One-step synthesis method of surface loaded magnetic Fe2O3 nano-particle colloidal carbon ball

A nano-particle and surface-loading technology is applied in the field of one-step synthesis of surface-loaded magnetic Fe2O3 nanoparticle colloidal carbon spheres to achieve the effects of good spherical shape, easy operation and easy control of conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] (1) Disperse 10 mg of 4-ferrocenylbutyric acid in 8 mL of deionized water.

[0024] (2) Add the mixture obtained in step (1) into a reaction kettle with a volume of 13 mL.

[0025] (3) Place the reactor containing the mixture in step (2) in a temperature-controlled furnace and heat it to 160° C. for 24 hours, then take out the container, and let it cool down to room temperature naturally. A black product was obtained, and the synthesized product was sequentially washed with deionized water, absolute ethanol and acetone, and centrifuged to obtain the desired product.

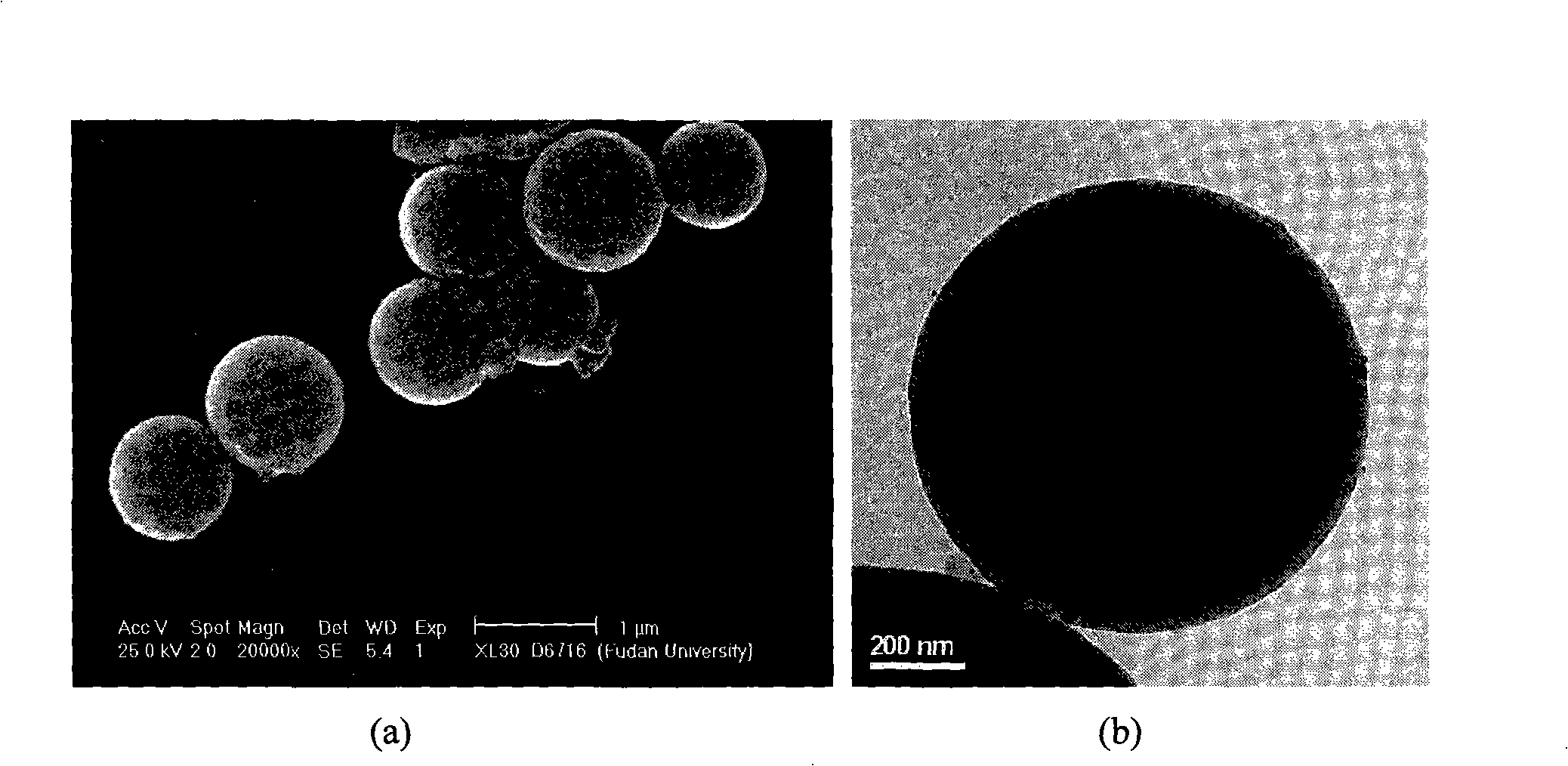

[0026] figure 1 In the SEM image of the product obtained under this reaction condition, the average size of colloidal carbon spheres is about 500nm.

Embodiment 2

[0028] (1) Disperse 50 mg of 4-ferrocenylbutyric acid in 8 mL of deionized water.

[0029] (2) Add the mixture obtained in step (1) into a reaction kettle with a volume of 13 mL.

[0030] (3) Place the reactor containing the mixture in step (2) in a temperature-controlled furnace and heat it to 160° C. for 24 hours, then take out the container, and let it cool down to room temperature naturally. A black product was obtained, and the synthesized product was sequentially washed with deionized water, absolute ethanol and acetone, and centrifuged to obtain the desired product.

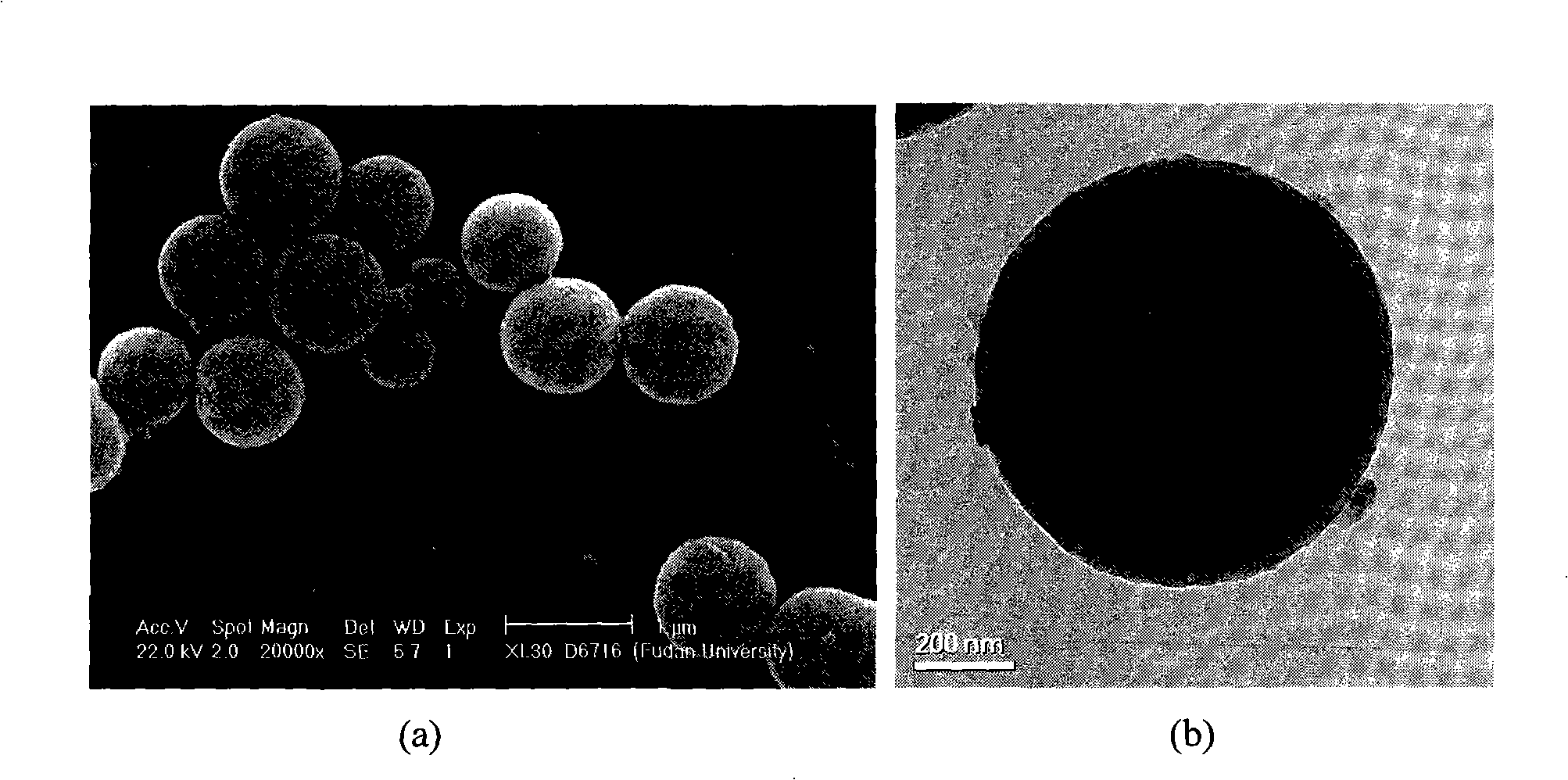

[0031] figure 2 According to the SEM and HRTEM images of the product obtained under this reaction condition, the average size of colloidal carbon spheres is about 950nm. From the HRTEM image, it can be seen that the surface of colloidal carbon spheres is loaded with magnetic Fe 2 o 3 Nanoparticles.

Embodiment 3

[0033] (1) Disperse 70 mg of 4-ferrocenylbutyric acid in 8 mL of deionized water.

[0034] (2) Add the mixture obtained in step (1) into a reaction kettle with a volume of 13 mL.

[0035] (3) Place the reactor containing the mixture in step (2) in a temperature-controlled furnace and heat it to 160° C. for 24 hours, then take out the container, and let it cool down to room temperature naturally. A black product was obtained, and the synthesized product was sequentially washed with deionized water, absolute ethanol and acetone, and centrifuged to obtain the desired product.

[0036] The average size of colloidal carbon spheres obtained under this reaction condition is about 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com