Ferromagnetic multiporous silica gel microsphere and its preparation method

A technology of porous silica gel and ferromagnetism, applied in the direction of magnetism of inorganic materials, liquid separation into beads and granulation, etc., can solve the problems of small specific surface area and unsuitable for application, and achieve large specific surface area, easy industrialization, and easy control of conditions Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

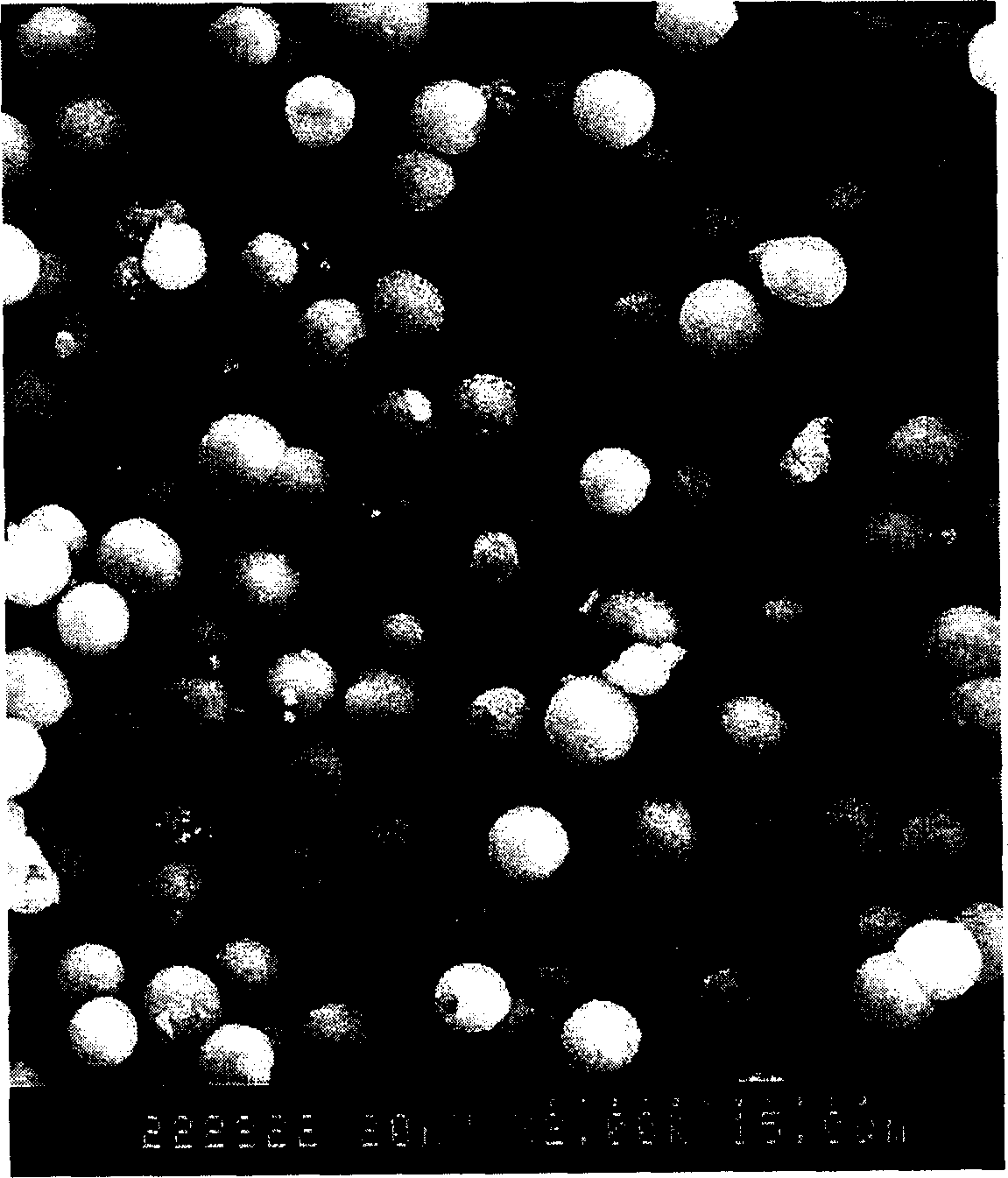

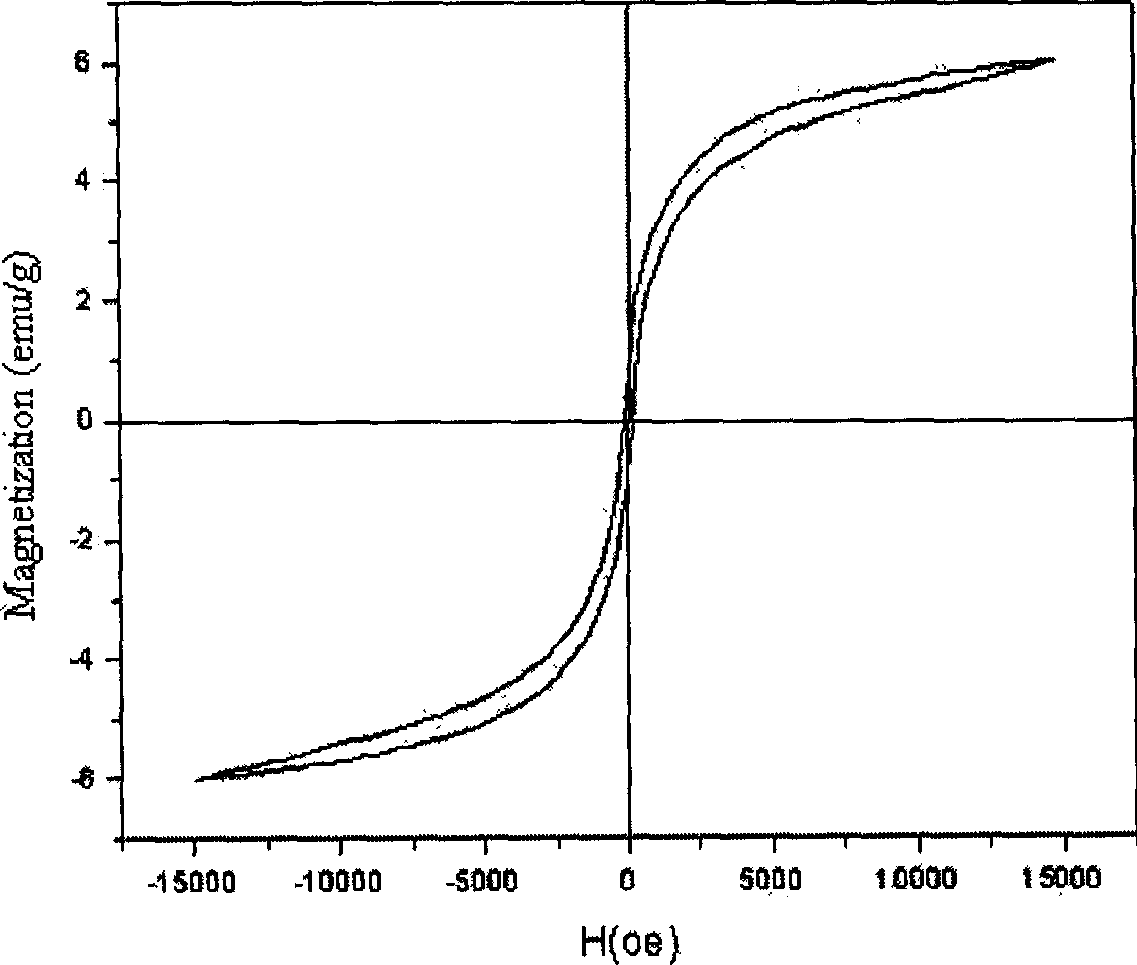

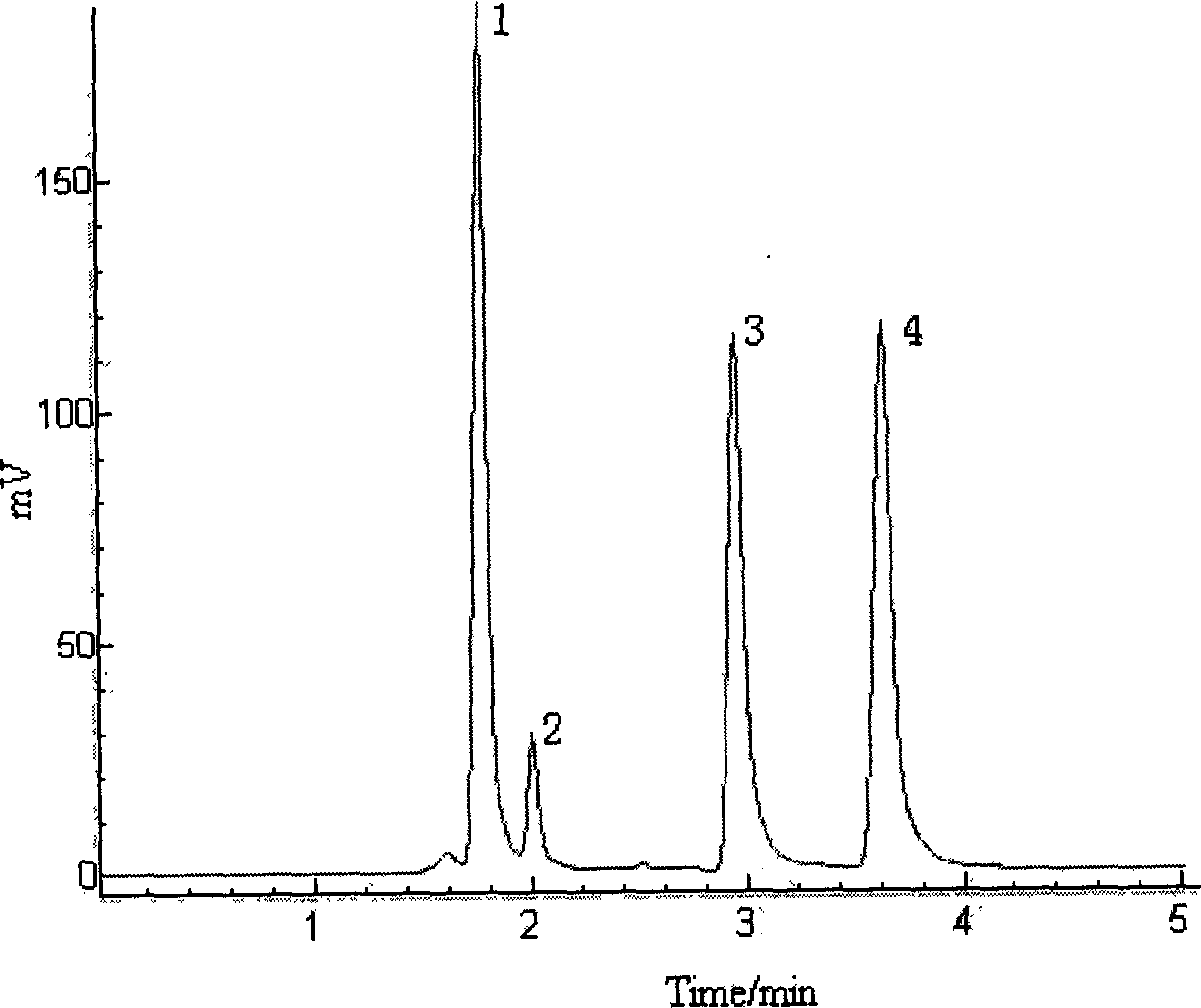

[0022] Example 1: Synthesis of magnetic porous microspheres

[0023] In a beaker containing 150ml distilled water, add 21.5g FeCl 3 .6H 2 O and 15g NaHCO 3 , And stirring to obtain a clear red iron sol with a pH of 2-2.5. In another beaker, add 225ml silica sol (30%) and 16g urea respectively, stir to dissolve, add concentrated HNO 3 Adjust the pH to 1.5. While stirring, mix the iron sol and the silica sol, adjust the pH to 1.5, quickly add 22ml of formaldehyde (37%) solution under stirring, stop stirring after mixing, and let stand at room temperature overnight for reaction. The composite microspheres generated by the reaction were collected by centrifugation, and washed with water, water-methanol (1:1), methanol and acetone in sequence. Dry under vacuum at 60°C overnight to obtain 31 g of free-flowing yellow microspheres. The composite microspheres are heat-treated and calcined at 300-350°C, 600-650°C and 900-950°C for 2h. After the non-magnetic silica gel particles were removed...

Embodiment 2

[0025] Example 2: Synthesis of magnetic porous microspheres

[0026] In a beaker containing 110ml distilled water, add 5.7g FeCl respectively 3 .6H 2 O and 4.0g NaHCO 3 , And stirring to obtain a clear red iron sol with a pH of 2-2.5. In another beaker, add 90ml silica sol (30%) and 6.4g urea respectively, stir to dissolve, add concentrated HNO 3 Adjust the pH to 1.5. While stirring, mix the iron sol and the silica sol, adjust the pH to 1.5, quickly add 8.8ml of formaldehyde (37%) solution under stirring, stop stirring after mixing, and let stand at room temperature overnight for reaction. The composite microspheres generated by the reaction were collected by centrifugation, and washed with water, water-methanol (1:1), methanol and acetone in sequence. Vacuum drying at 60°C overnight to obtain 11.6 g of yellow microspheres. The composite microspheres are heat-treated and calcined at 250-300℃, 500-550℃ and 850-900℃ for 1-2h. After the non-magnetic silica gel particles were removed ...

Embodiment 3

[0027] Example 3: Synthesis of magnetic porous microspheres

[0028] In a beaker containing 110ml distilled water, add 8.6g FeCl 3 .6H 2 O and 6.0g NaHCO 3 , And stirring to obtain a clear red iron sol with a pH of 2-2.5. In another beaker, add 90ml silica sol (30%) and 6.4g urea respectively, stir to dissolve, add concentrated HNO 3Adjust the pH to 1.5. While stirring, mix the iron sol and the silica sol, adjust the pH to 1.5, quickly add 8.8ml of formaldehyde (37%) solution under stirring, stop stirring after mixing, and let stand at room temperature overnight for reaction. The composite microspheres generated by the reaction were collected by centrifugation, and washed with water, water-methanol (1:1), methanol and acetone in sequence. Vacuum drying at 60°C overnight to obtain 11.6 g of yellow microspheres. The composite microspheres are heat-treated and calcined at 250-300℃, 500-550℃ and 850-900℃ for 1-2h. After the non-magnetic silica gel particles were removed by magnetic se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com