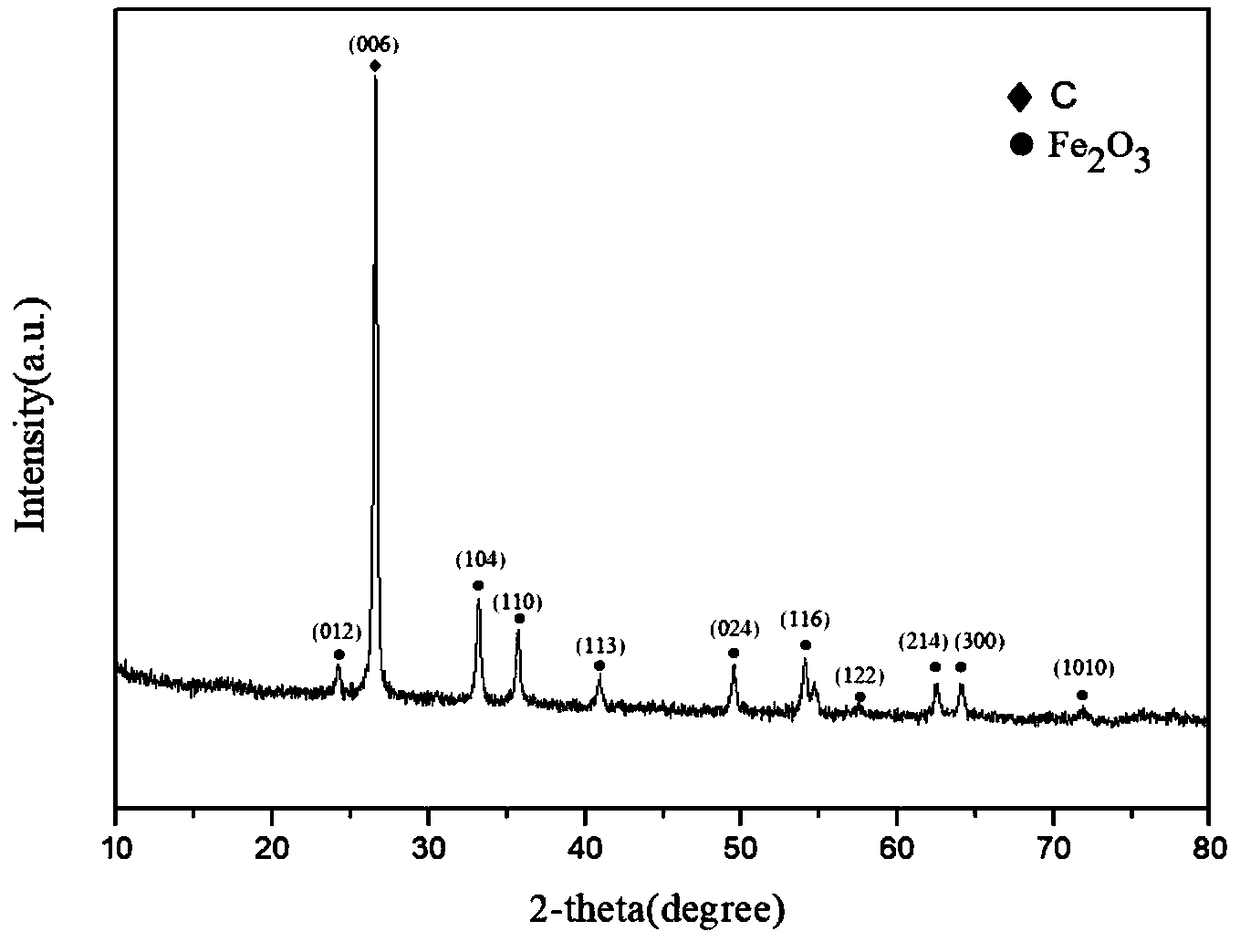

Preparation method of alpha-type fe_2O_3 nanoparticles/multilayer graphene composite material

A multi-layer graphene and composite material technology, applied in the field of materials, can solve the problems of inability to obtain α-type iron oxide nanoparticles, expensive ferrous chloride, easy water absorption of ferrous chloride, etc., and achieve good redox reaction characteristics , Obvious charge and discharge platform, improve the effect of redox current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] see Figure 7 , showing the α-type Fe of the present invention 2 o 3 The preparation method of nanoparticle / multilayer graphene composite material specifically comprises the following steps:

[0035] Step S1: Measure DMF and deionized water with a volume ratio of 8:2, and mix them uniformly as mixed solvent A.

[0036] Step S2: Weighing a certain amount of expanded graphite and adding it to the mixed solution of DMF and distilled water, ultrasonicating for 3 hours, exfoliating the expanded graphite into multi-layer graphene and uniformly dispersing it in the solvent to obtain multi-layer graphene dispersion B. The concentration of multilayer graphene in mixed solvent A is 0.5-2 mg / mL.

[0037] Step S3: Measure nitric acid and deionized water to prepare 2 mol / L dilute nitric acid solution C.

[0038]Step S4: Weigh iron powder with a concentration of 1-5 mg / mL relative to solvent A and anhydrous sodium acetate of 10 mg / mL, and pour them into liquid B. Then measure so...

Embodiment 1

[0043] Mix 8ml DMF and 2ml distilled water as a mixed solvent, add 15mg expanded graphite, and obtain the desired multilayer graphene solution after ultrasonic oscillation for 3 hours, add 100mg anhydrous sodium acetate and 10mg iron powder to the multilayer graphene solution, and then add 2ml is prepared into a dilute nitric acid solution with a molar concentration of 2mol / L. Then, it was stirred in a water bath at 80° C. and a rotation speed of 320 / min for 4 hours. The reactants were taken out and centrifuged three times with alcohol and distilled water respectively, and finally dried in a drying oven at 60°C for 24 hours to obtain α-Fe 2 o 3 Nanoparticle / multilayer graphene composites.

Embodiment 2

[0045] Mix 8ml DMF and 2ml distilled water as a mixed solvent, add 5mg expanded graphite, and obtain the required multilayer graphene solution after ultrasonic oscillation for 3 hours, add 100m anhydrous sodium acetate and 20mg iron powder to the multilayer graphene solution, and then add 1ml dilute nitric acid. Then, it was stirred in a water bath at 70° C. and a rotation speed of 320 / min for 6 hours. The reactants were taken out and centrifuged three times with alcohol and distilled water respectively, and finally dried in a drying oven at 60°C for 24 hours to obtain α-Fe 2 o 3 Nanoparticle / multilayer graphene composites.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com