Graphene/porous iron oxide nano-rod compound and preparation method thereof

An iron oxide nanometer and graphene technology, applied in the field of material chemistry, can solve problems such as unreported, and achieve the effects of easy acquisition, simple method, and multiple lithium storage sites.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of graphene / porous iron oxide nanorod composite:

[0032] (1) Mix 0.05g of graphene oxide with 16mL of silk protein solution with a mass fraction of 5.06%, adjust the pH to 10, and add 0.2mL of hydrazine hydrate for reduction induction, thereby obtaining graphene-silk protein nanofiber composites;

[0033] (2) Add 2.15g FeCl to the above compound 3 ·6H 2 O, continue to stir until completely dissolved;

[0034] (3) Pour the above mixture into the reactor and react at 160°C for 20 hours;

[0035] (4) Naturally cool to room temperature after the reaction is finished, and centrifuge and wash, and finally the product is vacuum-dried;

[0036] (5) The solid powder obtained above was calcined in an argon atmosphere at 400° C. for 5 hours in a vacuum tube furnace, and then naturally cooled to room temperature.

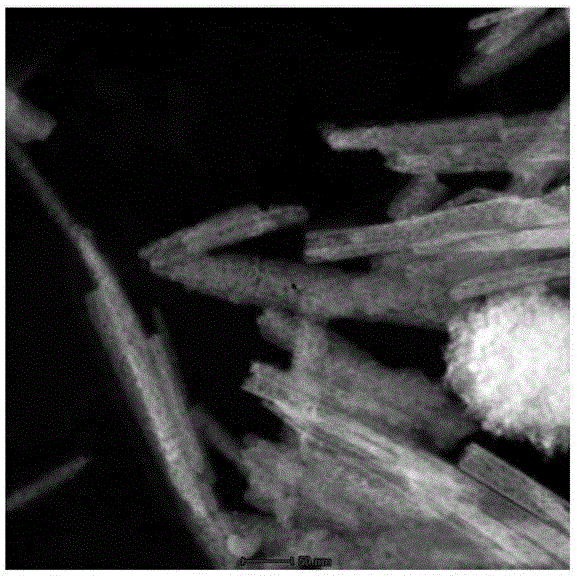

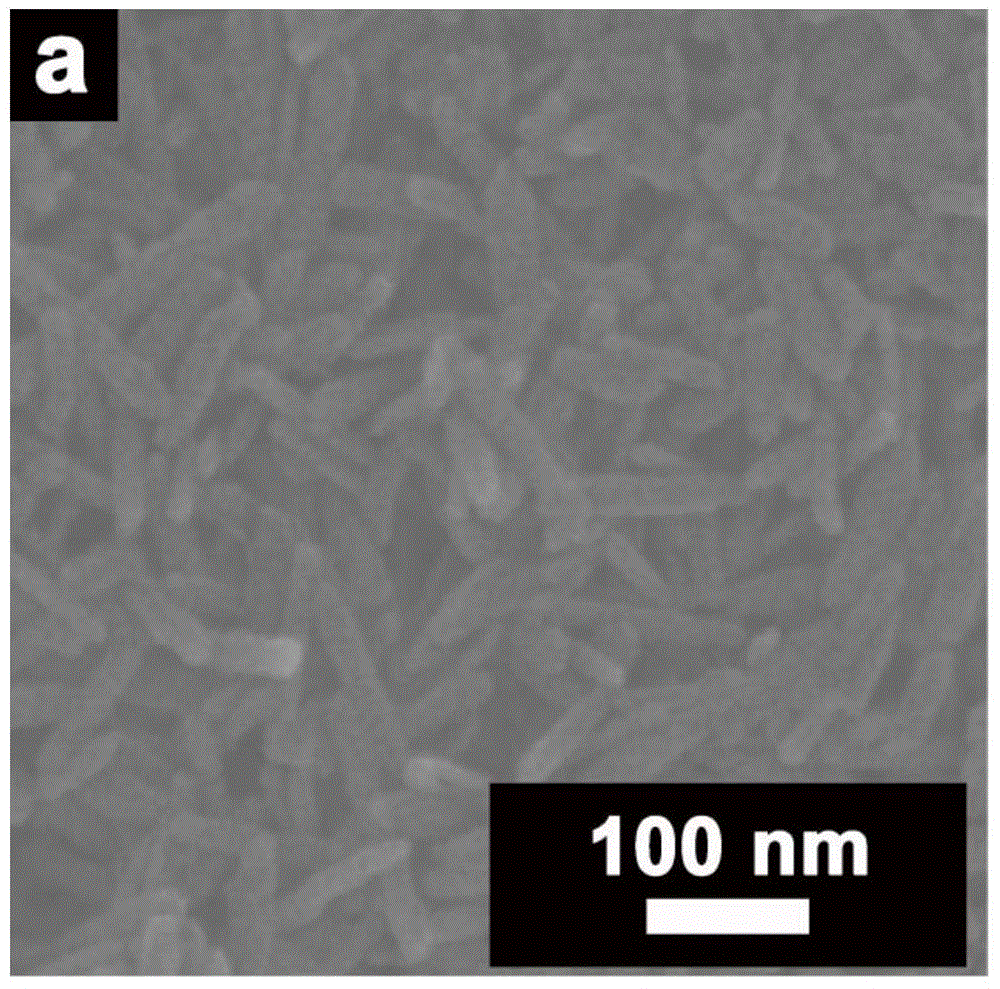

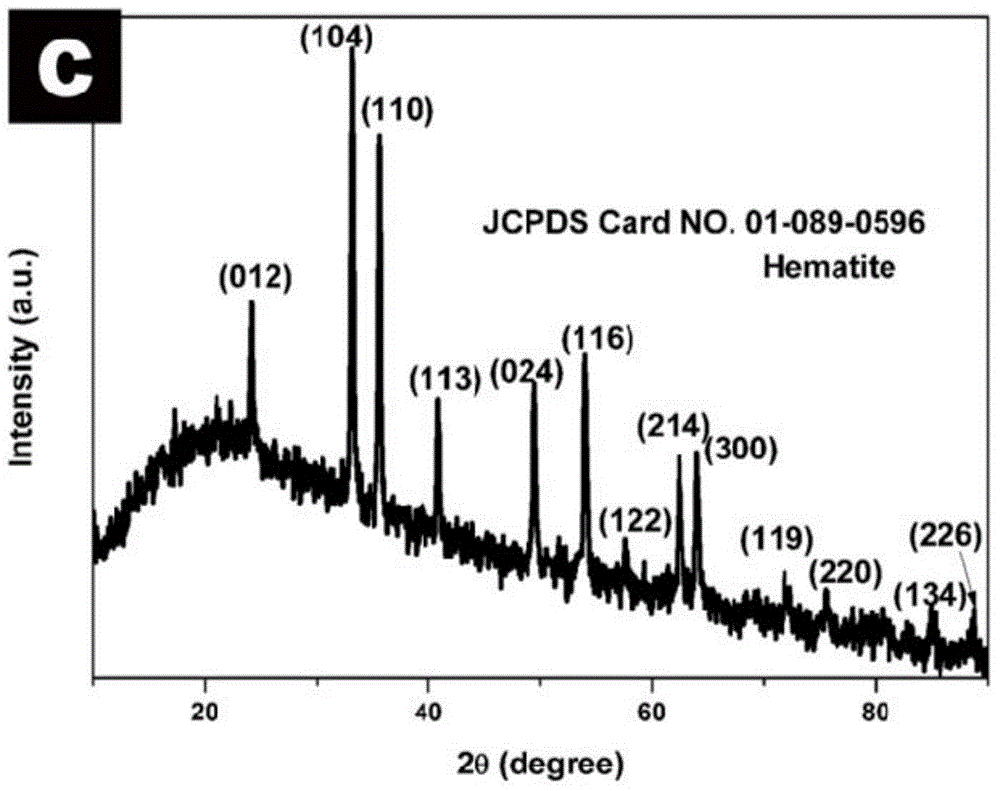

[0037] Figures 1 to 4 They are the scanning electron microscope figure, transmission electron microscope figure, XRD figure and Raman spect...

Embodiment 2

[0039] The preparation method of graphene / porous iron oxide nanorod composite:

[0040] (1) Mix 0.05g graphene oxide with 0.19mL silk protein solution with a mass fraction of 5.06%, adjust the pH to 10, and add 1mL hydrazine hydrate for reduction induction, thereby obtaining graphene-silk protein nanofiber composites;

[0041] (2) Add 1g FeCl to the above compound 3 ·6H 2 O, continue to stir until completely dissolved;

[0042] (3) Pour the above mixture into the reactor and react at 120°C for 36 hours;

[0043] (4) Naturally cool to room temperature after the reaction is finished, and centrifuge and wash, and finally the product is vacuum-dried;

[0044] (5) The solid powder obtained above was calcined in an argon atmosphere at 320° C. for 8 hours in a vacuum tube furnace, and then naturally cooled to room temperature.

[0045] Figure 5 It is the scanning electron microscope image of the sample. It can be seen from the figure that the complex is partly rod-shaped and pa...

Embodiment 3

[0047] The preparation method of graphene / porous iron oxide nanorod composite:

[0048] (1) Mix 0.05 g of graphene oxide with 10 mL of a silk protein solution with a mass fraction of 5.06%, adjust the pH to 10, and add 20 μL of hydrazine hydrate for reduction induction, thereby obtaining a graphene-silk protein nanofiber composite;

[0049] (2) Add 3g FeCl to the above compound 3 ·6H 2 O, continue to stir until completely dissolved;

[0050] (3) Pour the above mixture into the reactor and react at 200°C for 8 hours;

[0051] (4) Naturally cool to room temperature after the reaction is finished, and centrifuge and wash, and finally the product is vacuum-dried;

[0052](5) The solid powder obtained above was calcined in an argon atmosphere at 450° C. for 3 hours in a vacuum tube furnace, and then naturally cooled to room temperature.

[0053] Figure 6 is the scanning electron microscope image of the sample, and it can be seen from the image that the complex is rod-shaped. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com