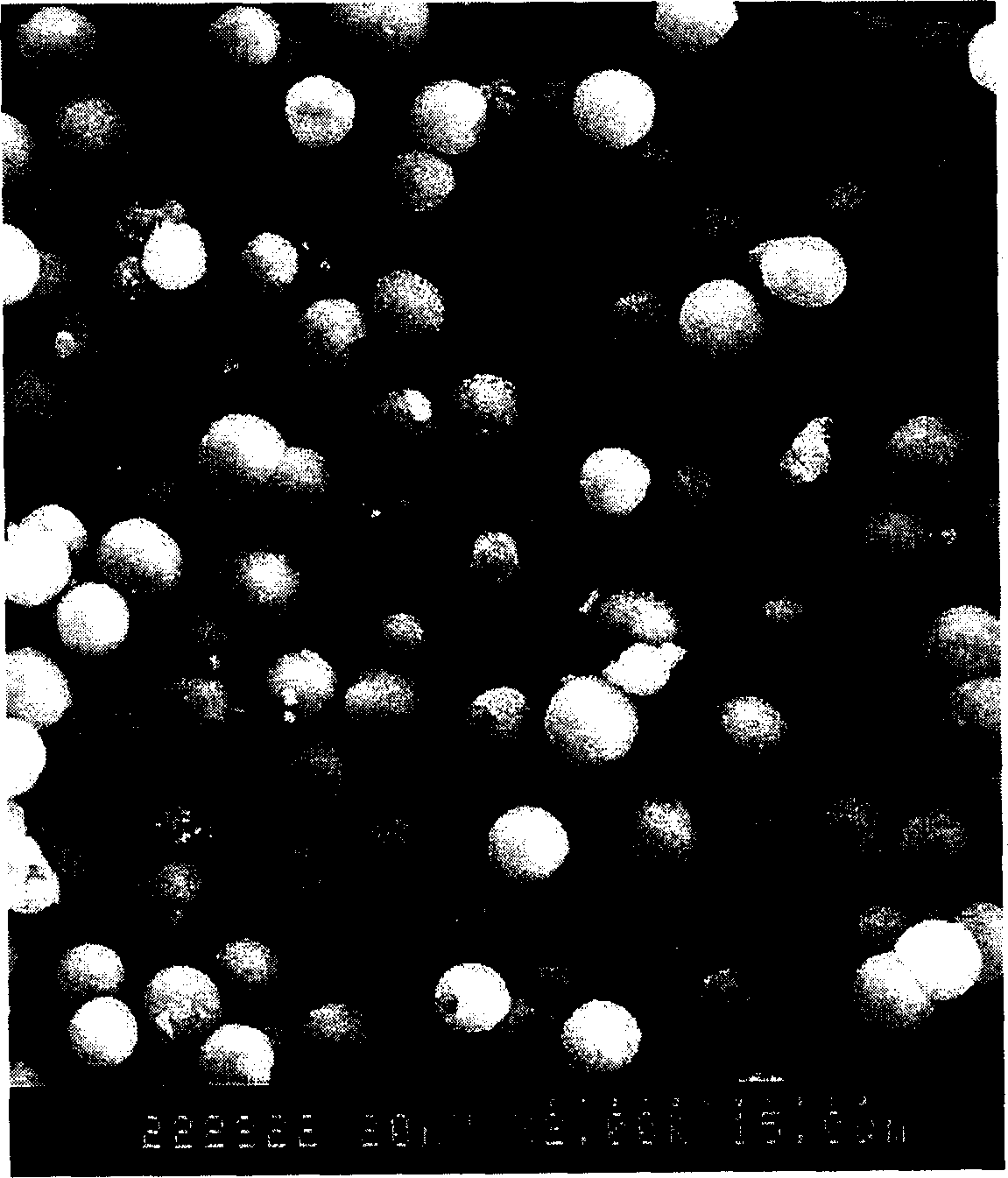

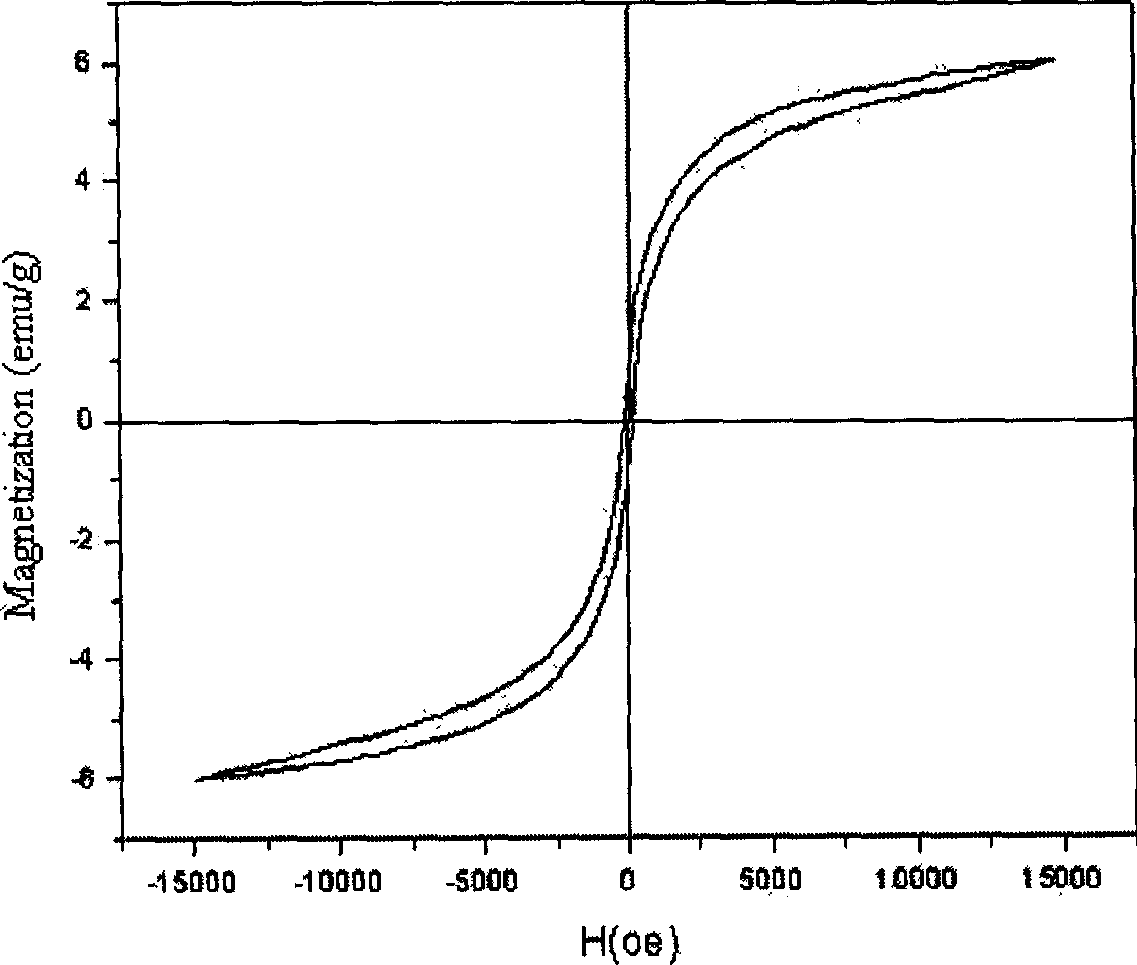

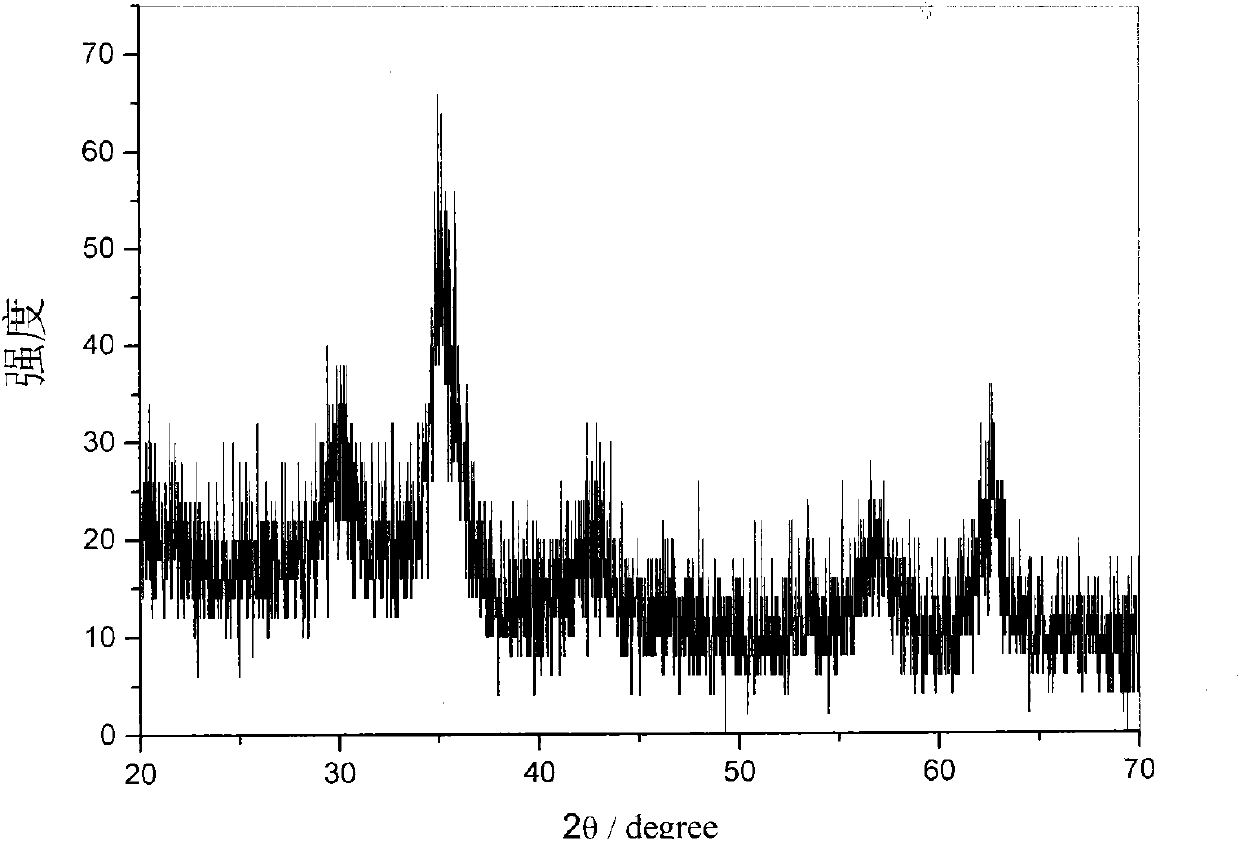

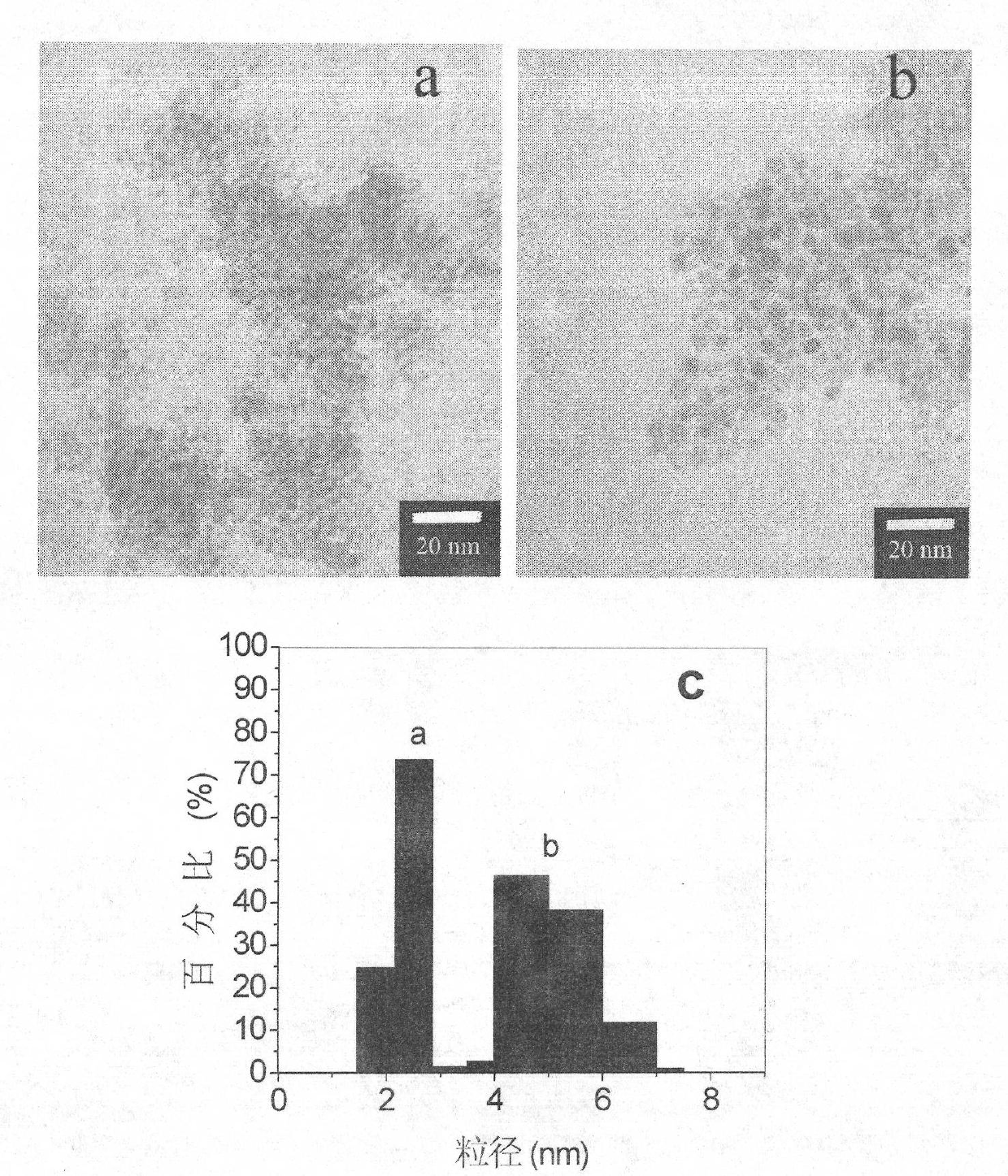

Low-temperature industrial preparation method of monodisperse superparamagnetic gamma-Fe2O3 nanoparticles

The invention discloses a novel low-temperature sol-gel industrial synthetic method of monodisperse superparamagnetic gamma-Fe2O3 nanoparticles, organic small molecules are adopted as novel gelling agents, and the sol-gel reaction is carried out while stirring under water bath conditions in ferrous salt solution; and the obtained sol is dried for obtaining products of the gamma-Fe2O3 nanoparticles. The characterization results show that the prepared products are the monodisperse spherical gamma-Fe2O3 nanoparticles with narrow particle size distribution, and the particle size can be controlled between 2-10nm by regulating the concentration of ferrous salt in reaction solution. The method adopts cheap raw materials, the used process is simple, the reaction can be carried out under low temperature and normal pressure, and no or few pollutants are discharged, thereby being applicable to large-scale industrial production.

Owner:YANTAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com