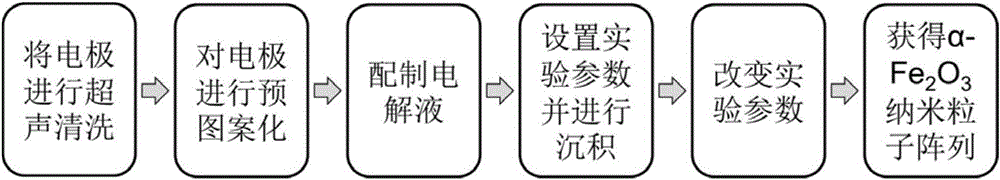

Method of adopting electrochemical deposition to prepare patterned orderly alpha-Fe2O3 nanoparticle array

A nanoparticle and electrochemical technology, which is applied in the field of nanomaterial preparation, can solve the problems that limit practical application, and achieve the effects of low preparation cost, mild reaction conditions, and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be described in detail below in combination with specific embodiments.

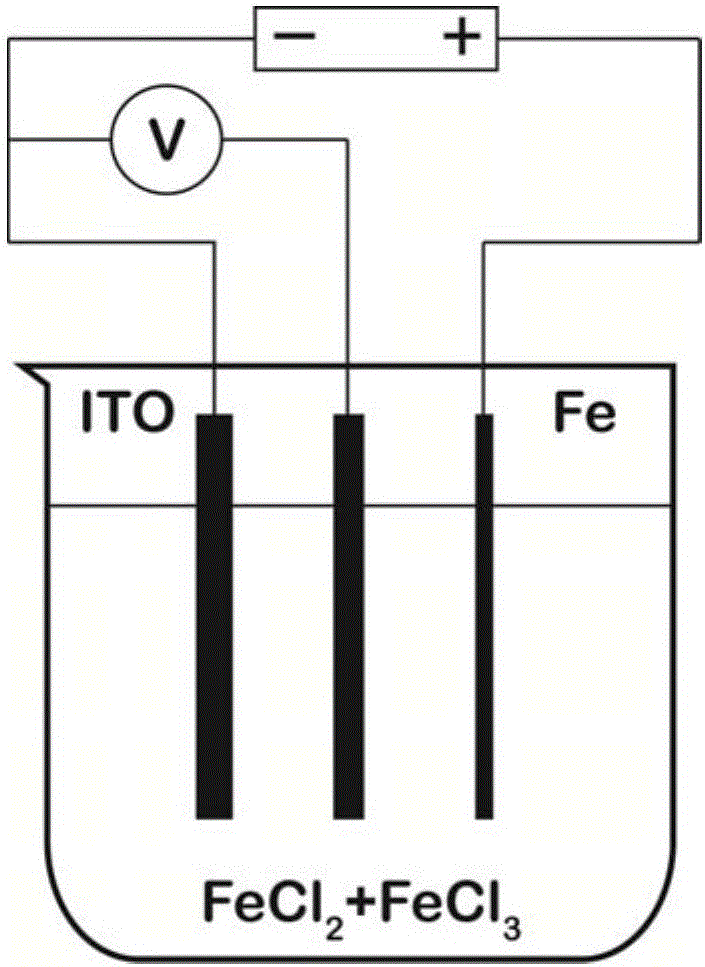

[0048] The present invention adopts an electrochemical workstation, with the ITO conductive substrate after laser interference lithography as the working electrode, the saturated calomel electrode as the reference electrode, the high-purity iron sheet as the counter electrode, and the FeCl 2 and FeCl 3 The mixed solution is used as the electrolyte, using a three-phase electrode system, immersing the working electrode, counter electrode, and reference electrode in the electrolyte at the same time, and setting the required temperature for electrochemical deposition. Electrochemical deposition of patterned and ordered α-Fe with good dispersion on the working electrode by chronoamperometry 2 o 3 Nanoparticle Arrays.

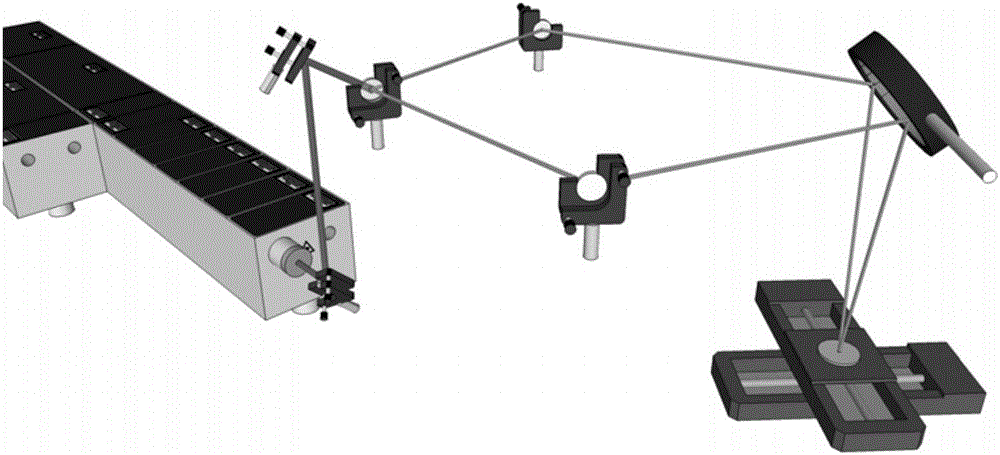

[0049] In the invention, the electrode is pre-patterned by double-beam single-exposure, and a nano-particle array with a large-area patterned and ordered str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com