Application of magnetic graphene carbon nanomaterial in aflatoxin adsorption

A technology of magnetic graphene and carbon nanomaterials, applied in the direction of selective adsorption, other chemical processes, ion exchange, etc., can solve the problems of small adsorption capacity, large amount of magnetic graphene adsorbent, long adsorption time, etc., and achieve cost-effective solution , avoid nutrient loss and save cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

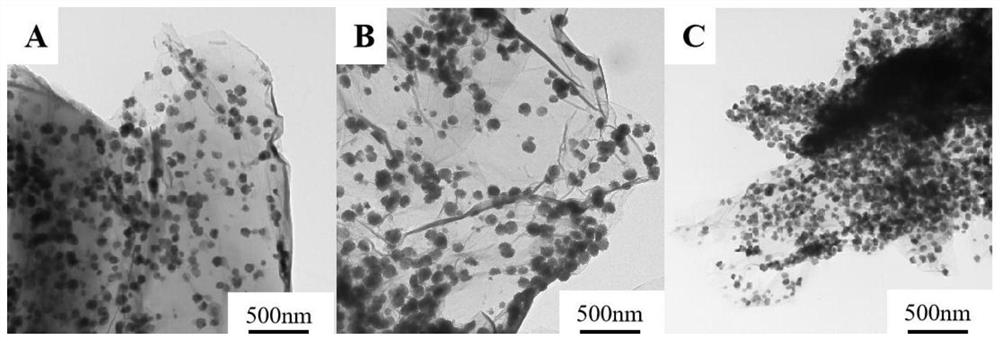

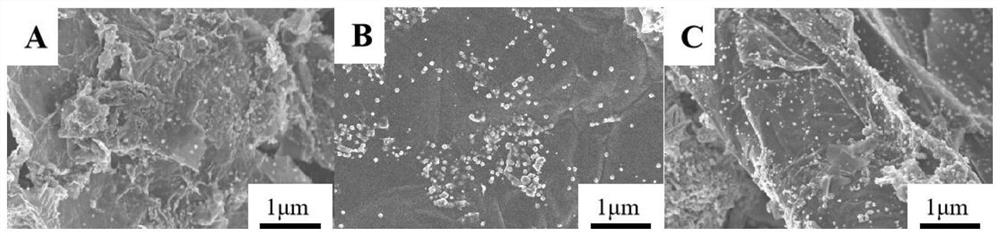

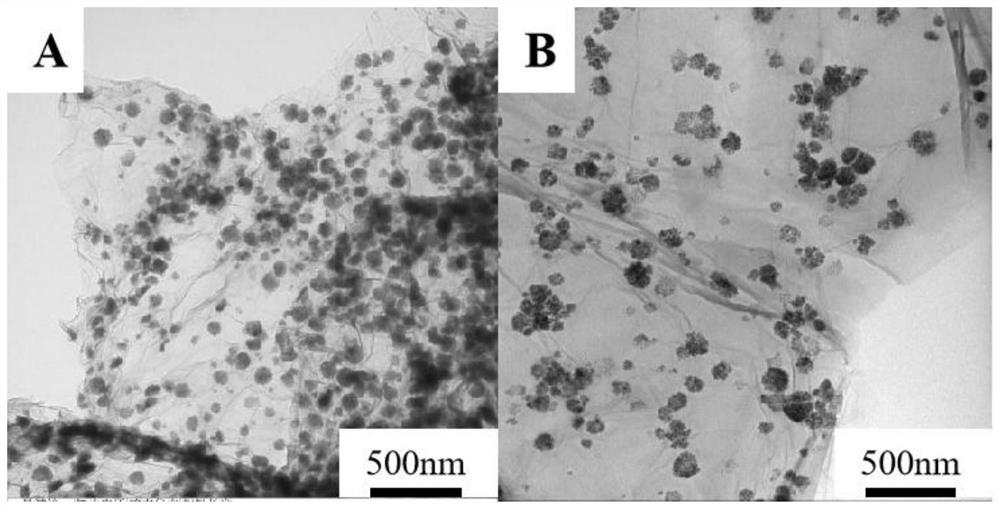

[0056] A magnetic graphene carbon nanomaterial for adsorbing aflatoxin, the preparation method is as follows:

[0057] (1) take by weighing the graphene oxide of 40mg and add 6mL ethylene glycol solution in a beaker that is placed with a magneton, and ultrasonically at room temperature until graphene oxide is completely dispersed in the ethylene glycol solution;

[0058] (2) Weigh 65 mg of anhydrous ferric chloride powder, add it to the solution of the above step (1), ultrasonicate at room temperature for 20 min to ensure that the ferric chloride is completely dispersed in the solution, then add 0.26 g of anhydrous sodium acetate, and at room temperature Stir for 0.5h.

[0059] (3) Pour the mixed solution of step (2) into the polytetrafluoroethylene liner of the high temperature reaction kettle, carry out solvothermal reaction, the reaction temperature is 180 ° C, and the reaction time is 4h. After the reaction is completed, take out the reaction kettle and cool to room tempe...

Embodiment 2

[0062] A magnetic graphene carbon nanomaterial for adsorbing aflatoxin, the preparation method is as follows:

[0063] (1) take by weighing the graphene oxide of 40mg and add 6mL ethylene glycol solution in a beaker that is placed with a magneton, and ultrasonically at room temperature until graphene oxide is completely dispersed in the ethylene glycol solution;

[0064] (2) Weigh 65 mg of anhydrous ferric chloride powder, add it to the solution of the above step (1), ultrasonicate at room temperature for 20 min to ensure that the ferric chloride is completely dispersed in the solution, then add 0.26 g of anhydrous sodium acetate, and at room temperature Stir for 0.5h.

[0065] (3) Pour the mixed solution of step (2) into the polytetrafluoroethylene liner of the high-temperature reaction kettle, carry out solvothermal reaction, the reaction temperature is 180 ° C, and the reaction time is 6h. After the reaction is completed, take out the reaction kettle and cool to room tempe...

Embodiment 3

[0068] A magnetic graphene carbon nanomaterial for adsorbing aflatoxin, the preparation method is as follows:

[0069] (1) take by weighing the graphene oxide of 40mg and add 6mL ethylene glycol solution in a beaker that is placed with a magneton, and ultrasonically at room temperature until graphene oxide is completely dispersed in the ethylene glycol solution;

[0070] (2) Weigh 65 mg of anhydrous ferric chloride powder, add it to the solution of the above step (1), ultrasonicate at room temperature for 20 min to ensure that the ferric chloride is completely dispersed in the solution, then add 0.26 g of anhydrous sodium acetate, and at room temperature Stir for 0.5h.

[0071] (3) Pour the mixed solution of step (2) into the polytetrafluoroethylene liner of the high-temperature reaction kettle, and carry out solvothermal reaction, the reaction temperature is 180 ° C, and the reaction time is 8 h. After the reaction is completed, the reaction kettle is taken out and cooled to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com